Appointment of mats

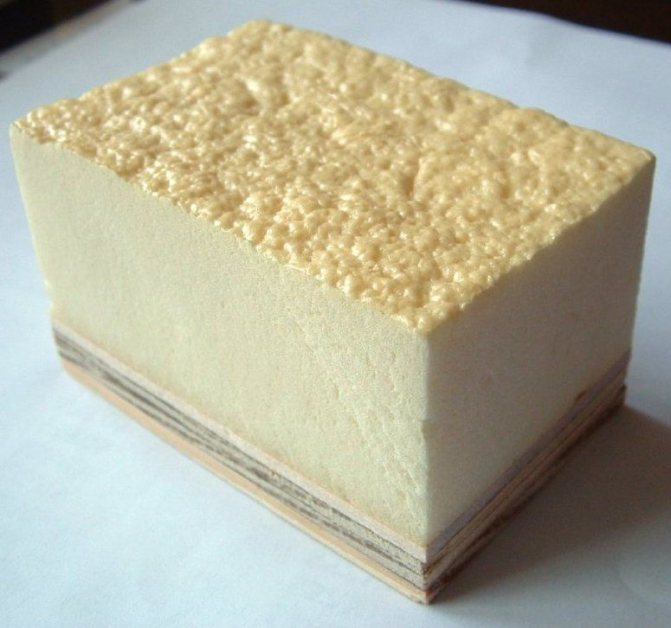

Thermal insulation mats (also called slabs) are the main component of the efficient operation of underfloor heating, and it would be foolish to dispute their necessity. After all, if this layer is not there, then the heat generated by the floor will go away (moreover, in large volumes) for heating the overlapping slabs, which is hardly advisable. The mats prevent heat energy from leaving "nowhere", therefore special requirements are imposed on them. They must withstand the weight of the pipeline with water, concrete screed, final coating and all kinds of loads that arise during operation. For this reason, the density of the heat insulator must be at least 35 kilograms per cubic meter.

The waterproofing layer, which is laid under the mats, has the following functions:

- protection of insulation from the negative effects of the screed;

- ensuring the reliability of the floor covering, its safety for neighbors below.

Note! If the installation was carried out correctly, then it will additionally soundproof the apartment!

Characteristics of expanded polystyrene used in warm floors

Below are the main parameters that this material should have.

- Density of about 40 kilograms per cubic meter, in order to be resistant to any kind of mechanical stress.

- Insignificant thermal conductivity (no more than 0.05 W / m * K), providing a minimum amount of heat loss.

- Due to its cellular structure and physical properties, the foam provides excellent sound insulation.

- The material is protected from the harmful effects of moisture not only by a laminated coating, but also by centering locks, which are located at the ends of the panels. And thanks to the excellent adhesion of the mats, the possibility of gaps and crevices at the joints is practically zero.

- Finally, mats can be different in size - 60x80 centimeters and 100x100 centimeters. Therefore, the installation step is also different.

How to make a warm water floor with your own hands

We advise you to look at our instructions on how to install a warm water floor on your own. All details are here

The main advantages of mats for a warm water floor

- First of all, they fully comply with all European standards. In the manufacturing process, for example, self-extinguishing raw materials are used.

- On top of the material, it is possible to lay both semi-dry and wet screeds.

- Due to the increased density of the material, excellent strength characteristics are achieved, therefore, over time mats for water floor heating do not change sizes.

- Installation of the heating pipeline is carried out according to the markings, which are applied to the surface in a special way. This contributes to a more efficient distribution of heat energy in the room.

- The mats are equipped with special clamps that allow quick installation of the pipeline.

- There are excellent physical and operational properties.

- Good thermal and sound insulation.

- Such mats are fireproof and harmless to the body.

- They withstand and do not allow moisture to pass through, without swelling.

- Self-centering locks make it easy to assemble slabs.

- The mats are resistant to decay and harmful bacteria.

- Finally, they are able to withstand temperatures from minus 180 C to plus 180 C.

