Improper operation of boiler equipment often leads to undesirable consequences. To control the operating parameters of the coolant, a temperature sensor is installed on the heating circuit. Below we will talk about the principle of operation and the rules for installing devices.

To control the parameters of the boiler coolant operation, it is recommended to install a temperature sensor.

Sensor features

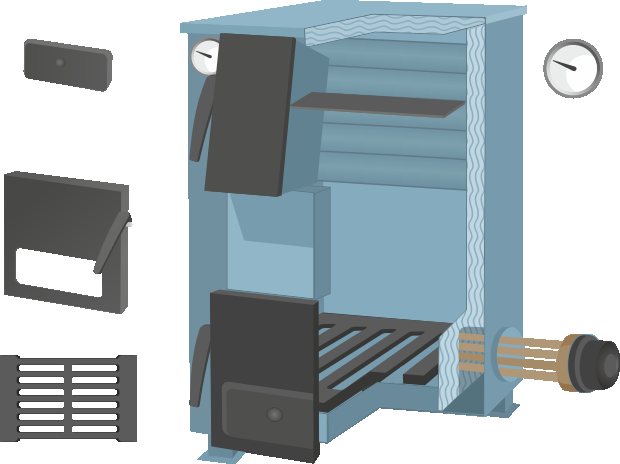

The set of heating equipment, in addition to the boiler itself, includes a thermoelectric heater (TEN). The control panel must be purchased separately. PU for the heating element unit allows you to quickly switch the heater operation to automatic mode. This is very convenient, since it frees the user from constantly monitoring the work and setting the necessary parameters manually. With a decrease in the intensity of combustion in the firebox, using the remote control, you can easily and quickly adjust this indicator and prevent a decrease in the comfortable temperature in the room.

There are two types of sensors:

- air temperature - located in a room or boiler room;

- coolant temperature - mounted on the pipeline.

There are a number of varieties of temperature measuring devices. Thus, overhead wire elements are used in the Teplodar boilers.

Below we will analyze the feasibility of installing a liquid temperature sensor.

Choosing a device

Very often this device is called a control valve among ordinary people. In any case, it is very similar to a valve. The modern market offers several options for such a device - mechanical, electrical and automatic. And then a logical question arises, which one to choose, and what to look for when choosing.

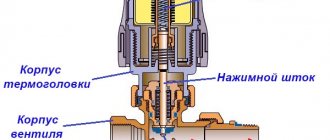

Let's take a look at the thermostat design first. This is a valve, which means that it must be installed between the heating battery and the coolant supply pipeline. The device consists of two parts - a valve and a thermostatic element.

The thermostatic element is a cylinder whose walls are not straight, but corrugated. It is filled with a special substance that quickly reacts to changes in the temperature regime inside the rooms. If the temperature rises, the substance begins to expand in volume. And if it decreases, then its volume, on the contrary, decreases.

Attention! Pay attention to indicators such as compression and extension of the cylinder. In branded products, it is designed for one million such actions. Approximately this is enough for 100 years, no less.

So decide for yourself whether it is profitable to install a thermostat in the heating system. Now about the valve. Manufacturers offer two design options - RTD-N and RTD-G. There is one more division - straight or angular. The choice of valve will depend on the heating system, the diameter of the pipes used and the inlet in the radiator.

The thermostat is installed from the end of the radiator into the hot water supply hole. Please note that the device is positioned horizontally. This is necessary so that the influence of the battery and the supply pipe is minimal. The substance inside the cylinder will react to the heat that they generate, which can lead to improper operation of the thermostat.

Principle of operation

The device has three outputs. One is designed to be connected to a heating radiator. The second is for contact with the coolant supply line. And the third is for connection to the return line.Why is it so difficult? The fact is that in this device there is a mixing of two coolants - from the supply and return - so you can get a coolant of a certain temperature.

Now you understand how the control over the coolant in the thermostat takes place - by mixing the coolant with different temperatures. It is necessary to make one remark - with the help of a thermostat, you can control the temperature not only on heating radiators, but also on entire sections of the highway.

