The issue of insulating various pitched roofs is especially relevant today. The rise in energy prices is forcing owners of private houses to reconsider their approach to roofing. After all, it is through it that up to 30% of the heat leaves. And even a well-conducted thermal insulation of the floor is not a guarantee that heat loss is completely eliminated. Particular attention is paid to the thermal insulation of mansard roofs, where the roof structure additionally performs the functions of a protective structure, that is, walls.

Thermal insulation of the attic roof from the inside with mineral wool

Roof insulation

It is necessary to start dealing with the insulation of pitched roofs with heat-insulating materials. They are presented on the market with a fairly wide range, but only four are used for roofs:

- mineral wool slabs are mineral wool pressed into mats;

- expanded polystyrene plates;

- polyurethane foam;

- ecowool.

What insulation to choose

Mineral wool slabs

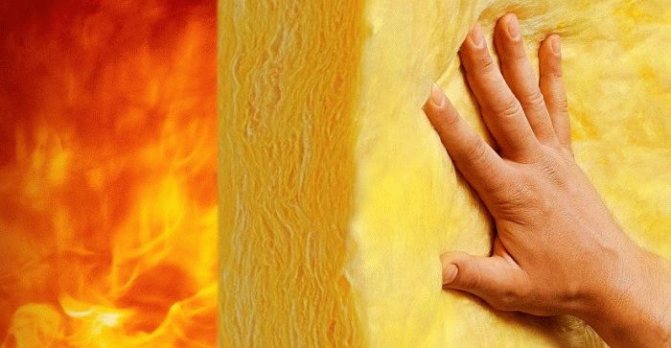

It is a rock material that is heated, melted and pulled into threads. The latter are in a chaotic state in the material itself.

As for the technical characteristics:

- thermal conductivity - 0.042 W / m K;

- density - from 50 to 200 kg / m3;

- 100% environmental friendliness;

- ease of installation by hand;

- service life is 50 years;

- flammability class - NG (non-flammable).

Mineral wool mats

Expanded polystyrene plates

It is expanded polystyrene with a structure of closed balls filled with air. At the same time, air occupies 90% of the volume, which reduces the weight of the insulation and its thermal conductivity.

Specifications:

- thermal conductivity - 0.034-0.044 W / m K;

- density - 25-45 kg / m3;

- flammability class - G3 (burns and supports combustion);

- environmental friendliness is high;

- installation method - manual;

- service life - 20 years.

It should be noted that the higher the density of the insulation, the higher its thermal conductivity.

Expanded polystyrene boards

Polyurethane foam

It is a foamed mass that hardens in air, turning into a durable, seamless coating. In fact, this is polyurethane foam, only modified. The insulation itself of this type is a two-component material. Its ingredients are mixed in a special container and supplied under pressure through a hose and a nozzle to insulated surfaces.

Specifications:

- thermal conductivity - 0.019-0.028 W / m K;

- density - 55 kg / m3;

- flammability class - G2;

- service life - 80 years;

- environmental friendliness is high;

- installation method - special equipment is required.

Polyurethane foam is applied to the attic roof

Ecowool

This insulation is pure cellulose made from wood. It looks like cotton wool. Here are its characteristics:

- thermal conductivity - 0.038 W / m K;

- density - 40-45 kg / m3;

- flammability class - G1 (low flammability);

- service life - 100 years;

- laying method - with the help of equipment;

- environmental friendliness - 100%.

Ecowool - one hundred percent natural insulation

Comparative analysis

It is incorrect to make such an analysis of insulation materials for roofs (different pitched roofs). Each material has its own pros and cons. In addition, the price is different, and the installation method varies greatly. For example, polyurethane foam is better than others in terms of its heat engineering characteristics. But it cannot be applied to the roof without special equipment. And this increases its already high price.

In this regard, mineral wool and polystyrene foam boards are the best option. They are easier to install and inexpensive. But their service life is short.

Price comparison:

| Tinsulation type | Mineral wool | Expanded polystyrene plates | Polyurethane foam | Ecowool |

| price, rub. | 50-100 per 1 m2 | 250-300 per 1 m2 | RUB 1,500 per 1 m2 50 mm thick | RUB 2200-2700 for 1 m3 |

And one more criterion by which insulation materials can be compared is the thickness of the layer to be laid. Here are the positions:

- mineral wool - 214 mm;

- foamed polystyrene - 120-150 mm;

- foamed polyurethane - 50-100 mm;

- ecowool - 150-200 mm.