The main types of thermal insulation for a water floor

Styrofoam

This is the cheapest insulation for a warm floor. It is waterproof, keeps warm very well. On the construction market, this material is presented in various shapes, sizes and densities.Despite the availability of foam and a wide variety, serious firms prefer not to use it under a water floor. The fact is that when heated, this material releases substances harmful to human health. Therefore, even if the owners of the premises are constrained in finances, it is not worth saving not on the insulation.

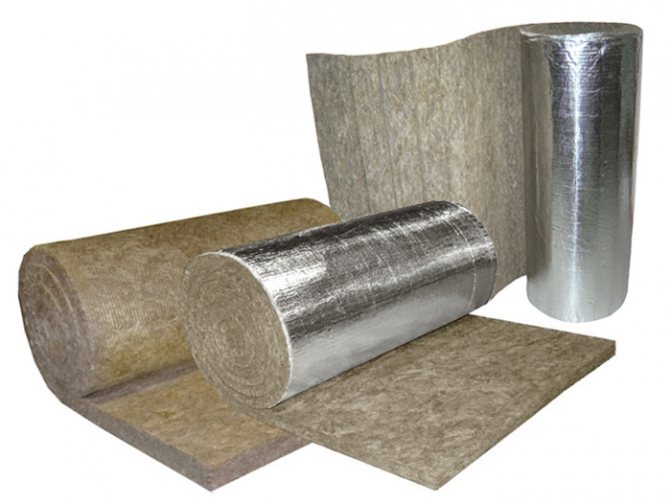

Mineral wool

There are two types of this thermal insulation material: solid board and flexible mat. For a water-heated floor system, mats with a density of more than 35 kg per cubic meter can be used. If you take a less dense material, then it will sag under the weight of the screed. Here it should be borne in mind that mineral wool of the required density is not cheap. But she has her merits. It possesses not only heat, but also sound insulating properties. The material is resistant to fire, has a high heat transfer. Among the disadvantages, professionals single out the hygroscopicity of mineral mats. Cotton wool gets wet and loses its properties. Due to the deformation of the insulation, cold bridges appear and, as a result, heat is lost.

Cork insulation

If the lifting height of the floor is to be kept to a minimum, then the roll cork is the ideal thermal insulation for a warm floor. It is a natural ecological material, durable and warm. When heated, it does not emit any harmful substances. The cork has a high density, so it will not sag under the screed. Of the minuses, the tendency to destruction and sensitivity to moisture should be distinguished. Before laying this insulation, it is necessary to carry out a high-quality sealing of the base.