But how to determine which pipe and where to connect the device? Manufacturers have installed decals on the thermostat housing. The arrow is the connection to the radiator, the red bar is the connection to the supply line, the blue bar is the connection to the return circuit. We hope you can figure this out without any problems.

Without exception, all thermostats have the same design and the same operating principle. The only difference is the way of controlling the device.

A mechanical or, as it is also called, a manual heating thermostat, has a temperature gradation on the valve. If you need to change the temperature regime inside the room, you just have to turn the handle to one side or the other. It is important here to accurately catch the required division. Sometimes this has to be determined empirically.

With this thermostat, everything is just as easy. Only here you will not have to turn the valve head, but a small wheel placed in the electrical control system. In this case, everything happens in a semi-automatic mode.

Using the wheel, you set the parameter of the required temperature, and the electric regulator itself will already work in automatic mode. When the temperature in the room reaches the desired value, a key closure process is triggered inside the thermostat, which gives a signal to the actuator. The latter either opens the valve or closes it. As you can see, nothing too complicated.

What is a Servo Drive? It is a small electric motor that is installed in the place where the mechanical valve should be. That is, it is attached to the thermostat housing. Such a motor can be controlled by any team.

For example, it can be a signal from a temperature sensor installed anywhere in the room. If the signal is applied, the engine is triggered. It turns the stem in one direction or the other, and, accordingly, one of the sides of the thermostat opens or closes.

Read more: Dishwasher Bosch SMS24AW01R review reviews features specifications

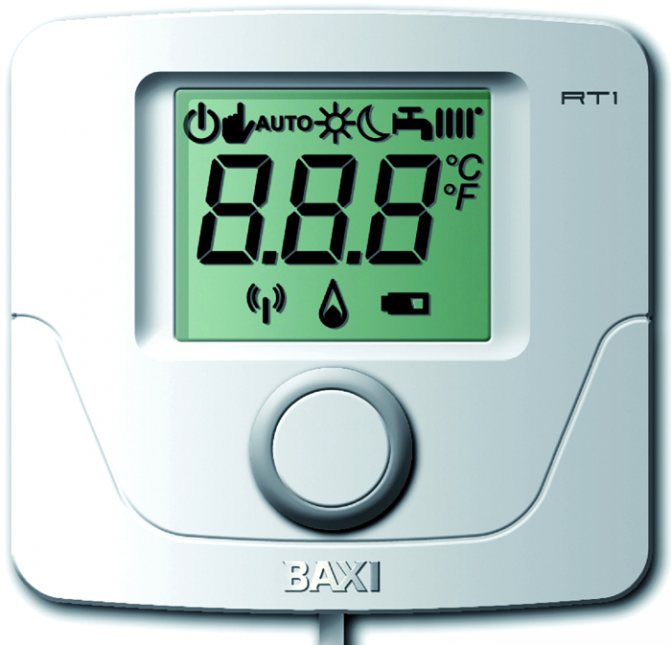

These are the most advanced and most accurate instruments, but also the most expensive. The principle of their operation is the same, but the temperature regime is set using an electronic device with a display. You just need to press the buttons with numbers that indicate the temperature of the coolant, and they will be highlighted on the display of the device - the temperature is set.

Manufacturers offer different types of electronic devices. The difference between them depends on the range in which you need to set the temperature regime. For example, for a day or a week.

Suppose you are a working person and are rarely in the house during the day. This means you can save a little. That is, you set the mode with a reduced temperature inside the rooms from 7 am to 7 pm, and from 19 pm to 7 am you can raise the temperature to normal. All this is displayed on an electronic display. You will not have a headache, what and how to do - the device will do everything for you on its own in automatic mode. Conveniently? Certainly.

If you need a weekly schedule, which is also convenient, you will have to choose just such a device. This will be especially pleasant for those who work on a rotational basis. You come to the house, and you are warm, but at the same time, in your absence, the heating worked in the economy mode.

