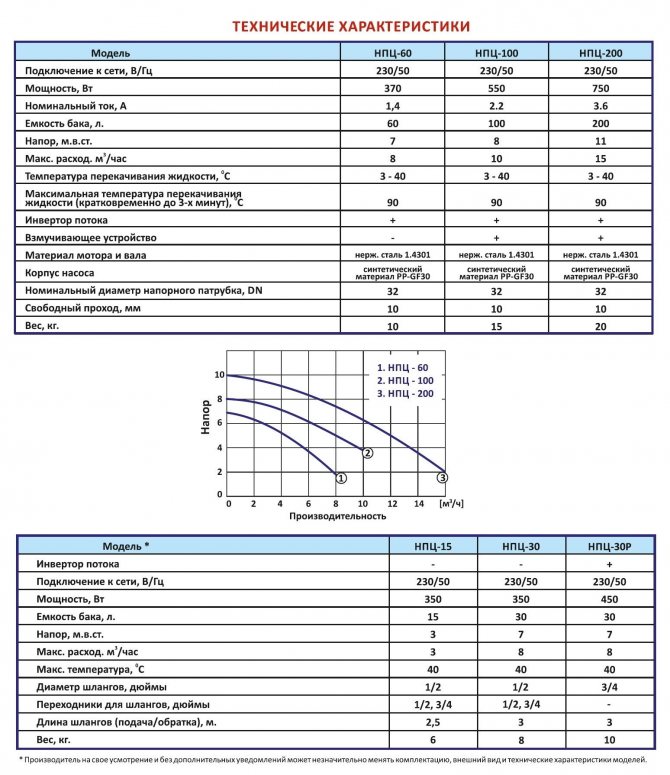

How to choose a pump for flushing a heat exchanger?

Heat exchanger flushing plants differ in:

- Vigor

- Performance

- Tank size

- The presence of a reverse

To select the installation, you need to understand the volume of heat exchangers you need to flush.

In practice, it is best to choose an installation with a tank volume 2-4 times less than the volume of the heat exchanger with automatic reversal. In this case, flushing will be the most comfortable and convenient, the performance and pressure of the pump will also be more optimal.

The volume of the heat exchanger can be found in the passport. If you can't find your passport, don't worry, pump with a tank volume of 20-40 liters will be sufficient for flushing heat exchangers for heating and hot water supply of most residential apartment buildings.

POOLS

Heat Exchanger Circulation Pump - Instructions for Use

The circulation pump of the heat exchanger pumps the coolant through its interior. Heat from the coolant is transferred to the pool water, which is why the pool heats up. The circulation pump is paired with a solenoid valve and a non-return valve. One circulation pump is not enough to control the flow of the heating medium through the heat exchanger. The circulation pump is split and consists of 2 parts: a 220 Volt electric motor (maybe 380 V, but rarely) with an impeller and a pump body with split couplings for connecting pipes and fittings. The pump must be installed in areas affected by fire and caustic substances. Orientation of the pump is allowed as convenient when mounting along axial split couplings, but the rotor axis of the pump electric motor must be strictly horizontal. The horizontal limitation is due to the fact that the bearings on the pump rotor normally work only in the rotor horizon. Otherwise, the resource from the activity is sharply reduced and as a result, the bearings wedge, the electric motor burns out, the machine turns off from the short circuit to the heat exchanger in the pool electrical panel, or even the RCD. The circulation pump is installed on the heat exchanger at the outlet of the coolant for a reason, but with intent: at the outlet of the coolant from the heat exchanger, its temperature is 15 - 20 degrees lower than at the inlet. Thus, we save the pump from high temperatures and save its resource. For reference: according to the Terms of Reference, the temperature of the coolant should be 70 - 90 degrees Celsius. If less than 70 - heat transfer slows down, the initial heating of the pool after filling, instead of one day, may be delayed for several days. If it is more than 90 degrees, the heat exchanger and related units are not designed for such a temperature, a breakthrough of the coolant is possible. And the supply pipes, if they are not metal, can be damaged. The coolant can be either hot or cold. For cold hot tubs, this may be relevant if there is a great desire to bring the temperature closer to zero. Ice formation in the housing and impeller jamming are important here. Warning: Be careful when bleeding air - you can burn yourself. You can burn yourself with coolant vapors if the system loses pressure and the pump is running. Here he heats himself up to boiling water and his service life tends to zero. About electricity The electric motor of the circulation pump is almost always 220 volts, therefore it is connected with a 3 x 1.5 mm wire: phase, zero, earth (required). There are 3 working speeds, our speed is the third.The terminal box should be oriented with the sealed lead-in downwards, meaning - under no circumstances should moisture get into the box, since the pump always stands among the pipes. The pump is turned on and off simultaneously with the solenoid valve, this action is carried out by a thermostat or controller through a temperature sensor. The flow sensor can interfere with the pump operation, turning off the heat exchanger during the absence of water flow through it. If the pump has been in storage for a long time, it may acidify and will not start when the power is turned on. Of course, intense heating of the electric motor housing will begin, but you will not know about it until you touch it. On the servants and "on the finger", the operation of the pump can be determined with difficulty, the vibration of the pipelines of the pool water circuits and the coolant, the noise of other pumps in the technical room conceals these feelings. There is a reliable way - take a wide screwdriver and unscrew the slotted plug. The tip of the rotor shaft is visible through the hole; use the same screwdriver to check whether it rotates. The same plug serves as an air vent when the pump is first started and the system is filled with coolant.