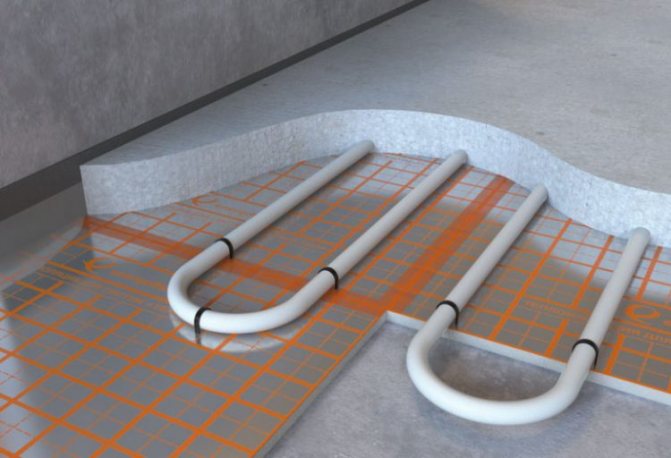

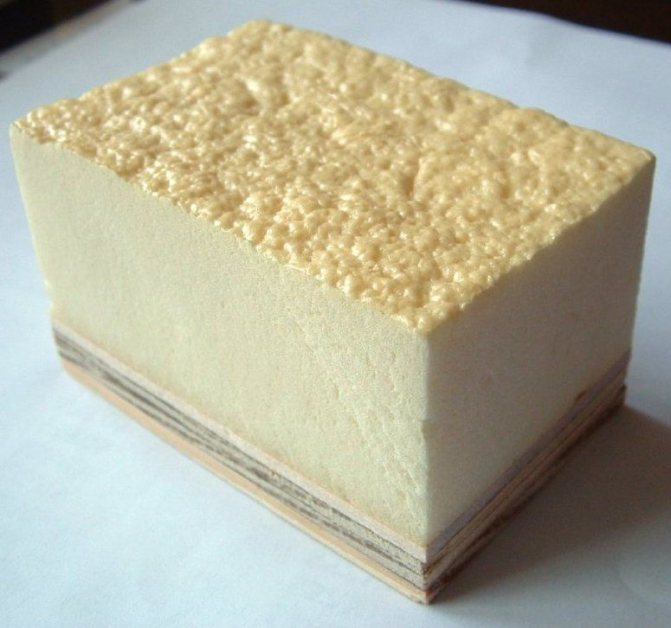

Expanded polystyrene

This type of insulation is most often used for underfloor heating systems. It is produced in sheets of different sizes, so the installation is quite simple. The thickness of expanded polystyrene is from 3 cm to 12 cm. If there is a heated room under the apartment where the warm floor is installed, then you can buy the material of the smallest thickness. In cases where there is a basement below, the thickest insulation is needed.

The advantages of this heat insulator include high density, the material does not absorb moisture, retains heat well, is safe for human health, is not susceptible to fungi and mold, withstands temperature drops from -50 ° to + 75 ° C.

Of the shortcomings, the thickness of the insulation is distinguished. When using it, it should be taken into account that the floors will rise noticeably. This material is highly fragile. Before applying a concrete screed, the insulation layer must be additionally reinforced.

Polyurethane foam

This is the best floor insulation. During its installation, no vapor or waterproofing is required. All work is carried out as quickly as possible. The floor level practically does not rise, moisture does not accumulate, and cold bridges do not form. Polyurethane foam is a highly durable material. It does not require additional reinforcement. It is an ideal insulation material for rooms with complex geometric shapes.

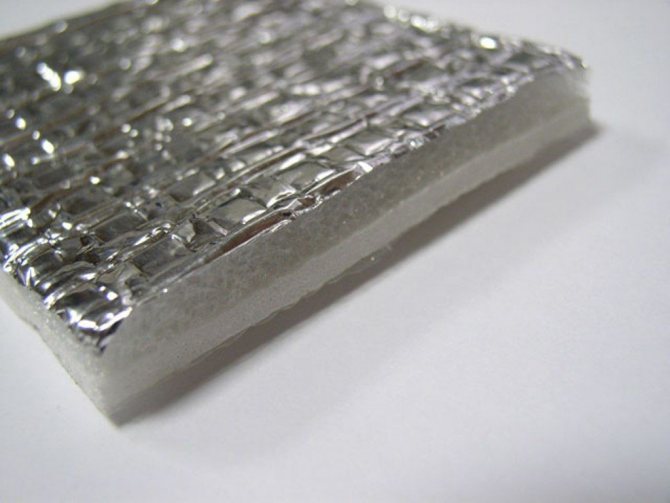

Penofol

This roll material is made of foamed polyethylene, a layer of foil is applied on top. This surface will reflect heat rays. Insulation works like a thermos. Manufacturers distinguish 4 types of penofol:

- View "A". The foil is located only on one side of the heat insulator.

- View "B". The foil layer is glued on both sides.

- View "C". Self-adhesive material. One side (reflector) is made of foil and the other is adhesive.

- View "ALP". On the one hand, the surface of the heat insulator is covered with foil, and on the other - with plastic wrap.

Any kind can be used as insulation for a warm water floor. An important point is to choose the right thickness of the insulating material. It can be from 3 mm to 1 cm. The thickness depends on the floor covering that will be used in the future.