It is recommended to equip one-pipe systems with thermostats with a Kv value greater than 1, and even better - greater than 1.5. For two-pipe regulators, regulators with a Kv in the range of 0.5 to 0.9% are more suitable.

The sequence of installation works is as follows:

- after closing the supply riser, water is drained from the heating system;

- at a short distance from the battery, horizontal pipe lines are cut;

- disconnect the cut section of the pipeline together with the valves;

- if the system is one-pipe, a bypass is welded. This is a jumper that will allow the coolant to circulate along the circuit when the valves are closed and there is no access to the battery. In two-pipe heating systems, the thermostat is mounted on the inlet upper pipe, and the valve on the lower one;

- shanks with nuts are removed from the shut-off valve and thermostat, after which they are wrapped in radiator plugs;

- piping is assembled and installed and then connected to horizontal supply pipes.

Nuances of location

The axis of the thermal head must always be in a horizontal position in order for the device to measure the temperature accurately.

In an upright position, the sensor will be in the range of ascending and descending heat flows, due to which the temperature readings will be incorrect.

If the stem shaft is mounted vertically, it is better to use an electrically driven or radio-frequency remote electronic transmitter.

Thermoregulators with a built-in sensor must be positioned so that they are in sight, but do not fall into the area of operation of thermal devices. Also note that the heat is shielded by thick curtains. The optimum height for the thermostat is at least 80 cm from the floor surface.

Installation of thermostats on bimetallic, steel and aluminum batteries is allowed. If the radiator housing is cast from cast iron, it is not recommended to install a thermostat due to the high inertia of this alloy.

If the radiator is connected to a working heating system, then drain the water from it. This can be done using a ball valve, a shut-off valve or any other device that blocks the water supply from a common riser.

After that, the battery valve, located in the area of the place where water enters the system, is opened, all taps are shut off.

After the water has been removed from the battery, it must be blown to remove air. You can also do this using a Mayevsky crane.

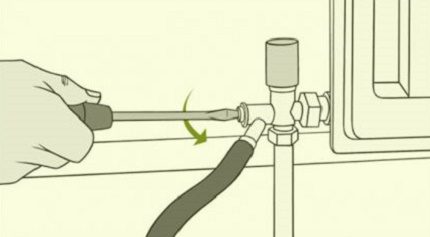

The next step is to remove the adapter. Before the procedure, the floor is covered with a material that absorbs moisture well (napkins, towels, soft paper, etc.).

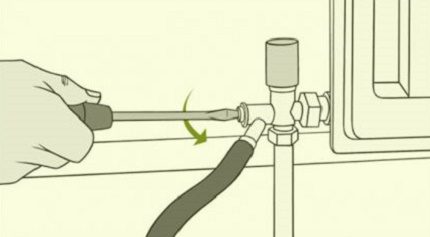

The thermostatic valve body is fixed with an adjustable wrench. At the same time, the second key is used to unscrew the nuts located on the pipe and the adapter, which is located in the battery itself. Next, unscrew the adapter from the case.

When unscrewing the adapter, it may be necessary to use the valve located inside the battery

After dismantling the old adapter, a new one is installed. To do this, place an adapter in the structure, tighten the nuts and collar, and then thoroughly clean the internal thread using a clean material.

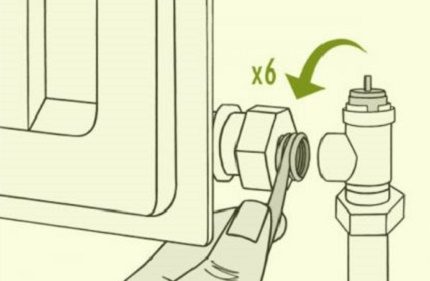

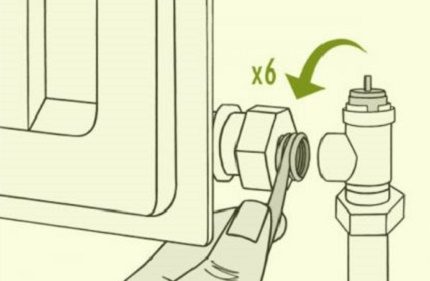

Next, the cleaned thread is wrapped several times with plumbing white tape (it is purchased separately in specialized stores), after which the adapter, as well as the radiator, and corner nuts are tightened tightly.

