Consequences of a clogged heat exchanger

The heat exchanger of a gas boiler is a bent pipe made of metal or cast iron. It is heated by the flame of a gas burner, and then transfers heat to the heat transfer fluid, which moves throughout the entire heating system. If the heat exchanger is clean, it gives off heat efficiently. When salt deposits accumulate in it, then its thermal conductivity decreases. Then the gas boiler has to heat the coolant longer, which entails an increase in fuel and electricity consumption.

In case of severe contamination of the element, in order to maintain the desired temperature, it must be in the maximum heated state for a long time - this leads to overheating of the heat exchanger and its failure.

Deposits and scale also impede the movement of the coolant along the circuit. As a result, the load on the circulation pump increases.

Thus, a contaminated heat exchanger threatens failure not only of the element itself, but also of other important units of the unit. To prevent damage, the boiler should be cleaned regularly.

…

Note! In double-circuit models, the secondary heat exchanger, which works to heat hot water, often fails.

Choosing a heat exchanger for the boiler

Heat exchangers for boilers are an important element of the heating system. They are installed inside the combustion chambers, where the outgoing flow of thermal energy heats the coolant. The quality of the boiler operation, the comfort of being in heated rooms and the service life of expensive equipment depend on how correctly the heat exchanger is chosen.

In the Prime Energy catalog, you can familiarize yourself with the products of well-known brands. Consultants will tell you how much the heat exchanger for a gas boiler costs (the cost depends on the brand, material and design features), and will also give recommendations on the choice.

By design, heat exchangers are divided into evaporative, heating, cooling and condensing. For production, cast iron, steel, copper and stainless steel (equipment material), aluminum alloys (boiler material) are used. Taking into account the methods of heat transfer, a primary and secondary heat exchanger is distinguished, as well as bithermal (combined). In each case, there are advantages and disadvantages that you should be aware of in advance.

How often should the heat exchanger be cleaned?

The frequency of cleaning the heat exchanger of a gas boiler is usually indicated in the operating instructions. If there is a filter on the water inlet pipe, then cleaning can be done less frequently. If there is no filtration and there is hard water in the region, then the heat exchanger will clog up faster.

Usually, without a water filter, cleaning is done once a year or two. If the tap water is filtered, it is sufficient to take care of the heat exchanger once every 4 years.

Exist signs that urgent circuit cleaning is needed:

- Fuel consumption has increased - with a clogged circuit, gas consumption can increase by 15-20%.

- The performance of the heating system has decreased. Signs of this may be as follows: poor heating of the batteries, the unit cannot reach the required temperature and works continuously.

- Weak water pressure from the DHW system or insufficient heating.

- Noises in the heat exchanger.

- An increased load on the circulation pump is created.

If at least one such "symptom" appears, the heat exchanger should be cleaned as soon as possible, otherwise inaction will lead to costly repairs.

Frequency of maintenance and cleaning of the gas boiler

At the very beginning, we note that it is always easier and easier to do the prevention of heating equipment than to eliminate malfunctions that appear in the middle of the winter cold. The heat exchanger of the gas unit is no exception, which, for prophylaxis, can be flushed from the inside once every 2-3 years, depending on the hardness of the water used. If there is a hot water heating circuit for DHW, it is also advisable to flush the secondary heat exchanger for the boiler once every 2 years, since untreated tap water passes through it, leaving scale, as in the image.

As for the removal of soot from the outer surface of the heat exchanger, then cleaning the gas boiler depends on many factors, such as the operating mode, the quality of natural gas, the presence of filters on the fuel pipeline, and so on.

But, regularly doing internal flushing of the boiler, you cannot help but pay attention to its appearance and, of course, you will not bring it to such a deplorable state as in the photo.

Because of this, the efficiency of the boiler can drop by 40-50% due to a thick soot deposit on the outside and half-clogged internal channels with scale. With the same gas consumption, the efficiency of the heater will become 40% and it will be cold in your house in winter. But since calling a specialist for this event will cost you a pretty penny, you can clean the gas boiler at home on your own.

Gas boiler cleaning options

There are several basic methods for cleaning gas boiler heat exchangers:

…

- manual;

- chemical;

- hydrodynamic.

Which method to use depends on the degree of blockage. Let's take a closer look at each of the listed methods.

Manual cleaning

Not all users of gas boilers know how to clean the heat exchanger of a gas boiler themselves. Manual cleaning is easiest to do on your own. There are two ways to accomplish this method:

- mechanical - with a brush and a brush;

- flushing with active solutions is a more effective option, especially relevant for boilers with two circuits.