Insulation must be laid with foil up

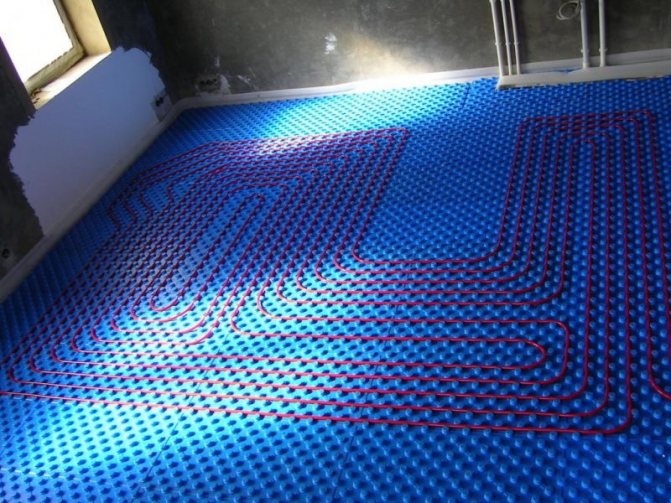

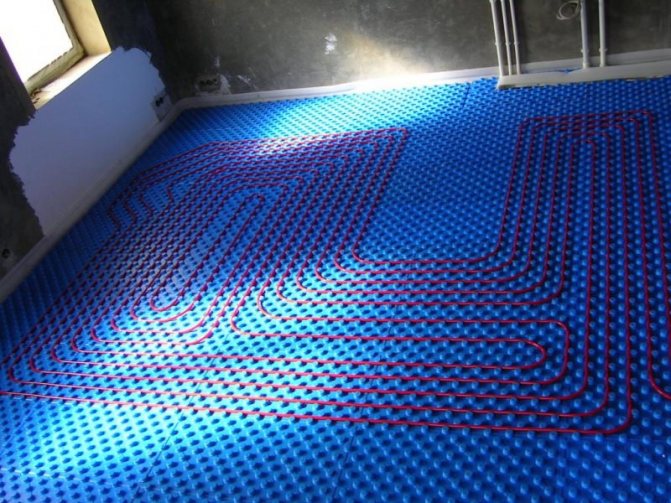

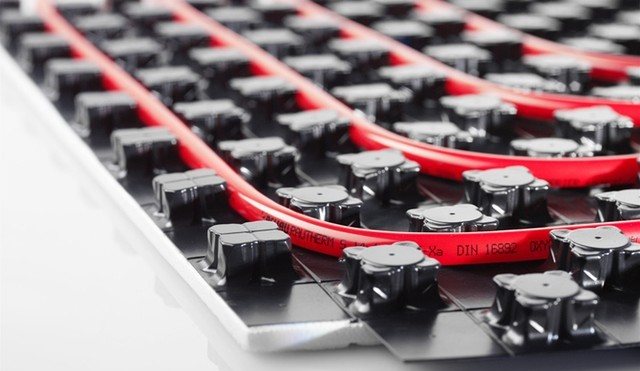

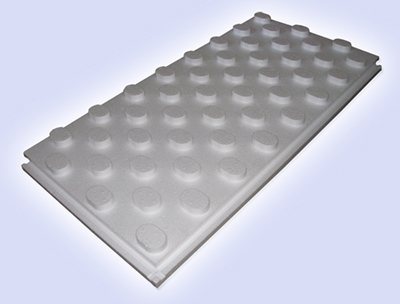

Thermal insulation mats

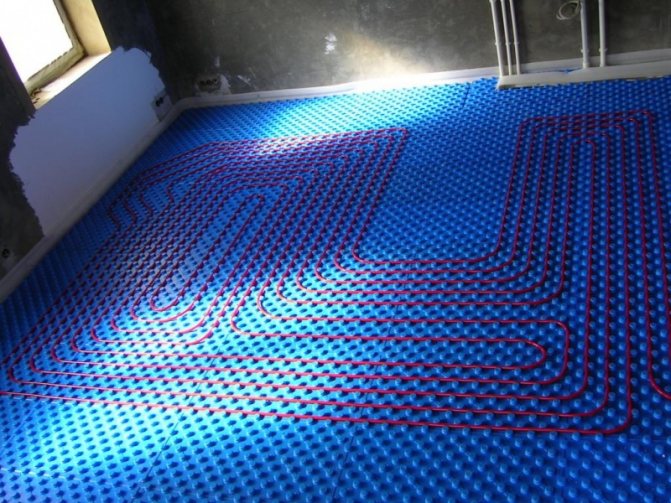

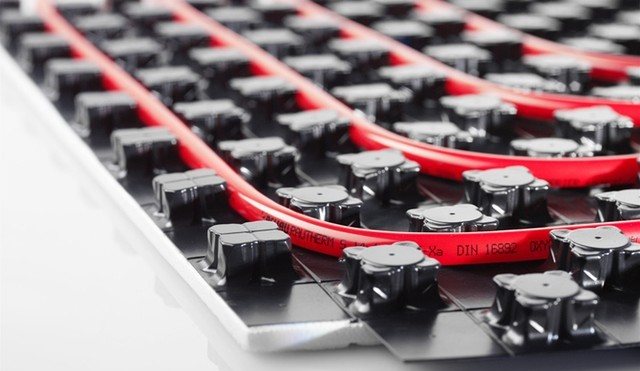

Special profile mats have been created for the underfloor heating system. They are used as insulation for water floors. When using this material, no additional vapor barrier is required. The surface of the mats has numerous projections. Water pipes are laid between them. This job is very difficult and requires professional training. If the pipes have a non-standard diameter, then they cannot be positioned between the protrusions.

Thermal insulation mats are among the best insulators for a water-heated floor.

Classification of expanded polystyrene mats

The products described in this article can be:

- foil;

- with film;

- flat;

- with "bosses";

- profile.

Let's get acquainted with each of the options in more detail.

Option number 1. Foil

These mats are made of foam foam and have a special foil coating on one side. Due to their technical characteristics, they can only be used for floors that are used as an auxiliary heat source. But if you use them, say, for the floor of the first floor, under which the basement is located, then their effectiveness will be insignificant.

