Heating equipment mounted on walls and ceilings, including portable heating devices, is to a certain extent an integral part of the interior that needs decoration and occupies a certain volume in the room.

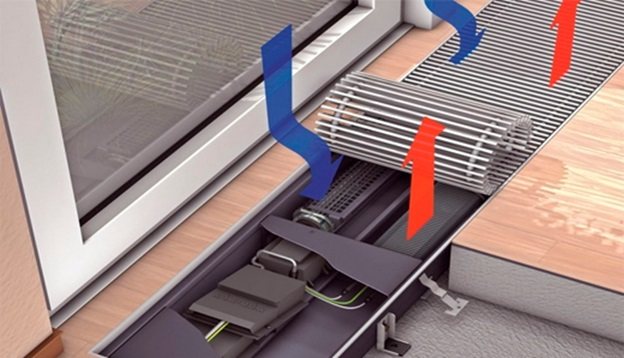

With the development of technologies for the production of heating equipment, units appeared on the heater market that do not reduce the useful volume of premises - heating convectors flush-mounted into the floor.

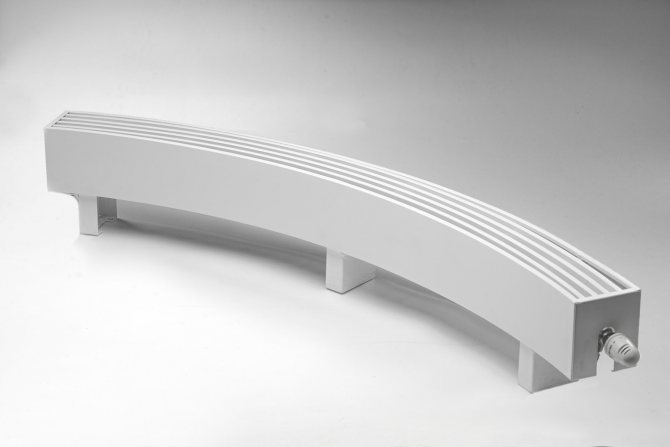

Group sequential arrangement under a common grate of convector-type heaters installed in the floor along the perimeter of the circular arrangement of panoramic window openings

Floor convectors for heating are widely demanded in spacious administrative and residential premises with glass enclosing structures, as well as public transit facilities (corridors, passages, waiting rooms), where they, without being conspicuous, effectively fulfill their purpose - maintaining the required temperature regime.

Floor convector heater, mounted along the observation exterior glazing of the room.

