09/20/2017 3573 Pechnik (Moscow) Fans for strengthening the chimney draft, allow you to improve the operation of both wood and gas heating units. Such designs have a simple and predominantly standard structure, however, despite this, the choice of such an installation should be approached with all responsibility and knowledge. You can get acquainted with all the most accurate and up-to-date information on this topic from the materials presented below, as well as by watching the video in this article.

Traction check

Installing a deflector on a pipe allows you to increase air circulation and increase traction

The anemometer device determines the pulling force when the smoke moves at a speed of 1 m / s or more. In the off-season, the device shows unreliable results due to a small difference in temperatures between the external and internal environment and a low flow rate. The Advanced Gas Analyzer measures pulling force in pascals (Pa) and is accurate but expensive. A reading of 10 - 20 Pa is considered sufficient.

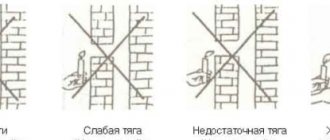

The color of the fire in the firebox shows the pulling force:

- yellow and gold tongues indicate normal flow rates;

- white flames and hums indicate excessive thrust;

- dark shades indicate insufficient speed.

The presence of gravity is determined in simple ways. A piece of thin paper is brought to the opening of the chimney. Its deviation indicates the movement of streams. A burning match works in a similar way, the flame of which must deviate from the vertical in the direction of the thrust. Smoke in the boiler room indicates the reverse movement of smoke in the chimney.

Preventive measures

In order not to have to use any means to artificially increase traction, it is necessary to periodically carry out preventive measures. This will keep the chimney in good condition. The main reason for the deterioration of the circulation of air masses is the narrowing of the diameter of the exhaust hole.... Ways to combat this phenomenon:

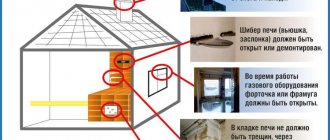

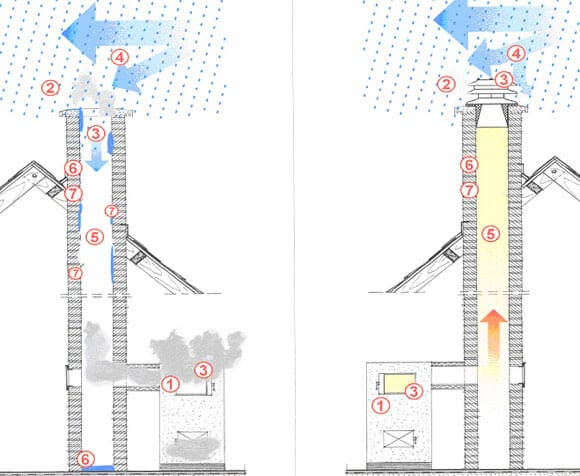

Back draft in the chimney

It is required to use high-temperature materials regularly (at least 4 times a month). This will prevent soot from accumulating in the flue ducts. If preventive measures are not taken, a serious fire can occur, as the ash generates a lot of heat during combustion.

You can also find specialized products on the market. They work on the principle of thermal or chemical decomposition of soot. Thanks to regular preventive measures, it is possible to do without exhausting the chimney.

The need to install equipment for forced air circulation sometimes arises in connection with any natural reasons. For example, trees in a garden plot could grow strongly, which changed the direction and strength of wind currents. Of course, you can remodel the chimney, but it is very expensive and difficult. It is better to use a forced draft hood for a fireplace or stove to create normal draft.

Reasons for poor traction

Traction is impaired in strong winds outside

A difficult situation arises if the chimney is designed and laid incorrectly. An inexperienced person selects the wrong pipe diameter or makes mistakes with the length. The smoke exhaust system must be rebuilt in order to generate traction.

There is no thrust if the tightness of the pipe joints, elbows, bends is broken. Smoke extraction can be increased by sealing all openings through which hot air seeps.Clogging of the discharge channel with soot also causes a decrease in draft or a reverse movement of combustion products. Sometimes heat exchangers of various designs are placed in the smoke removal channel to collect heat and reuse. But built-in installations affect the traction force and worsen the combustion of the fuel.

Traction force weakens under conditions:

- rain, fog;

- high air humidity;

- high temperature outside;

- high wind speed.

Backdraft or overturning occurs when there is no vacuum in the chimney. Combustion products are not removed from the room into the atmosphere and are drawn into the boiler room, which is dangerous for humans with carbon monoxide poisoning.

