Facade decor made of polystyrene has recently been widely used, which is facilitated by the relatively low cost and originality of the appearance. The interior with styrofoam decorations changes beyond recognition. You can purchase and install ready-made decoration parts, which significantly reduces the time for arranging the facade. However, when doing work with your own hands, it is possible to realize the most daring imagination and old ideas. With a high-quality implementation of this event, it will be almost impossible to distinguish imitation from stone or marble statues.

Facade decor made of polystyrene is widely used today.

What are the advantages of the material

Polyfoam is a versatile polymer material that is widely used for various purposes. Most often, this term is called polystyrene foam and polyurethane foam plates. Polyfoam has a number of positive qualities: light weight, ease of cutting, thermal insulation properties, whiteness, rather low cost.

Styrofoam - light, warm, inexpensive - excellent material for decoration

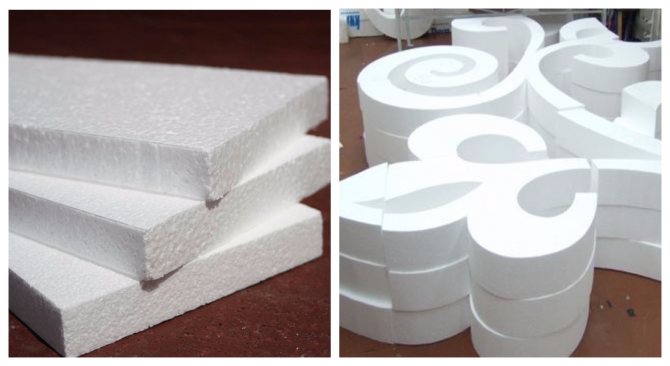

This material has different density and grain size. Dense structures can be easily confused with gypsum and natural stone, even marble. This effect is the basis for the use of foam as decorative elements. The ease of processing of the material makes it possible to manufacture any figures, patterned carvings and other products. Styrofoam molding in appearance is almost indistinguishable from gypsum creations, while it is lightweight and easy to manufacture.

Along with the positive qualities, the material also has one important drawback. This polymer (especially expanded polystyrene) has a low melting and ignition temperature, and when it burns and simply exposed to high temperatures, it can release substances harmful to humans. This condition is important to consider when using it. In addition, the foam breaks easily, and therefore should not be subjected to mechanical stress.

When the facade is being set up, foam plastic can be used in several grades: PSB-S-15, PSB-S-25 and PSB-S-35. The last type of material (which is the most expensive) is considered the most durable, so it is used in harsh climatic conditions. The most widespread is PSB-S-25 foam, which has a density of 20–25 kg / m³, and the permissible bending load is no more than 0.26 MPa. It is also important that the water absorption of the material is practically 0.

Material capabilities

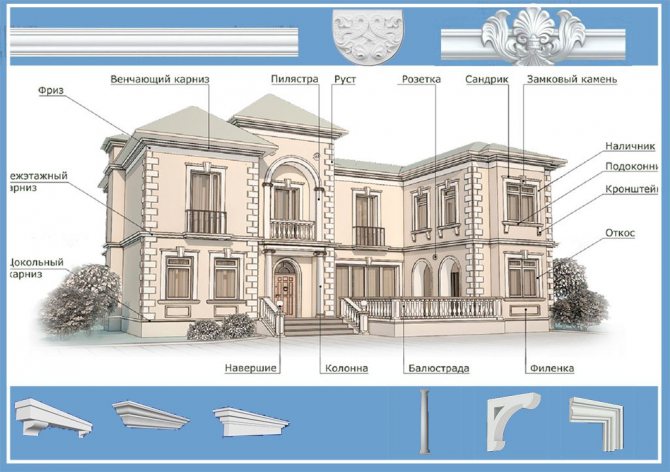

Firstly, the possibility of using finishing material for decorating a private house. Numerous elements are shown on the façade of a large two-story building. However, this does not mean that styrofoam facade decor can only be used on mansions. In any building, you can install individual elements or other details, including those of an exclusive nature.