Pumping units for flushing heating systems

Heating flushing equipment creates increased pressure in the pipeline. The system is cleaned by forced circulation of the injected reagents. Chemicals, moving through the pipes of a closed line, remove a large amount of salts, deposits and contaminants.

It is possible to determine that the heating system is dirty and requires flushing by the following signs:

- Decreased heat transfer;

- Weak heating of individual radiators or heating circuit;

- Clogged dirt filter;

- Frequent stopping of the boiler;

- Increased fuel consumption.

The powerful flushing pump is an indispensable unit used in complex branched heating circuits. The equipment is used in residential apartment buildings, as well as in private households, in commercial and industrial buildings. With regular use of the pumping unit and special reagents, the risk of blockages in the pipeline is reduced to zero.

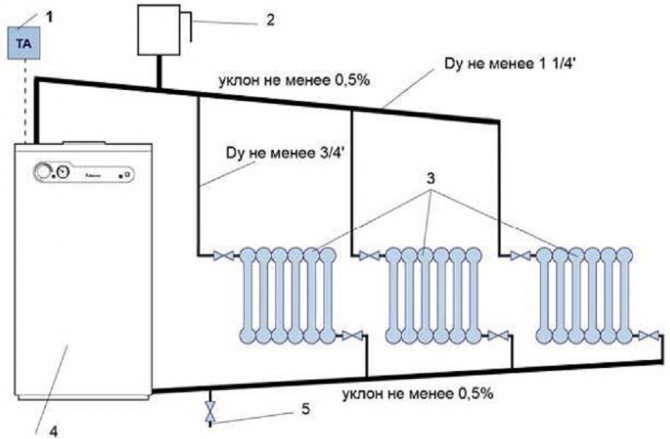

Natural circulation water heating

Open heating system

Heating water systems without a pump are usually classified according to certain characteristic criteria that reflect their functionality.

Depending on the type of expansion tank, heating with natural circulation is usually divided into the following types:

- Open heating system. With this design, the expansion tank is located as high as possible in order to create excess pressure, as well as to allow air to be vented. In this case, the reservoir also serves to add fluid to the system.

- A closed heating system with natural circulation is distinguished by the fact that instead of an expansion tank, a membrane accumulating cylinder is installed, with the help of which an additional pressure of no more than 1.5 atm is created. To ensure safety, a unit with a pressure gauge is built into the design of the system, which regulates the internal pressure.

You might like the article on how to install an additional pump in a heating system. You can read about the features of the Wilo circulation pump here.

Also, heating structures with natural circulation are divided depending on the method of connecting the heating elements. According to this classification, there are the following types of heating:

- One-pipe heating system. The principle of operation of this type of heating is that all heating devices are connected to the system in series, in other words, the circulation of the coolant occurs from one element to another.The undoubted advantage of this type of heating is that the installation is quite simple and requires a minimum of materials.

- Natural circulation two-pipe heating system. In such a heating design, the heating elements are connected in parallel to the main pipe. In other words, the coolant enters each device at the same temperature, and the cooled liquid returns to the boiler through the pipe, which is usually called the "return".

This heating scheme is the most optimal for heating a living space. The only drawback is that the installation of such heating requires a large number of pipes and other plumbing fittings.

Builder's tip: having chosen a heating system for your home, be sure to calculate your capabilities when purchasing all consumables for heating installation.

