Gas columns operate on the basis of natural and liquefied gas. Manufacturers of space heating devices equip boilers with a security system. The occurrence of a breakdown or the threat of an emergency situation provokes the activation of the protection, after which the blocking of the unit's operation is turned on. The draft sensor of a floor gas boiler (or wall-mounted) can be located in various parts of the equipment. Before turning on the unit, it is important to make sure it is working properly and to know the principle of operation of the gas boiler draft sensor.

A pneumatic relay with a membrane (draft sensor) prevents an emergency situation

The principle of operation of the traction sensor in the gas water heater

A sensor is called a bimetallic relay, endowed with the ability to start and turn off the boiler burner. In the inner part of the element, you can find a strip made of metal, which reacts to temperature changes. The manufacturer sets it to 75-900 ° C (in cases where natural fuel is used) or 75-1500 ° C (for liquefied gas). In situations where there is a deterioration in the draft in the chimney, the degree of concentration of the flue gas increases, against which the temperature indicator rises. The main function of the pneumatic relay of a gas boiler is to control and transmit signals about a change in the temperature indicator to the control unit. After the signal has reached the block, it enters the area of the gas valve. The supply of liquefied or natural gas is shut off. Sensor operation is also possible in cases of a violation of the draft in the chimney, which brings combustion products to the street.

The AOGV gas boiler draft sensor does not allow poisonous vapors to enter the house.

In boilers with closed combustion chambers, products are removed through a coaxial channel using a fan. A pneumorel with a membrane serves as a sensor that does not respond to a change in temperature, but to a change in flow rate.

At the moment the speed is within the normal range, the membrane looks curved. The contacts are closed. As soon as the flow rate indicator weakens, the contacts begin to open. The membrane is gradually straightened. The gas supply valve is closed.

Gas heating boiler automation

Modern heating devices using natural gas are high-tech and safe thanks to the introduction of automatic control and monitoring systems.

Automatic tracking systems improve equipment efficiency while providing ease of use that does not require constant human monitoring.

The boiler automation is conventionally divided into volatile (electronic) and non-volatile (mechanical).

The principle of operation of a gas boiler is simple. When gas is supplied, the electronic ignition device is triggered. The wick lights up, which then burns constantly - the automatics will not supply gas if it does not burn.

It ignites a burner - a heating device. The burner heats the heating medium (water) to the required temperature. As soon as the water heats up, the automation turns off the burner. When the water temperature drops, the thermostat will give a signal to the valve, and gas will begin to flow. The burner will start again and so on.

Today, heaters receive systems, the list of functions of which includes automatic provision:

- Security.

- Continuity - automatic on and off.

- Management by various criteria - by time, temperature throughout the day and other parameters.

The components, the automation device and the set of sensors of the boiler are different, but in any case they meet the basic requirements for reliability and safety. They are divided into several element groups that perform various functions and are present in one form or another as part of the control systems for gas heaters for various purposes:

- Gas fittings.

- Valves.

- Gas and water pressure switch.

- Thermostat. A room thermostat can be included in the circuit.

- Controller.

- Water presence sensor.

- Traction sensor.

- Programmers (daily and weekly, including wireless)

Gas fittings

With the help of gas fittings or devices that process the execution of the command of the control circuit, the processes are regulated - starting and stopping the boiler, changing the gas flow rate and direction, and the heater power. But the main purpose is work safety.

- Locking. Includes dampers, various valves and taps. The connection is made with flanges, couplings and unions.

- Regulatory. To correct the flow rate by changing the flow area. This includes mechanical and electronic valves.

- Safety. This equipment includes shut-off and safety valves.

- Emergency. This includes shut-off valves that shut off the fuel supply.

The main function in a gas heater is to open or close the fuel supply to the burner.

Any heater is designed for a specific working gas pressure. A deviation from the norm will lead to a drop in performance or burnout of the case.

In the event of a fall, the minimum gas pressure switch comes into operation, turning off the boiler.

The limit value is adjusted during commissioning. It is mounted on the inlet line upstream of the control unit or upstream of the gas supply valve.

Minimum pressure switch

When the pressure rises, the maximum pressure switch comes into operation. The device prevents possible overheating and destruction of the burner. The connection is made in series in the same circuit with the previous relay.

The thermostat is considered one of the most complex devices in the automation scheme of a gas boiler. The main purpose is to maintain the set water temperature. Adjustable thresholds.

The draft sensor performs an important function - it monitors the process of exhausting combustion products.

