Ferroli Italian gas boilers are the products of one of the strongest European manufacturers.

The equipment manufactured by this company demonstrates high quality and stability of operation, all units and parts of Ferroli gas boilers are assembled on the basis of advanced technologies and fully meet the most stringent technical requirements.

Each unit is equipped with an extensive self-diagnosis system, consisting of a network of sensors, which are located on all critical nodes and parts of the boiler.

If any malfunction occurs or the unit leaves the specified mode, the self-diagnosis system immediately reacts by alerting the user using an alphanumeric code on the boiler display.

Let's consider her work in more detail.

The main malfunctions of gas boilers Ferroli

The design of Ferroli boilers is distinguished by a well-thought-out and high-quality study of all units and parts.

However, any system has weak points, and gas boilers are no exception..

The operating conditions of some parts of the units are very difficult, temperature loads contribute to the appearance of the phenomenon of fatigue of metals and other materials.

According to experts, the most common malfunctions include:

- The boiler does not turn on. There can be different causes and ways to fix them, one of the most common problems.

- Pressure drops or rises. This is a serious problem that either leads to a leakage of the heating medium, which causes overheating and blocking of the boiler, or to overpressure and blockage. An increase in pressure is especially dangerous, from which the parts of the unit can burst.

- Fan or circulation pump failure. The loss of both functions means the inability of the system to work - the impossibility of extracting smoke causes sudden overheating and blocking, and the lack of fluid movement has the same consequences, only detected by other sensors.

- Electronic control board problems. These problems are most often caused by unstable supply voltage or lack of good grounding. The boiler electronics are very sensitive to any changes in the operating mode. When jumps or jumps appear, it begins to produce a continuous series of errors that do not repeat when restarting. Often there is an accumulation of static charge on the case, which is transmitted through the ground to the control board and the ionization electrode, which causes the A02 error to appear (the system sees a flame when there is none). The solution to the problem is to completely disconnect the boiler from the power system for a while and restore (or create) high-quality grounding.

In addition to the above, there are a lot of problems with the combustion mode.:

- Flame too small.

- Spontaneous combustion start.

- There is no DHW heating.

- A sharp flare-up of a flame with a clap.

All these problems are associated with a deterioration in gas supply due to clogged injectors, failure of the thermocouple or the fuel valve coil.

IMPORTANT!

The elimination of all problems should be entrusted to qualified technicians from the service center; self-repair of the boiler may give the opposite result to the expected one.

Features and benefits of Ferroli boilers

Of course, this is far from the only manufacturer using new technologies. Therefore, in a competitive environment, engineers strive to offer effective solutions in a variety of ways. First of all, gas-fired Ferroli provides the required level of performance, consuming the minimum amount of fuel. Together with automated control and the ability to control temperature conditions, this allows the owner to optimize heating costs.By the way, about automation: the manufacturer also provides for the possibility of self-diagnosis of boilers, which is very important for users without technical training.

It is for Russian clients that it is valuable that the company adapts the models to harsh operating conditions. Poor water quality and voltage drops sometimes become the main problem of heating equipment. In turn, it is completely ready for use in such conditions: according to the manufacturer, the service life of the equipment is more than 40 years.

All major error codes and their decoding and solution

Consider the main errors of Ferroli gas boilers and options for their elimination:

| The code | Decoding | Ways to solve the problem |

| A01 | No flame (unsuccessful ignition attempt) | Check the presence of gas in the line, open the gas supply valve, |

| A02 | False flame presence (voltage detected at the ionization electrode when the burner is off) | Check the condition of the ground loop or the presence of condensation drops on the control board |

| A03 | Boiler overheating | Flush the heat exchanger, check the condition of the circulation pump |

| A06 | No flame after ignition cycle | Check the gas supply system, clean the gas burner nozzles |

| A08 | Failure of the coolant temperature sensor | Replace element |

| A09 | Gas valve failure | Check function, replace element |

| F04 | Overheating of the flue gas thermostat | Clean the chimney, check the operation of the fan |

| F05 | Failure of the smoke exhaust system, shutdown of the fan | Replace fan |

| F08 | Overheating of the primary heat exchanger | Flush the heat exchanger, replace if necessary |

| F10 | Open or short circuit of the extract air temperature sensor | Restore contact or replace sensor |

| F11 | Open circuit or short circuit of the DHW temperature sensor | Restore contact or replace sensor |