The pipeline is laid on the foil-coated surface of the mats, while special fixing accessories are used for fixing - clamps, brackets, steel mesh, etc. And this, of course, comes with some inconveniences.

Option number 2. With film

Such boards include a foil and polystyrene foam layer, as well as a protective film. This insulation material has a high density - about 32-35 kilograms per cubic meter. To make the installation of pipes as easy as possible, special markings are made on the film.

Due to the excellent tightness, the fastening brackets that fix the pipeline are attached as securely as possible. And unlike the option described above, these mats can be used for a warm floor, which serves as an additional source of heating.

Option number 3. Flat mats

These expanded polystyrene products have a thickness of 0.4-0.5 centimeters and a density of approximately 40 kilograms per cubic meter. They are characterized by resistance to loads and deformations. The pipes are fixed with special plastic brackets. It is characteristic that before the start of installation work, markings are applied to flat plates, which makes the installation procedure somewhat more complicated.

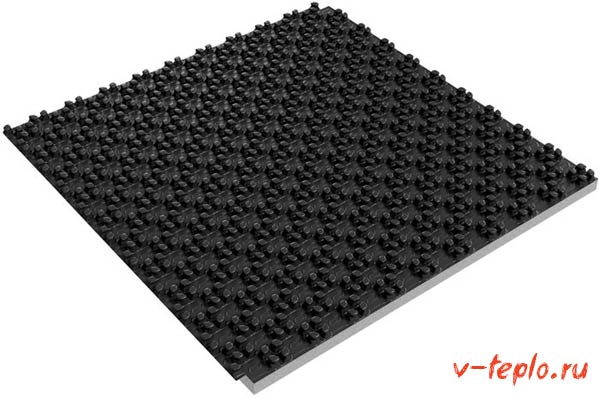

Option number 4. Flat slabs with "bosses"

In their manufacture, a special technology of hydropellant stamping is used, as a result of which even rows of figured protrusions appear on the surface of the material (it is they who are called by this strange word "bosses"). This is one of the most modern designs that allows you to easily install the underfloor heating pipeline.

