What do you need to assemble a stove?

The steel from which the pipe is made should not be alloyed and high-carbon. This material has a negative effect on the weld seams. After their welding and subsequent cooling, cracks may appear, which will lead to deformation of the furnace. The most suitable steel grade option is St10 and St20.

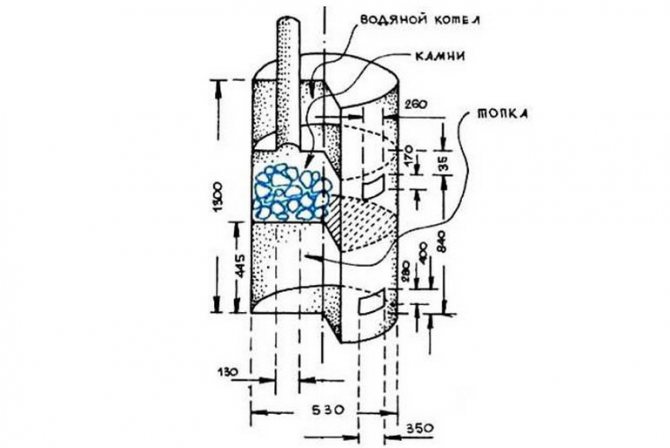

It is necessary to determine the exact dimensions of a vertical stove for a bath from a pipe with your own hands, based on the size of the room itself. Ideal dimensions of a pipe for a bath:

- diameter - 50-55 cm;

- thickness - 0.8-1.2 cm.

Required material:

- steel pipe, with a diameter of 50-65 cm, a length of 120-150 cm and a wall thickness of 0.8-1.6 cm, for a water tank and a firebox;

- another, 35 cm in diameter with a wall thickness of 0.5-0.8 cm for laying stones;

- one more, with a diameter of 12-15 cm and a wall thickness of 0.2-0.4 cm, for the chimney;

- cut reinforcement made of low-carbon steel for grates with a diameter of 1.2-2.0 cm and a length of 50 cm;

- asbestos cord - needed to seal the doors;

- metal sheet for doors, 0.4 cm thick;

- door handles;

Required tools:

- electric welding machine;

- locksmith tools;

- drill and grinder.

Why is it important to make a vertical bath stove with your own hands from a 530 mm pipe with a wall 0.6 cm thick? The pipe of this diameter has passed the hydro-pressure test. This will help create a stove without holes and burnouts.

Horizontal oven from a pipe

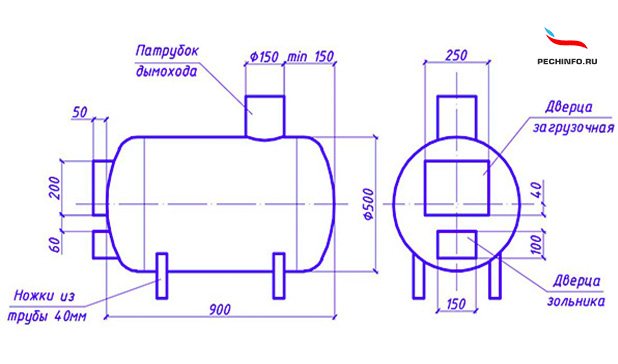

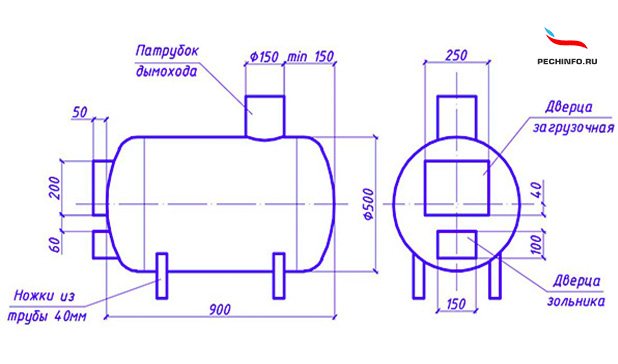

A horizontal pipe furnace is made of the same materials as a vertical one, however, the dimensions of the pipes for it are slightly different:

- The main pipe should be 75 cm long and 53 cm in diameter;

- The second pipe should be smaller (11.4 cm).