Styrofoam will help to embody any ideas for indoor and outdoor decoration

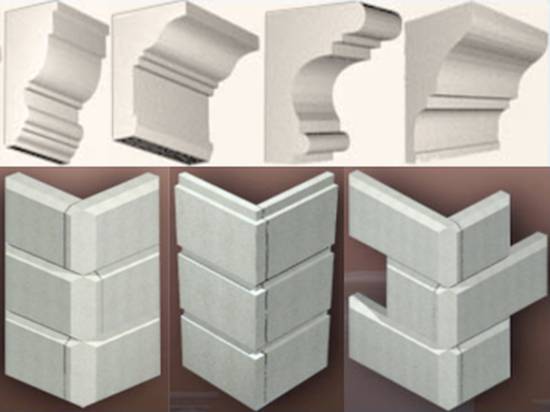

The following are the most common styrofoam decorative elements for the facade:

- moldings;

- cornices;

- rusty;

- columns;

- pilasters.

Different techniques can be used when performing them:

- stucco molding;

- bas-reliefs;

- thread;

- ornaments;

- patterns;

- vases;

- flowerpots, etc.

Secondly, the cladding can be made of standard parts, exclusive items purchased ready-made or made by hand.

Finishing the facade of a house with foam plastic can include the following solutions:

- threaded styrofoam cornice;

- porticoes;

- architectural modilions;

- rustication of the basement or the entire corner of the building;

- carved foam window frames;

- console elements;

- portals and flutes.

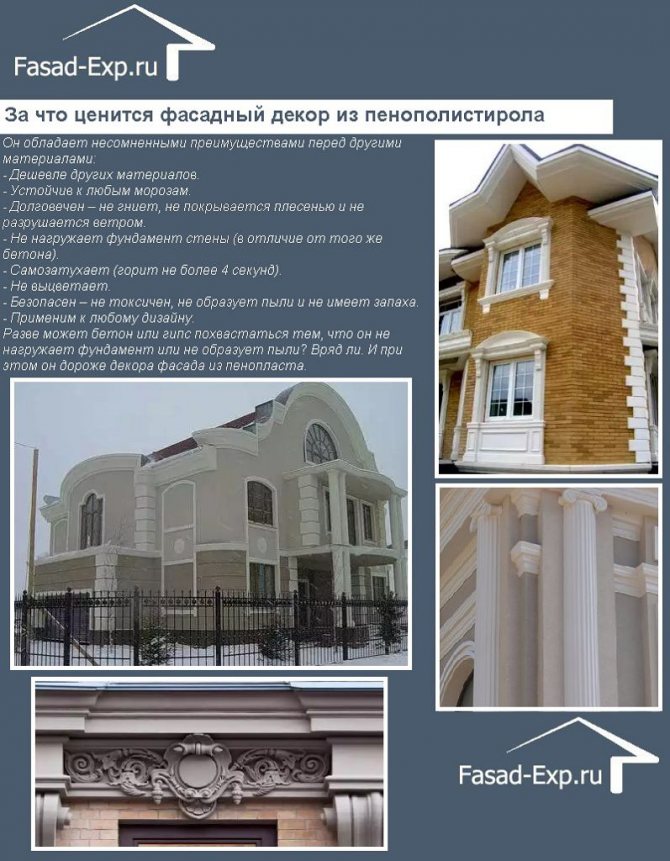

Third, facade decorative foam has the following advantages:

- fairly quick and easy production of parts;

- low cost;

- high service life;

- no size limitation;

- the ability to carry out work independently;

- absence of significant additional mechanical loads on the wall and foundation, taking into account the low specific weight of plastic;

- fairly high compressive strength;

- no risk of rotting and mold;

- high resistance to any climatic conditions in all regions of the country;

- long-term color retention.

Styrofoam molding in the interior - 10 photos

Most often, imitation of polystyrene stucco molding is used on the ceiling and walls of the interior.

To improve the appearance and quality of such a stucco decoration, a finishing layer of putty, paint or a special protective layer is applied to it. This will allow a smoother plaster-like surface to be achieved, albeit with additional material and labor costs, which will significantly increase the overall cost of the repair.

A protective layer, paint or cement-adhesive composition is applied to foam products after they are installed on the walls or ceiling. In addition, the installation uses a thin mesh that enhances grip and helps to hide the joints between individual segments. As a result, your styrofoam molding will meet the highest quality requirements.