In case of heavy dirt, two methods of descaling are used - first rinsing, and then mechanical cleaning. This process is carried out in the following stages:

- turn off the gas and disconnect the unit from electricity;

- open the lid of the gas boiler;

- dismantle the heat exchanger;

- place it in an active substance, for example, a solution of hydrochloric acid;

- pull the heat exchanger out of the solution and clean the dirt with a brush or brush;

- rinse the element with water outside and inside;

- dry and reinstall the circuit.

Dry cleaning

Chemical cleaning is characterized by the use of a booster or its analogues, as well as aggressive chemicals. An important condition for chemical cleaning is to maintain a safe concentration of the substance so that it does not corrode the surface of the heat exchanger.

Dry cleaning is carried out using a booster, but many craftsmen create its cheap analogue with their own hands. To do this, take a container of 10 liters and attach two hoses and a pump to it.

Find out here how to change a gas boiler - rules and responsibilities

Maintenance and repair of gas boilers

Replacing the heat exchanger in a gas boiler with your own hands

If the limescale layer is too large, you can use a sulfuric or hydrochloric acid based substance for cleaning. The simplest cleaning solution is from citric acid: 200 g of powder is diluted with 5 liters of water.

The chemical cleaning process is quite simple:

- the chemical solution is diluted in containers and poured into a booster;

- two hoses are connected to two boiler nozzles - inlet and return;

- turn on the device and run the liquid through the heat exchanger several times.

Factory boosters have a heating function, which allows you to flush the circuits with greater efficiency.

After the procedure, it is necessary to drain the reagent and flush the system again with a neutralizing agent or clean water.

Of course, dry cleaning is more effective than manual cleaning, but the active substances contained in solutions can lead to corrosion. Therefore, this method cannot be used often.

Heat exchanger cleaning solutions

Some owners of gas boilers on the forums are interested in how to rinse a gas boiler from scale at home. Usually, the following agents are used for dry cleaning:

- Cleaning gel - This is considered to be the mildest cleaning agent. After that, it is enough to rinse the heat exchanger with running water. Despite the gentle effect, the gel copes well with scale and lime deposits.

- Adipic acid - in order to flush the heat exchanger of a gas boiler with acid, it is important to dilute it with water in the correct proportion, otherwise the substance will damage the metal surface. Adipic acid well softens all deposits inside the heat exchanger. After flushing the system with this agent, the neutralizing liquid should be driven through it.

- Sulfamic acid - good for tough dirt. The substance is diluted with water and filled into a booster. After completion of the process, it is necessary to flush the heat exchanger with a neutralizing liquid.

Note! When performing dry cleaning, you should wear rubber gloves on your hands, and protect your body with overalls through which the acid solution cannot get on the skin.

Hydrodynamic cleaning

This method of cleaning the heat exchanger is carried out only by specialists. It is unnecessary to disassemble the boiler and remove the heat exchanger for its implementation. The principle of hydrodynamic cleaning is as follows: the liquid is pumped into the system and driven under pressure several times. For greater efficiency, abrasive cleaning agents are added to the water. It turns out that due to the rapid movement of water, scale disappears and contamination is washed off.

However, with this method, it is important to correctly calculate the pressure force - if it is too large, a pipe break may occur. Therefore, hydrodynamic cleaning cannot be performed on your own.

Do I need to conclude a contract for the maintenance of a gas boiler?

How to properly ground a gas boiler? -

https://oteple.com/kak-pravilno-vypolnit-zazemlenie-gazovogo-kotla/

What are the differences between cleaning a double-circuit gas boiler?

How to flush the secondary heat exchanger of a gas boiler with your own hands? There are no fundamental differences between flushing the DHW circuit and the heating heat exchanger. It's just that in the case of a two-circuit model, you will have to clean not one, but two elements.