Types of structures for increasing chimney draft

Types of structures for the chimney

The installation of technical devices helps to increase the removal rate. Mechanical and electrical devices increase and decrease the speed of smoke movement, while maintaining optimal pressure in the pipe.

It is possible to increase the draft in the chimney if you set:

- rotary turbine;

- vane;

- electric fan;

- stabilizer;

- deflector.

The solution is chosen taking into account the design of the smoke channel, the type of heating equipment. The height of the pipe above the roof level and the presence of multi-storey buildings in the neighborhood matter. Any device on the pipe causes the accumulation of soot and condensation inside the duct, therefore it is better to correctly design and install the smoke exhaust ducts.

Rotary or rotary turbine

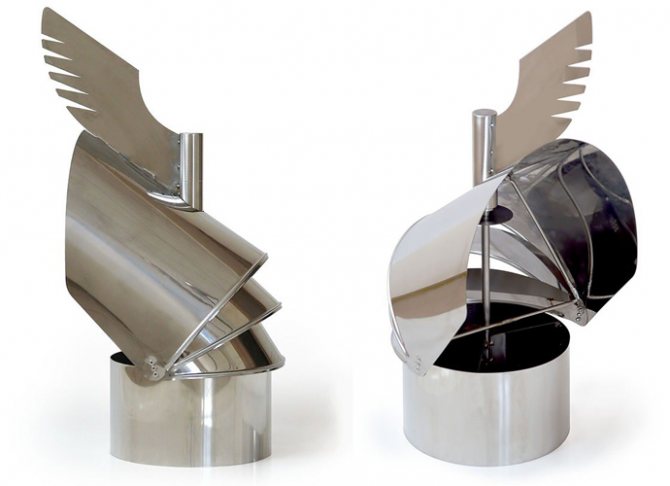

The turbo deflector is air-driven and helps the smoke escape

The traction amplifier contains one or more rotary devices in the structure, is placed at the end of the pipe and functions due to the movement of the wind. The temperature of the outgoing smoke should not exceed 150 - 200 ° C, depending on the type of turbine. More often, such devices are placed on gas stoves and boilers.

The device rotates in one direction and rotates to create an area of reduced pressure above the apex of the channel. The nozzle additionally protects the outlet from debris and precipitation.

The disadvantage is the inability to work in calm weather. The turbine continues to rotate with the heating turned off during the summer months and creates increased draft in the room.

Vane

The weather vane turns against the wind and protects the pipe from blowing out

The chimney nozzle for increasing the draft is made in the form of a weather vane, which turns against the wind due to a special design. The task of the chimney is to counteract the back draft and give an aesthetic appearance to the head of the chimney.

Construction details:

- central axis;

- figure;

- Rose of Wind.

The cap has bearings inside that require regular lubrication. In frost, ice appears on the surface of the case, it must be knocked down.

The weather vane deflects wind currents and prevents them from entering the channel, and the smoke freely leaves the leeward side. The design protects against rain. Special drippers direct the condensate jets along the inner surface of the housing and prevent them from flowing into the pipe.

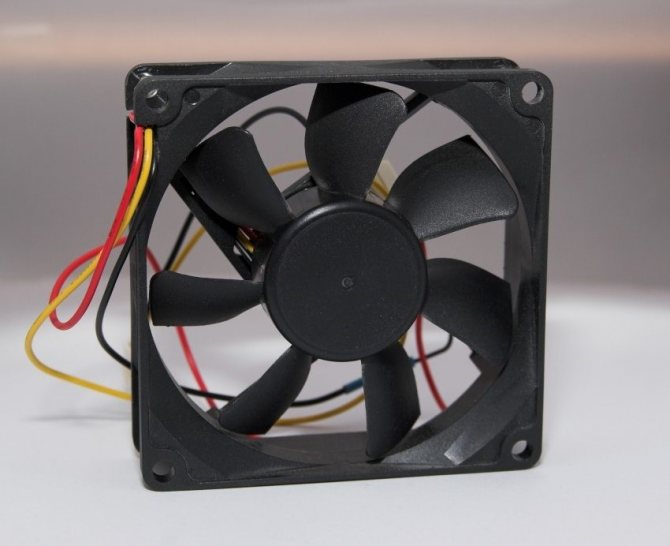

Electric fan

Smoke speed can be increased by using an electric fan.