Understanding of floor-mounted convectors

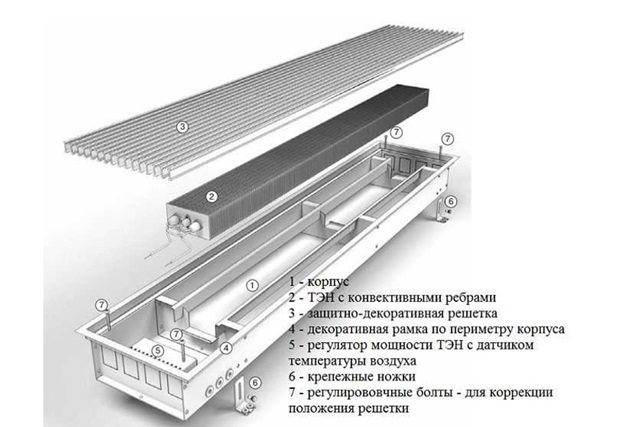

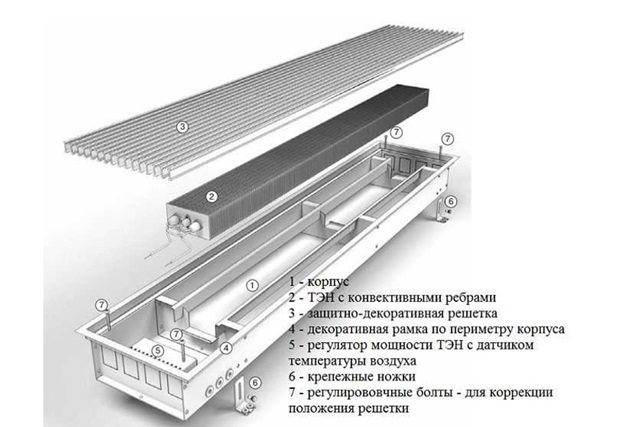

Convectors, which are simply recessed into the floor, are a robust rectangular case, often of frame design, sheathed on the front side with a decorative metal grill. A heat exchanger is located in the housing, which heats up, depending on the type of heating device, by a coolant circulating through it or an electric heater.

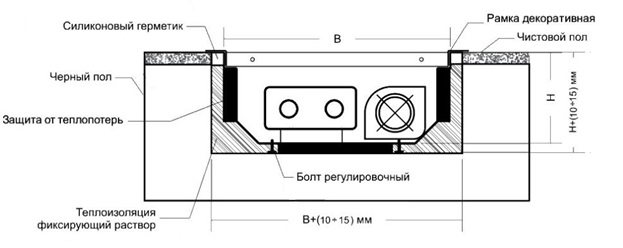

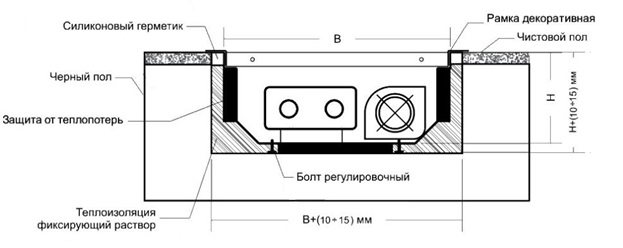

Floor convectors for heating are installed in separate point or common linear niches made in the supporting floor according to the dimensions of the heaters, as well as in the space between the raised floor and the concrete base. To reduce heat loss, the bottom and side walls of the casing of floor convectors are equipped with external thermal insulation.

In the design of such heaters, adjusting screws are provided, which allow precise adjustment of the horizontal position of the front grille plane to the level of the finished floor covering so that the protruding parts of the case do not create obstacles when walking on them.

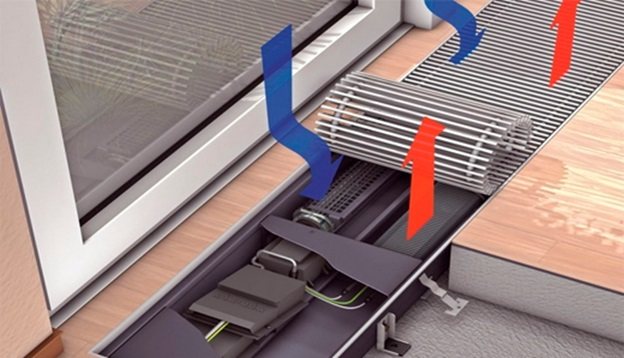

Diagram of the device in the floor of the floor-mounted convector in section

For more efficient use, floor-mounted heaters are placed along panoramic glass enclosures and window openings in order to use convective flows also as a thermal curtain between the room space and the cold glazing surface.

Variant of installation in the floor of the TURBO VKN5 duct convector with a fan.