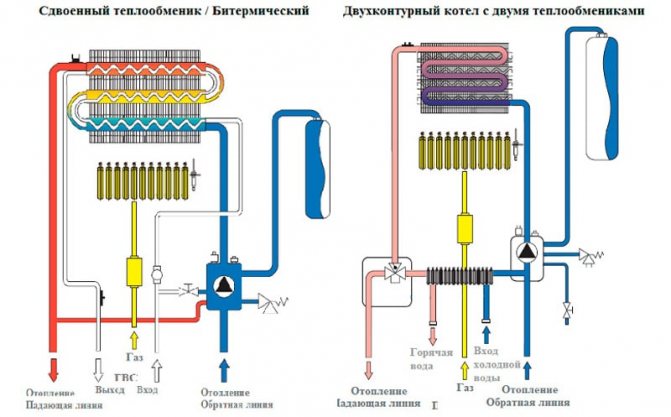

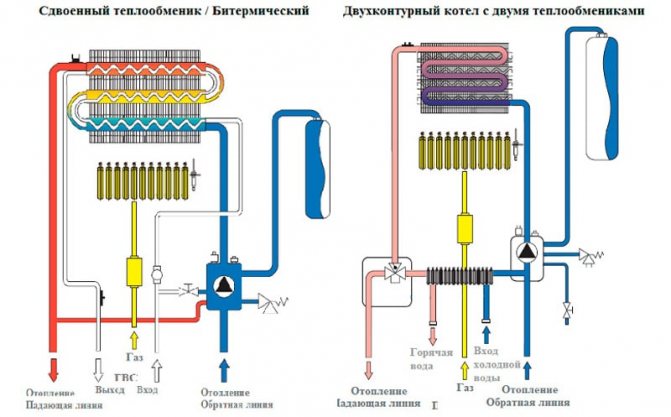

Double-circuit gas boilers can be equipped with two types of heat exchangers:

- removable secondary;

- bithermic.

The first option is cleaned in the same way as the primary circuit using manual or dry cleaning using a booster:

- connect the hoses of the booster with nozzles for cold water supply and hot water outlet;

- the apparatus is put into operation with heating of the reagent (t = 50-55ºC).

For manual cleaning, the secondary circuit is dismantled and immersed in a citric acid solution. Then brushed outside and dried.

A bithermal heat exchanger consists of two pipes inserted into one another: a coolant moves along one of them, hot water flows along the other. Its cleaning is much more difficult to carry out, especially since such a circuit cannot be dismantled as a separate analogue. Therefore, flushing of the bithermic circuit can only be performed using a booster. If such an element is heavily contaminated, then it is simply impossible to clean it. Then you will have to buy a new bithermal heat exchanger and install it instead of the old one.

What is the best way to flush the heat exchanger?

Some people get lost in the variety of contouring agents and often choose the most powerful ones that, with regular use, negatively affect the metal. Experts say that it is better to use such funds as a last resort, if more gentle solutions did not fit. The most versatile remedy is citric acid - it cleans scale no worse than all kinds of expensive products, but at the same time does not damage the surface of the heat exchanger.

If you rinse the circuit in time, and do not wait until the pipes are completely overgrown with salt deposits, then you will not have to use aggressive substances to clean a small layer of scale.

Heat exchanger flushing fluids

In conclusion, consider the question of how to flush the heat exchanger of a gas boiler

Despite the abundance of recommendations in various sources, some care must be taken when choosing a cleaning agent.

Many experts recommend using hydrochloric acid for flushing. It removes limescale really well, but it is a rather aggressive compound that can break the protective coating of the inner surface of the heat exchanger.

In addition, there is evidence that rinsing with hydrochloric acid can cause the metal to become brittle.

Citric acid is less dangerous for the heat exchanger material. It perfectly copes with all types of deposits, as well as special reagents: DETEX, Cillit, Sanax and others.

Timely and proper care of the heating system elements will increase its service life and reduce the cost of maintaining operability. Cleaning the heat exchanger, as one of the most important operations performed during the maintenance of boilers, will make the most significant contribution to this process.

You may be interested to know

How to flush radiators

Natalia, depending on the design of the boiler, the following operations must be performed: 1. Using a long screwdriver, remove the front cover of the unit, the protective casing and reflectors of the combustion chamber. 2. Disconnect the interfering wires of the flow sensors, temperature sensors, etc., as well as the pressure pipes (so as not to forget how they are connected, you can take a picture of the internal filling of the unit). 3. Remove the fan and flue gas deflector. 4. The plate heat exchanger itself is similar to the radiator of an automobile stove and is fastened with latches. 5. When removing the device, avoid sudden movements and mechanical impact - it is very easy to damage the heat exchanger. 6. When disconnecting the copper pipes from the radiator, be sure to use the second wrench to hold the nuts located at the base of the device, otherwise the outlet pipes of the device may be damaged. After cleaning the heat exchanger, reinstall it upside-down.

11 December 2015

Cleaning is necessary in the following cases: 1. The calculated parameters of the device differ significantly from those stated in the passport - the heat exchanger consumes more heat, but at the same time it works with less efficiency. 2. The scheduled replacement of the heat exchanger rubber seals has come. 3. So dense build-up of dirt, scale, scale has formed on the heat exchanger plates that it can only be removed mechanically.

11 December 2015

Based on my own experience, I can say: before choosing a method for flushing a heat exchanger, it is necessary to take into account all its technical characteristics, analyze the degree of pollution, the intensity of work in order to dwell on the option that will allow the heat exchanger to be put in order as carefully as possible without damaging the plates or seals with chemical reagents ...

More information on the topic: https://all-for-teplo.ru