Comparison of building materials in terms of thickness and heat engineering characteristics

Basic requirements for heaters

When choosing insulation for a pitched roof, you need to carefully read its characteristics. It should be as light as possible so as not to create unnecessary stress on the roof structure. It must also have a low coefficient of thermal conductivity. The insulation should not absorb moisture. Otherwise, its weight due to the absorbed moisture can significantly increase, which can lead to damage to the roof. And the reliability of the insulation in case of moisture ingress is reduced by more than half.

Not affecting the main purpose, but also a very important condition - resistance to weather extremes. The operational life of the insulation directly depends on this. It must also be environmentally friendly, otherwise it will inevitably affect the health of those living in the house. Also, he must meet fire safety requirements.

Basalt mineral wool and mineral fiberglass wool meet the described characteristics most of all. The best insulation for a pitched roof will be basalt mineral wool, which is a fairly tough material, which is very important, given that the insulation layer will be located between the rafters at an inclined angle. In addition, it is easier and, most importantly, safer to work with basalt mineral wool, in contrast to glass wool. And it is important that in comparison with glass wool, basalt mineral wool can withstand higher temperatures.

Pitched roof thermal insulation technology

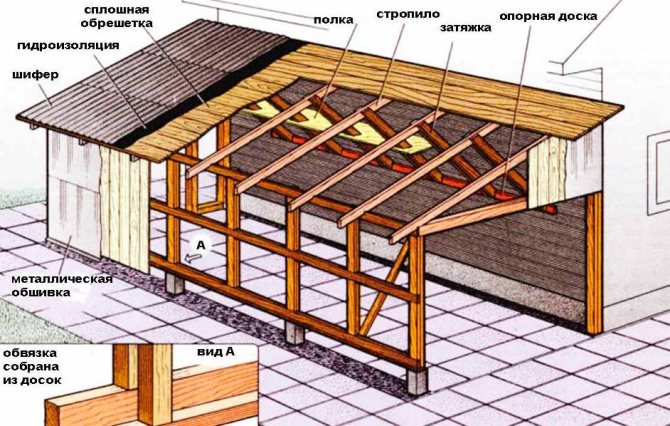

Insulation of mansard gable roofs is very different from thermal insulation of single-pitched roofs. Because the latter have a small attic space, hence the difficulties of carrying out work from the inside. They are carried to the outside from the side of the roof covering. In this case, we immediately denote that polyurethane foam is not used in a single-pitched structure.

Thermal insulation of a pitched roof

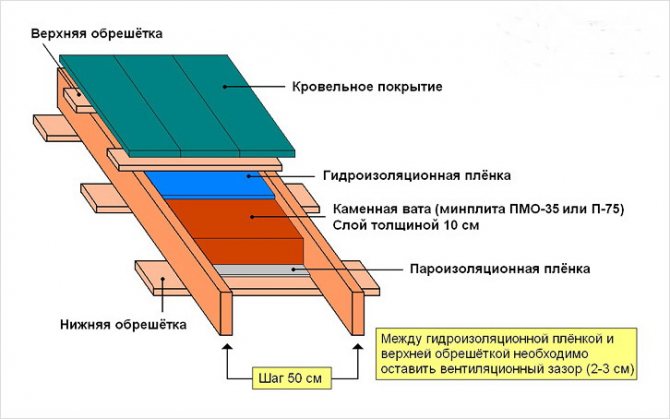

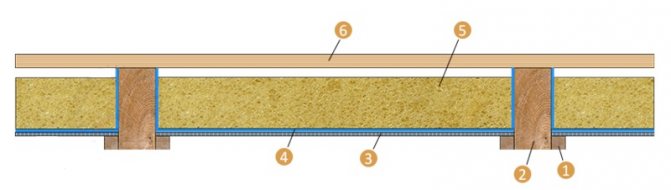

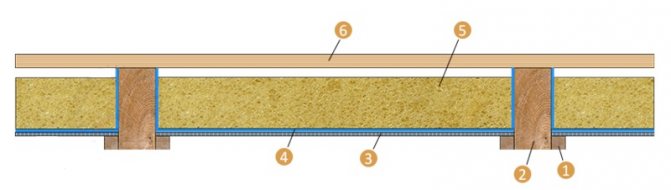

So, how to properly insulate a pitched roof:

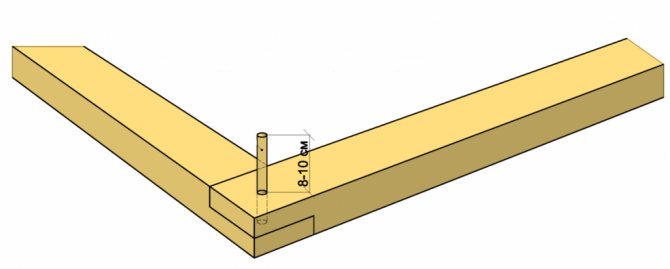

- Along the rafters, at the ends, at the lower edges, the so-called cranial slats are stuffed along.

- Between the rafter legs, boards or any durable plate or sheet material are laid on the rails: plywood, chipboard, OSB, and so on. The feet are fastened with self-tapping screws. Niches are formed.

- A vapor barrier membrane is laid along the rafter system. Installation is carried out in strips with an overlap of 10-15 cm, after which the joint is closed with self-adhesive tape. Laying should be carried out so that the film covers the niches, emphasizing their shape.

- Insulation is being installed in niches.

- On top of the rafters, a waterproofing film is laid in the same way as a vapor barrier, only tightly without sagging. Fastening to the rafter legs with staple staples.

- Installation of the lathing.

- Installation of roofing material.

As you can see, insulating a pitched roof is not the most difficult process, so even a person who is far from the construction industry can do it with his own hands.

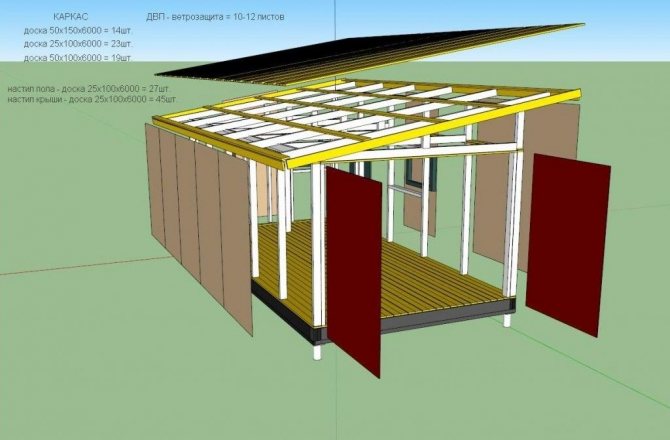

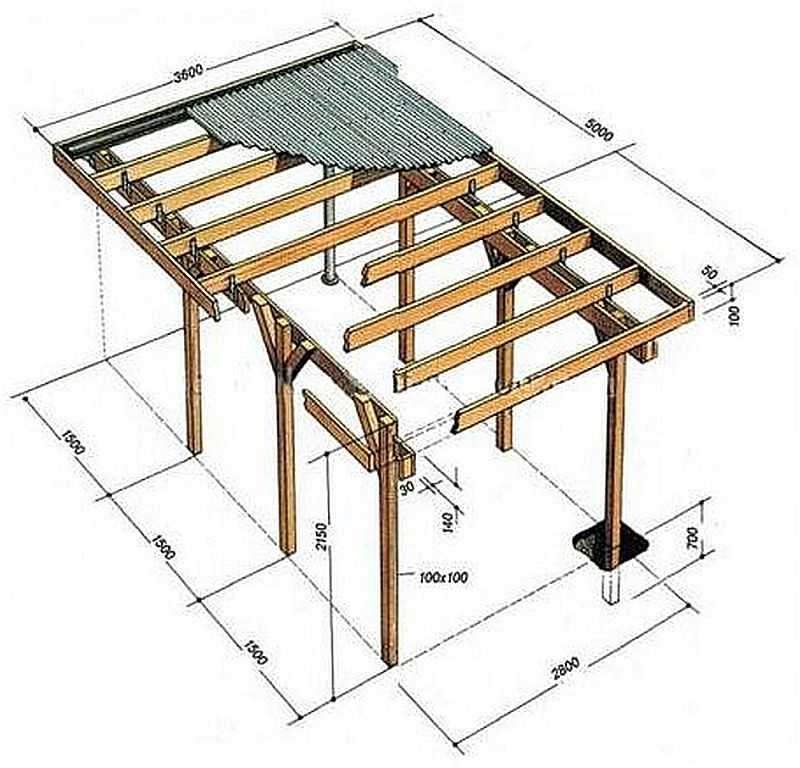

Shed roof construction with insulation

Do-it-yourself shed roof step by step

In principle, a pitched roof can be covered with any roofing material, but you should always pay attention to a few points:

- on the weight of the roofing material - not only the construction of the foundation (its width and depth), but also the pitch of the rafters depends on how much weight your roof will press on the walls;

- on the recommended roof slope (for the roofing material you have chosen) - it also depends on the type of roofing material and its ability to withstand a snow load (in other words, to hold on to a certain amount of snow without being deformed);

- the kind of lathing (solid or from separate elements).

Tip: If you cannot remember which lathing should be laid under the roofing material of your choice, take a close look at its seamy side:

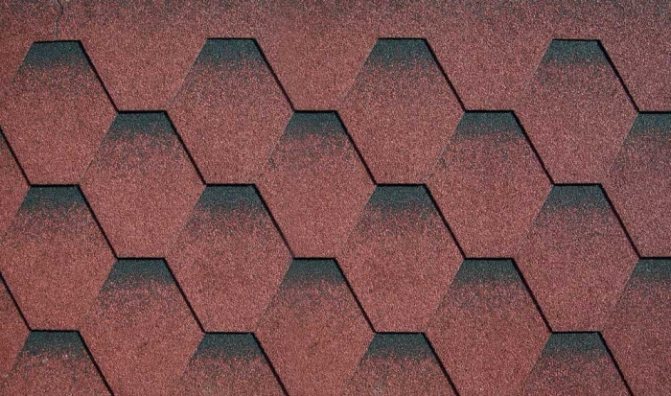

- if it is smooth (like bitumen shingles), then a solid lathing is required for this material (in the form of a solid surface made of boards, OSB or other similar materials);

- if it has protrusions and pits (like tiles or slate), then the lathing will have a certain step (that is, you will lay boards or bars with a certain distance between them).

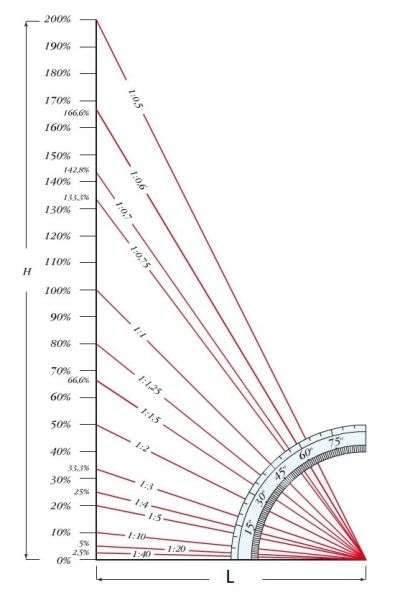

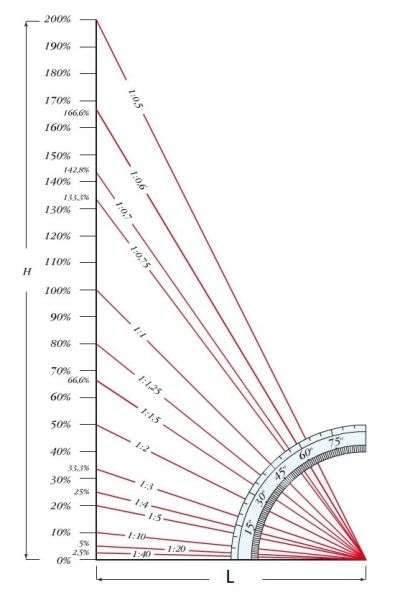

Slope

If you do not go into special details, then only three characteristics of any roof depend on the slope:

- its ability to withstand the weight of snow (until the moment when the snowdrift accumulated on it slides down under the influence of gravity);

- impermeability - all rainwater, or water generated by melting snow, should "roll off" from the surface of the roofing material, without remaining in its irregularities, seams and attachment points;

- withstand wind load (the stronger the slope of the roof, the more pressure the wind will exert on it).