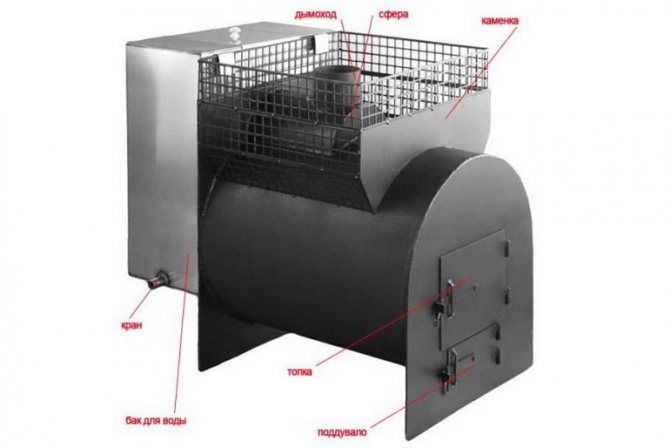

Horizontal stoves from a pipe for a bath are made a little more complicated, however, with such a design, you can independently decide where you place the water tank. Most often, the tank is installed on the firebox or behind it.

If you decide to build just such a furnace, then following our instructions, you will easily cope with the task:

- Position the pipe

horizontally and weld the legs to it; - Make a grate

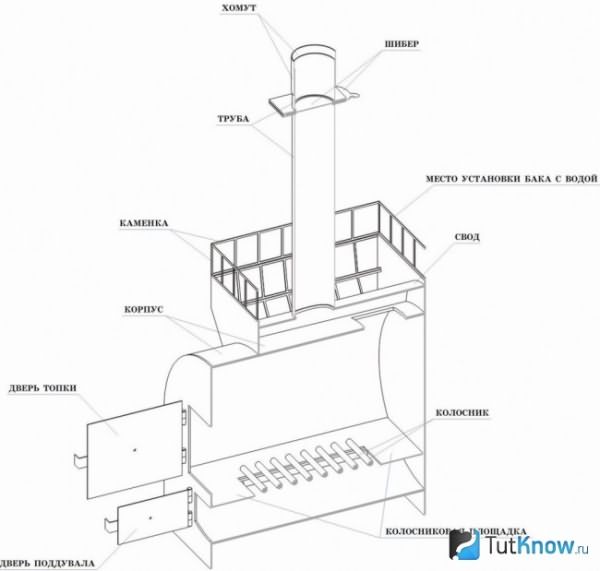

... To do this, measure a distance equal to 1/3 of the pipe diameter from the lowest point of the pipe. Next, you need to cut out a rectangle from a sheet of iron, the length of which will be 75 cm, and the width should be equal to 1/3 of the diameter of the main pipe. This rectangle will serve as the bottom of the firebox, so it is also necessary to make a hole in it for the grate. Then it remains only to weld this rectangle to the bottom of the pipe. - Furnace ends

... To make the ends of the furnace, cut out two rectangles (53 x 70 cm) from a sheet of metal, then weld them to the ends of the pipe. At the front end, make the ashtray and firebox doors, which we talked about in detail when making a vertical pipe. - Chimney

... To make a proper chimney, first make a hole in the main pipe, closer to the back end. Next, take a small pipe and cut it in half. In one of the halves, it is necessary to weld the ends with iron sheets with a recess in order to later install the resulting structure on the surface of the main pipe. Also, in the center of this vault, it is necessary to make a hole for the chimney. After all the work done, weld the made vault to the main pipe. - Stone basket

... For the manufacture of the stove, you can use reinforcement rods. Weave a basket out of them and weld to the oven. - For making a tank

use stainless steel. The made tank can be attached to the back wall of the stove or above the firebox.

As you can see, a homemade stove for a bath from a pipe is quite simple, but also do not forget about additional devices that will make the operation of the stove safe.

Assembly instructions

The entire assembly must be carried out in accordance with the drawings so that there are no difficulties and errors. This design can cause slight difficulties during assembly, since there will be a section for laying stones in the firebox compartment.

- The bottom of the pipe is welded with a blank or sheet metal.