| F14 | Malfunction of the sensor No. 2 of the direct line of the heating circuit | Restore contact or replace sensor |

| F34 | Supply voltage dropped to 180 V | Check the line, install a stabilizer or uninterruptible power supply |

| F37 | Air supply pressure drop | Find an OM leak and eliminate it |

| F40 | Excessive air pressure | Check the condition of the expansion tank |

| F47 | Open or short circuit of the pressure switch of the extract air | Restore or replace the relay |

| F50 | Control board malfunctions | Replace control board |

Errors of Ferroli boilers are divided into critical (A) and non-critical (F). Those with the letter A lead to an independent blocking of the boiler, and those with the letter F do not.

Installation nuances

The Ferroli wall-mounted gas boiler, the installation instructions for which are presented in the user manual, must be installed in a room where the ventilation system is constantly operating. If the air supply is insufficient, the device will not be able to work properly, and the combustion products will not be removed. If such conditions are created, then harmful substances can penetrate into the premises of the house, which can harm human health. If you purchased hanging equipment, you can use a bracket kit that attaches to the wall. A metal template can be supplied on special order to mark the surface of the suspension points.

Operating instructions - how to start correctly

The operation of Ferroli boilers does not differ in any specific actions and procedures.

The owner is only required to organize periodic maintenance, cleaning the body and interior of the boiler, keeping the burner nozzles in proper order.

The boiler start-up procedure resembles the method of ignition of other gas units..

A special feature is the need to maintain a pause between start attempts, during which the D3 or D4 code appears on the display (50 or 30 seconds).

Download instruction

Download instructions for gas boilers Ferroli.

The first code occurs after a critical error appears and the unit is blocked..

Until the required time interval has been met, a repeated restart is not possible.

The second code appears between attempts to start in normal mode, if the previous one was unsuccessful.

This is usually due to the presence of air in the pump, piping or heat exchanger.... Attempts are repeated until the air is removed from the boiler.

Components

For any category of its products, the company also produces various kits. Wall-mounted dual circuit models can be supplemented with a smoke extraction kit or a device that allows the structure to run on LPG. The boiler installed on the floor can be equipped with boilers, thermostats, systems with a priority to hot water supply, turbo nozzles and control devices.

Condensing products are often supplemented with sensors that take into account the outdoor temperature, control boards with multiple circuits, hydraulic switches, and complete sets to guarantee trouble-free boiler operation.

The most popular models:

- "Domina N" with bithermic compact thermal device. The state of operation of the unit can be visually observed using an indicator with LEDs. Domina N is a unit that has a DHW function, it guarantees excellent heating and has an electric ignition. The advantages of Domina N are increased efficiency, light weight and oversized parameters, an electrical system for control, which contributes to a very high operability of the device, and a self-diagnostic function. The product will be able to operate on both liquefied gas and regular fuel.