Option number 5. Profile mats

The profile products are based on rectangular polystyrene foam plates. Along the entire surface of these slabs, there are special cylindrical protrusions, the height of which is about 2.5 centimeters. And this is quite enough to place a heating pipeline between them (its diameter usually does not exceed 2 centimeters) and practically reduce to zero the possibility of pipes shifting during the pouring of a cement screed. The mats themselves are 1-3.5 centimeters thick. It is characteristic that if a warm floor is equipped on the basement floor or on the ground, then the plates of the insulating material should be wide.

Basalt insulation mats

While expanded polystyrene mats are an excellent modern solution, basalt material has been used for many years, and it also has many advantages. First of all, it is worth noting its effectiveness, which certainly cannot be compared with the capabilities of expanded polystyrene.

Often this material is used to insulate large industrial buildings, however, it is also an excellent option for warm floors. The following advantages are worth noting:

- Security. Obviously, the basalt insulating resource is actually an excellent solution, given that it consists exclusively of natural materials. In addition, these products are non-flammable and have a good level of vapor permeability.

- High operating temperature. As we have already said, expanded polystyrene is able to interact only with low temperatures. But basalt insulation is almost ideal if the warm floor is heated to high temperatures. Of course, we are not talking about a water field, but about other types of systems. Many manufacturers indicate that their basalt thermal insulation mats can easily withstand +700 degrees Celsius or more. Accordingly, it will be extremely difficult to even melt such a material, which, again, has a positive effect on its safety.

- Efficiency. As already mentioned, basalt thermal insulation has a high heat preservation efficiency. This is probably the most important advantage that will be decisive for many owners.

Often on sale you can find mats based on this material of rather large dimensions, so the issue of compactness here immediately disappears. Manufacturers note that, unlike many other insulating resources, the material has dimensional stability. The bottom line is that the mats will not deform even under heavy loads. Of course, this strong point of the material is most relevant when creating large buildings, as well as industrial premises.

Well, in the end, I would like to note that it will most likely be possible for each owner to lay this material with his own hands, but the difficulty lies in fixing the pipes of the underfloor heating system to the insulating resource. Accordingly, for this case, you need to purchase special fasteners and additionally analyze the location of all elements of the installation.

Other features of the insulation

Mats for a warm water floor are made of two types:

- laminated (that is, covered with a vapor barrier film);

- not laminated.

How to insulate the floor in a wooden house?

We advise you to look at our instructions for floor insulation in a wooden house, you can learn more here

The first option differs in that it does not require additional laying of the vapor barrier.

Note! We also note that a warm floor cannot be installed over such a base if the diameter of the latter is non-standard.

At the ends of the slabs are equipped with special locks. The ruler, which is applied, simplifies the adjustment of the mats to one another, and this, in combination with the locks, creates a continuous insulating field without any thermoacoustic seams. Consequently, heat loss is excluded in principle.

As for the thickness of the slabs, it is selected in accordance with the thickness of the topcoat and cement screed. The possibility of the presence of an insulating layer in the floor itself is also taken into account. And if its thickness is sufficient, then you can restrict yourself to mats with "bosses", which are not intended for thermal insulation, but for reliable fastening of the pipeline. Also, as noted above, not only the laminated coating protects from the negative effects of moisture, but also the centering locks located at the ends of the plates. And thanks to the excellent adhesion of the mats, the possibility of heat loss is excluded.

Video - Thermal insulation boards made of expanded polystyrene

Varieties of insulating material for a water type underfloor heating

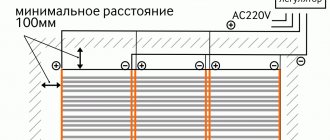

Modern manufacturers of insulation materials present many options for the procedure.The thickness of the insulation is influenced by financial capabilities, as well as the technical features of a room or apartment, where thermal insulation is required. Any kind of material has sound insulation. The thickness of the material depends on what is under the underfloor heating. If the soil or basement, then use a substrate equal to more than thirty millimeters. When insulating floors located above a warm room, it is enough to lay a substrate of ten millimeters.

Thermal insulation for a water floor must have the following parameters:

- The material should have a low level of thermal conductivity.

- Must cope with the load carried by the water flowing through the pipes.

- Its functioning should not be affected by the floor screed.