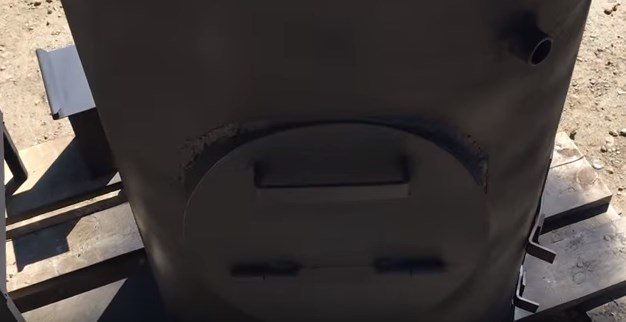

- At a distance of 1-2 cm from the bottom, a rectangular 24 × 8 window is cut out for the blower. This will give oxygen access to the combustion chamber and where the ash is extracted.

- At a distance of 15-20 cm from the upper part of the blower, another hole is cut to lay the fuel. Its size will be 20-24 cm. Special thin discs are used.

- On top of the firebox there is a chamber in which stones are placed. A round hole is cut out at a distance of 12-18 cm from the top of the combustion compartment. Note: the round hole must be 35 cm in diameter, the offset around the pipe circumference is 900.

- The other, 35 cm in diameter, is cut to a length that is equal to the outer diameter of the larger pipe. The upper segment is cut by ¾ in the form of a "scapula", to the border of the anterior edge.

- A blank wall is cooked to the rear end, and a plug with a door below to the front. Stones will be laid through it and water will be poured to create steam.

- The cut-out "spatula" is inserted into the opening of the main pipe. Its outer protrusion should be 2-3 cm. A gap should remain inside along the entire perimeter, which is completely welded. To enhance the stability of the structure, rods are welded to the body.

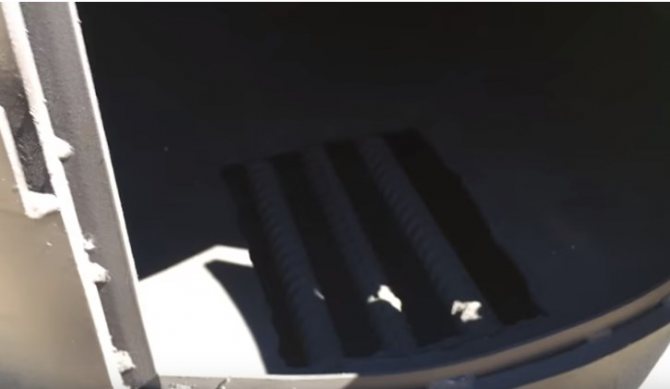

- Based on the diameter of the main pipe, a round piece is cut out of the sheet steel. To fix the grate, rectangular holes are cut in the cut out round piece of steel;

- The firebox is welded into the main pipe, parallel to the floor, 2 cm above the upper edge of the blower hole.

- The base of the blower is cut out of metal based on the outer diameter of the main pipe. Legs are welded under the stove to hold it. Then weld to the bottom.

- The main pipe is the wall for the water heating tank.

- In the cut out bottom of the tank, a compartment for the chimney is made from the edge by 3-5 cm.

- A piece of chimney pipe is welded into the hole, protruding at a distance of 10-12 cm.

- The bottom of the tank is installed on the main pipe. Then it is welded 10-12 cm above the stone compartment. The chimney should be on the side of the "blade".

- The bottom of the tank is completely scalded. A hole is drilled at the bottom for a water pipe inlet.

- To make a double tank lid, 2 semicircular parts are cut out. One is fully welded, and the other serves to open the tank and is attached to the hinges.

- As a result, you should get this kind of oven:

Furnace materials

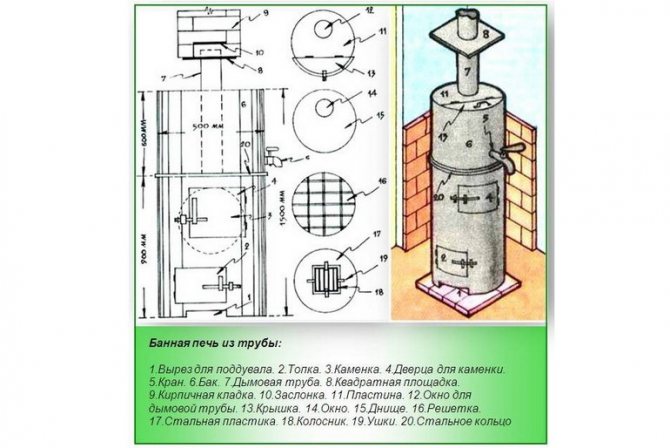

Welding of such a furnace must begin with the preparation of the cut for work. You will need a DN 500 cylinder itself; two pieces of sheet steel grade C30, for arranging the doors of the cells; two metro 150 pipes, for the chimney; pieces of 20 fittings for welding the grate; corner 25 mm long 40 cm; cutting steel for the fuel channel of the required length.

You should not use high-carbon steel grades, their welding is a rather complicated process that requires certain experience and skills in working with these types of materials.

Chimney arrangement

The chimney is an important component for the removal of combustion products.

They are of three types:

- Ceramic. The ceramic chimney has the longest shelf life. Maximum resistance to high temperatures.

- Brick. Due to the rough surface, the brick chimney quickly accumulates soot and slows down the draft of air.

- Steel. Steel chimney, the most suitable for a bath in connection with an affordable price.Also, due to the rapid heating of the metal, they put a tank, after which they are used for procedures. The stainless steel chimney is the most relevant. This material is not afraid of water, high temperatures, is not susceptible to corrosion, lightweight, durable and cheap.

Build process:

- Before installation, you need to designate a place for making a hole.

- A galvanized steel casing is installed on the pipe, then rings are put on, which are fixed on the ceiling. The lower pipe is secured with self-tapping screws. Clamps securely fix the chimney.

- The second part is installed on the roof. The openings between the roof and the chimney are filled with expanded clay, clay or asbestos.

Metal bath stove: manufacturing instructions

Homemade metal stoves for baths have always competed with their brick counterparts. This is due to the rapid heating and simple installation of such units. You can find instructions for making a metal furnace in our article. Today there are many designs of metal stoves: wood, electric and gas. Wood burning appliances require a lot of fuel, careful maintenance, but they give a "live" fire. Electrical devices are enclosures equipped with heating elements and heat insulators. Gas ovens are the most modern and reliable, they have thermostats for power regulation and safety devices that are triggered when the gas is attenuated.

Advantages and disadvantages of metal sauna stoves

Metal stoves for a bath have significant advantages over other heating structures:

- The small dimensions and mobility of the metal stove make it indispensable for small baths.

- A massive foundation is not required to install the device, which facilitates the installation process.

- Unlike brick appliances, their metal counterparts burn constantly.

- Low cost. A metal apparatus, in contrast to a brick one, is easier to manufacture at no extra cost. Searching for drawings of metal stoves for a bath is not a particular problem - a huge number of them are posted on the Internet and in the media.

- Fast heating - after a couple of hours, the steam room is ready for the procedure.

- The service life is up to 25 years, depending on the thickness of the stove metal and the quality of its welding.

- Operational safety when following the rules for assembling the furnace.

The disadvantages of metal ovens are:

- Rapid cooling due to the inability of the oven to retain heat. Continuous fuel combustion support is required.

- Heating problems in large rooms.

- Lower fire safety compared to a brick oven. The inner lining of the firebox with refractory material is required.

Material for a metal stove in a bath

For the manufacture of the stove, metal with a thickness of more than 5 mm is used; with a lower value, the device will not last more than 5-7 years. Reputable furnace manufacturers offer products in ten mm steel for furnaces and slightly thinner for water tanks and stone bins. To make a do-it-yourself sauna stove out of metal, you first need to decide on its shape. The rectangular section of the furnace will require a large number of welds and complex metal bending processes. To simplify the work, home craftsmen use pipes of large diameters or ordinary barrels, if their dimensions and wall thickness are suitable for the device of the furnace.