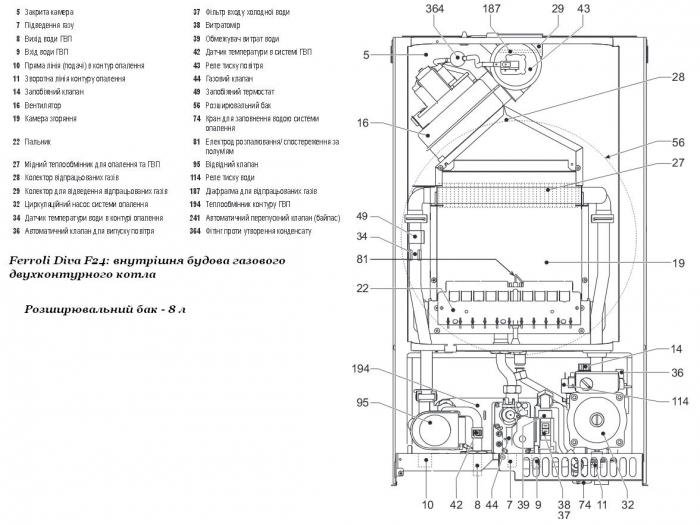

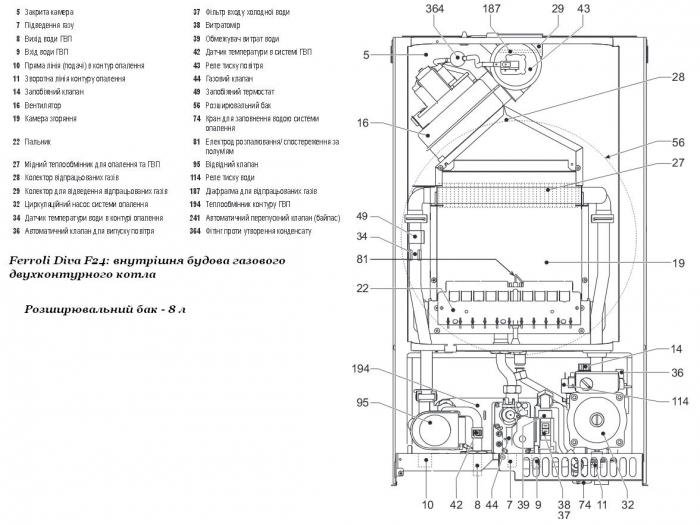

- Model "Diva" has another steel heat exchanger, when using which you can heat water for domestic needs. A rather large LCD screen is installed on the control panel, there are also buttons for task parameters, various service settings and, most importantly, diagnostic buttons. Diva are produced with open and closed combustion chambers. "Diva" is very easy to maintain, has an efficiency of almost 93%, it has a digital control of the product, which contributes to an increase in the efficiency of the unit.

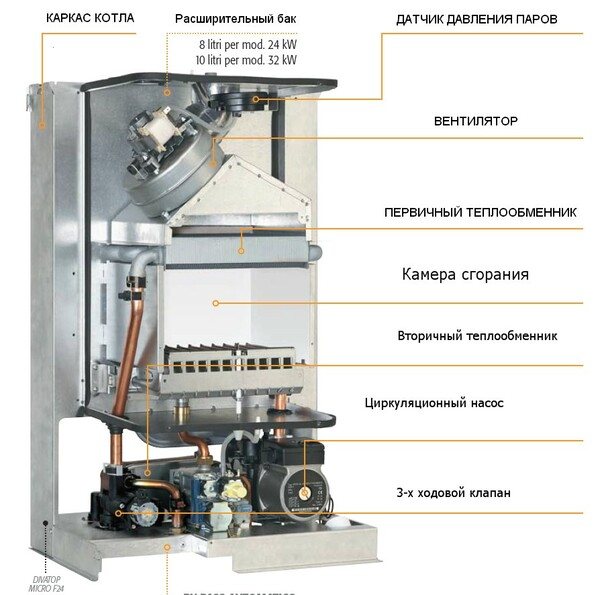

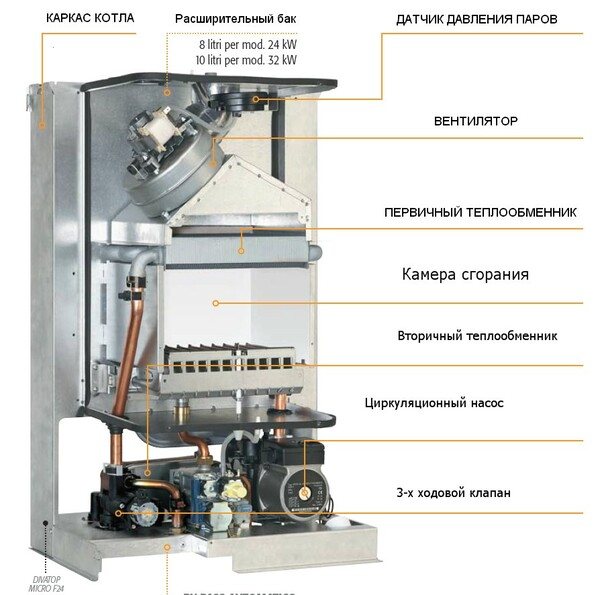

- Boiler "Divatop Micro" with two contours can be called a completely new development. The product includes a large number of innovations that have begun to qualitatively affect the reliable operation of devices and their high efficiency. 2 copper heat exchangers were installed to heat the water and the heating system. The product has 3 way inverter valves. The device can maintain the temperature you need for a long time without outside interference. Convenient self-diagnosis system will ensure the safety of the unit. The Divatop Micro design has a separate connection to the Oscar element, which is installed in the room, so that rooms can be air-conditioned and heated at the same time.