If something goes wrong, for example, for some reason a back draft appears, it will cut off the gas supply to the burner. This is a vital element as carbon monoxide poisoning occurs imperceptibly. Installed in the fume extractor above the boiler.

For cases of problems with the water supply, a minimum and maximum pressure switch is provided. Dangerously low blood pressure. It causes the water to boil and, as a result, leads to the ingress of air into the system and overheating of the boiler, with the ensuing consequences. To set the relay, use the minimum temperature values at which the functionality of the boiler is ensured.

The operation will resume only after the elimination of the factor that caused the operation. After shutdown due to pressure increase, manual activation is required. For this, a special button for disabling the protection of the gas heater is provided.

In rare cases, a water presence sensor is included in the automation circuit. It is placed in the cauldron itself. If the water level is below the required level, it will not allow the automation to start the boiler.

Controller

The controller or multi-unit is the most important and most complex part of the automation. This device is designed to implement a gas boiler control algorithm depending on changing external factors. Such devices can vary greatly in functionality.

The control part or control panel is of two types - mechanical and electronic. In the first case, the parameters are set using "knobs", and in the second - using buttons, sometimes even touch.

The controllers differ in operating algorithms, methods of connection with the boiler, other parameters and capabilities, but they provide ease of reading information, light signaling of modes and failures.

The design of the device must include temperature sensors, pressure sensors, draft and filters. The elements are combined in a single housing, to which a gas supply pipe is connected. The device has a capillary tube coming from the sensors, a tube for supplying gas to the wick and a cable for connecting the ignition element.

For a simple buyer, all gas boilers look the same, but this is only at first glance. In fact, there are a lot of nuances and subtleties that professionals can tell you about, and all these subtleties greatly affect the characteristics of the boiler.

Each boiler removes combustion products in different ways, even heats water in different ways, their burners are different, and the methods of direct control of the boiler, in particular, the methods of its automation.

What does automation include? How does the automation of a gas boiler work?

There are so-called volatile systems that operate from the mains, and, accordingly, need electricity, and therefore are bulky, huge and complex electrical appliances, the automation of which allows you to regulate the fuel supply, flame power and a number of other parameters. All this allows for good savings. The system can consist of:

- Room thermostat

- Daily programmer

- Weekly programmer

- Boiler heating

The thermostat is a device that is located in a room, in which, in turn, the temperature regime needs to be regulated. The thermostat sensors take the necessary measurements. In the event that the heat level becomes less than that programmed into the thermostat, the device will send a signal to the boiler equipment, and it, in turn, will automatically turn on the boiler and it will start working.

When the temperature reaches comfortable values, the automation will also automatically stop the operation of the boiler. ...

This device is very similar to a thermostat and performs a similar function, however, it has the ability to program the boiler operation schedule for 24 hours.

A cycle is set in which the temperature level for heating is indicated by time. The cycle is restarted every day. It is possible to connect the device to the boiler by wire or by radio - it depends on the boiler model and its capabilities.

More advanced device. It has broader functions and capabilities for controlling the indoor climate. You can choose either a preset mode or customize it yourself. The cycle is set for a week and, accordingly, repeats on a weekly basis. The most commonly used connection is by radio.

Devices differ in design and color, so you can choose a programmer to suit your taste and interior, which is also a small but pleasant plus.

Read next: Non-woven wallpaper in the interior - 60 photo examples

Such control devices can be, for example, mechanized or completely mechanical, that is, they do not need electricity, but the regulation of the gas boiler automation is provided partially by a person. Of course, in the full sense of the word, such devices cannot be called automation, but the role of man is here minimized.

All functions of such automation are controlled and ensured by qualitative changes in the details of the device itself under the influence of various temperatures.Oddly enough, with all the variety, convenience and simplicity of electronics, many people decide to use mechanical devices.

Perhaps the price plays a special role here, which is several times lower, but more importantly, such devices should not be afraid of a power outage, any drops in the power grid and do not need additional accessories, for example, a voltage stabilizer.

The principle of operation is the simplest: a person sets the required temperature on his own, using a regulator with a graduated scale. There is a thermocouple inside the boiler that lengthens when heated and shrinks when cooled. The thermocouple, which is a rod, thereby acts on the internal valve of the boiler and regulates the gas supply. For example, a draft sensor, which is installed in a smoke hood, can work according to approximately the same principle.