The design of the stove-heater made of metal for a bath

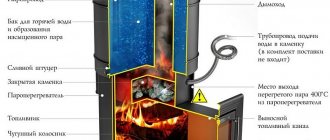

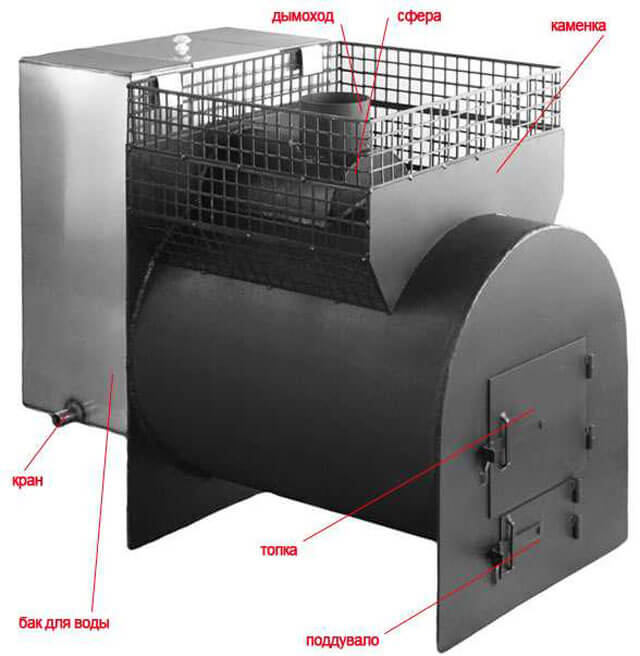

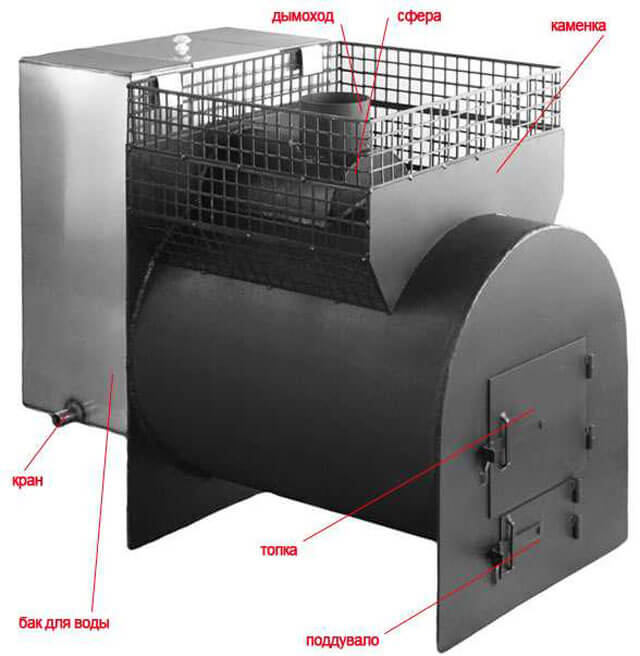

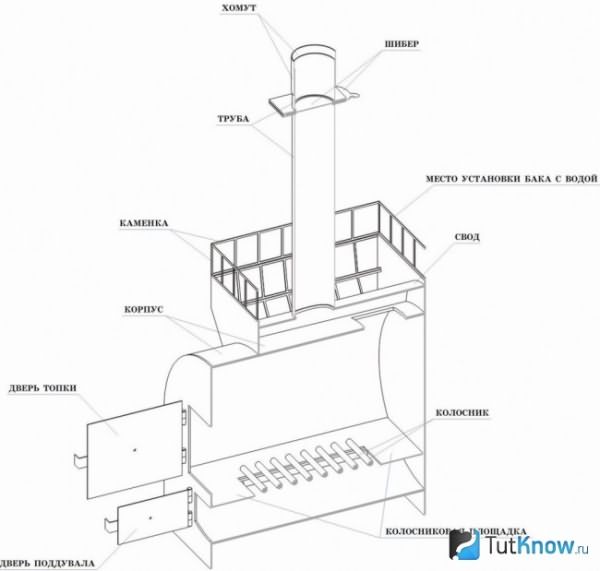

A metal sauna stove consists of three main parts, such as a fuel combustion chamber, a stone hopper, and a water heating tank. Let's take a closer look at the purpose of these elements:

- The combustion chamber

... Here is the process of burning wood. To control it, the doors of the firebox and the blower are used. The latter serves to supply air to the firebox. The removal of combustion products from the furnace is carried out through an ash pan - a metal grate. From the firebox, the heat from the burning wood rises to the bunker with stones. - Bunker

... Can be open and closed.To prevent soot and soot from the furnace from falling on the stones when they are heated, our bunker will be of a closed type. To provide access to the stones, a special door is made in the side of the stove. - Container for water

... Rising higher, hot air heats up the water tank. For convenient drainage of hot water, a faucet is welded near its base. Water is poured into the tank from the top. For maximum thermal effect, the furnace chimney is located in the center of the water tank.