- Wall-mounted steel unit "Domitech C32" has a high-quality anti-corrosion coating. The device will work without any problems on natural and liquefied gas. The product is used for heating homes and providing heating of domestic water. It can be controlled using a digital system with two microprocessors. One will help control the boiler, the other will control the combustion. Electric ignition will make it easier to start the unit.

- Device "Divatop 60 C 24" produced for high-quality heating and fast water heating. These boilers with two circuits have a backlit LCD display, where you can see all the performance characteristics of the product. To get hot water, you can use a 60 liter boiler. The company has foreseen fuel economy, so this model is very popular among consumers.

- Model "Pegasus" - a boiler with a cast iron heat exchanger, which is installed on the floor.These units are focused only on heating the home, for this reason, the power in them reaches a maximum of 150 kW. The "Pegasus" boiler is ignited by means of an electrical system without a special igniter.

- Ferroli DomiTech Is a wall-mounted device with two circuits, with a built-in function of instantaneous heating of water. Control over the operation of the product is carried out by a digital control system. The device includes a copper heat exchanger. It is considered the most effective and can work successfully for ten years.

- Product "Atlas D" Is a floor-standing device that is produced for heating spaces up to 900 m2. These are 3-way cast iron boilers that can function with a burner that can be changed. They are used not only for space heating, but also for water heating. There is an LCD screen and an anti-freeze protection system.

How to setup

The basic setting of the Ferroli boiler is carried out at the manufacturer.... At the first start, an additional adjustment of the parameters of all communications is made to ensure full compliance with the operating modes of the system and the supply of resources - gas, water, voltage.

Also, the upper and lower boundaries of the temperature and pressure of liquids, gases, and other important parameters are determined.

Most of the actions are performed from the external control panel; you have to open the casing only when carrying out complex repairs or to connect a room thermostat.

NOTE!

The adjustment must be made by a master from the service center, otherwise the warranty agreement will expire or important units of the unit will fail due to improper operation.

The best and most famous models: characteristics and prices

Wall mounted

Fortuna

The most common double-circuit model. It is distinguished by extremely high technical characteristics, the efficiency, depending on the power, is in the range of 92.4-93.1%, and the maximum gas consumption of the most common version with a capacity of 24 kW is 2.72 m3 / h. The primary heat exchanger is made of copper, which is more thermally conductive and resistant to corrosion, and the secondary (for hot water supply) is made of stainless steel. The boiler implements the previously mentioned preheating system of the secondary heat exchanger, which significantly reduces the delay in the supply of hot water.

Available in 10, 13, 16, 18, 20, 24, 32 and 40 kW versions. Modifications with a closed combustion chamber (F) are mainly in demand, but there are also cheaper and slightly less efficient modifications with an open combustion chamber (C). There are also single-circuit models - Fortuna H, but their cost is only 5-10% lower. The production of the Fortuna models is now carried out in China, and not in Italy.

Cost: RUB 25,600-34,000

How to choose a programmable room thermostat and save up to 30% per month on heating

Domiproject

An obsolete dual-circuit model, discontinued, but still available in sufficient quantities in warehouses. Due to obsolescence, it also has an appropriate, extremely affordable price, thanks to which it is in demand.

It differs from Fortna in a slightly lower efficiency, a bithermal (double) heat exchanger, which is cheaper to manufacture, making it possible to make the dimensions of the boiler more compact, but extremely difficult to descale. The rest of the design is as simple as possible, the most budget materials are used, which, of course, also determines its price. There are 24 and 32 kW versions.

Cost: RUB 15,800-23,000

BLUEHELIX K

Noteworthy condensing model, one of the best and most hassle-free Ferroli gas boilers for heating a private house. The condensation principle of operation implies the presence of another additional heat exchanger, which accumulates the heat of the condensate formed from the waste products of combustion.Thus, a significant part of the heat no longer "escapes into the pipe", but is additionally accumulated and directed to heating the heating return line.

The efficiency is 109%, the heat exchanger is steel, however, it is made according to a special technology without welding seams, which in theory and even in practice implies its durability.

The main difference is the presence of a built-in boiler for 50 liters in the body, which significantly increases the performance of hot water heating and increases the comfort of operation. Produced exclusively in Italy, but only available in 25 and 50 kW versions.