It is used for extracting smoke from solid fuel, gas boilers, stoves of baths and saunas, fireplaces, open hearths, with a temperature of combustion products not exceeding 200 ° C, as well as in the air purification system. The fan in the chimney for improving draft is a draft-blowing device to increase the heating efficiency. Installation of the device allows you to make the boiler furnace and other elements compact, and the combustion process does not depend on the weather.

The gas circulation speed increases, the air supply to the burners is organized, the air is evenly distributed over the combustion zones.The use of a fan is not always justified in small household stoves, low-power boilers, since they make a complex design and depend on electricity.

Stabilizer

The device is a breaker for the metered supply of oxygen and maintaining the pulling force in the chimney. There is a safety valve in the design to stop work when there is overpressure in the pipe.

The stabilizer is installed on the chimney outlet and performs the following functions:

- stabilizes the pressure in the furnace;

- weakens excess draft in the pipe and improves boiler efficiency;

- protects the room from smoke back suction.

A draft sensor is mounted under the umbrella head, which reacts to an increase in the temperature of the combustion products. Smoke builds up under the dome when the flow is reduced and heats up the controller, which interrupts the gas supply to the burner.

Deflector

Deflector with different nozzle diameters enhances smoke velocity

The device is placed at the end of the pipe and converts the energy of the wind flow to reduce the static pressure in the duct. The Bernoulli effect is used, which consists in the fact that with an increase in the wind speed and a decrease in the channel diameter, a rarefaction appears in the pipe and an additional tractive force is created.

The standard design assumes three parts:

- the upper cylindrical body, which has an extension at the bottom, it is attached to the base using racks;

- lower metal glass, sometimes asbestos cement or ceramics is used as a material;

- cone-shaped cap.

Above and below the deflector ring-shaped rebounds are placed to prevent air gusts. Some variants are made without an upper housing, in which case the deflector consists of a lower cylinder, diffuser, return and straight hood.

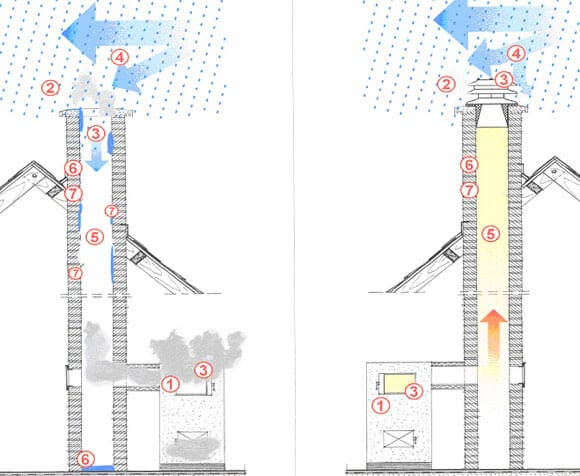

Design and principle of operation

An exhaust smoke exhauster for a factory-made boiler includes the following elements (the device is shown in the diagram, the positions coincide with the points):

- Heat-resistant metal impeller with blades bent at 90 ° relative to the impeller.

- Fastening plate.

- Low performance electric motor (20 ... 50 W).

- Power cable connector.

- Control panel with controls and controls.

- Flask and capillary tube of the temperature sensor connected to the emergency thermostat.

- Power cord with plug.

Note. As an example, the DM-01 boiler smoke exhauster from Kalvis is taken. The design of other types of fans differs in the shape of the case - a snail, a box, a hemispherical landing area. The set of parts is similar.

The unit is attached to a special box located on the rear panel of the domestic TT boiler next to the chimney pipe. The temperature sensor bulb is inserted into the immersion well of the water jacket, the control panel is placed separately.

The principle of operation of the smoke exhauster consists in the forced removal of high-temperature gases from the fire-tube heat exchanger of the boiler into the chimney. The algorithm looks like this:

- The firebox is filled with firewood, firing is performed.

- The loading door is locked, the blower door is opened. The fan is turned on with a key on the remote control, then the performance is adjusted.

- When the heating system and the chimney are warmed up, the speed of the impeller is manually reduced to a minimum. If the heat generator has enough natural draft, it is recommended to turn off the smoke exhauster.

- When the coolant heats up to a critical temperature of 100 ° C or more, at the command of the sensor, an emergency thermostat is triggered, turning off the fan automatically.