The thread must be wrapped with plumbing tape hour hand, making 5-6 turns. It is important that the tape lies flat, therefore it is necessary to smooth it in a timely manner, if necessary.

As soon as the installation of the adapter is completed, it is necessary to proceed with the removal of the old collar and the installation of the new collar.In some cases, it is difficult to remove the collar, therefore, cut out its parts with a screwdriver or a hacksaw, and then tear it apart.

Device assignment

The operation of heating boilers must be carried out in strict accordance with fire safety requirements. For example, the temperature of the coolant must not rise above 95 ° C. Failure to comply with this condition will lead to decomposition of the boiler paintwork, and paint from the inner walls, getting into the pipes, will clog the heating circuit.

The latter circumstance is fraught with a whole range of unpleasant consequences - from uneven heating of rooms to a breakthrough in the system. Therefore, overheating is categorically unacceptable, which is also regulated by sanitary standards.

A temperature sensor (DT) monitors the state of the coolant during the operation of solid fuel and electric boilers. The device immediately transmits the readings to the controller, which processes the information received, converts it into a signal displayed on the control panel display.

The controller converts the temperature sensor readings into a signal that is displayed on the control panel display.

Prices for outdoor temperature sensors for air

An air temperature sensor, the price of which in our company allows without restrictions to optionally complete the heating equipment, despite its narrow functionality (its purpose is to measure the air temperature and report the obtained data to the device controlling the heating system), is very important in the overall picture of the boiler operation. Installation of an air temperature sensor ensures that the heating system is adequate for atmospheric conditions and is economical.

The cost of the devices does not exceed three thousand rubles, while the benefits from operating the sensors are obvious. Temperature sensors are available in stock and on request. Turning to specialists, you will always receive competent advice on the technical characteristics of devices, installation conditions, etc. All equipment is accompanied by the necessary documentation from the manufacturer.

Also in our catalog are presented such control devices for optimal operation of heating equipment as thermostats, control modules, relays and timers.

Consequences of sensor failures

If problems appear in the operation of the boiler, the reason may be hidden in the incorrect functioning of the sensors. Below are examples of such deviations:

- Sudden shutdown of the boiler. There is a possibility that the temperature sensor switch-on relay has burned out. Less often, the reason lies in a malfunction of the control unit.

- Attenuation of the pellet / gas burner. A sensor malfunction will sometimes cause the main burner to automatically shut down. This leads to the fact that non-standard equipment also stops working.

- Apparent malfunction of the control unit. This can result in a sticking temperature sensor relay.

We strongly recommend that in the event of the above situations, pay attention to the condition and serviceability of the temperature sensors.

Varieties of sensors according to the method of taking readings

The temperature sensor for heating can be classified according to the method of taking readings, devices can be:

- bimetallic;

- alcohol.

The first of the listed designs presuppose the presence of two metal plates and a dial gauge; the plates are made of different metals. One of them is deformed when heated, creating pressure on the arrow. This technique is distinguished by high accuracy, but it is characterized by the disadvantage expressed in high inertness. The average cost of such sensors is from 600 to 900 rubles.

PUVN-10 and PUBT-03: main characteristics

It manufactures itself and offers to purchase control panels together with heating boilers. The most demanded of them are PUVN-10 and PUBT-03.

Please note that the correct installation of the external temperature sensor is also of decisive importance in the case of the remote control.

The control panel for water heaters PUVN-10 is compatible with most models of Kupper boilers. These include the series:

- OK

(models 9, 15, 20); - OVK

(models 10, 18); - Missile defense

(models 22, 28, 36, 42).