Cost: RUB 96,000-125,000

Floor standing

Pegasus D

Single-circuit atmospheric gas boiler, practically hassle-free against the background of Ferroli wall models. It features a cast-iron heat exchanger that is corrosion-resistant and therefore durable. It also has good efficiency indicators - 90.9-91.7% and just excellent gas consumption for an atmospheric floor stand, the maximum consumption of natural gas for the 23 kW version is 2.68 m3 / h.

All safety systems of mounted boilers are inherent in the model: protection against overheating, freezing, pump blocking, etc. A safety valve and an air vent are preinstalled from the factory, which facilitates and minimizes the boiler piping. It is possible to connect underfloor heating and external control. In comparison with other cast iron counterparts, the boiler is quite light - from 106 to 164 kg, which simplifies the requirements for the boiler room floor. Available in 23, 32 and 45 kW versions.

Cost: RUB 60,000-93,500

Pegasus 2S

All the same atmospheric floor-standing boiler unit with a cast-iron heat exchanger, with a similar device and technical characteristics, but much higher power. It is produced in versions with a heating capacity of 56, 67, 77, 87, 97 and 107 kW, designed for heating large private houses and commercial premises, for its price it has not many analogues.

Unlike the previous Pegasus D, it is equipped only with overheating protection and an air vent, it is possible to connect an external control. There is an auto-ignition, the burner is two-stage. In general, it is a fairly simple and straightforward design.

Cost: 118,000-180,400 rubles.

The boiler does not start (the burner does not start)

Problems with starting the boiler are most common, since there are a lot of reasons for such a situation.

Among them there may be:

- Gas supply valve closed.

- Gas valve malfunction.

- Burner nozzles clogged with soot.

- Control board refused.

- The boiler is blocked due to a malfunction of a component.

Most of the possible causes are detected by the self-diagnosis system, and the corresponding code is displayed on the display.

However, some possible reasons - a failure of the gas supply system, a closed valve and other mechanical obstacles, the system may not notice, so you should make sure yourself that it is ready for work... In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes on the dashboard after the connections made, the wires are mixed up.

IMPORTANT!

If a phase is connected to the wrong electrode, the boiler will not start. It is also highly undesirable to have an electrical potential between the working zero and ground, which causes the A02 error to appear.

