Any heating system, in principle, can work without additional taps and valves. But at the first breakdown, the owner runs the risk of being left without heating. Shut-off valves will be needed, first of all, in the event of various emergencies, namely leaks, clogging of pipes, the occurrence of air jams and scheduled repairs of the heating system.

The presence of shut-off valves, or, as it is also called, radiator piping, will significantly extend the life of the heating system and greatly facilitate the life of the owner of the house.

Tasks

Taps and valves are called shut-off and control valves. To choose the right set of valves, you need to take into account what tasks certain devices perform.

During operation of the radiator, an air lock collects in the upper part of the heating system due to convection. It interferes with the normal flow of the coolant: the upper part of the pipes remains cold, the lower one heats up to unthinkable temperatures. Especially for the release of unnecessary air in the system, there should be Mayevsky taps.

In the event of a sudden leak or a clogged radiator, it is strongly recommended to remove the damaged sector without draining the entire system. In order to remove the problematic section of the system, shut-off equipment is installed on the inlet and outlet pipes. The valves function in two working positions: open and closed. The valve in the open position does not interfere with the flow of water in the system, and in the closed position the flow is completely blocked. Simple ball valves are most suitable for this task.

If it gets very hot in the rooms, you have to ventilate the room unscheduled in order to bring the air temperature into an acceptable range. But in this case, the heat goes out into the street. To save fuel for the boiler and not waste money on the wind, they use control valves - a thermostat or a manual thermostatic valve.

Manual control valves

They are distinguished by their ease of use, high accuracy and a variety of models. It can be a straight control valve or an angle valve. The devices are highly reliable. They are very easy to maintain. A control valve with a detachable fitting on the boiler side is very convenient and practical. Such an element with a union nut is convenient in that when installing it, you can not use a sealing material (sealant, tow). In addition, the structure is easy to dismantle.

There are valves commercially available that can be used with a thermostat. In stores, you can find devices that perform not only their regulatory functions, but also have design solutions.

Limitations during the use of control valves

Control valves should be used in strict accordance with their purpose.

There are some restrictions when using the devices:

- If drinking water is transported in the system, then brass valves must not be used, since brass emits harmful substances that are dangerous to the body.

- If the control valve is intended for a plumbing system, then it is not recommended to use it in pipes where other liquids are transported.

Following the rules specified in the technical characteristics of the devices, you can ensure high-quality and long-term operation of control valves.Each valve has special seals that are designed for use at a specific temperature.

Elevator unit

The standard diagram of any heating circuit is pipes with a direct flow of hot water (supply) and a return flow of cooled water (return). Such a system will work only within the permitted temperature range. If the water in the system is heated above 95 ° C, then such water cannot be supplied to the radiator.

In order to cool the coolant in the heating system to permissible values, an elevator unit is used. It is a container in which water from the supply and water from the return is mixed, a nozzle, a diffuser and a piping, which includes temperature and pressure meters. The most efficient operation of the elevator unit is observed when:

- accurate calculation of each of its parameters;

- there must be a differential pressure of up to 25 bar between supply and return.

Unfortunately, the elevator unit cannot guarantee that the water in the supply line will be at any specific temperature. It all depends on how correctly the nozzle cross-section is selected. Recently, manufacturers have been offering elevator boilers in which the nozzle solution can be changed in one direction or another. Thus, the process of mixing water in the elevator unit is regulated and the temperature of the water in the supply line is optimized.

Shut-off valves and shut-off valves

Shut-off and shut-off valves perform several important functions:

- helps to cut off the damaged or clogged section of the heating main without prejudice to the further operation of the system;

- stop valves help regulate the flow of water in the heating main and relieve air locks.

The process of regulating the movement of water in the heating main is carried out using various shut-off valves. Basically, such elements include latches, valves, taps and shutters for a radiator.

Gate valve

Gate valve is a type of shut-off valves that can be used to stop the movement of the coolant in the system. The gate valve design provides for an element located perpendicular to the direction of flow of the coolant. With the help of the regulating mechanism, it is possible to increase or decrease the clearance in the valve, thereby affecting the speed of movement of water in the system. Flanged and coupling ball valves

This type of shut-off valves got its name due to the shape of the valve. Most often this part is in the shape of a ball, in which there is a through hole. As a locking mechanism, taps with a straight hole are cut into the heating system. By turning the lever, we change the position of the ball, thereby opening or closing the path for the coolant flow.

