The first types of ovens

It is worth saying a little about what the first types of this device were. In ancient times, there was an expression "wash in black". This expression came from the fact that the first home-made sauna stoves did not have a chimney. All carbon monoxide was removed from the bath through the door. Despite this disadvantage, the rest of the devices were very practical. They were made from environmentally friendly clay bricks. This material is characterized by a high level of fire resistance. The furnace itself looked like a domed hearth.

Oven requirements

Over time, homemade sauna stoves became more and more popular and acquired new elements, for example, a chimney. Today, there are already formed concepts and requirements that the furnace must meet in order for it to be successfully operated.

- The first is the availability of sufficient thermal power, as well as the possibility of its regulation. It is very important to note here that this parameter is highly dependent on the type of material that was used to construct the building. A homemade stove for a bath with the same power can be perfect for a bar object, but at the same time be completely unsuitable for a frame building.

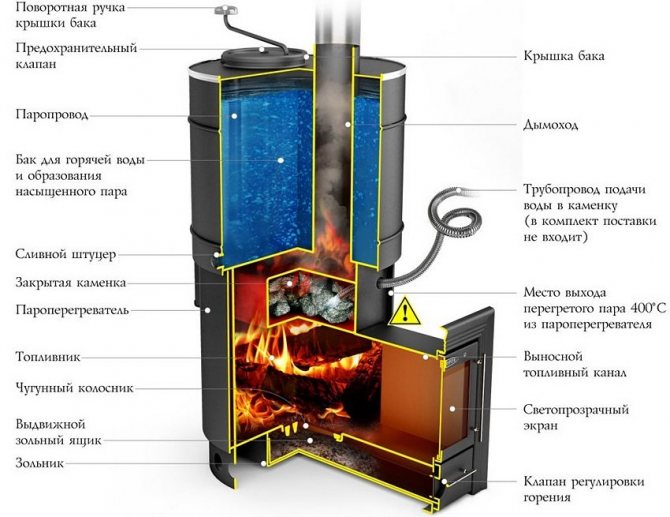

- The presence of a heat accumulator and a steam generator is considered quite important. These devices are necessary in order to be able to change the mode of heat and moisture.

- There should be practically no materials in the room, whose temperature, when heated, will exceed 150 degrees Celsius.

Varieties of metal furnaces

The simplest version of a metal stove is an ordinary potbelly stove. It consists of a casing with a door and legs, inside which a grill is installed. Firewood is burned on it. As with all stoves, a chimney is required. Let's face it - this is not the best option, although it heats the bathhouse perfectly. But at the same time it consumes too much fuel. You simply will not have time to throw firewood into the mouth of the stove in order to maintain the required temperature in the bath. Many people say that this is generally a relic of the past.

But let's not immediately write off this sample, which has served the baths with faith and truth for many years. Today, modern kulibins offer an improved potbelly stove, which is classified as a long-burning stove.

What has changed inside the structure itself?

- First, its combustion chamber was divided into two parts by a horizontal partition. Firewood burns at the bottom, and flue gases at the top. They pass along the channel left on the side in the form of a gap between the partition and the vertical wall of the device.

- Secondly, the wood is stacked tightly to each other so that they burn with less oxygen.

- Thirdly, special channels are installed through which fresh air enters the second combustion chamber.

Yet these metal ovens are not the most economical. And their efficiency is not very high. Therefore, we offer other types of products.

Traditional metal home-made stoves are a kind of structure in which there is a place for a firebox, heating planes, a stove, and a water tank. That is, there must be a complete set that will provide the bath not only with heat, but also with hot water. By the way, about the water tank. Its volume may be different, but the masters say that for small bath rooms with a small metal stove, the best option is 60–70 liters.

True, there are two very important warnings:

- A metal sauna stove must be made of sheet iron with a minimum thickness of 4 mm. You can also make it from a pipe.

- It must be covered with bricks. This will increase the safety of the structure and create conditions for an even distribution of heat throughout the room.

Attention! One of the biggest advantages of homemade metal stoves is that there is no need for a large and solid base. There are many options for founding. For example, a concrete screed lined with ceramic tiles, refractory bricks, or a piece of sheet metal.

Types of structures

Metal stove for a bath

Homemade metal stoves are divided into three main types by design:

- Closed.