TOP MANUFACTURERS OF FLOOR CONVECTORS.

| Varmann | Mohlenhoff | Eva | Isoterm |

| Ntherm without fan Qtherm with fan Width from 140 mm - up to 370 mm Height from 75 mm - up to 600 mm price from 10 373.22 rub. | WSK without fan QSK EC with fan Width from 180 mm - up to 410 mm Height from 90 mm - up to 190 mm price from 17 956.93 rub. | COIL K without fan COIL KB with fan Width from 203 mm - up to 403 mm Depth from 65 mm - up to 250 mm Price from 12 167.75 rub. | Golfstream M without fan Golfstream V with fan Width 140 mm - up to 430 mm Depth 80 mm - 190 mm Price from 6 066.40 rub. |

| Techno | Jaga | Minib | Kampmann |

| Power without fan Vent with fan Simple robust design price from 5 558.00 rub. | Mini Canal JR without fan Mini Canal (Belgium) Perfect appearance price from 10 376.32 rub. | COIL without fan COIL – KT with fan Maximum thermal comfort price from 20 133.08 rub. | Katherm NK without fan Katherm QK with fan Fine temperature control price from 32 443.61 rub. |

| Vitron | KZTO Breeze | SanGalli | IMP Klima |

| Vitron VKB without fan Vitron VKB with fan Space saving price from RUB 8 344.75 rub. | Breeze without fan Breeze B with fan Form flexibility price from 7 953.30 rub. | SNC without fan STC with fan According to interior design price from 8 214.02 rub. | TK-13 without fan TKV-13 with fan Energy saving price from 14 186.91 rub. |

Types of in-floor heaters

There are many models of underfloor heaters today, and they all differ in some way from each other. If we do not consider the parameters that are of secondary importance, then all heating convectors built into the floor can be divided into two groups:

- water;

- electrical.

Units within each of these two groups differ in size, configuration, power, design of the outer grille, type of convection - natural or forced (with a fan) and performance class.

Water heaters for internal floor placement

Floor water convector is a heating device connected to a central or autonomous heating system.

The scheme of functioning of the water floor convector is the flow of cold air from the glazing of the window opening to the heating device, its heating and exit to the room.

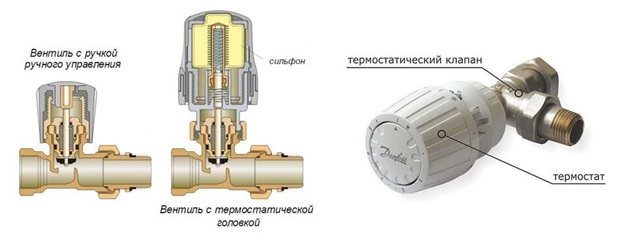

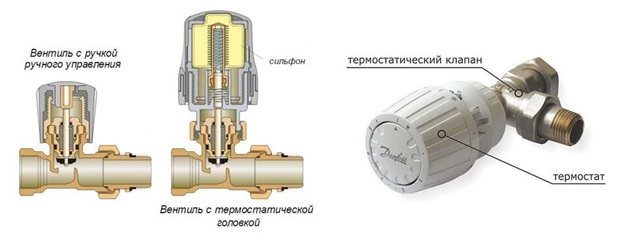

A valve is installed at the tie-in point to the system, which can be used to regulate the amount of coolant circulating through the floor water heater.

The main element of the unit is a radiator with inlet and outlet fittings, through which flexible hoses or fittings are connected to the heating system, and hot water is circulated through the heat exchanger.

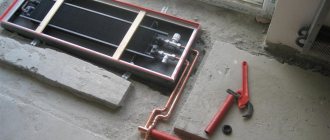

Connecting the radiator of the underfloor heater with flexible hoses.

The radiator is made of a copper tube, on which aluminum fins are made to increase the heat exchange area. Modern water heating convectors are equipped with valves for automatic venting of air entering the system along with water, which eliminates the formation of air jams and ensures efficient operation of the unit due to a stable rate of circulation of the coolant.

Installation of a water convector in a niche and its rigid connection to heat-insulated pipes in groove-channels.

The intensity of the coolant supply to the convector can be manually changed with a valve at the point of connection to the heating system, but it is more efficient to install a mechanical thermostat at the heater inlet, which regulates the flow of hot water into the heat exchanger depending on the temperature of the water in the radiator.

On the left - a schematic sectional view of a manual valve and a mechanical thermostat, on the right - a natural image of a thermostatic head.