Photos of decorative styrofoam moldings on the walls and ceiling in the interior:

Also read: Stylish do-it-yourself cement decor - ideas with photos

Decorative stucco molding is gaining more and more popularity not only in interior design, but also on the facades of private houses and cottages. See the article about the elements of facade decor with original photos.

What is required for decoration

For decorating with foam, you will need a set of tools and additional materials

In order to equip a foam facade, you should take care of such consumables and accessories in advance:

- polyurethane-based polyurethane foam;

- foam glue;

- dowels 12–20 cm long, umbrella type;

- reinforced fiberglass mesh;

- acrylic type putty;

- facade primer composition;

- paint for facade works;

- mineral plaster.

Such a tool will help to carry out all the work qualitatively:

- glue gun;

- "String" for cutting foam;

- knife;

- jigsaw;

- hacksaw for metal;

- putty knife;

- paint brush;

- construction mixer;

- electric drill;

- screwdriver;

- plumb line;

- roulette;

- metal ruler;

- protractor;

- building level.

Technological stages

Styrofoam facade decoration, although it is considered a fairly simple event accessible to any person, is carried out in several stages, taking into account certain principles.

Styrofoam decor is a simple task, the main thing is to observe the phasing

The following main stages are distinguished:

- preparatory work;

- making or purchasing decoration elements;

- leveling the surface;

- installation of polystyrene with its reliable fixing in the right place;

- application of protective and finishing coatings.

The preparatory phase begins with the development of a project for the overall design of the facade. At this stage, the style of decoration and the number, type and size of decorative elements are determined; a diagram of their placement is drawn. Next, a thorough preparation of the surface is carried out for the imposition of foam:

- leveling the surface;

- cleaning the installation site from dirt and grease.

Installation of foam decor includes the following processes:

- Alignment of the facade structure on which the decor is planned to be installed.As a rule, such areas include cornices, window sills, certain zones on the wall, jambs of window and door openings. Leveling is carried out by applying plaster.

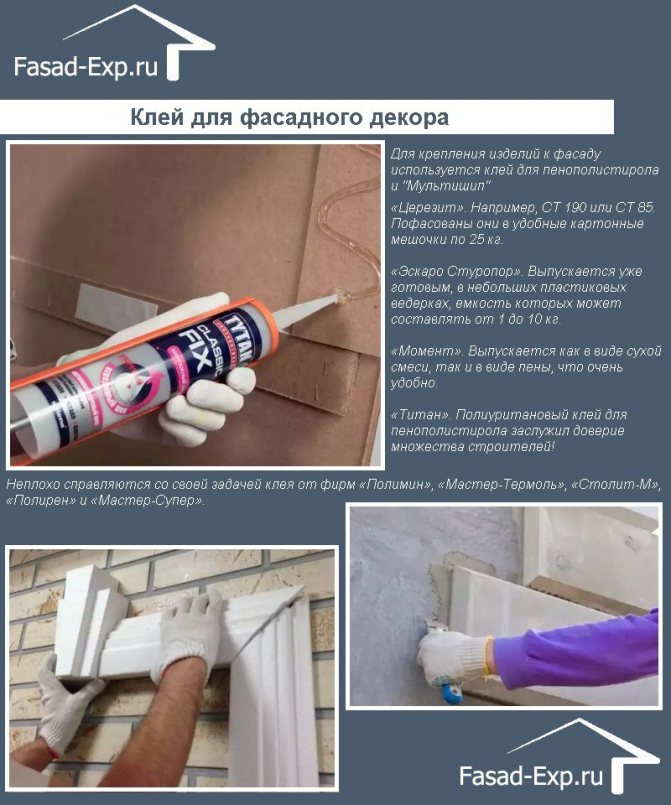

- Installation of decor. The facade foam is attached with a special glue designed specifically for this material. In particular, you can about. The adhesive is applied to the entire back side of the part, and then it is pressed against the installation site and held until it is adhered with glue. When installing large parts or in cases where they protrude above the wall surface by more than 10–12 cm, the fastening is reinforced with dowels or anchors. For their installation, holes are carefully drilled in the foam. If such a need arises after installation, then drilling is carried out after the glue has completely hardened (2-3 days). In the appropriate places on the wall, the filling elements are installed. When mounting parts vertically on a wall, it is recommended to keep them pressed for 30–40 hours.