- Open.

- Combined.

How do they differ from each other? In the first case, it is a simple model, the body of which is lined with refractory bricks from the outside and from the inside. Of course, this is an expensive option, so many people use ordinary red brick for cladding. By the way, the bricks are attached to the walls of the unit and to each other with a special wire. In the middle of the oven, a grate is installed inside, on which stones are placed.

The second option is simpler. To do this, the stove is trimmed around the entire perimeter with a metal grate so that a sufficiently impressive gap remains between the walls of the device and the grate. Stones are poured into it.

The combined option is the most difficult. For this, the stove is placed on top of the boiler, for which an additional solid structure is being constructed. This complicates the unit and increases its cost. But it works much more efficiently due to the installation of additional elements for the return of thermal energy.

Fuel types

There are only three product groups in this category:

- Electric ovens. Their package includes a metal case and heating element. Good insulation of terminals and connection points is a requirement.

- Gas. In addition to the body, they include a burner that supplies fuel to the furnace. Experts recommend installing a safety unit in the form of a simple automatic control system. For example, thermostat, temperature sensor and flame sensor. The latter is especially important - it will control the gas supply. When the flame goes out, he will give a command to the valve, which will shut off the gas pipe line.

- Wood burning. These are the simplest designs that do not use the supply network of energy carriers. Incidentally, these include potbelly stoves.

Furnace type

Currently, there are two fundamentally different types of ovens. You need to choose one of them before you start making a homemade sauna stove.

The first option is called a "hot" bath. The temperature of the walls of such a bath can reach 100 degrees. The advantage of this type of stove and bath is that it melts quite easily in a short period of time. This option is perfect for those objects that are used occasionally, rather than on a permanent basis. However, there are also disadvantages to such devices. It is quite easy to heat them up too much, which makes the bath easy to turn into a sauna.

The second option is the "cold" type of oven. The process of kindling such a device is longer than in the first case, but the walls will not heat up too much. The maximum temperature will be 50 degrees, which means that it will be impossible to burn yourself about them. The process of heating a room with a "cold" stove takes longer, since the heating takes place in the following way. Special channels absorb cold air from the floor, which then passes through the furnace firebox, heats up and is released through the top already warmed up. This makes it possible to adjust the temperature inside the building.

Types of water tanks in bath stoves

Wood stoves for a bath with a water tank can have a very different design. They are assembled on their own or bought ready-made. The same applies to the location of the tanks. They may be:

- Built-in - here you see a single structure with a firebox and a stove, in which a tank for heating water is built. An excellent combination for a bath, completely ready to use;

- Hinged - such water tanks are installed directly on the furnace body. This approach cannot be called the most effective due to not the most efficient way of transferring heat;

- Connected to the built-in heat exchanger - most often these are external tanks intended for placement in an adjacent room;

- External, for connection to a chimney - a universal option for upgrading almost any stove for a bath.

Let's analyze these types of tanks in more detail.

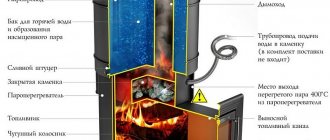

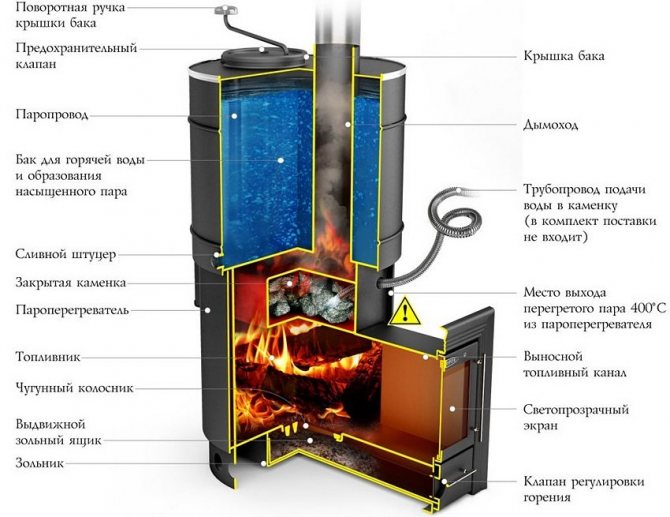

Oven models with built-in tanks

Built-in water tanks in sauna stoves are good because they are an already finished structure that takes heat directly from the firebox. Heating is carried out very quickly here, which is an indisputable advantage. There are stoves with tanks, the steam from which goes directly to the steam room. Also on sale are models with steam extraction - they are designed for dry steam rooms.