Underfloor heaters with natural convection are designed to heat medium-sized rooms (16-25 sq. M.).

To ensure the natural movement of convective flows, the depth of the housing box must be at least 20 cm, and yet even multi-pipe devices of the natural type of convection do not always cope with the role of the main and only heating means, forcing homeowners to additionally use other heating devices.

Multi-pipe radiator for a water convector built into the floor with increased heat transfer.

The main advantage of this group of underfloor heaters is safety, due to the absence of factors associated with the use of electrical appliances. Floor convectors for water heating do not need to be grounded, they are not afraid of direct contact with moisture (it often happens on the floor), the surface temperature of these units is safe for humans with short-term contact, and the outer grille can be made of valuable wood species.

Methods for the arrangement of floor-mounted heaters: on the left - angular arrangement, on the right - installation in steps.

The cost of such devices, depending on power, class of technical equipment and performance, ranges from 20 to 100 thousand rubles.

Important! When connected to a central heating system, water heating convectors built into the floor are heaters that do not require energy costs (with the exception of models with a fan).

Forced convection water heating devices

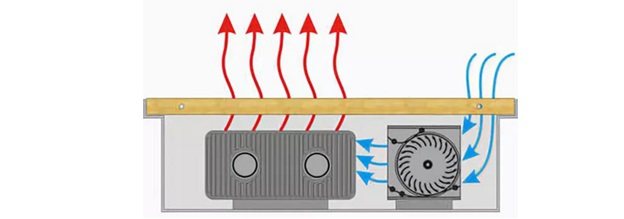

Equipping the device with a fan accelerates convective flows, but at the same time reduces their temperature - the air heats up less due to the shorter duration of contact with the heat exchanger. Therefore, radiators of underfloor heaters with forced convection are made of a more complex design (two-three-four-pipe), up to 3 meters long, which prolongs the contact of air with the heat exchanger and raises its temperature at the outlet of the unit.

Conditional diagram of the movement of convective flows in a floor convector with a fan.

A forced-type convection heater built into the floor is several times more efficient than models without a fan, therefore, they are used in large rooms, and the energy consumption of such devices is low due to the absence of electric heating elements. However, the complexity of the design of tangential fans, which are most often used in modern heating units (with a reduced noise level, operating from a voltage of 12 V) or the equipment of the heater with several ventilation mechanisms of the traditional, diametrical type, design significantly increases the cost of the convector, which can range from 50 to 160 thousand roubles.

Varieties of equipping floor convectors with fans: on the left - single, on the right - block, below - tangential fan.

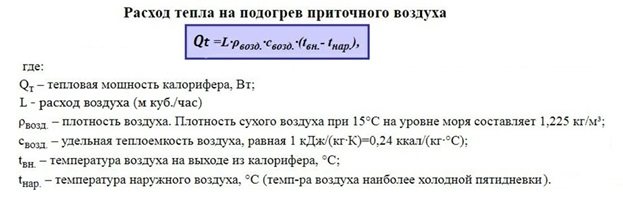

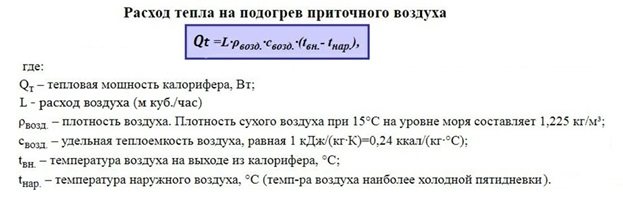

The thermal power of a water heater is determined by the dimensions of the unit, the temperature of the supplied heat carrier and the type of convection, but the required calorific value (Qt) is determined by a special formula:

The formula for calculating the required power of the convector with the decoding of the constituent elements.