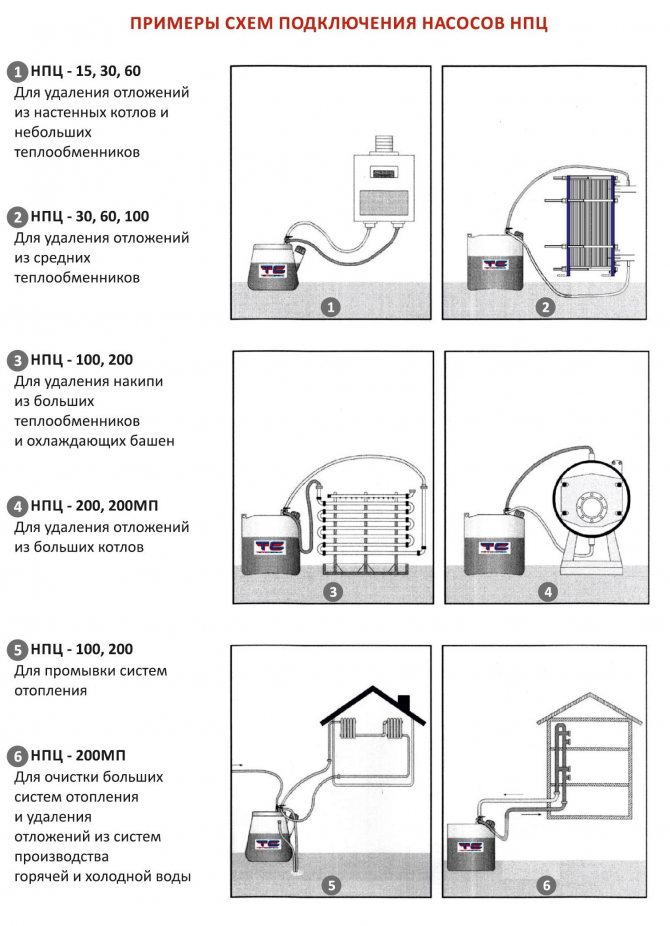

Features of flushing heat exchangers

Untimely maintenance of heat exchangers leads to the formation of scale on the walls and premature failure of the units. To prevent damage, it is necessary to regularly use equipment for flushing heat exchangers in combination with acid reagents.

Once inside the unit, the acid-containing solution softens solid deposits and peels off scale and rust under the influence of the forced circulation created by the pump. The booster for heat exchangers allows you to clean the circuits without disassembling the structure. The advantage of this technique is the integrity of welded or rolled joints. For more efficient operation, the units are equipped with a function of changing the direction of the flow of the washing liquid.

The unit for washing heat exchangers is a professional equipment widely used by service companies serving boiler houses of residential, public and industrial buildings. You can order a high-performance pump for flushing heat exchangers.

We also offer to purchase concentrated reagents that quickly and effectively remove lime, corrosion and other contaminants. Remember - timely prevention, washing and cleaning of heat exchangers increases their service life!

UPS models

PN-1000 energy is a powerful backup power source. Thanks to the built-in stabilizer, the device provides the rated output voltage when the mains voltage changes within 120-275 volts. The waveform in the form of a smooth sine wave is perfect for supplying reactive inductive loads, such as the electric motor of a heating system pump. The PN-1000 energy together with the Delta DTM 12100L 100A / h accumulator provides uninterrupted power supply for the 150W heating pump for 8 hours. The device has a built-in line noise filter, information display and RS-232 interface.

This and other voltage stabilizers for the heating system from the Energia company can be found on the website of the official representative of the Energiya.ru company.

The compact emergency power supply Teplokom 222/500 is intended for use in heating gas systems. This simple device with a single-phase relay-type regulator allows operation with a load not exceeding 230 W.

The universal stabilizer Skat ST 1515 provides a voltage of 220 V with network fluctuations from 145 to 260 V and a frequency of 50 Hz ± 1%. If the voltage exceeds the specified parameters, the load will be disconnected automatically.

Summing up

Based on the operational requirements for electric motors of pumps for heating systems, the UPS must provide the following parameters:

- The voltage form is a smooth sinusoid;

- Power reserve - not less than 20%;

- Automatic load disconnection;

- Minimum switching time to reserve.

In addition, the device must operate in a certain temperature range, have a device for indicating modes and physical quantities.

Read with this:

The choice of a single-phase voltage stabilizer: types, features and characteristics

Voltage stabilizer for giving 220V: selection criteria and types

Uninterruptible power supply for a gas boiler: types, features and selection criteria

Choosing a battery for a UPS: characteristics, features and types of batteries

Did you like the article? Share with your friends on social networks!