Good time of the day, dear reader! Are you familiar with the situation when the faucet in the kitchen or bathroom breaks down and starts constantly leaking?

If it is not repaired or even replaced in time, then you can flood not only your apartment, but also your neighbors below. In order for the repair to be able to suspend the water supply at the entrance to the apartment, a water valve must be installed. It is also desirable to have a separate valve-type shut-off device in front of the washing machine and each plumbing fixture, so that, in the event of an emergency, only a certain area is disconnected from the water supply system, and not completely the water supply.

What kind of valves are there?

The valve is a shut-off and regulating device mounted on a threaded spindle, which closes the passage in the horizontal plane.

The technical conditions for its manufacture are regulated by GOST 12.2.063-81, GOST 5761-74. The water valve is produced in several modifications, which differ in:

- body structures (straight-through, straight-through, corner, mixing);

- a method of sealing the junction of the cover with the movable element of the shutter (bellows, stuffing box);

- the location of the running nut (thread of a submersible or remote type nut);

- the material for the manufacture of the main elements (brass, cast iron, steel);

- the method of attachment to the pipeline (flanged, coupling, pin, choke, welded fittings);

- locking element design (ball, valve, plug, wedge);

- the type of force transmission to the working mechanism (manual control, from an electric drive).

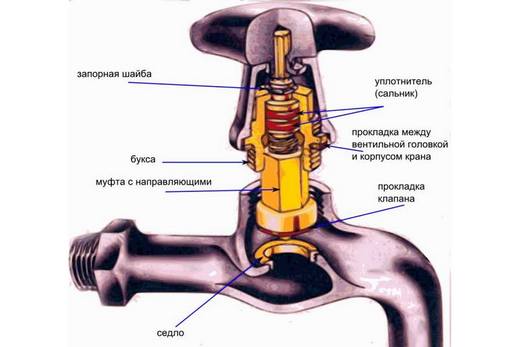

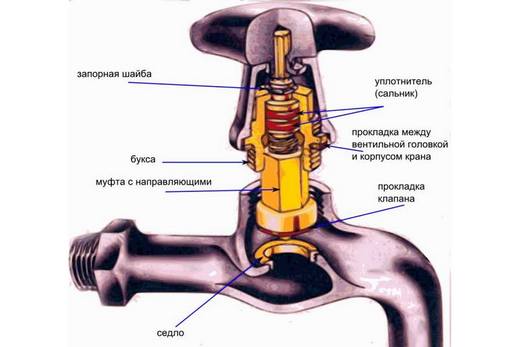

The design and principle of operation of the classic water valve

The valve (classic) valve consists of a cast two-chamber body and a movable locking mechanism with a drive. A straight-through (straight-through) valve is installed on straight sections of pipelines to shut off or regulate the fluid flow.

The design features of the angle valve allow it to be installed in the places of pipe turning. The principle of operation of these types of fittings is similar to each other, and the difference lies in the shape of the body.

In the straight-through valve, water is supplied to the lower, pressure chamber and through the hole enters the upper chamber, and then through the pipe to the consumers.

The locking mechanism is a threaded stem (spindle) and a valve disc with sealing material fixed to it. When the handwheel rotates, the spindle moves the disc down towards the valve seat (hole), thereby reducing its cross section.

In this case, the liquid is throttled, and the pressure in the upper chamber decreases, which leads to a decrease in the liquid flow rate.

The weak point of the design is the threaded block, since with excessive force when closing, the threads are torn off. This leads to the failure of the entire node. A gland packing is used to seal the stem.

To eliminate leaks on the spindle, tighten the union nut, which presses the packing to the stem through the packing follower.