However, the required heat release power also depends on other factors - the region, the dimensions of the room, the glazing area, the degree of thermal protection of the enclosing structures, etc., therefore, more often its value is determined using special tables that take into account certain operating conditions.

Electric underfloor heating units

These units differ from water floor convectors in the way the heat exchanger is heated and, of course, in the design.

The heat exchanger is a heating element placed in a finned casing. Thus, electric underfloor heaters are to some extent infrared heaters, the main principle of which is based on convection.

Schematic device of an electric underfloor heater of natural convection type.

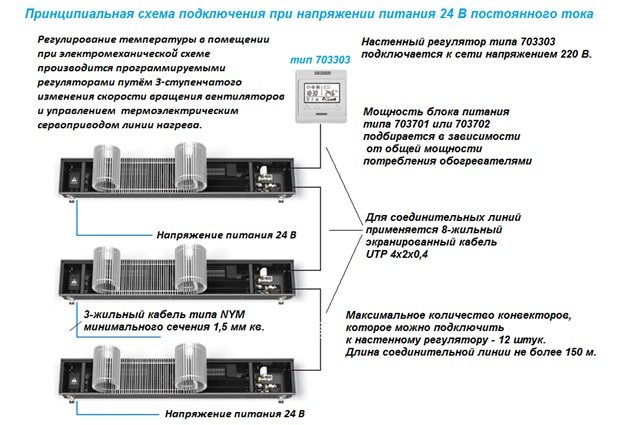

The presence of an electric heating element in the unit allows it to be connected to an automatic heating control system in order to minimize human involvement in the operation of the heater. For this, a remote mechanical thermostat is installed in the power supply circuit of the unit, which turns off the device when the temperature in the room reaches the set value.

Important! Automatic temperature control is effective only when installing units with forced convection, since the fan provides a uniform air temperature in the room and allows the temperature sensor to record its real value.

Option of wiring the thermostat to a floor-mounted electric heater.

All models of electric underfloor appliances are equipped with a temperature sensor inside, which protects the heater from overheating.

Important! When installing electrical heaters, the distance from the unit to the glazing plane should be no more than 300 mm - if this value is exceeded, nothing will prevent the formation of condensation on the glass, which, flowing down to the floor, can accumulate in the niche where the heater is located.

The height of the ceilings of most apartments does not allow painlessly filling the floor with a layer of concrete, which allows the underfloor heater to be drowned. It is also unrealistic to cut the floor in the interfloor to such a depth. Therefore, an electric, and, moreover, a water heater, built into the floor, cannot be found in an apartment building. But floor convectors, similar in design, are produced, which do not require installation of mounting niches in the floor for installation.

With such heating devices, both electric and water, it is possible to effectively heat spacious rooms of apartments and utility rooms for industrial purposes.

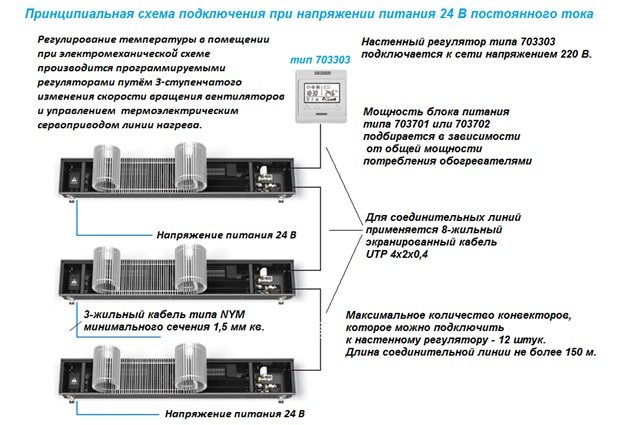

Important! The use of electric floor convectors is associated with sensitive electricity costs, but there is a way out of this situation - the use of a 24 V DC network, which will not only reduce costs, but also increase the safety of the heating unit.