According to all regulatory documents, any automation equipment for gas boilers and installations must stop their operation and stop the fuel supply in various potentially dangerous situations:

- The flame in the igniter is extinguished

- High pressure in the pipeline

- On the contrary, the pressure in the pipeline is too low

- Low draft in the chimney

These episodes can lead to a strong gas contamination of the room, which is very dangerous. Therefore, safety automation must be installed on all boilers, both new (already built in advance) and old (by additional installation). Sometimes it is easier and cheaper to buy a new boiler with built-in automation than to install the system on old models.

Where in gas boilers is the draft sensor installed

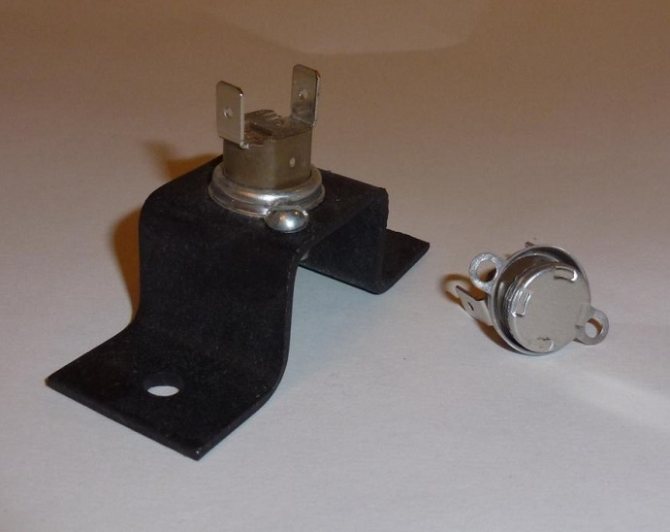

The design of the pneumatic relay may differ, depending on the type of combustion chamber that the manufacturer has installed on the boiler.

Cameras on sale can be of two types:

- open combustion;

- closed combustion.

Each manufacturer is obliged to install a pneumatic relay with a membrane in gas appliances with an open type of combustion chamber. As a rule, the place for installing the sensor is located in the area of the smoke extractor.

Important! As soon as the set temperature indicator inside the boiler rises, the fuel supply to the column stops. The functions of the pneumatic relay in this case are similar to the operation of the overheating sensor. It is better to entrust the replacement of pneumorel to a specialist.

How to install a gas boiler draft sensor

There are times when it is required to replace the draft sensor of a floor-standing gas boiler (or mounted). The process of installing a pneumatic relay with a membrane is simple. It is enough to fix the regulator in the chosen place and connect it to the gas column. For the correct fixing of the temperature regime, it is important to position the regulating element, adhering to the recommendations of specialists:

- the indicator of the minimum height from the floor surface reaches 150 cm;

- the maximum height from the floor is 170 cm.

Any heating devices, household, climatic appliances that distort the temperature indicator inside the gas appliance should be located at a distance of 100 cm. It is important to prevent drafts. Installing the boiler in a cold room is not permissible.

It should be borne in mind that you should not allow the sensor to be too tightly fixed to the body of the equipment. The installation is carried out on paronite gaskets, which helps to reduce the heating of the sensor through contact with the column body and makes it possible to achieve a gap between the hole in the area of the gas duct and the plane of the sensor.

It is important to make sure that the thermostat contacts are firmly attached to the housing. The presence of traces of oxidation on the device is unacceptable.

Step by step installation process:

- After the device has been fixed in the chosen place, you should start laying the wire to the heat source using hidden or open methods. One part of the end of the cable is connected to the contacts on which the COM and NO markings of the thermostat are displayed.For wireless versions, you will find the terminals in the area of the relay box.

- The front panel of the gas appliance must be removed as it prevents access to the control board and connectors. The jumper located between the terminals is removed.

- The wires that go from the contacts of the regulator are connected to the freed terminals. Polarity is optional.

How to check the draft sensor on a gas water heater

In some cases, during normal operation of the smoke exhaust system, the column may turn off. The reason for this phenomenon is a malfunction of the pneumatic relay with a membrane. In this situation, it is worthwhile to check the thrust sensor, the step-by-step process of which is described below:

- A mirror is installed in the sensor placement area for 10-20 minutes.

- After a specified period of time, it is necessary to check whether it fogs up during operation.

- If the mirror is not fogged up, you don't have to worry, the device works. A fogged mirror indicates a breakdown. It is important to identify the cause of the malfunction as soon as possible and take steps to eliminate it.

To use the second method of checking the pneumatic relay, partially cover the chimney with a damper. In cases where the device is fully functional, the boiler is turned off.

You can also check the gas boiler draft sensor with a multimeter. After connecting the probes of the measuring device, you need to wait for the readings. In cases of normal switching, the multimeter needle will display the minimum resistance level. In the absence of a response from the device, we can talk about a violation of the switching channel.