Ball valves are divided into full bore and standard. Standard valves allow up to 80% of the water flow in the system to pass without blocking. A full bore ball valve has almost one hundred percent throughput, so this option should be chosen for radiators. You should also pay attention to another design feature of the ball valve.

Flanged

Flanged devices can only work in two positions - open or closed. Such a design will not be able to provide a half-pass water flow in the system, therefore, ball valves are not suitable for radiators. But they do an excellent job with the pressure of water inside the pipeline.

Therefore, flanged ball valves are installed only on pipelines. Thanks to their simple and efficient design, these cranes are easy to use and durable.

Couplings

Coupling ball valves are threaded at the edges, which provides this device with a reliable fixation.Such a faucet is able to pass liquid through itself and regulate its flow. Thus, coupling valves are optimally suited for installation on a radiator.

When purchasing this device, you should carefully read its technical characteristics. Typically, this information is contained in the manufacturer's documentation.

Material and type of connection

Shut-off valves can be made of various materials. The bodies of modern valves can be made of steel, bronze or brass, there are also polymer valves. In a classical heating system, pipes and batteries are made of metal, therefore brass or bronze valves are placed in such a heating main.

Attention should also be paid to the type of pipes in the pipeline. In each case, the most suitable type of connection is determined - with union or crimp nuts, with an internal or external thread.

Much attention is paid to the tightness of the shut-off of the coolant flow in the system. For this, special gaskets are installed, and the metal balls in the tap are ground, achieving absolute smoothness. The smoother the surface of the ball, the more tightly it will stick to the inner surface, the less chance of leakage.

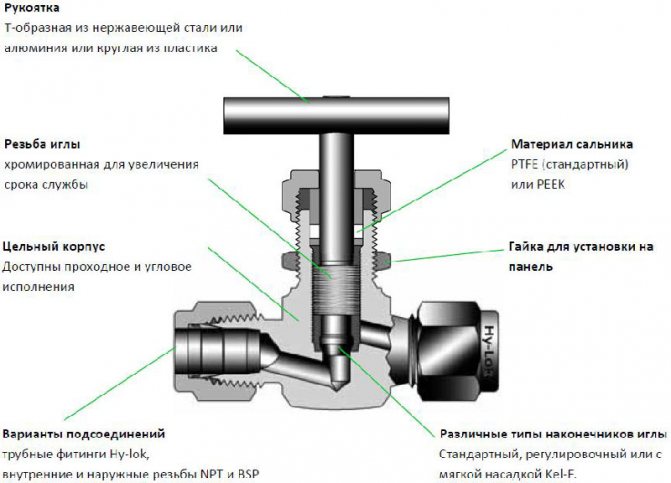

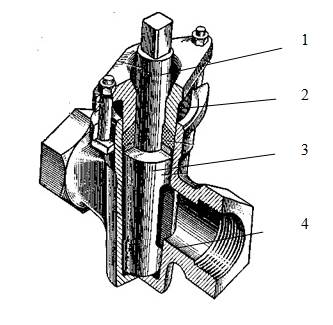

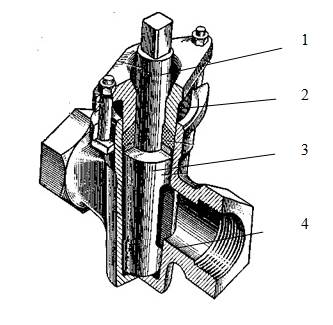

Globe Valve Specifications

A shut-off and control valve is a device in which the flow regulation is carried out by means of a reciprocating movement along the main axis of the shut-off mechanism stem.

This type of assembly allows you to increase or decrease the power of the fluid flow, as well as tightly close the shutter. The shut-off and control valve uses a spindle as a movable mechanism. It is screwed into the nut thread, which is located on the body.