- Sealing joints and seams. This operation is carried out using special facade sealants, which are applied with a facade brush. After the composition has dried, grouting is carried out. Merolith S1 can be recommended as such a sealant.

- When a facade decor made of coated foam is provided, a number of additional work is carried out. A thin layer of primer is applied to the surface of the plastic. After hardening and grinding, the facade elements are covered with acrylic paint in 2 layers.

Decorations installation rules

Installing a foam facade yourself is quite simple. To do this, observe the following instructions:

- The surface of the walls of the building must be well cleaned of dirt and mold. For this, you can use special solutions.

- The mounting base must be dry and level. If there are irregularities more than 1 cm deep on the plane, then you will need to level the wall with plaster. It is also advisable to check the old coating for voids. For this, the surface should be tapped. If the old coating is peeling, it must be well cleaned with a stiff brush.

- The facade decor is mounted from foam plastic using special glue. You can also use anchoring devices or embedded parts. In any case, it is imperative to apply glue, as it will ensure a tighter adhesion of the decorations to the wall.

- The styrofoam facade should be completely covered with adhesive and then firmly pressed to the base. After drying, if necessary, you can fix the structure with dowels.

Advice! The use of the dowel is only possible on a completely dry structure. Its installation is necessary if the decorative element is more than 10 cm thick.

- After the main installation work, the facade made of foam plastic will need to be treated with a sealant in those places where the holes for the dowels and the joints of the elements are visible.

- When the sealant is completely dry, the foam facade needs to be painted with a special acrylic-based paint. But first, each element should be coated with a primer.

Such a façade made of coated foam is visually indistinguishable from products made from traditional materials. In addition, the installation of the structure is much easier. You can paint a foam plastic facade in any color - like stone, granite, malachite, metal, wood and other textures. Therefore, the structure is a versatile tool for decorating buildings.

Styrofoam decoration

The production of shaped elements from polystyrene, first of all, provides for its accurate cutting. When carrying out such a procedure, crumbling of the material must not be allowed. That is why its cutting is provided by a heated "string". If the composition is composed of several parts, then the accuracy of their alignment should not exceed 1 mm.

Use a heated string to get neatly cut pieces.

In general, the production of decorative foam elements is carried out in the following order:

- Decoration of a decor sketch or selection of a ready-made idea with a drawing of all the details, methods of their articulation, attachment points, choice of colors.

- Drawing the element on foam in full size, and so that you can cut the material.

- Cutting out the conceived shape from the styrofoam.

- Strengthening the decoration element. For this purpose, a fiberglass mesh is fixed using an adhesive composition applied by spraying with the formation of a layer with a thickness of about 2–2.5 mm.

Foam molding

Facade moldings are usually made of plaster and are considered a very common decorative element. Recently, styrofoam molding has become a worthy competitor to such parts. It is lightweight so it can be easily attached to the wall. The facade of a house with a similar decor looks no worse than with a classic design.

Foam stucco molding perfectly replaces gypsum, both in time and in financial costs

Of course, the facade stucco molding is more difficult to manufacture, since it is a volumetric figure. It is best to use finished products that are manufactured by pressing in the factory. However, you can do it yourself, but for this you should use the densest foam - PSB-S-35. Shapes such as curls, voluminous flowers, bas-reliefs, etc. are cut from it.

Decorating the facade of a house with polystyrene foam has gained wide popularity. The ease of manufacture and installation allows you to do everything yourself, while the decor is difficult to distinguish from the classic options - gypsum, natural stone.

Styrofoam facade decor has an attractive cost. In addition, such products have an original appearance.

Decorative elements, despite their low cost, are not inferior to decor made from other building materials in terms of their reliability, durability, and durability.