Most often, consumers choose steam bath ovens, as most people prefer dry heat.

Sauna stoves with hinged tanks

Hinged water tanks are placed on top of any stoves. You can just as well put an aluminum pan or bucket with a lid here. This approach should be called universal, but water heating will be slow, although in some cases it is quite justified - most often hot water is needed at the very end, and not when people just enter the steam room.

In specialized stores, we can buy stoves with hinged tanks for a bath and separate tanks of various designs. In some models, the tanks are placed on top, and in some they are hung on the side, which is safer. Their volume varies widely, but for carrying out bath procedures, a capacity of 20-30 liters is enough, no more.

Many Finnish stoves with a wood-fired water tank for a bath are made according to this scheme. For example, such units are manufactured by Harvia.

Stoves and boilers for a bath with heat exchangers

A bath boiler with a built-in heat exchanger is one of the simple and reliable solutions for organizing hot water supply. Here we see an analogy with traditional stoves used to heat multi-room houses and summer cottages. The tank itself is most often located in an adjacent room and is connected to the furnace using metal pipes. Taps and shower heads are connected to the tank.

This scheme has many advantages:

- The ability to get rid of the water tank in the steam room;

- Ability to do without steam extraction;

- Fast preparation of hot water;

- High efficiency.

Burning wood heats the water in the heat exchanger, as a result of which it begins to circulate along a small circuit connected to the tank. Users will have to control the temperature of the water and its amount. The main thing is not to add water to the system when it completely dries up, since in this case the heat exchanger may suffer - the temperature difference will affect. Also, you should not allow water to boil in the hot water supply system.

In order to be able to adjust the temperature in the tap or in the shower, the system can be supplemented with a mixer by running cold water into the bath.

A wood-fired sauna boiler with a water tank, equipped with a heat exchanger, has a high performance. If the hinged tanks are small in volume (they are only suitable for washing after the steam room), then the external tanks can have a large capacity - there is enough heat from the stove for any needs. Theoretically, nothing prevents you from connecting a very large container to the stove, for example, 100 liters - this is enough for several people to wash in the shower after bath procedures.

Tanks on the pipe

Despite the ideality of the design of the stove for a bath with a heat exchanger, such a scheme is not very popular. But the tanks installed on the pipe have earned special popularity. A variety of samples are on sale - roomy, small, rectangular, rounded, triangular and many others. Their installation is extremely simple - it is enough to cut out part of the chimney and mount a tank in the resulting space (some models are simply put on the pipe).

Please note that this scheme has one drawback - the steam from the water will go into the steam room, creating a humid atmosphere there. Since in most cases this is not necessary, the tank can be positioned behind the ceiling, equipped with a branch for supplying cold water and a hot tap. Accordingly, the steam will go into the attic space, from where it will quickly disappear and go into the atmosphere. Water taps can be drained directly into the steam room or into an adjacent room.

The combustion products of the sauna stove contain a large amount of heat, because their temperature can reach + 200-300 degrees. Therefore, the water tank installed on the chimney will warm up rather quickly. But heating can be even faster - for this, boilers and stoves for a bath with water, equipped with double heating, are on sale:

- From the chimney - a container with water is installed directly on the chimney, taking some of the heat from it;

- With the help of a small built-in water circuit - provides additional heat intake.

In this scheme, we can place a container with water at a high height, behind the ceiling, and from there we lower pipes to the taps and shower head.

Metal type furnace

A fairly common type is a homemade sauna stove with a tank. The view, which will be described later, will also be distinguished by the presence of a built-in stove in the upper part of the stove. The flame will heat the stove from all sides, which will significantly increase the efficiency of the device. Naturally, the size is a completely individual matter. They will depend on two criteria: the size of the bath and the number of people who wash. A medium-sized object will be described as an example.

A homemade metal bath stove will have the following parameters:

- External heater dimensions. Width - 50 cm, length - 50 cm, height - 80 cm.