The reason for the operation of the pneumatic relay with a membrane may be the occurrence of a blockage in the chimney

Oleg Nikolaenko from Samara asks:

We live in the private sector and have recently switched to autonomous heating. Many questions arise, but the main one is how to check the draft sensor on a gas boiler without calling the master?

Our expert's answer:

Owners of private houses often prefer not to depend on the central heating system and install gas boilers that heat the room autonomously. Since gas is a potentially dangerous substance, for safety reasons, a so-called thermal relay is installed on such devices - a device that gives a signal in the event of a threat to the health and life of people living in the house due to a change in the direction of carbon monoxide circulation. In such situations, you need to know how to check the draft sensor on a gas boiler.

How to turn off the draft sensor in a gas boiler

Frequent actuation of the draft sensor causes outrage. Property owners are starting to look for ways to turn off the regulator, but such actions are unacceptable, since:

- systematic triggering of the sensor indicates a poor draft of the chimney, against which the fuel will not be able to burn out and will begin to accumulate in the house;

- there is a risk that the situation is triggered by the reverse thrust indicator, which has arisen against the background of the formation of an air lock (in this case, the exhaust gas, having reached the plug, returns back).

The formation of a back draft arises from a lack of natural vacuum in the area of the chimney of the gas column. A similar problem arises in boilers with an open combustion chamber. Disruption of the air flow prevents carbon monoxide from escaping, so it enters the living space and causes poisoning.

If necessary, you can still turn off the sensor. For example, if it stopped working and needs to be replaced. To do this, it will be enough to remove from the circuit the communication wires with the thermocouple breaker and the electromagnetic valve. However, when disabling the sensor, it is important to understand that this is a safety violation. In case of an emergency, the unit will not shut down, but will continue to work.It is not worth the risk, it is better to invite a specialist who will help eliminate the cause that triggers the sensor.

Diagnostics of errors of the smoke exhaust system of traditional gas boilers

One of the most popular mistakes that the user of a gas boiler encounters is the error of the combustion products removal system. If the normal flow of combustion air cannot be ensured into the combustion chamber and the combustion products cannot be removed normally, then for safety reasons the operation of the boiler must be blocked!

Sometimes the problems that arise may not be significant, and are eliminated by the user on his own. In this article, we will consider the most common cases of such problems and ways to eliminate them. It should be noted that the recommendations will be valid for most household gas boilers, but if the user has only a superficial understanding of the principles of the gas installation, it is advisable to use the services of a specialist with appropriate qualifications.

So, mainly boilers are atmospheric - where combustion products are removed due to natural draft and turbocharged, where a fan is used to remove flue gases. Therefore, first of all, you need to figure out which version is your boiler and which chimney system is used. The principles of traction control and, accordingly, troubleshooting will differ.

In the atmospheric version of the gas boiler (with an open combustion chamber), combustion air is drawn from the room. That is why for such boilers it is necessary to ensure a normal air flow in the place where it is installed. To control the draft in such boilers, a safety thermostat is often used.

In atmospheric boilers, a draft stabilizer is used - this is a boiler structural element located above the burner, which is needed to ensure stable combustion and metered supply of secondary air. A safety thermostat is located on this stabilizer and reacts to temperature. If, during the combustion of a gas boiler, the draft has tilted (air from the chimney goes into the room, and not vice versa), the sensor will inevitably be heated by the exhaust gases and the boiler will be stopped.

Problems with fume extraction in atmospheric boilers can be associated with design errors, a clogged chimney, a lack of normal air flow, or the operation of exhaust devices. The use of such boilers in the area of operation of additional exhaust devices is in principle not permitted.

To summarize, then to diagnose a malfunction of the atmospheric version of the boiler in case of a draft error, it is required:

- Make sure that the air flow in the room and in the boiler is not blocked - the boiler is not overgrown with dust.

- With the equipment turned off, check that there is a natural draft in the chimney and it is directed out of the room. Experts can measure the amount of thrust accurately with a device (special holes are provided in the boilers), the user can only “by eye”, by sensations, with a burning match or a strip of paper, etc. Often, boiler owners are convinced in advance that everything is in order with the draft! The probability of a malfunction of the control board for a thrust error is close to zero! The reasons for blocking the chimney can be different: birds, spiders, dirt, ice, etc.

- Checking the serviceability of the thermostat (traction control sensor). The procedure for most boilers is described above. The sensor in most cases is a bimetallic plate and has two positions: closed and open.