Decorative styrofoam molding - a modern alternative to plaster

Unlike more traditional gypsum products, polystyrene stucco molding does not lose its appearance over time, does not lend itself to impacts, is easy to clean and is not afraid of moisture, which allows it to be used in places of high humidity, for example, in the interior of a bathroom or kitchen.

Imitation of polystyrene stucco molding is made from sheets and granules of different sizes and grain sizes. As a rule, ready-made cornices, columns, moldings and other elements of stucco decoration are presented unpainted on shop windows. The modern industry also offers the consumer a variety of styrofoam products for interior decoration, which are covered with a special film that makes it possible to imitate marble columns, wood or stone.

This is what the styrofoam decorative molding looks like before installation:

Now let's take a look at the photo of decorative foam molding in the interior.

Distinctive features of styrofoam decoration

Styrofoam decorations for the facade are made by pouring into special molds.

Attention! When installing foam products on the facade of the house, you must use a special protective coating.

It is necessary to increase the resistance of foam products to external negative actions, increase its strength, and extend the service life.

There are many reasons why ordinary buyers should buy styrofoam decorative items.

Facade decor elements are offered by manufacturers in a different color range, moreover, at quite affordable prices.

Polyfoam does not have high reliability, mechanical resistance, durability, but with the help of modern technologies, all these minor disadvantages can be easily eliminated.

Advice! Facade decor made of expanded polystyrene (polystyrene) without additional processing is appropriate only in places that are reliably protected from the environment.

For example, you can use foam facade elements to decorate the cornice, which is located under the roof slope. This area is reliably protected from moisture penetration, besides, the material is not threatened with mechanical damage.

The facade decor made of foam plastic, made in the form of arches, must be processed so that weather conditions do not spoil its appearance. Sometimes decorative elements made of expanded polystyrene are used in conjunction with other materials that will allow the decoration to be used much longer.

Among the fashion trends of recent times, we note the option of non-standard decoration of the external walls of a private house.

Styrofoam decor for the facade is lightweight, easy to process, so the material is in demand among architects. It is the styrofoam decor that makes it possible for the owners of country cottages to embody original design ideas into reality.

Production of decorative beams Amaro

Liquid polyurethane foam is poured into a special mold, where it hardens and gains strength. Then the beam is removed from the mold, stripped and painted.

The quality of the shapes and painting determines the quality of the finished beam, which makes Amaro compare favorably with other manufacturers.

We make beams and boards for processed planed wood (Art Nouveau style) and unprocessed wood, as if chopped with an ax (rustic style). You can choose what you need for your interior.

By the way, beams made of polyurethane foam are not afraid of moisture like wood, so they can be used outdoors.

The polyurethane foam beams are extremely lightweight, making them very convenient for ceiling or wall mounting.

Polyurethane beams are not susceptible to microorganisms and, unlike wooden beams, do not create a favorable environment for the development of mold and fungi.

Original ideas for decor

Styrofoam facade decor is a way to add some romantic warmth to a building.

Advice! If you complete the upper part of the residential building with a foam decorative entablature, add decorative columns to it, the house will become a real castle.

Such a house, decorated with figured decor made of polymer material, will become your pride in front of guests. Decorative chips applied to the facade decor made of expanded polystyrene can make your home more original.

Among those architectural elements that can be made of foam, we highlight:

- moldings;

- carved cornices;

- fragments of the console;

- modillons;

- decoration of the basement of the house

Distinctive characteristics of foam decorative elements

The decor of the facade of the house made of foam plastic has some distinctive characteristics:

- affordable price of products;

- ease and speed of installation of finished products;

- the ability to decorate without the involvement of specialists;

- minimum weight that does not lead to additional load on the foundation of the building;

- long operational life;

- excellent moisture-repellent characteristics;

- increased strength;

- environmental friendliness and resistance to decay processes

Installation work associated with the use of polymer makes it possible to carry out installation in any climatic conditions, regardless of temperature indicators.

Advantages of decorating facades with foam elements

Coated styrofoam facade decor for exterior walls of houses has the following advantages:

- affordable cost of products - this is one of the cheapest options for today;

- the process of installing decorative elements is so easy and fast that it allows you to do the work yourself;

- light weight, giving a minimum load that does not lead to destructive changes in the elements of the house;

- strength and durability;

- environmental friendliness;

- possesses moisture-repellent characteristics;

- fire safety;

- not subject to decay processes;

- the ability to perform installation work at any temperature and climatic conditions.