- Insulation must cope with thermal expansion in pipes when the pressure and temperature of the water changes.

The most optimal option as a heater is considered to be a material with a density of more than thirty-five grams per cubic meter.

Leading manufacturers and average cost

Despite the large assortment, we advise you to pay your attention to well-known (read: proven) manufacturers who have already managed to perfectly establish themselves in the market. Let's consider the most popular models.

Oventrop

German company engaged in the production of polystyrene foam mats. Below are the most common models.

- NP-35 - mats with "bosses", which have excellent sound and thermal insulation qualities. One side of them is covered with a polystyrene film. They are used not only with a conventional screed, but also with self-leveling floors. The average cost is about 950 rubles.

- WLG-045 - roll-type slabs covered with polypropylene film. Suitable for pipes with a diameter of 1.4 and 1.6 centimeters, as well as for a laying step within 5-30 centimeters. The area of one roll is 10 square meters, the approximate cost is 5000-5700 rubles.

- NP brand products do not have thermal insulation and will cost about 665 rubles.

Energoflex

Domestic company producing quality products. Consider popular models.

- Energoflex TP. Foil polystyrene foam plates, on the surface of which a coordinate grid is applied with a step of 50 millimeters. Dimensions: 2.5x100x500 centimeters, the average market price is up to 250 rubles.

- "Expanded polystyrene plate". It has two-centimeter "bosses" that allow you to lay pipes without additional fasteners. There are self-centering locks, markings are applied. It fits in 5 centimeters increments and is designed for pipes with a diameter of 1.6-1.8 centimeters. Price - up to 680 rubles.

- Energoflex Super TP. Rolled mats for warm water floors. Foiled, applied with a coordination grid with a step of 5 centimeters. Dimensions: 0.5x120x150 centimeters. They cost about 250 rubles.

REHAU

A well-known company from Germany, which also produces expanded polystyrene insulation boards. The products are equipped with clamps for fastening the pipeline, have a sound and thermal insulation layer made of expanded polystyrene. The thickness is 3 centimeters. The average market value is 725 rubles.

How to choose the right model? First of all, the diameter of the pipes is taken into account, as well as the thickness of the insulating layers. If ceramic tiles will be laid on top of a warm floor, then the plates should be thin. By the way, it is ceramic tiles that are considered the ideal material for covering a heating water floor, since they are durable, perfectly conducts heat, and are resistant to temperature extremes and mechanical stress.

Features of installation of expanded polystyrene plates

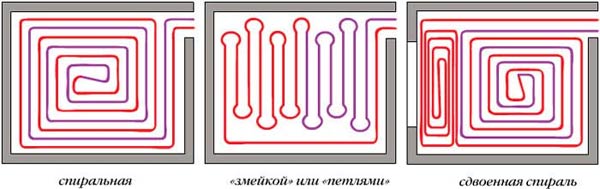

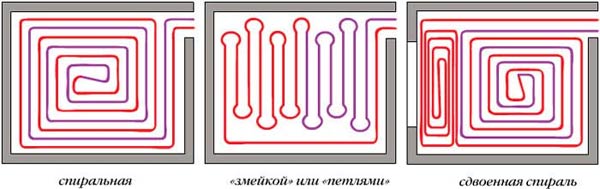

Before proceeding with the installation of insulating mats, it is necessary to carry out several preparatory measures. The most important of them is the calculation of the heating power, which is measured in watts per square meter, as well as the area that the material should occupy.After that, you should decide on the installation diagram of the pipeline. There are several such schemes:

- spiral - it is advisable in rooms with a small area;

- double helix - used in large rooms;

- "Snake" - underfloor heating pipes are installed parallel to each other.

Note! If under the room there is an unheated or basement room and the floor, as a result, plays the role of a source of cold, then it should be insulated. For this purpose, you can use any thermal insulation material - expanded clay, mineral wool or, say, polystyrene. But it is characteristic that before installing the slabs, it is imperative to perform a screed and level it using special mixtures.

Having laid the pipes, you can start checking the system's performance - run the coolant into the pipeline, check the temperature and the presence of "cold" places. It is recommended to do this at extremely high temperatures, and also to check if the properties of the mats have changed. If everything is normal, then fill in the finishing screed.