- Internal heater dimensions. Width and length - 40 cm each, height - 50 cm. It is important to note here that the distance between the walls of the outer and inner heaters should be 5 cm along the entire perimeter.

- The oven itself will have such dimensions. Width - 50 cm, length - 90 cm, height - 50 cm. The length of the equipment can be changed at your discretion. For example, if you shorten it to the size of a heater, that is, up to 50 cm, then the water tank will be mounted on separate stops. If you increase the length, then the volume of the tank will also increase.

- Liquid tank. Width - 40 cm, length - 50 cm, height - 60 cm. The tank will hold 120 liters of water. This is usually enough for 3-4 people to wash.

Potbelly stove and barrel oven

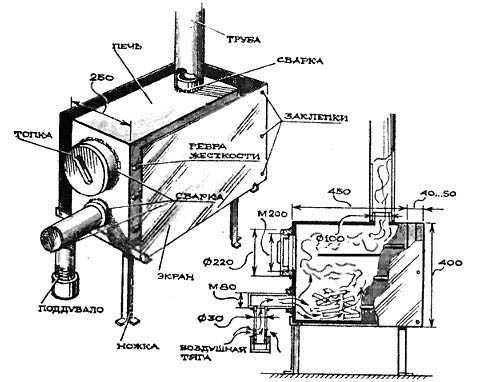

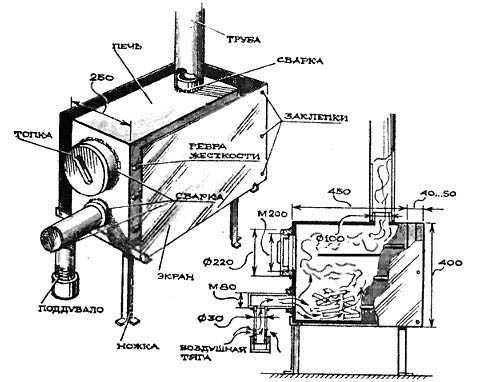

A homemade sheet metal stove-stove is suitable for a small individual bath for three to four people.

Sauna potbelly stove differs from the usual stove-stove by the presence of a container for stones and a firebox lined with fireclay bricks.

The design and installation of the potbelly stove is very simple. The exact drawings of the sauna stove can be seen in the photo below.

This sauna stove is just a firebox with a chimney, set on four legs. From above it is covered with stones, laying them out in the recess of the case.

Photo:

The following sizes of a potbelly stove (without legs) are optimal:

- height - 40 cm;

- width - 50 cm;

- depth - 75 cm.

The stove must be installed in a permanent place in such a way that its doors are facing the exit, and the stove is turned to the corner of the room.

To make the guy in the bath comfortable, the shelves are installed along the wall with the stove at such a height that the person sitting on them does not touch the ceiling with his head.

On the sides of the stove, metal arches are made, on which buckets are placed. The water is heated by streams of heat circulating between the screen and the stove.

Two buckets in half an hour heat up to 50 degrees - this is quite enough for washing a family. The potbelly stove can be installed on a sheet of basalt cardboard, it does not need a foundation.

The chimney is made without a gate, the height of the straight part should be 4-5 meters. Such a stove can be heated directly during washing. Water is also supplied to the heater at any time.

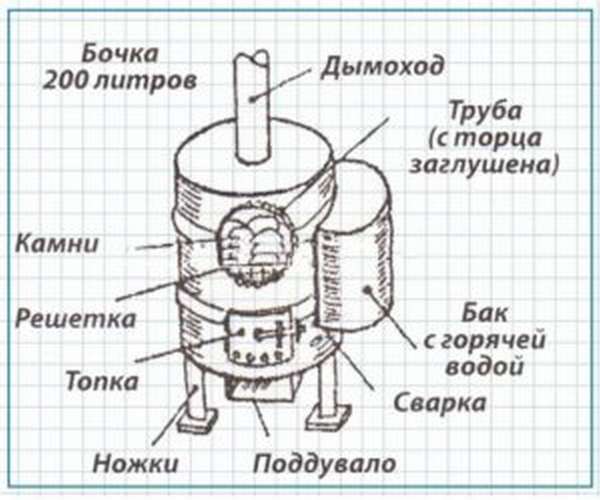

A homemade stove from a metal barrel for a sauna is another design in which it is impossible to shove a water boiler.