Installation of decor on the facade of the house

When carrying out such work, you must follow the algorithm of actions. First, you need to carry out preparatory work with the surface on which the decor will be attached. To do this, remove the remnants of old plaster from the surface, remove dust and dirt. Armed with facade plaster, it is important to eliminate all internal irregularities.

Advice! If voids are identified, cement mortar can be used to level them.

Then, they designate the places where the decorative facade elements will be attached. If some elements of the product will protrude by 10-15 centimeters, you will have to strengthen the structure with dowels driven into the walls of the house in advance. Before starting work related to the design of a foam plastic facade, professionals recommend checking the evenness of the surface.

The next stage of the installation work will be diluting the glue, applying it to the back of the decorative fragments

When attaching them to the wall, a little effort is required to improve the quality of adhesion of the adhesive to the surface to be formed.

Attention! Be careful when working with decorative fragments, as the product is fragile.

The installation process is completed by sealing the fastener gaps with polyurethane foam or sealant. After it is completely dry, you can remove the remnants with a spatula.

Further, a high-quality priming of all decorative elements is carried out using a special solution. At the final stage, the polymer decor is painted with acrylic dyes according to the design project. To increase the service life of products, professionals recommend painting 2-3 times.

Applying additional protection to the facade decor is an obligatory stage of finishing work. This will protect the finished product from sudden temperature changes and high humidity.

How to install facade decor

The most important thing is to observe a clear sequence in performing work on the installation of facade decor made of polyurethane foam.

The first step is to prepare the surface where the foam decor elements will be mounted.

It must be flat and absolutely clean:

- remove old plaster, remove all dust, as well as other types of dirt;

- level the surface using facade plaster and, which is very important, avoiding internal voids. If voids are found, level them with cement mortar;

- prime the surface, let it dry.

Further, it is necessary to indicate the attachment points for the decorative elements of the facade and the sequence of installation. If part of the part extends beyond the overlap of centimeters by ten to fifteen, you will need reinforcement with dowels, which must be driven into the walls in advance.

Installation of the facade foam must be carried out on a clean and level surface.

Start preparing the elements of the facade decor made of foam:

- check the cleanliness of their surface;

- drill holes for dowels.

Please note that in no case should they be cross-cutting!

Dilute the glue, and then apply it to the back of the decorative fragments to be mounted.Attach them to the wall with slight pressure, allowing the adhesive to bond securely to the wall surface. However, be careful not to damage the parts.

The installation process ends with the sealing of the fastener gaps. For this, special sealants or polyurethane foam are used. Remove any remaining excess with a spatula and wait until it is completely dry.

Then the facade decorative elements are primed with a special solution for subsequent painting.

The final stage is painting the decor using water-based acrylic paints in accordance with the design project, at least in two layers.

Foam elements are attached to special glue

It is important to take into account such a moment - the mandatory need to apply additional protection to the surface of the facade decor to extend its service life and withstand the constant effects of temperature conditions and natural phenomena.

List of materials and tools:

- cement;

- facade plaster;

- sealant for sealing seams and gaps;

- water-based acrylic paints of the required shades;

- primer mixture;

- assembly adhesive for foam elements;

- putty knife;

- drill;

- dowels (for each part, two to five pieces, depending on the size of the element).

With the help of foam plastic, the facade of the house can be decorated in the most unusual way.

Features of the manufacture of foam decor

There are stringent requirements for the polymer that is made for the facade decoration of houses. The material for production is PSB 25f. It has all the most important characteristics and qualities in order to be used in exterior wall decoration. Thanks to modern automatic equipment, you can burn and cut contours, create products of different sizes and shapes. In order to achieve reliable protection of the created element from high humidity, sharp temperature jumps, sheets of polymer material are covered with a reinforcing compound. For example, you can treat a sheet blank made of polymer material with mineral mixtures created on the basis of acrylic paint.

Next, the sheet is sent to drying. In order for the polymer not to lose its technical and operational characteristics, it is necessary to withstand a certain temperature regime. As soon as the protective layer dries up, the workpiece is sent to the last stage of production: cleaning and polishing.