The scheme of the boiler smoke exhauster

Reference. On TT boilers equipped with an automatic one, you do not need to open the ash pan door. The thermostat by means of a chain will open the air supply damper to the required angle.

High or low performance of the traction fan is set individually, depending on the quality of solid fuel, combustion mode and the degree of heating of the chimney. The main thing is to avoid the accumulation and seepage of smoke into the room.

It is also impossible to overdo it with revolutions - the lion's share of the heat will go into the pipe. Before opening the door and reloading, it is better to increase the rotation speed to the maximum.

A ready-made fan unit of the famous Russian brand Zota is mounted on wood-burning heaters with a rear gas outlet

Making a deflector with your own hands

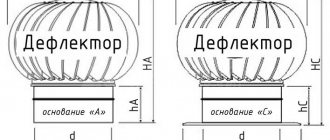

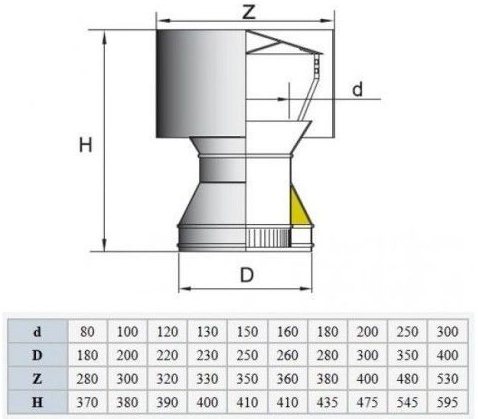

Deflector sizes different chimney pipes

The walls of the upper cylinder receive the wind pressure and direct the air around, the smoke suction is obtained by sliding along the inner surface of individual jets. The deflector cannot be attributed to the group of fans, since the device is simple in shape and does not have working mechanisms.

The outlines of the parts are drawn on the cardboard, which have been calculated and plotted on the drawing, and cut out. With the help of templates, parts are transferred to the metal with the addition of 1.5 - 2 cm along the edges of the lines for ease of assembly. Structural elements are obtained in expanded form after cutting with metal scissors.

A hacksaw is used to cut metal strips or corners to join parts into a finished product. The prepared parts are bent and folded in accordance with the drawing. During assembly, the elements are superimposed on each other and connected by rivets.

Required tools

In the manufacture, materials and tools are used that do not require professional skills from the master:

- rubber or wooden mallet;

- scissors and a hacksaw for metal;

- ruler, tape measure;

- chalk for drawing lines on the metal surface;

- electric drill, rivet gun;

- drills for metal;

- pencil and regular scissors.

The material is thin galvanized steel, a metal strip or a corner of a small section. The size of the rivets is selected according to the drill diameter. Nuts and bolts are used for pipe mounting.

Sizing calculation

A drawing is made on paper, which indicates the key dimensions for creating a pattern of a draft vane-amplifier for a chimney.

Sizing ratio:

- the deflector height is 1.7 d;

- the width of the cap is taken equal to 2 d;

- the width of the diffuser is taken as 1.3 d.

The d symbol stands for the chimney diameter (internal). A different aspect ratio will result in poor performance.

Features of increasing thrust depending on the design

If the device of the deflector on the pipe is not included in the design documentation, its installation is agreed with the employees of the gas service. Only then can traction be increased using this device.

Deflector TsAGI

Deflector designs differ:

- TsAGI deflector;

- round fixture;

- disc type;

- in the form of a star;

- H-shaped device;

- turbo deflector.

The deflector model is selected according to the value of the average wind speed in the area and the diameter of the flue duct. The devices are effective only in the presence of wind, in calm weather they do not work and can reduce thrust. Strengthening of smoke removal occurs with a different direction of the wind flow, except for the horizontal one, when vortices occur inside and the path of combustion products is blocked. The problem is solved by installing a reverse cap.

Improvement in the chimney of a gas boiler

If gas is used for heating, not all models of deflectors can be installed, since some are intended only for installation in the ventilation system. In order not to block the flow of exhaust gases, you need to consult with specialists.

In systems with a gas boiler, a deflector-vane is used. It is designed so that smoke comes out of the leeward side and increases chimney draft.The device is made of heat-resistant metal that resists heating and does not collapse from condensation. The bearing assembly helps to avoid rolling problems. Chimney weather vane is unstable in strong winds.