Schematic connection of the floor convector to a 24 V network and a thermostat

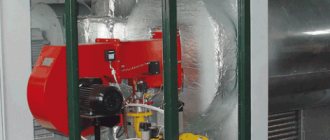

Fan coil units

On the basis of floor-mounted convectors, another type of heaters is produced that work not only for heating, but also for cooling. At the place of installation, in addition to the interior, they are also wall, floor and ceiling. The Russian-language name of such a unit is fan coil, from the English fan-coil, which means fan-heat exchanger in translation.

This definition means a combination of two devices working in pairs:

- fan coil unit itself - a floor-mounted mechanism for influencing the air temperature, including one or more heat exchangers;

- chiller - a separately installed unit for cooling the coolant (water) supplied to the fan coil during the summer period.

Fan coil units are single-circuit (two-pipe) and double-circuit (four-pipe).

In single-circuit units, hot water from the central heating system or antifreeze from the heating boiler is driven through the heat exchanger in winter. In the summer, cold water from the chiller passes through the same heat exchanger - a device that does not use freon or another gas with identical characteristics for cooling.

In double-circuit fan coil units, the movement of hot and cold heat carriers is carried out through separate heat exchangers.

Schematic representation of a double-circuit fan coil unit (without chiller).

Thus, depending on the set mode, the fan drives the room air through a hot or cold heat exchanger.

There is no universal installation scheme for the chiller-fan coil system pair, its installation is possible in any room, but the installation project will be tied to specific conditions.

One chiller with the correct capacity can be connected to a system of many fan coil units (wall, ceiling, floor) serving several rooms and even buildings.

Such a system for ensuring the required temperature regime in the premises is used mainly in public and industrial buildings, as it is difficult to maintain and expensive.

Varieties and materials for the manufacture of radiators

Built-in floor heating radiators can be made from a wide variety of materials. It can be steel, aluminum, cast iron. In addition, bimetallic models can often be found on sale, and therefore we propose to dwell on their properties in more detail.

Steel radiators

Most popular models on the market - these are steel, because according to the data of the Yandex. The market is a frequently chosen model.Radiators made of steel are usually quite compact, have high thermal efficiency and pressure resistance from 10 to 16 atm. Their design is quite simple and may resemble the structure of old steel batteries that previously worked in multi-storey buildings. The advantages of such a device include low cost, and this is really the cheapest heating device that can be used for rooms with panoramic windows.

It will provide high-quality convection of heated air, as well as heat the room well. It is also worth noting the long service life - if you follow all the rules, then this is from 20 to 25 years or more. If you want to buy inexpensive and at the same time reliable floor-standing radiators, then you should take a closer look at the steel models - they are able to provide good heating and will not spoil the interior. By the way, they even include beautiful tubular models.

Bimetallic copper and aluminum radiators

The high heat conductivity of copper is its indisputable advantage, but such a material is extremely expensive, and this is a big drawback. To create an efficient and affordable heating radiator, experts decided to combine aluminum and copper into a single structure, and the result was a very good bimetallic radiator. The tubes in it are made of copper, and the fins are aluminum. This appliance has excellent heat dissipation and is quite durable. Compared to the same radiators made of steel, copper models are much more expensive, but better in terms of heat transfer. In addition, unlike steel, copper will not rust and has a longer service life.

Bimetallic radiators made of steel and aluminum

The combination sounds familiar, doesn't it? It is this combination of metals that is used for standard wall-mounted radiators. the floor-standing models are made in a similar way and are extremely similar to their older brothers. The heat carrier flows through steel tubes, and the heat transfer is carried out by means of aluminum fins. They are slightly cheaper than the previous version.

Aluminum heating radiators

The aluminum floor-standing models are similar in design to the most common wall-mount models. You can find them on sale, but very rarely - most often they are made to order. Models made of aluminum are not able to withstand high pressure and do not tolerate the effects of aggressive heat carriers, and because of such shortcomings, simple and reliable bimetallic radiators are installed instead.