The nuances of the production of foam decor

For polystyrene, produced for the manufacture of finishing elements for the facades of houses, special requirements are imposed on quality. Styrofoam decor for facades is mainly made of psb 25f material. It possesses the necessary qualities and characteristics to reliably and effectively serve for the exterior walls of houses. At the same time, the price is quite affordable. But the price shouldn't play a decisive role. It is noteworthy that the installation and decoration of the house itself with such elements is easy, and we will talk about this in more detail.

Now I would like to note exactly how the decorative foam trim is made, what are the nuances of the production of these elements.

- Most often, manufacturers use PSB 25f foam, although expanded polystyrene is an excellent analogue.

- The blank sheet is sent to a special equipment. These are programmed machines in which the contour cutting and burning is set by the computer. Due to these manipulations, it is possible to obtain decorative elements of various shapes and sizes.

- In order to provide further protection, the sheet is covered with a reinforcing compound. As practice shows, for this, the sheet is treated with acrylic-based mineral mixtures.

- The next step is drying. In this case, it is important to adhere to a certain temperature regime.The protective layer is seized, the workpiece is sent to the final stage of production.

- The last step is cleaning and polishing.

The nuances of manufacturing make it possible to ensure that the finish will be able to withstand various atmospheric influences. The material is manufactured to exacting specifications.

How to make styrofoam decor by hand

Returning to the issue of making facade decor with our own hands, let's consider the technical and practical aspects of the foam products themselves and the most frequently asked questions on this topic:

- how to make styrofoam decor

- do-it-yourself styrofoam platbands

- DIY styrofoam crafts

- do-it-yourself curly cutting of polystyrene

The main criterion for making a decision to buy ready-made facade products or to give an assignment to facades - those who insulate your house is the geometric shape of the elements that you want to apply on the facade of the house. You have probably seen very often the facades of houses with simple frames around the windows and with two or three stepped eaves under the eaves of the roof. Simple rectangular rustic stones are also often found at the corners of the house. This kind of facade decor is made manually by the performers of the facade work when the facade is insulated.

The simple rectangular shape of the decor elements allows you to make them yourself right on the spot. The elements, like the wall of the house, are reinforced according to the usual technology of reinforcing the insulation on the facade - glue, mesh. The corners of the parts are additionally reinforced with special corners. It's another matter if you want to apply architectural details of complex geometric shapes. Rounds, waves, many steps, bulges - such details are the difference between the imitation of architectural elements from their real application on the facade of the house.

The complexity of the geometry of the products does not allow manual reinforcement of the foam plastic with a protective layer. Therefore, in this case, there is one correct solution - it is to buy ready-made elements of facade decor from the manufacturer.

Houses of the same type are a thing of the past: moreover, this applies not only to private buildings, but also to multi-storey buildings. People want their homes to be unique and special. To create a unique exterior of the building, foam plastic facade decor is used: you can create a real masterpiece with your own hands.

The positive properties of the material made it popular:

- affordable cost,

- a light weight,

- resistance to temperature extremes and ultraviolet light,

- moisture resistance.

This decor will last a long time without losing its original appeal.

Until recently, facade elements for decoration were made exclusively of concrete and plaster. Such decorations were very heavy and quickly deteriorated from high humidity. In addition, concrete and plaster parts increased the load on the supporting elements of the structure, so sometimes such heavy decorations had to be abandoned.

Modern designers use lighter materials for facades. Facade decor made of expanded polystyrene is characterized by ease of installation and durability. Unlike wooden and plaster structures, the material is not afraid of moisture. Compared to stone products, foam is lightweight. By choosing the desired shade in a wide range of colors, you can favorably set off the main color of the building or choose a contrasting finish.

- The indisputable advantage of expanded polystyrene is resistance to alkalis, water, acid, mineral oil.

- The material is easy to cut, glue with mastic, plaster or cement mortar. Even a novice master can do the decor of the facade on his own.

- The material does not contain hazardous chemical compounds and does not burn, and also has good compressive strength.