Most builders recommend the following values for the angle of inclination of the roof, at which a do-it-yourself single-pitched roof will be strong, reliable and durable:

- ordinary slate - not less than 1:10;

- soft (flexible) tiles - not less than 1:10;

- ceramic tiles - not less than 1: 5;

- metal tile - not less than 1: 3;

- cement tiles - not less than 1: 5;

- ondulin - not less than 1: 3.

Roof slope calculation scheme

Tip: In order not to get confused in determining the correct dimensions (width and height of a pitched roof) for the selected slope, use the following calculation method:

- Measure the width of your building.

- Divide the resulting number (in centimeters) by the second digit of the roof slope (for example, if the recommended slope for your roofing material is 1: 5, then you need to divide your number by 5).

- The result of dividing the numbers and will represent the height of the second edge of the pitched roof (in centimeters).

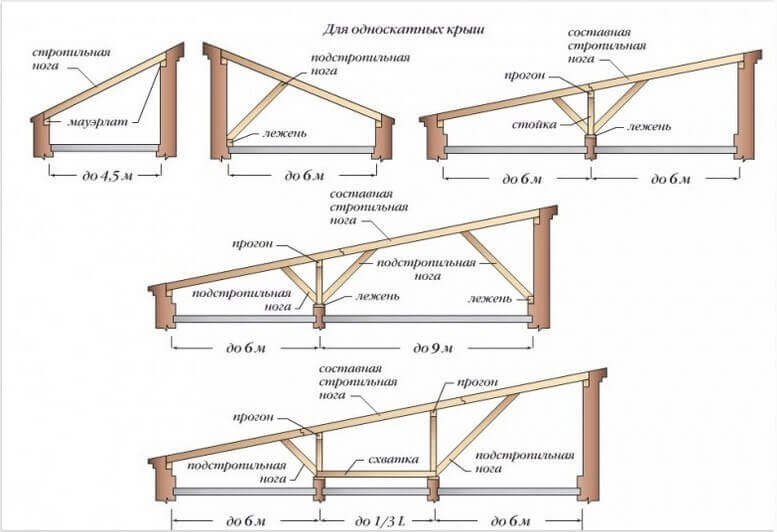

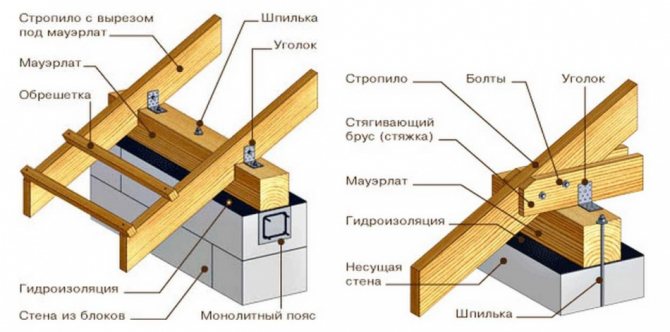

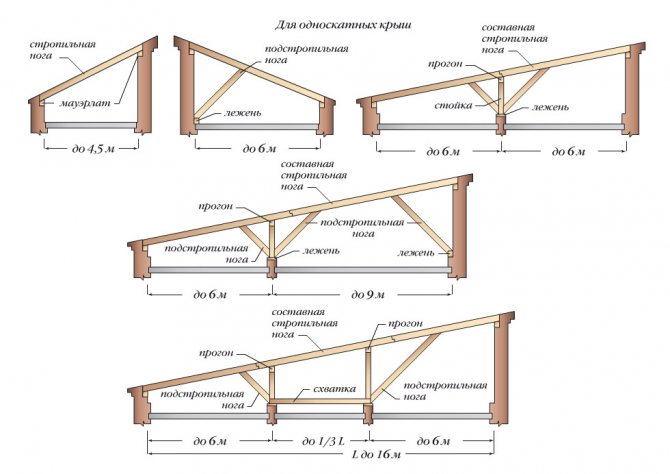

Rafters

However, no matter how attractive the pitched roof is for those who like to do everything on their own, there is a certain limitation for such a roof: the length of the rafter leg should not exceed 6 meters. Where did this figure come from? The fact is that it is customary to saw wood for sale into separate boards (or timber) 6 or 4 meters long. Therefore, if the width of your building does not allow the use of boards less than 6 meters long for rafters, then you will have to do one of the following methods:

- instead of a gable roof, make a gable roof on your structure;

- replace a simple rafter leg with a more complex structure - a triangular truss;

- strengthen a long simple rafter leg in its central part by placing a column of timber or brick under it.