If the design of a metal stove for a bath is clear to you, we proceed to the process of its manufacture.

Making a stove-heater for a bath from a metal pipe

The stove will be made from a pipe with a diameter of 700 mm, its height will be 1600 mm. For work we need: a steel sheet with dimensions of 2200x1000 mm and a thickness of 10 mm, a metal pipe 1600 mm long with a wall thickness of 7-10 mm, a chimney pipe with a diameter of 100 mm and a wall thickness of 5 mm, a metal rod 10 mm, a cast-iron grate (from the store), door hinges - 8 pcs, latches - 3 pcs, a drain valve for a tank, a tape measure, a building level, a grinder, metal scissors, a welding machine. The procedure for making a furnace from a metal pipe looks like this:

- We cut the pipe into two parts: one of them is 0.9 m long, the other is 0.7 m.

- At a distance of 7-10 cm from the lower end of a long pipe segment, we cut out a rectangular hole for a blower 20x5 cm. We work carefully, because the piece cut from the pipe will later be used to make the door. In the same way, we cut out a window for the furnace firebox; we do not throw out the material for the future door.

- Then we weld ears and hinges to our pipe, and latches on the doors. Now you can attach the blower and fuel chamber doors.

- Cut out a circle D = 0.7m from a sheet of metal, in its center there is a hole corresponding to the dimensions of the grate. If it was not possible to buy it, you can make the lattice yourself from a steel bar. The prepared circle must be welded in the pipe slightly above the blower. The manufacture of the firebox is completed.

- In the side of the stove, cut out a window for moistening hot stones and install a door for it.

- We make a platform for placing stones. For this, metal rods are suitable. The dimensions of the cells are taken taking into account the size of the stones taken for filling the heater into the bunker.

- After laying the stones, we cut out another circle of the same diameter from the sheet of metal. A hole for the chimney is made in it, located near the far wall of the furnace. We weld on the chimney and a circle with a hole under it at the top of the bunker.

- We are preparing a water tank. For this, a 0.7 m pipe section is welded to the stove.

- We make a tap hole in the water tank.

- We cut out another circle of the same kind from the sheet and cut it so that we get two parts of different sizes. For the most part, a hole is made for the chimney. We cover the entire structure with this element, passing the chimney through the hole, and scald it along the hole.

- A smaller part of the circle will serve as a water fill hatch cover. Therefore, this part is attached to the stove with hinges.

The dimensions of the metal stove for the bath depend on the dimensions of the steam room. Such a furnace will be able to warm up well a room with a volume of 20-25 m3.

Advantages and disadvantages

A significant advantage of a vertical oven over a horizontal one is its compactness, which allows it to occupy a minimum space in the bath. Suitable for small spaces.

Other benefits include:

- saving money investments;

- metal, as a reliable material, has excellent mechanical strength, withstands temperature surges that do not affect this property;

- sufficiently thick walls of the material provide high heat transfer. After the fuel has completely burned out, further retention of heat occurs;

- a rounded cut of the pipe gives a powerful heat distribution and the formation of the necessary traction;

- fast warming up of the room in less than 1 hour;

- a metal stove will last more than 10 years if you skillfully approach its manufacture;

- the cylindrical shape of the pipe will eliminate unnecessary right angles and long welds. The main reason for the appearance of corrosion and holes through which the leakage of carbon monoxide will go is precisely the welds.

The main and common disadvantage of a metal structure is that it is more susceptible to corrosion.

Pros and cons of homemade construction

The stove for a bath from a pipe is characterized by a low price, heat resistance and durability.

The materials used for the manufacture of steam room stoves must have the following qualities:

- heat resistance;

- mechanical strength;

- corrosion resistance;

- resistance to sudden temperature changes;

- durability;

- high thermal conductivity and heat capacity.