But her drawings are very simple and making such a furnace with your own hands will not cause difficulties. A home-made stove from a barrel can be made for a summer residence with a primitive bath-shed with a volume of up to 15 m3.

To make a stove from a metal barrel, proceed as follows: a piece of concrete slab is laid on the ground, on which a cube with sides of 65 centimeters must be folded from an ordinary brick.

From above, reinforcing rods are embedded directly into the brick - they will become a grate for the heater. Then you need to install a metal barrel on the brick and line it with fireclay bricks on clay from the inside.

Video:

If it is not possible to impose a brick on the inside of the barrel, then you can simply coat it from the inside with a greasy clay mortar.

Clay is diluted with water to the consistency of plasticine. The thickness of the clay layer must be at least 5 cm.

Stones are placed on the grate, the barrel is covered with 4 mm thick sheet steel with a welded-in pipe cut, which will become the lower bend of the chimney.

Preparatory work

Since a homemade iron sauna stove is made of a material that is prone to incandescence, it must be hardened before assembling the device. After all the necessary parts are cut out, they must be heated in any way until the metal turns red. When this moment comes, then you can begin to slowly cool the material. It often happens that after the procedure for dispensing the raw material, it jars. It's not a problem. You can return the shape with a hammer. It is also worth re-measuring all sheets. If some are too far out of scope, then you need to cut them again to the desired dimensions. This is a very important point, since it will exclude the possibility of metal warping during the operation of the furnace.

Types of bath metal stoves

The simplest one has been known since ancient times; she got the name "Potbelly stove". Its design is very simple: a metal box with a pipe, equipped with a door for placing firewood. Such an iron stove for a bath is easily made by hand. But it is quite fire hazardous, it does not have a water tank, plus it consumes a lot of fuel.

Modern furnaces are made of metal up to 0.5 cm thick. During installation, as a rule, they are lined with bricks, which avoids burns during use. In addition, a brick is a conductor of heat, accumulates it and releases it into the air more evenly.

Modern metal ovens

A modern metal furnace can have a different design:

- Closed ovens completely bricked, both outside and inside. Such stoves are very compact, not bulky, fit perfectly into the interior of a small family bath. They have a high heat capacity and have a stone grate.

- Open design allows you to warm up the bath much faster, as it is equipped with an open heater. To preserve heat and stabilize heat transfer, a special galvanized steel cover is provided, which is used to cover the stones.

- Combined sauna stove made of metal combines the advantages of the previous two. It is more complex in design; the fuel compartment is equipped with a blower, valves, and a grate for stones. They take up more space, but are convenient: you can set the desired temperature in them.

Some features of the metal furnace

Features of homemade iron bath stoves are that the metal will heat up very soon, which will ensure rapid heating of the room. However, the metal also cools down very quickly. If firewood is used as fuel, they will burn out very quickly. All this leads to the fact that you will have to add new portions of fuel quite often in order to ensure a consistently high temperature in the room. Fast combustion is also due to the fact that a grate is often made inside the device. This part is made of sheet metal with many holes. Such an element significantly increases traction, due to which the air flow is too large, which causes the wood to burn quickly. The way out of this situation is quite simple - you do not need to make a grate.

It is necessary to seal the firebox door as much as possible, as well as make several holes that will be covered with a sheet of metal. Thus, it will be possible to adjust the air supply.

Metal stoves for a bath: design

Many owners install metal bath stoves with their own hands. The simplest are potbelly stoves... If we talk about the design of such stoves, then they are a box equipped with a door and having a pipe. Such designs have certain disadvantages. One of them is low heat output. In addition, when using them, high fuel costs arise. Therefore, in modern baths, such stoves can be found extremely rarely.

If we talk about modern models of metal stoves for baths, then they are products related to to a high safety class... In the manufacture, sheet metal is used as the main material. Usually, metal is used with a thickness of at least 4 mm. In their equipment, these furnaces have a thermal chamber, which is used for stone filling. Most models have the ability to install an additional water tank. Its volume can be up to 70 liters.