For solid fuel boiler

Correct installation of the deflector on different pipes for a solid fuel boiler

Wood-fired and coal-fired boilers use a mechanical, non-volatile draft control device. The device eliminates the need for manual adjustments and saves fuel. The regulator coordinates the amount of oxygen supplied by opening the oven damper.

A thermomechanical device automates the process:

- when the fuel burns, the energy carrier in the system is heated and the liquid in the working cylinder of the device expands, drives the mechanism and activates the spring;

- the lever loosens the chain, the damper closes, and the air passage decreases, smoldering begins instead of burning;

- cooling the antifreeze leads to the reduction of the spring and the opening of the firebox door, the process is repeated regularly.

The device regulates draft, prevents overheating of the heat exchanger, coordinates pressure and ensures independence from the weather.

In the chimney of a garage stove

Such stoves are capricious about traction, since almost all the heat is spent on heating the garage. The temperature of the outgoing smoke is low, the channel does not warm up, and condensation falls out. The phenomenon can be prevented by increasing the height of the pipe (up to 2-3 meters). A cylindrical or circular chimney section is used to prevent turbulence. The pipe of the garage oven is insulated to improve traction.

A damper is placed at the end of the pipe, partially covering the pipe perimeter. The damper regulates the intensity of the flame during kindling. If you use a large amount of fuel, the heated smoke will go up in a large volume and a kind of plug will be formed on the border with the cold air. In some models of ovens, the gate is sold as a set.

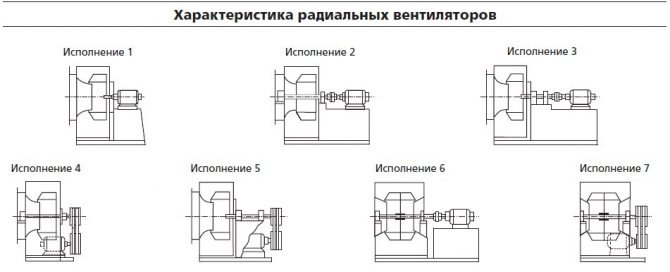

Types of traction fans

Several types of smoke exhausters are sold for wood-burning fireplaces:

- boiler room (the design is discussed above);

- centrifugal duct;

- overhead;

- fireplace / stove (aka roof).

Various nozzles that improve natural draft should not be attributed to smoke exhausters - deflectors, round rotary elements and rotating weather vane. The effectiveness of these hoods depends on the wind speed, which changes with the weather.

Varieties of duct smoke exhausters, some models are equipped with temperature sensors

The duct fan has its own casing with two connecting flanges or branch pipes. The unit is installed vertically or horizontally in the gap of the chimney duct. The device and principle of operation is similar to that of a boiler smoke exhauster.

Surface-mounted smoke exhauster for a household boiler is equipped with a semicircular platform and clamps-ties. Installation is carried out on a vertical section of the chimney (not insulated):

- An opening is cut out in the pipe using a paper template.

- The impeller of the traction machine is inserted into the hole, the platform with the electric motor is pressed against the surface by the clamps.

- The connection is sealed with an asbestos cord glued to the inner side of the exhaust fan mounting platform.

Note. The overlay is matched to the diameter of the flue pipe. The installation process is demonstrated in the video.

Electric hoods are mounted on the head of a brick chimney and are fastened with spacer bolts. The power cable is routed through a pipe and inserted into the room next to the home stove.

To choose a traction machine, you need to be guided by 3 criteria:

- heat generator power, smoke exhauster models are designed for boilers performance up to 20, 30, 50 and 100 kW;

- the installation point is on the boiler itself, pipe or head;

- for overhead models - the diameter of the non-insulated gas duct.

Overhead (left) and roof exhauster (right)

Installing the deflector

Once installed, the deflector is bolted to the roof to prevent it from being blown away by the wind

A homemade and purchased model is assembled into a finished product below, before being mounted on a pipe. The aerodynamic structure is bolted to a round metal, asbestos pipe, usually 3 holes are made in the pipe for this. If there is little play, a wrap-around clamp is used.

An adapter is used for mounting the deflector in a brick pipe of rectangular or square section. The device is tested after installation. The spark arrester is made independently from metal thin mesh or stainless steel sheet.

The diameter of the structure must be larger than the outlet of the pipe so that the deflector does not fall into the channel and does not block the smoke outlet. Rotary damper do not work well in cold regions with heavy snowfall. Icing will interfere with the operation of the device. The devices are installed in accordance with technical standards and requirements.