Ferrous metal is not characterized by high resistance to the formation of corrosion, however, the manufacture of a bath stove from a thick-walled pipe is possible if its diameter is at least 50-60 cm.

The advantages of this design:

- Ferrous metal is characterized by excellent performance characteristics: mechanical strength, high heat transfer rate and resistance to temperature extremes. At the same time, the linear thermal expansion of the material is low.

- The thickness of the pipe is at least 8 mm, which provides a high heat capacity of the structure, which can retain and gradually release heat for some time even after the fuel has burned out.

- The large thickness of the material extends its service life, despite the fact that the metal is susceptible to destructive corrosion properties.

- The stove has excellent natural draft, efficient distribution and extraction of heat energy, thanks to its internal cylindrical shape.

- The number of welds is minimal due to the round shape of the product. Therefore, the likelihood of corrosion, smoke leakage and carbon monoxide is minimized.

- The cost of a used pipe is low compared to a new one. The main thing is to carefully check it for corrosion before buying.

Pipes are different depending on the manufacturing method. The best option would be hot rolled seamless pipe or electrofusion pipe with one longitudinal seam. Products with a screw seam are not suitable, as they are deformed as a result of strong heating.

The main disadvantage of a homemade metal oven is the intense infrared radiation. A person feels it as a strong heat, so being close to the stove can cause discomfort. At the same time, the very presence of such heat does not mean the same effective heating of the room.

Important Tips

- To prevent the heat from leaving the oven container, an opening valve is installed on the edge of the chimney.

- A fire can be caused by a huge accumulation of soot. For this, two holes are drilled in the pipe. Steel tubes are inserted into them with a turn towards the pipe. This prevents the appearance of soot. The fuel will be completely burned out, and the accumulation of soot will be minimal.

- After completing the manufacture of the structure, it must be checked for holes, gaps and cracks.

- There should be no objects around the stove that are susceptible to fire: synthetics, wood and fabric.

- All cut edges of pipes and metal sheets must be cleaned from sharp edges to avoid cuts. If there is no experience in the correct installation of the chimney, then it is better to contact a specialist.

- The installation of this furnace should be done on a ready-made concrete foundation, its height is 250-300 mm. Brickwork with clay mortar is laid on it in one or two rows. The brick screen protects the walls from overheating.

What is

A bath without a stove is not a bath! This is not just a heating device, it is the soul of a bathhouse. The speed of heating the house and the heater, the microclimate in the steam room and your mood depend on the correctly selected stove.

We all saw - some with our own eyes, some in the films - the famous "potbelly stove".A stove made of a pipe is very similar to it, but the option for a bath is different in design - such a unit should have a heater and, possibly, a tank for heating water. All other elements are the same as for other stoves: a body, a blower, a firebox with grates, a pipe.

Trial furnace

- Before using the furnace, a test furnace must be carried out, which will test the entire structure for the tightness of the welded seams.

- The damper opens and the blower is opened. After that, a small bookmark is made of firewood and set on fire. The door is closed and oxygen is supplied to the upper compartment.

- Complete heating, the presence of traction and a check of the tightness of the seams are traced.

This is how this sauna stove is made cheaply and practically. Anyone can afford such a simple luxury.

How not to make a bomb out of this stove?

The main elements of the stove from the pipe

No matter how ridiculous it may seem, you can make not only a stove for a bath out of a pipe, but also a real bomb. This is due to the fact that gross mistakes are made during the welding process. For example, if the draft of the future stove is too strong, for which it is necessary to make a valve in the chimney in advance, and it must be movable.

Secondly, it is important to prevent the possible ignition of soot, especially a large amount of it. And for this you need to equip the stove, if it is horizontal, with an afterburner: in the upper part of the pipe, a horizontal tray is welded for this purpose - to the floor of the stove deep. Further, almost at the top of the pipe, separating the main chamber from the entrance to the pipe, two holes are made in the wall of the stove itself. And so that they do not smoke, they need to be made in tubes, slightly bent towards the pipe. Such a simple design will add oxygen and help burn all combustion products, significantly reducing soot deposition.

And a couple more design touches - and the chimney stove that you got almost for nothing will become your pride!