When installing a metal stove for a bath with their own hands, the owners often cover the structure with refractory bricks. This is necessary to ensure uniform heating of the air in the room and safe operation of the product.

Sauna stoves can have a different design, which should initially be determined by the drawing. Based on this feature there are several types of them.

- Closed sauna stoves. The dimensions of stoves for baths of this type are very compact, therefore, most often they are installed in family-type baths. In order to increase the heat capacity when installing such furnaces outside and inside, they are lined with red refractory bricks. Metal clips are used to fix bricks. The stone grate is installed in the middle of the stove.

- Sauna stoves of open design. Their main feature is the presence of a small tank. The stove of these stoves is open. In this regard, when installing such a furnace in the twin compartment, it is possible to ensure rapid heating of the room. To increase the heat capacity of the furnace, it is necessary to cover the stones with a galvanized lid.

- Combined sauna stoves. Their main feature is the presence of a firebox, which is equipped with two valves. Also in the design there is a grill, a blower and two pipes. The latter differ among themselves in their diameter. In the first, its size is 10 cm, and in the other - 14 cm. Four holes are distinguished in them, intended for the supply of the pipe and the bypass elbow. For the manufacture of furnaces of this design, steel sheets with a thickness of 5 mm are used as the main material.

Assembly instructions

Homemade iron sauna stoves are made according to the following principle.

The first stage is the preparation of raw materials. You need to purchase sheet metal. The thicker, the better, but too thick material is very expensive, and therefore it is better to focus on figures such as 1.5-2 mm.

The second stage is drawing up a drawing or sketch of the furnace, which will indicate all the dimensions. This will help you not to make mistakes in further work, and will also show you exactly how much sheet metal is needed to make the device.

The third step is cutting. All dimensions are transferred from sketch to metal and all parts are cut. It is very important to follow a few simple conditions. Any angle must be 90 degrees, the opposite walls must be as identical as possible. Burrs that remain after working with a grinder must be removed.

Welding

Naturally, to connect the parts of a homemade iron bath furnace, you will have to use a welding machine.

First step. Two sidewalls are placed on the edge at right angles, which is very important. They are caught among themselves. It is very important here to correctly adjust the current strength, since the arc should not overheat the metal, otherwise there will be an uneven and fragile seam. Each grip should be a few millimeters long. Such clamps will be enough for 4-5 pieces for each corner. During welding, it is important to control the position of the sheets, as they will be pulled to the side when the seam is formed.

Second phase. Two pre-welded corners are put together, the corners are checked, if everything is in order, then you can grab the opposite sides of the furnace. The result is a box to which you need to add a bottom and a roof.

Stage three. Naturally, the next step is fixing the bottom and roof. This is done in the same way as the assembly of the box.

Stage four. After the box with the bottom and the roof welded is assembled, you can start cutting out the door near the heater. For these works, you can use a grinder or welding. When the work is completed, the sheet of metal is knocked out with a hammer and removed to the side.

Fifth step. Several holes must be made in the outer heater from below. Pipes will be inserted into them, on which the inner heater will stand. It is important to note here that the holes must be horizontal, at the same level.

Pipe selection

A fairly common option is a homemade stove for a bath from a pipe. The main requirement for a pipe that will be used as a furnace is to ensure uniform and fast heating. At the same time, the thickness must be sufficient to successfully withstand high temperatures for a long period of time. The most optimal dimensions for such raw materials are considered to be a diameter of 0.5 to 0.55 mm and a thickness of 8 to 12 mm. It is worth adding here that the diameter of the material will affect the amount of fuel required for kindling. Therefore, for homemade wood-burning stoves for a bath, it is very important to choose the right pipe diameter.

Wood-fired sauna stoves with a water tank: design features

Furnace designs have several components. The body includes a grate, a firebox, a chimney and a space for placing stones, called a stove.

Wood-fired sauna stoves with a water tank of the modern generation are made of metal, sometimes of brick. But the leading positions are occupied by structures made of stainless steel.

The material for the manufacture of the grate is usually cast iron. It has excellent performance, can withstand severe temperatures, and is durable. To close the firebox, a sealed door is provided in the design.