Cast iron radiators

Underfloor heating radiators can be made not only of copper, steel, aluminum, but even cast iron. Such devices cannot be called the smallest ones, because in fact their size is quite large compared to the size of the same steel products. Most often, they are mounted as decorative elements to maintain the style of office or living space. They are not afraid of the effects of corrosion and high pressure, they differ in a long service life. As for the cost, it can be very high. The disadvantage of batteries can be heavy weight and the associated complexity of installation work. In appearance and resistance to negative influences, they practically have no equal.

Advantages and disadvantages of floor-mounted convectors

We list the positive and negative features of floor heaters without dividing by the type of energy carrier used and listing the characteristics inherent in all convectors as a whole.

Pros:

- due to the location of the unit, the lowest, coldest layers of air are heated;

- the installation of devices does not reduce the useful volume of the room;

- quick exit to working mode;

- preventing the formation of condensation on the glazing.

Minuses:

- with high ceilings, it is not effective to build units of a natural type of convection into the floor - convective currents of heated air are concentrated high under the ceiling and cool down before filling the current volume of the room;

- convection from the level of the floor covering initiates intensive movement of dust in the air, which is constantly present in the air during the operation of the heater;

- inconvenience of daily care of niches in which household waste accumulates.

Other types of water convectors

Convector bench

The name speaks for itself. In fact, this is an ordinary bench that performs an additional heating function. You can find these in shopping centers, car dealerships, honey. centers. In private construction, they are used quite rarely.

Warm convector skirting board

The same wall-mounted water heating convector, with the only difference that it is installed instead of the baseboard and performs the heating function. It is quite expensive and a meter of warm plinth gives out on average only 350 watts.

Facade convectors

An interesting solution that fits right into the windows. They perform the main function - cutting off cold air streams from the window. It can often be found in buildings with large glazing. For example, shopping centers, business centers.

Steel convectors heating

In addition to copper-aluminum convectors, there are also steel ones. They cost a little less. But they have a number of disadvantages.

- Have less convection (70% airflow, 30% radiation)

- Cannot be connected to district heating

- Heavy due to the use of steel as the main material

- Have a shorter service life

Benefits of floor mounting

Floor radiators are fundamentally different from conventional wall-mounted radiators in the way of fastening, which is their main advantage, allowing to realize original design ideas.

Floor radiators have two types of mounting. The first type is the placement of the convector in the floor screed, the second is the direct fastening to the floor. A heater placed inside the floor can function as a secondary heating.

The figure shows a floor mounted heating battery.

The structural elements of heating equipment are a heater with a ribbed surface, a channel, a grate. Often the design is made in a single block, which does not imply its disassembly.

Heating batteries, even in an expensive design or hidden under a grate, introduce an imbalance, destroying the harmony and volumes of living space. In such cases, a system located inside the floor allows the usable space to be allocated economically and to provide reliable heating.

In fact, water radiators installed inside the floor operate on the convector principle. A comfortable temperature is achieved due to intensive air circulation: the air heated by the battery rises to the ceiling, and cold air masses come in its place. Due to the circulation of warm and cold air, heating is carried out faster, which saves money on heating.

It is not always possible to attach a traditional radiator to the wall (this is especially important for modern offices), since it can be made of a material that cannot withstand heavy loads. In some cases, the openings of windows and doors start directly from the floor, which also excludes the possibility of attaching the radiator to the wall.

In the case of panoramic glazing of shops, museums, offices, it is important to consider the need for a thermal curtain, which will prevent the glass from freezing or fogging up. Its creation, from a technical point of view, is possible only when using a floor-mounted battery.

Example of 2 batteries: floor and wall mount.

In some cases, floor standing batteries, on the contrary, have a decorative function.They are installed in a special enclosure, for example made of natural wood, and are used as seating positions. This heating option is relevant for hospitals, sports clubs, swimming pools, saunas.