Shut-off and control valves are characterized by the following advantages:

- creation of fine adjustment;

- maximum simplicity, reliability and maintainability;

- minimum dimensions;

- any spatial position during installation.

The presence of the thread makes it possible to obtain and fix any intermediate position of the locking mechanism. In addition, it is guaranteed that it cannot spontaneously change its position at high pressures.

One of the disadvantages of such valves is that they can only be used to regulate the flow in the line transporting uncontaminated liquid.

Of the minuses of shut-off and control valves, one can single out an overestimated hydraulic resistance, the impossibility of using it in pipelines transporting contaminated liquid and restricting the flow in only one direction.

Installation of valves

Shut-off valves are installed in the following units of the heating system:

- at the entrance of the heating main into the building;

- on all risers of the heating system;

- at the point where the pipe leaves the elevator unit;

- at the top points of the heating circuit.

Adjusting the heating system using additional fittings will help to quickly and effectively establish its stable operation, perform a thermoregulatory function - turn off the heat supply in an emergency or dismantle a section for repair or replacement. Thus, the use of shut-off valves significantly increases the safety of the entire heating system and facilitates its repair and regular maintenance.

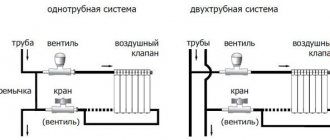

How to install a tap on a battery

In order to be able to shut off the water in the system, one ball valve should be installed on the supply and return. If the installation of other thermostatic equipment is not provided, it makes sense to connect the valves directly to the radiator inlet.

First, a valve is screwed onto the pipe, after that a squeegee is mounted in the radiator, after which the valve is brought to the radiator and the system is fastened with a union nut.

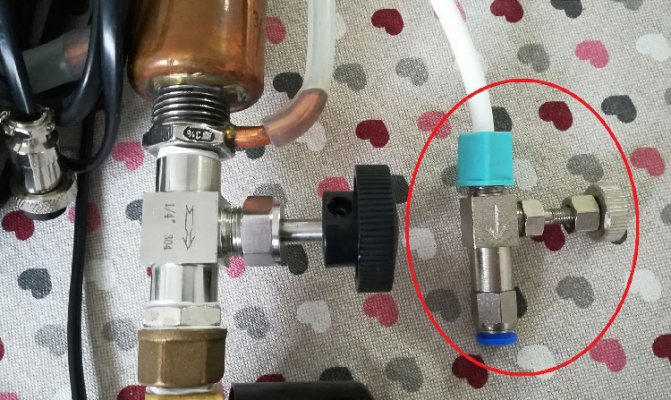

Mayevsky crane

The Mayevsky crane is a mechanical air vent designed to release air in the heating system. Usually placed at the top of the radiator, in any free space. The faucet is a small threaded washer with a needle valve inside.

The Mayevsky crane is installed at the opposite end from the water inlet into the radiator. By slightly opening the needle valve, air can be easily removed from the radiator. This mechanism is simply turned counterclockwise several times until the air hiss appears. As soon as the sound stops, the needle valve is turned in the opposite direction and tightly closed.

The air outlet is located either in the valve body or in its plastic gasket. If the water in the system is clogged, and the pipes are covered with rust from the inside, the hole can become clogged, and the needle mechanism is disabled. Therefore, the air hole must be cleaned regularly with a commercially available sewing needle.

Which valve to choose for a specific task

A person who had not previously had experience in plumbing work is unlikely to be particularly versed in the types of taps and will be able to answer without hesitation where it is better to use a ball valve, what should be a balancing valve and what should be a thermostat. Let's dwell on this in more detail.

We regulate the temperature in the room

The control valve on the heating radiator can be of several types:

- manual - in this case, a person manually, turning the knob of the regulator, changes the size of the passage in the pipe, and the flow changes accordingly. Quite an inconvenient way of adjusting, especially with a large number of installed batteries;

- automatic - after installation the device is calibrated. Subsequently, the flow rate of the coolant changes automatically depending on the ambient temperature. Such devices cost within a few hundred rubles (depending on the manufacturer), but the purchase is worth it;

- electronic control systems can also be noted; in addition to the valve, the kit includes an electronic unit that sends a signal to the valve. You can preset the operating modes of the device depending on the day of the week / time of day. For example, if the owners have left for several days, the system will maintain a temperature sufficient so that the water does not freeze in the pipes, and you can even give the command to switch to normal mode from the phone.