Arrangement of a wood-burning stove with a water tank

Most models can offer a wide range of functions.Therefore, consumers have the opportunity to buy inexpensive wood-fired sauna stoves with advanced functionality (for example, from the manufacturer of sauna stoves Teplodar, or another brand).

This list may include the ability to:

- carry out work within several modes;

- regulate the working time;

- control the duration of the heating of the bath rooms;

- set parameters in relation to steam quality;

- adjust the temperature inside the tank and steam room.

Wood-burning sauna stove with water tank

Furnace construction from a pipe

Before starting work, it is important to decide on the design of the furnace. The thing is that they can be both horizontal and vertical. Each option has its own advantages and disadvantages.

The vertical version differs in that it takes up quite a little space on the floor. Therefore, it is most often used in rooms with limited space.

If you use the horizontal version, it will be possible to position the stove in such a way that the firebox will be taken out into the dressing room. In the steam room itself, only the part responsible for steam generation will be located - the heater.

Preparatory work for the production of the furnace

Initially, you need to prepare the necessary materials, equipment and tools.

Barrel selection

For this design, it is better to use stainless steel cylinders or barrels with thick walls. But such materials are difficult to find, and they will be expensive. Therefore, we will consider the option of using the simplest steel 200 liter container with stiffening ribs on the body.

The thickness of the side walls is sufficient, and for the bottom we will use a grate made of reinforcement. Stiffeners will strengthen the walls. The simplicity of the design and work will allow you to quickly replace a burnt-out furnace after 7-10 years of its use, during which time all the work will pay off many times over.

But when buying at a metal collection point or when you find a barrel in a landfill, be sure to make sure that it does not contain gasoline or oil. Such a vessel will need to be pre-rinsed and cleaned of fuel residues. Only after making sure that there are no flammable liquids and gases can you start work.

200L barrel

Consumables and their quantity

You will need to prepare a number of blanks for the grate and fastening the grate to the compartment with stones.

| Steel barrel 200 l | 1 PC |

| Hot water tank, volume 50-70 l | 1 PC |

| Armature 10 mm thick | Sections of the required length for the manufacture of a grate with a pitch between bars of 5-6 mm |

| Steel corner with shelf 40 mm | 2 sections in the middle of the barrel for attaching the grate under the stones |

| Armature, with a diameter of 10-12 mm | Lattice sections in the stone compartment |

| Stones for filling the compartment and the top of the furnace | At your discretion |

| Bar and profile tube for door hinges | 2 pieces of a bar 8 mm by 100 mm. 4 parts from a profile pipe 20 mm by 50 mm |

These are just the basic materials for work. We need to prepare refractory bricks for lining the inside of the firebox. A piece of pipe suitable for a sandwich chimney pipe. All these materials can be purchased before installing the stove and leading the chimney to the roof.

Tools

For the production of work, prepare:

- welding machine:

- welding mask and clothing,

- electrodes for welding structural steel,

- grinder with stripping and stock of cutting discs,

- locksmith tool,

- trowel and container for mixing the solution.

Scheme

Diagram of a furnace from a barrel for a bath

Many people make such a stove with the ability to open the lid and pour stones for steam. But in this case, carbon monoxide is released into the room. We are making an option where the furnace lid will be recessed into the body by 100 mm and a row of stones will be placed on top. In this case, steam lovers will be able to splash water from the gang onto the bricks without opening the lid.

We will fix the hot water tank on the side.Such a container can be found at the purchase or made yourself from sheet steel. The container will be secured to the side wall. A hole is made in it for filling water and a branch pipe is welded for winding the water tap.

Horizontal version of the oven

The first thing to do is cut out the firebox. A piece of pipe of the required size is removed. Most often, a sufficient length will be 0.7-0.9 m.

Next comes the process of assembling grates from metal frames and rods. They are welded parallel to the frame at a distance of about 50 mm from each other.

Inside the existing firebox, prepared grates are mounted. If ready-made products were originally purchased, then they can be welded onto the corners inside the oven. On the upper side, it is imperative to cut a hole 15-20 cm in diameter. A very important point. It is best to place the hole at least 15 cm from the back wall. Thus, the gases will not be immediately removed from the device, but will take part in heat exchange for some time. This is very important, especially for homemade sauna stoves in Yekaterinburg, for example, where the temperature drops quite low in winter.