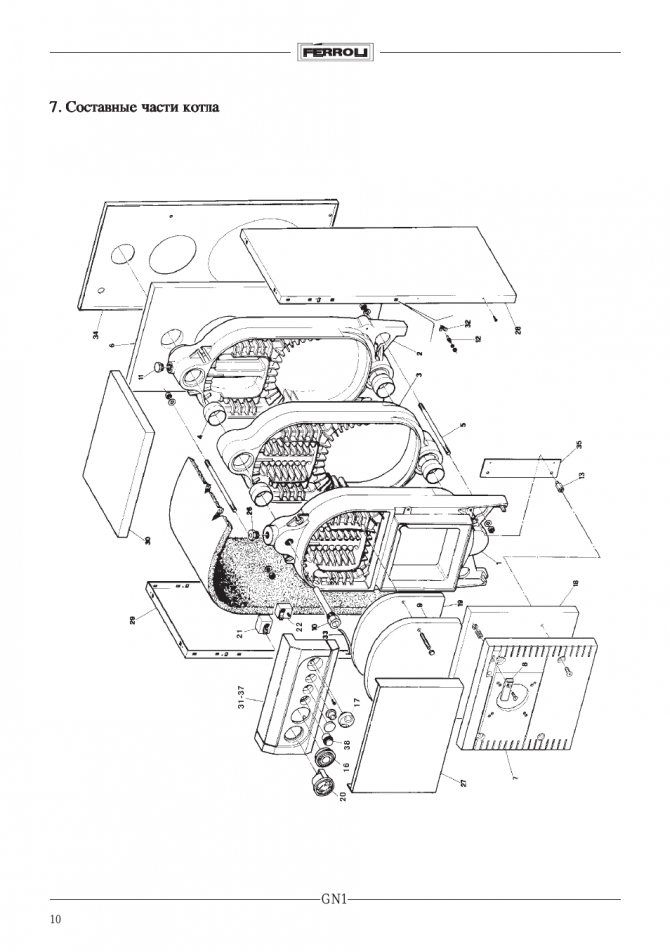

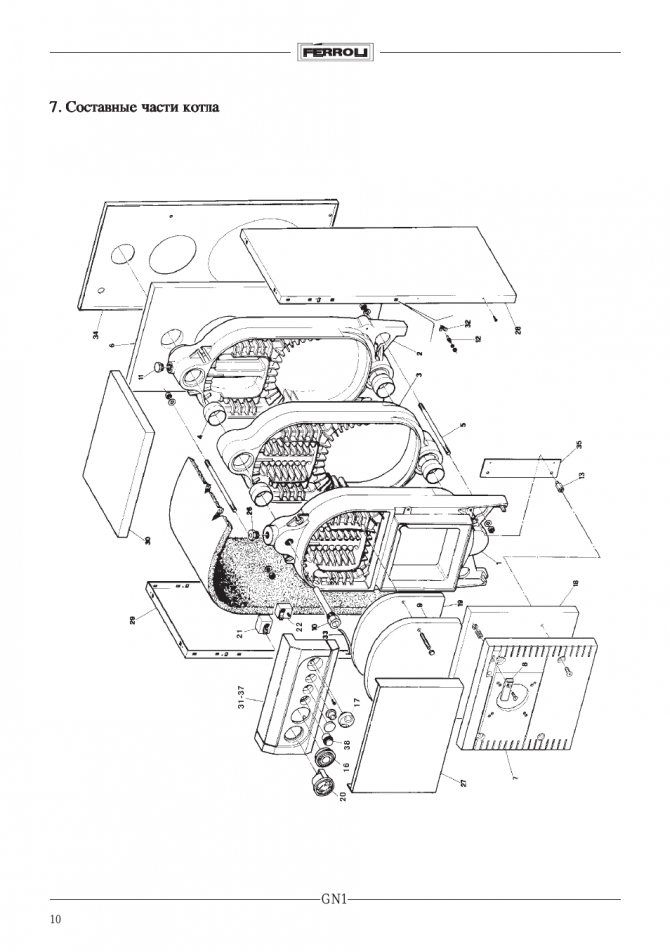

... Boiler components ...

Page 10

- Picture

- Text

RENNOi

7. Components of the boiler

-OK1-

10

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

From the instructions for a Chinese fire extinguisher: - Do not spray near an open fire!

Manualza! Manualza.ru

Still not with us?

Why is the pressure dropping

The pressure drop in the boiler can be due to three reasons:

- The appearance of a leak in the heating circuit (including in the boiler itself). A feature of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is fed.In this case, you need to find the place of the leak. First of all, you need to check the condition of the drain valve or valve, whether it is open, or whether it is out of order. If no malfunctions are found in this unit, the entire heating circuit is sequentially checked. Sometimes they forget to close the drain valve on the radiators, there are fistulas in the pipelines, and the connections fail. The most difficult thing to detect is a leak if the tap is feeding a water floor heating system that is poured into a concrete screed. You can detect a problem by a wet spot on the floor or on the ceiling of the lower floor, and then for this you often have to remove the floor covering or stretch ceiling.

- Failure of the circulation pump. This problem is immediately detected by the self-diagnostic system, and it is easy to check the pump's performance. It is enough to make a visual inspection of the element and take appropriate measures.

- Expansion tank diaphragm rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process stops. Then, an uncontrolled increase in pressure is possible, especially intense when the temperature of the extract air rises. If it turns out that the problematic element is precisely the expansion tank, urgent measures must be taken to repair or replace the unit. Otherwise, with the temperature expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant expenses for repair and restoration of the boiler's operability.

teplomex.ru

Electric boilers Ferroli have been supplied to Russia since the end of the last century, and to European countries for more than 60 years. Affordable quality, good technical characteristics and functionality make this brand more and more popular. But, despite this, reviews for Ferroli Zews electric boilers are still not as common as for Proterm Skat boilers.

Therefore, today we will try to make an overview, a detailed description of the features and instructions for operating an electric boiler from the Ferroli company, consider all the pros and cons, which may help you make a choice: is it worth buying a Ferroli boiler or preferring equipment from other manufacturers.