If the control valve for radiators is still manual, then only screw models should be chosen. The fact is that there are ball valves on the market, and models with a locking part in the form of a cone or cylinder, but they are used only for quick, almost instantaneous isolation of the battery from the system, this is necessary, for example, in the event of a rupture.

They cope with this function perfectly, but they are absolutely not suitable for adjusting the flow, the fact is that they have only 2 working positions - either the valve is open or closed, it cannot be in an intermediate position.

It often happens that after installation, the valve does not have to be used. Centralized heating can work very badly, and accordingly, there is no need to restrict the flow of the coolant.

In this case, it is recommended to periodically close everything equal to open the valve, this must be done so that it does not become unusable, the deposited scale simply will not allow it to be closed completely after a while. And periodic opening / closing allows you to avoid this.

As for the installation, it can be done by hand, you just need to place the thermostat correctly. It is installed only on the supply pipeline, first there is a bypass, then a ball valve to cut off the radiator and only then a thermostat.

There are no special subtleties in the installation, except that you need to especially carefully seal the threaded connections, but FUM tape or oiled tow will help to cope with this.

Note! It is undesirable for the thermostat sensor to be in an enclosed space (for example, in a niche under a window, closed with curtains). This will lead to incorrect operation of the heating system.

Such devices can be produced both straight and angled. Radiator angle valve 1 2 "will fit batteries with bottom piping and camouflaged pipes in the floor.

Balancing the heating system

The balancing of the heating system can be either automatic or manual. In autonomous heating systems, if balancing valves are used, then, as a rule, they are intended for manual balancing.

A control valve of this type differs from those discussed above in that the manufacturer uses a special shaped shutter, which makes it possible to derive the relationship between the position of the valve and the volume of water flowing through it. Based on these dependencies, an adjustment scale is applied to the handle.

Note! A significant disadvantage of this type of device can be considered that they cannot be used in conjunction with other devices that automatically change the coolant current.

Modern valves of this type are installed in the supply and return pipelines. They make it possible to adjust the flow rate based on the temperature of the coolant and the pressure in the circuit. They can also act as a locking and drainage device.

In principle, the instruction requires the use of separate valves if automatic devices are used in the heating system (the same thermostats). But some manufacturers, like Honeywell, have managed to get around this limitation.

The use of conventional balancing valves is allowed, only some auxiliary equipment is needed - a diaphragm block. And you can install it even without interrupting the operation of the heating system.

Shut-off valves

A ball valve can be considered a classic representative of this type of device; cylindrical and cone valves can also be found. The obturator of this type of valve looks like a ball / cylinder / cone with a through hole in it.

In the open state, nothing interferes with the passage of the coolant through it (the hole in the obturator is equal to the inner diameter of the pipeline). When you turn the handle, the ball turns 90ᵒ, and the pipe is closed, this happens almost instantly. Tightness is ensured by a gasket that adheres tightly to the metal of the ball.

A straight radiator valve of this type can also be tapered, but this is the worst option from the listed ones. The fact is that the conical version requires more effort when turning the valve, and if this is not critical due to its small size, then accelerated wear in comparison with the ball version does not allow recommending it for purchase.

Note! A screw valve will not be suitable for the role of a shut-off valve due to the fact that it will take too much time to close the passage, and its wear is increased compared to the ball valve.

The price of ball valves is low, so it is recommended to provide 2 such devices for each radiator when installing a heating system. So even the failure of one battery will hardly affect the operation of the heating system.

Thermostat

About 30 years ago, modern devices appeared to control the temperature of water in the system, which were called "thermostat". Outwardly, this thermostatic device looks like a valve, which was modified and a display with temperature indicators was installed on it.

The thermostat must be installed between the battery and the supply.The appliance should be placed horizontally to limit the influence of extraneous heat sources. The design of the thermostatic device allows mixing hot water from the supply with chilled water in the return. In this way, the optimum temperature is reached and heating resources are saved.