The temperature sensor from the PU is installed on the supply and return pipes (outlet / inlet to the boiler). The attachment is also suitable for appliances with a pellet or gas burner installed. Its use provides the ability to automatically shutdown the boiler in case of overheating or short circuit.

Universal control panel for heating elements in boilers "Kupper" PUBT-03.

The control panel for the PUBT-03 thermoelectric heaters unit, in addition to the previously named series, is compatible with the Kupper CARBO and Kupper Praktik boilers. The cost of devices varies - for the PUBT-10 line consoles it starts from 5920 rubles, for the PUBT-03 - from 10,990 rubles.

The higher price of PUBT-03 is due to the fact that the device has more functions and is considered more versatile. So, with its help you can adjust the following parameters:

- heating element on / off time;

- emergency on / off when cooling / overheating of the coolant;

- maintaining the set temperature of the heating element.

Also, using the control panel, you can set the date of turning on the heating element, the duration of its heating and set the desired cycle of operation.

PU installation is very simple. A little more difficult, perhaps, is the installation of a water temperature sensor on the "supply" and "return" pipes.

Further, according to the plan, electrical work is going on to connect the sensor to the switching unit.

Views

Depending on the type of placement and method of data transmission, temperature sensors are divided into several types.

By placement method sensors are:

- indoor - are installed indoors and control the temperature inside;

- external - located outside the house, adjusting the microclimate in the room, taking into account the temperature indicators on the street;

- waybills - mounted directly to the pipe of the heating system;

- submersible - located inside the coolant.

Photo 1. Temperature sensor of a submersible type for the heating system of a gas boiler in a private house.

Wired and wireless

Depending on the method of information transmission, temperature sensors are also divided into subtypes. There are wired and wireless... In the first case, the readings from the device are sent to the receiver through a wired connection. Wireless models transmit data remotely using a special device.

Types of boilers and the need for thermostats

Often use cast iron and steel boilers... Steel has high heat transfer, quick heating and a relatively low price, but can be exposed to the external environment. Then the entire heating system can deteriorate due to corrosion or clogging. To prevent this from happening, it is necessary control the temperature in the boiler and regulate temperature conditions.

Cast iron ones have high strength, practically resistant to corrosion and environmental influences, reliable and stable in operation, keep heat for a long time, consist of easily replaceable sections. Boilers for long-term burning of solid fuel made of cast iron can fail only in case of sudden temperature changes. Therefore, when installing such a boiler, it is necessary to correctly and professionally tie the boiler. It is necessary to constantly monitor the temperature regime.

How to connect temperature sensors for boilers with your own hands

When installing a wired device to adjust the temperature, we select a non-sunny area of the room. The fastening will be carried out at a distance of 150 cm from the floor.The sensor has terminals with the letters COM and NO, we connect a thin two-wire wire here, it must be connected to the special terminals (for the thermostat) of the boiler. The power supply unit will be finger-type batteries in the amount of two pieces. We will not pull the wires in the wireless type.

We connect the executive part to the boiler, and place the sensors at different points. The signal from the sensor is not afraid of concrete floors and other obstacles. The device also runs on finger-type batteries. They can be installed not in one copy on different pumps, but several, only the signals should be set up so that everyone understands their command. The setting of the devices is carried out according to the attached instructions, since each type has individual adjustment.

Temperature sensor selection criteria

The choice of a temperature sensor should be carried out taking into account the following criteria:

- range of measured temperatures, the sensor should be as sensitive as possible and respond to changes in heating with a minimum delay;

- technical features of the installation: submersible or fixed, whether there is enough space for installation, etc.;

- measurement conditions under which it is possible to minimize negative influencing factors;

- sensor characteristics: the need to supply voltage, the speed of the transmitted signal, the measurement error, the admissibility of operation in specific conditions;

- service life, maintenance periods, need for calibrations;

- output signal magnitude.

Immersion temperature sensor for boiler