Video - Installing a warm floor

Special boards as insulation

It is possible to use slabs as an insulating material in rooms with high ceilings, reaching at least two hundred and sixty centimeters.

Materials from which the slabs are made:

- The main material from which the plates are made is expanded polystyrene or polystyrene. Foam slabs are created using the non-extrusion method. In the device of the plate, channels are created through which steam and air pass. Foam boards have low weight, but high vapor permeability. Penopolsitrol is created by extrusion, in which the walls of the polymer cells are soldered together.

Therefore, the material does not have vapor permeability, but it is distinguished by its strength and resistance to mechanical stress. Expanded polystyrene, in contrast to foam plastic, has a high heat capacity, which is 1.34 KDl and 1.26 KDl, respectively. With a small difference, it is essential for determining the thickness of heated floors.

The slabs are typically 120 by 240 centimeters. According to GOST 15588 - 86, the slab should have a width within the range of 50 - 130 centimeters, a length of 90 - 500 centimeters. Material properties may vary and depend on the manufacturer.

Attention! Polystyrene boards have high noise insulation, they are able to absorb noise up to 50 kN per square meter.

Polyfoam is inferior in density to expanded polystyrene, and is unstable to mechanical stress. This contributes to a decrease in its functional properties. The foam material is suitable for laying between the joists of floor structures.

You can find cork prisms, which are also suitable for thermal insulation of a water floor. Due to the special structure, the corks have strength during compression, exclude adhesion in relation to the cement mortar. The cork cover is of high cost, it is laid on an almost warm base. Otherwise, you need a cork with a minimum thickness of thirty millimeters, which is very expensive. The downside of the material is considered hygroscopicity and one-component, as a heat insulator. Laying floors with such insulation requires the installation of a layer of waterproofing and vapor barrier.- Mineral wool is also used as insulation, which is considered an inexpensive alternative to other materials. Cotton wool is produced in the form of flexible mats or solid slabs. Cotton wool does not withstand the weight of the cement screed, so it is also placed between the wood logs. Attention! Mineral wool contributes to the maximum heat transfer of the heating floor. The composition of cotton wool contains penofol, which is harmful to health, and the material also has a low moisture resistance. These qualities refer to the negative properties of mineral wool. When laying a floor with cotton wool, you need to lay a high-quality waterproofing and the disadvantage will be eliminated.

Mat selection criteria

- As already noted, attention should be paid only to well-known manufacturers, because in their factories the quality is strictly controlled to maintain the brand. Therefore, the percentage of rejects is minimal.

- Price.

- The specific type of mat depends on the area of the room in which the heating cable is planned to be laid. And if the area is large, then you should give preference to products with "lugs".

- Thermal insulation properties, depending on the density of the material and the thickness of the insulation.

- Additional installation fittings. This includes elements designed to connect plates, as well as insulation for joints.

If you focus on this, you will find the model that is ideal for your situation.

Summing up

Mats for a warm water floor are a material that cannot be economized in any way. Their quality affects not only the efficiency of the heating system, but also the likelihood of emergencies. That's all, warm winters to you!

What are underfloor heating mats?

This is a profiled, heat-insulating foam, which is used for laying the pipeline in the water floor. Mats are made of foam plastic with a density of 40 kg / m3. They are made from dense polystyrene foam. Therefore, this plate does not deform. There are special clamps on the mats for convenient laying of the pipeline.

The effectiveness of an underfloor heating depends on the thermal insulation, and how the pipeline is distributed in it. They also put mats in a warm floor in order not to lose heat. After all, no one needs to warm up the floor slabs. And profile mats have thermal insulation properties, thereby preventing unnecessary heat loss, directing heat upward. It should be borne in mind that the mats carry quite heavy loads. This is the weight of the pipes themselves, filled with hot water. Also the enormous weight of the screed covering the pipeline. Well, dynamic loads. All this is inevitable during operation. Therefore, the density should be 40 kg / m3 so that the material does not deform.