In a boiler equipped with a fan for removing combustion products, ensuring the safety of work is somewhat more difficult. The thrust is checked by an external device - a pneumatic relay. A device for measuring the air flow rate (Venturi device or Pitot tube) is also installed in the chimney, which is connected to the pneumatic relay through plastic tubes.

That is, in this case, the principle of traction control is as follows: if the air flow generated by the fan in the exhaust pipeline is greater than the minimum value to which the pneumatic relay is set, then the relay contacts close and the board gives a signal for ignition, if the air flow is less (the thrust is not sufficient) - contacts open and the boiler will be stopped.

The inlet pipeline is a pipe through which air enters the combustion chamber (in a turbocharged boiler, it is closed). If, for example, the head of the pipe is covered with frost in winter, there will be no inflow, while the fan is typically quieter - the boiler will not start. Provided that everything is in order with the exhaust pipe and there are no other problems - if you open the combustion chamber, the boiler will start up normally.

The fan operation can be assessed visually (the blades are visible without dismantling). If the fan does not start when the boiler is turned on, then in most cases either no signal is received from the board (the board is faulty), or the fan itself is faulty. Damage to wiring is rare but rare. Service workers check the performance of the fan by directly applying voltage to it. If the fan works, it is most likely that diagnostics and repair of the control board will be required.

If the fan turns on and air enters the combustion chamber normally, but the boiler does not start due to a smoke exhaust error, you need to check whether the pneumatic relay works. You can check that the relay is triggered visually (the relay emits a characteristic click), and even better with a tester - check the closure of the contacts in the wiring, because the relay can work, but for some reason the signal does not reach the control board.

If the pneumatic relay does not work, you need to make sure that there is no pollution or condensation in the supply pipes, they are not damaged. Alternatively, you can independently create a vacuum in the supply tube and make sure that the relay is activated. If it does not work, it is likely that it is defective and must be replaced (in most cases they are not collapsible and cannot be repaired).

In the event that the relay is forcibly triggered, but normally, when the boiler is started, it does not, then the Venturi (or Pitot) device should be inspected for damage or contamination. The slightest deformation or contamination can lead to malfunction.

Since the Venturi device is located in the exhaust pipe, it could be deformed by the high temperature of the exhaust gases.

Problems with the outlet pipeline may be the same as with the inlet, but one can make sure that there is no blockage, perhaps, only visually or, by measuring, the actual discharge by the device through specially provided control holes.

The air flow control device is installed inside the exhaust pipe. There is a possibility of heat damage (tube deformation) or contamination.

In some modern boilers, fans with a variable speed can be installed, which is set in the settings depending on the type of chimney used and its length (for example, in some Buderus and Ariston models). Therefore, it will not be superfluous to study the instruction manual for the equipment, since in practice there have been cases when incorrect configuration of the board was the source of the problem.

Read more: Light in the interior design of the apartment

This article describes the most common and obvious causes of malfunctions in gas boilers associated with the removal of combustion products. Different boilers can be equipped with different control schemes - we have considered the most popular ones.

We also draw your attention to the fact that it is unacceptable to disable control devices - all of them are provided for the safe operation of the equipment. If there is a problem, you need to fix it!

Reasons for triggering the gas boiler draft sensor

There are many reasons that can trigger the device to operate.Among the main reasons leading to the disconnection of the column, it is worth highlighting:

- Poor quality cravings. Often, the problem arises against the background of improper installation of the exhaust structure. Poor extraction of combustion products can lead to poisoning of people living in the living room.

- Back draft resulting from the formation of an air lock in the area of the chimney, which prevents the decay products from escaping. Quite often, a sharp temperature drop leads to the formation of air jams.

- Blockage in the chimney area. Inexperienced homeowners believe the pipe will not clog. But it is not so. Birds looking for a place to build a nest often choose a chimney. When a bird makes a nest, it can fall into a pipe, get stuck there and die. In addition to birds, foliage and soot deposits on the inner walls of the chimney can also cause clogging. When it occurs, the intensity of traction decreases. The only solution to the problem is cleaning.

- Strong gusts of wind. If the pipe is incorrectly positioned, wind enters it and blows out the burner. The sensor triggering causes the fuel supply to be cut off.

- Improper installation of equipment. Incorrectly made calculation of the dimensions of the chimney often provokes the attenuation of the burner. It is recommended to measure the chimney height indicator depending on how far the pipes are from the roof ridge. The head should be 60-70 cm higher than the ridge.

Before proceeding with the replacement of the draft sensor, it is important to familiarize yourself with the device of the gas water heater