- All decorative elements that will be made of polystyrene are odorless and are not subject to decay or mold.

- Due to its low weight, the stucco molding is quite easy to fix.

Considering a number of the listed advantages, our company offers the production of foam decor. Decorative elements are used not only for exterior decoration, but also for interior decoration. Also, expanded polystyrene is useful for the restoration of old structures. Facade decoration elements are used to improve the appearance of the building, style. Also, finishing elements will protect sections of the structure from climatic influences. Facade elements increase the thermal insulation of the building, improve sound insulation and increase the service life of the building.

Advantages of styrofoam decor

Expanded polystyrene is now held in high esteem by builders and designers. Decorating a residential building with this light and practical material allows you to solve 2 problems at once: to warm the room and decorate it. In addition, the material ensures ease of installation and durability.

Elements for the facade made of expanded polystyrene are gradually replacing decorations made of plaster and concrete, which are bulky and heavy. After all, the presence of the latter on the construction greatly increases the load on the foundation and load-bearing walls, which requires their additional strengthening.

If we compare the decor made of expanded polystyrene with similar details made of plaster and wood, then there is also an obvious advantage of the former - it is not afraid of high humidity. In addition, the material is not afraid of the effects of alkali, acid and mineral oils.

Expanded polystyrene is easily attached to the walls using plaster or cement mortar and mastic. If desired, the facade is easy to arrange yourself.

Attention! Having painted the stucco molding in the right shade, you can favorably set off the color and texture of the walls of the house or play in contrast.

The material is completely odorless, mold fungi and putrefactive bacteria do not settle on it. Expanded polystyrene burns poorly, there are no harmful compounds in its composition. The decor can be installed both outside the building and from the inside. This is a great option for the restoration of old houses.

As a facade decoration, expanded polystyrene is suitable for use in regions with different climates. It does not react to either high or low temperatures. If you wish, you can order non-repeating shapes that will add originality to the house.

How to make styrofoam decor with your own hands

Foam molding can be used for self-assembly. Many architectural elements will help make your home beautiful: windows, window sills, gables, cornice, pilasters, balustrades. Each element of the facade is treated with a special coating, so we can confidently talk about the resistance of the material to external influences. Small decorative elements can change the exterior of the building beyond recognition.

Manufacturing and installation stages:

- Parts are cut by thermal contour cutting using a hot wire. In an industrial environment, you can pre-program the shape of the product, and perform cutting on a computer machine with maximum accuracy.

- After applying the reinforcing layer, the contact of the foam with the external environment ceases. The detail for the facade decoration is covered with a fiberglass mesh, which protects against alkalis.

- Next, a deep penetration cement-adhesive mixture is applied, which forms a film with a thickness of about one and a half millimeters. After such processing, the parts become resistant to ultraviolet light and cease to attract dust. The film is a good base for painting.

Since the facade decor can imitate natural materials, it can be used to decorate various areas of the building. The variety of topcoats allows owners to choose an imitation of stone, wood, plaster, marble. Foam facing stones are used in corner areas. Outwardly, they are no different from granite or marble.Due to the protrusions relative to the walls, a beautiful relief is formed.

Since the installation of the decor is not particularly difficult, it is often done independently.

In order for the material to serve for a long time, you should know the important norms and rules of work when installing foam decor with your own hands:

- At the place where the decor is installed, the surface is cleaned of dirt, mortar, and mold. This can be done using mechanical means or chemicals. Ideally, the mounting base should be flat and clean, completely dry.

- If the surface has deviations from the plane, then it should be leveled.

- Check old plaster for voids: they are removed before installation.

- After preparing the base and marking, the material is fixed with an adhesive mixture, the glue must be used, since it gives the foam plastic adhesion to the supporting structure. Excess uncured glue is removed with a spatula. The joints of the decor and the base are glued with a compound for seams.

- Then they are additionally fixed with dowels with drowning of the caps by three to four millimeters. Depending on the weight, size and type of product, embedded parts and anchoring devices can be used.

The use of various mounting techniques allows you to create optical effects of the masonry: horizontal and vertical directions, offset, diagonal. The vertical arrangement of the material gives the building solidity, and by laying out the elements across the column, you can give it grace.