Tip: For any type of roof (including for a pitched roof), when choosing a rafter pitch, it is better to focus on the recommendations of the roofing material manufacturer.

If the roof is already covered with roofing material

Here, the technology of thermal insulation differs little from the previous one. The peculiarity lies in the fact that all work is carried out from inside the attic space. And the main distinguishing feature is waterproofing, which is applied in strips along the rafter legs with the recessed film into the formed niches. To make it clear what is at stake, look at the photo, which shows how the waterproofing should be laid and fixed.

Waterproofing membrane installed from the inside of the attic on the roof slope

All other operations are carried out according to the technology described above. I.e:

- The laying of the slab insulation is in progress.

- Installation of vapor barrier film.

- Interior decoration of the attic.

If polyurethane foam is used, then it is simply applied to the rafter legs covered with a film. If ecowool is used, then a vapor barrier layer is laid, and the space between the two protective layers is filled with insulation.

Thermal insulation technology for a four-pitched roof

The process of insulating a hipped roof or hip roof is no different from the thermal insulation of a gable roof. These are all the same rays, only there are not two, but four. The amount of work being done is simply increasing.

The only negative point regarding plate heat insulators is a large amount of their waste. It's all about the shape of the stingrays. It is trapezoidal and triangular at the hip roof, only triangular at the hip roof. This means that in places where the structure is narrowed, the thermal insulation materials will have to be cut.

This does not apply to polyurethane foam and ecowool. Here, the consumption does not change, and it corresponds to the area of the insulated pitched areas.

What points should you pay attention to

Despite the seeming simplicity of the operations carried out, there are many nuances in them, on which the quality of the final result depends. And for those who decide to carry out the insulation on their own, it is recommended not to miss these important points:

- Before starting work, all wooden units and parts must be treated with an antiseptic and fire retardant. First, the first is applied, after drying the second. The antiseptic composition is protection against biological effects (microorganisms: mold, fungi). Fire retardant composition - protection against fire. That is, if a fire starts, the wood will not immediately catch fire, it will take several minutes.

Antiseptic treatment of rafters

- Waterproofing is installed at the roofing material. Its purpose is to prevent leaks, if such leaks suddenly arise, to penetrate the insulating cake. The second purpose is not to let through the moisture that has formed in the layer of heat-insulating material.

- A vapor barrier membrane is the same film, similar to a waterproofing membrane. But it is denser and does not allow steam (humid air vapor) to pass through. Therefore, its main task is to close the insulation layer with itself so that moisture emanating from the interior of the building and passing through the ceiling cannot penetrate into it. But even with very careful installation, small gaps remain in the vapor barrier layer through which steam enters the insulation. So that he does not stay there, they lay on top of the waterproofing. It is important not to confuse the two materials with each other. Otherwise, the thermal insulation cake will quickly lose its properties. This mainly applies to ecowool and some models of mineral wool.

- If it is decided to use polyurethane foam as insulation and do the whole process with your own hands, then it is recommended to purchase a mini-installation consisting of two cylinders into which the components are pumped under pressure. They are mixed when leaving the containers in a special mixer of small dimensions. And already through the hose with a nozzle, the foam is supplied outside. Manufacturers today offer installations with different volumes of cylinders, with different speeds of work. This equipment is reusable, just after the ingredients are used up, they are poured into containers. And you can continue to work.

- If foamed polystyrene plates were used as a heater, then they can not be covered with a vapor barrier film. This insulation is not afraid of even a large amount of water.

- Ideally, fill the space between the rafter legs completely, both in width and in depth.

If a decision is made to insulate the roof of your own house, then this process should not be postponed indefinitely.The main thing is to decide on the choice of thermal insulation. And the operation itself is simple. Strictly follow the steps and the high quality of the final result will be guaranteed.

Necessary materials

After you have made a drawing, you need to purchase and prepare materials for work. So, you will need:

- timber for the manufacture of rafters and Mauerlat (the correct timber must be made of coniferous wood, the moisture content of which does not exceed 15%);

Attention: all wooden elements must be protected from rotting and burning by treating them with fire retardants and antiseptics.

- boards for the manufacture of lathing;

- edged boards for end strips;

- fasteners;

- thermal insulation material (mineral wool);

- waterproofing and vapor barrier membrane;

- roof covering.