Features of electric boilers Ferroli Zeus

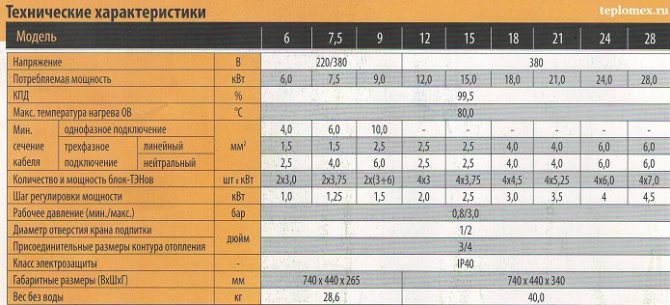

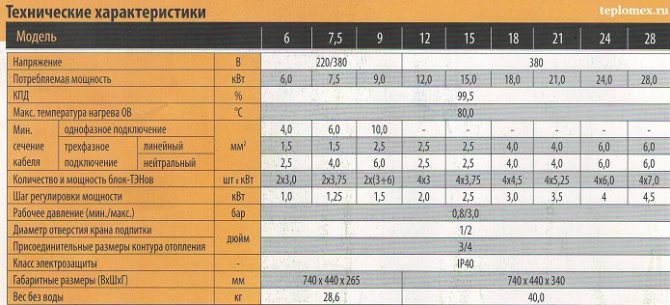

The Italian company produces electric boilers for heating the Ferroli Zews model range with a capacity of 6 kW, 7.5 or 9 kW - up to 100 m2, as well as for large rooms - 12, 15, 18, 21, 24 and 28 kW, as evidenced and her official website.

According to the type of connection, these heating devices are produced:

- single-phase 220 V (up to 9 kW inclusive); - three-phase 380 V (from 12 kW and above).

Electric boilers "Ferroli Zews"

The assembly of electric boilers is carried out at a factory in China under the quality control of Italian specialists, as indicated by the product barcode 693. This can be attributed to disadvantages, since the Russian consumer does not always trust the reliability of a product manufactured in the PRC. But there are also advantages here, for example, the price of an electric Ferroli boiler assembled in Italy would be much higher than for a Chinese one.

Ferroli Zews electric boiler device and its functions

All boilers of the Zews series are single-circuit, designed for heating only. However, they provide the ability to connect an external indirect heating boiler for hot running water. On the boiler control panel there is also a special knob-regulator of the water temperature, which is heated in this additional boiler.

In addition, the boiler has a built-in water temperature and air temperature sensor. However, in order to control the operation of the boiler depending on the room temperature, it is necessary to additionally buy a remote room thermostat.

You can also connect weather-dependent automation by installing a special outdoor temperature sensor, for which the boiler has its own connector. With such weather-dependent automation, you can significantly save on electricity, significantly reducing its consumption.

The main elements of the Ferroli electric boiler are:

- heat exchanger with a group of copper heating elements; - the electronic board; - a three-speed circulation pump of the Wilo brand with an automatic air vent; - membrane expansion tank with a volume of 10 liters; - copper hydrogroup; - safety valve.

Boiler control panel "Ferroli Zeus"

The Ferroli Zews electric boiler stands out for its large and bright LCD display, through which the user can monitor the main parameters of the heating and water supply system:

- water temperature in the heating circuit and in the indirect heating boiler; - pressure in the system; - current consumption of electricity; - errors when malfunctions occur in the operation of the device.

On the front panel, in addition to the LCD display, there is also a thermomanometer, on / off buttons and a "winter-summer" function, which allows you to consume as much electricity as required by a given season. It is also possible to operate the boiler in the "warm floors" mode in a certain temperature range.

Electric boilers Ferroli: technical characteristics and connection

To connect the boiler to the heating system, the bottom of the device is provided with threaded fittings with a diameter of 3/4 'and a valve for making up or filling the system 1/2'. To connect electricity to the boiler, you must use the connection diagram, which is in the operating instructions.

The cross-section of the cable can be different, depending on the power of the selected model: 4, 6, 10 mm2. All technical characteristics are described in more detail in the table.

Technical characteristics of electric boilers Ferroli

Advantages of electric boilers Ferroli Zeus:

- a wide range of different capacities; - good quality components and spare parts; - the maximum set of modern functions; - large informative LCD display; - the possibility of using antifreeze liquid in the heating system; - round-the-clock technical support by telephone "hot" line.

Disadvantages of an electric boiler of the Ferroli Zews brand:

- high price; - Chinese assembly; - lack of a room thermostat in the kit.

Having disassembled the technical specifications, device and functions electric boiler ferroli, we can conclude that this is a modern heating device that meets all the latest technical requirements. Its only drawback can be attributed only to a slightly overpriced compared to competitors. Yes, and the reviews of specialists and buyers are still not enough to really assess the quality of Ferroli Zews electric boilers. Watching the video.