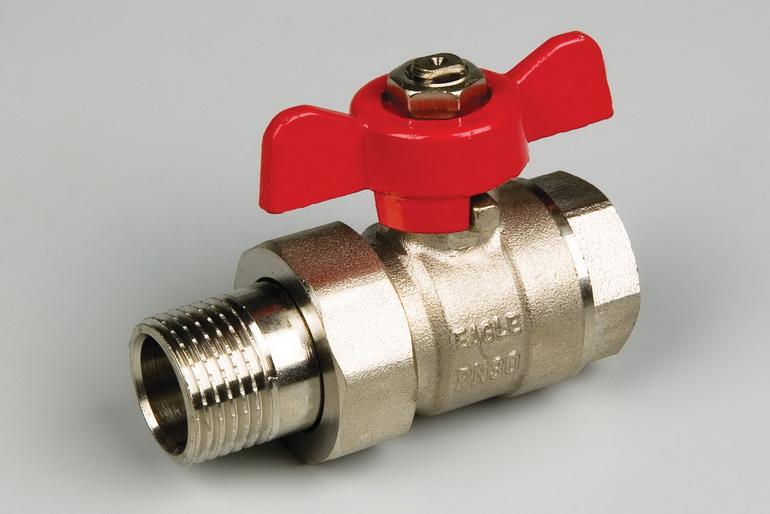

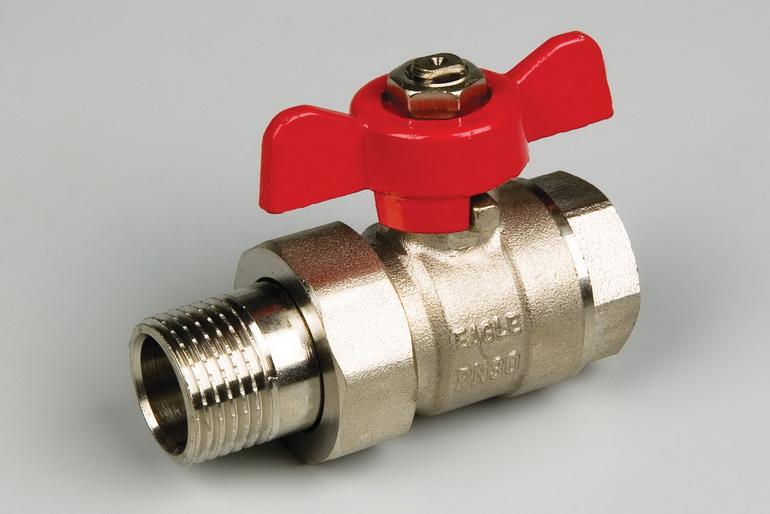

The design and principle of operation of the ball water valve

A valve with a spherical shut-off body has a simpler design. The body of a straight-through design is most often made non-separable. The role of the locking mechanism is played by a metal ball with a hole (valve).

The tightness is achieved by the presence of gaskets between the ball valve and the body. In most cases, they are made of fluoroplastic or rubber.Some more expensive models use wear-resistant Teflon seals.

The ball is made of chrome or nickel plated brass. This treatment of the obturator allows you to create a completely sealed structure. The valve is controlled by a manual actuator made in the form of a stem welded to the ball.

In order to shut off the fluid flow, the spherical valve is turned 90 °. There are stops on the body that prevent the circular rotation of the ball. This is done in order to ensure optimal closure of the fluid path.

Sealing of the stem exit from the body is achieved by installing gaskets, which are pressed by a threaded bushing. There are petals on the valve actuator, which do not allow turning the valve by more than a quarter of a circle.

Case design features

Valves, depending on the shape of the body and the method of installation on the pipeline, can be:

- direct-flow - in them the flow of the transported liquid moves through the housing from the inlet to the outlet, without changing direction, the spindle axis is located at an angle to the axis of the passage hole. This design helps to straighten the flow and reduce hydraulic resistance, but increases the valve travel, the parameters of the face-to-face length and weight of the product;

- straight-through - a product with the same direction of flow of moving water at the inlet and outlet and the axes of the inlet and outlet nozzles displaced parallel to each other. Passing through the valve body, the water flow is forced to make at least two turns at right angles, which leads to the formation of high hydraulic resistance and the formation of stagnation zones;

- angular - in them the flow is rotated by 90º once, therefore there is a lower level of hydraulic resistance. Such products have restrictions on the area of use - they are placed on the pipeline plan only on its turning sections;

- mixing - in them the adjustment of the proportions of water occurs due to the mechanical rotation of the internal elements of the body. Designed to shut off and mix flows of cold and hot water.

Selecting a thermostatic expansion valve for an air conditioner

A thermostatic expansion valve (TRV) in the room air conditioning system controls the refrigerant level at the inlet to the evaporator and prevents liquid from entering the compressor.

Air conditioning valves are divided into two types:

devices with external equalization. The pressure is determined at the outlet of the evaporator. The system has an additional tube that supports the specified parameters;

Thermoregulation device with external pressure equalization

devices with internal equalization. The system pressure is determined directly in the evaporator itself.

Thermostatic expansion valve

Internal equalization valves are installed exclusively on single-pass evaporators.

Locking elements. Principles and structure

Water taps are available with different closure configurations: ball, valve, plug and wedge design.

Ball valve

A ball valve is called a valve, the shut-off element of which has a spherical surface.

Its construction consists of the following elements:

- housing. It can be made in an all-welded or dismountable version. One-piece valves are lighter, cheaper, but not repairable. Collapsible products have a more complex design, are more expensive, but can be repaired;

- constipation in the form of a metal ball. Has a bore with a cross-section less than or equal to the nominal diameter of the valve, it can be floating or fixed;

- a movable spindle that rotates the locking part;

- removable handles;

- end fluoroplastic rings, ensuring the tightness of the connection between the body and the polished ball.

The ball valve has a through hole, the axis of which is parallel to the direction of the transported liquid. The stem is rigidly fixed, and together with the ball forms a rotating axis, which, when the valve is closed, is in a perpendicular position relative to the direction of movement of the water flow. When the stem is turned by 90º, the axes of the ball and water flow holes coincide and water is supplied.

Valve

The block valve assembly includes a threaded rod and a piston (valve). The cross-section of the piston corresponds to the diameter of the through hole in the product body. When the position of the valve is changed, it is screwed into the landing nut, and as a result, the flow of the moving medium is shut off.

The valve can be used not only as a shut-off device, but also to adjust the volume of water supply.

Klinovoy

A wedge valve is a valve for water, the movable part of the gate of which has the shape of a plate (wedge) tapering towards the end.

When the handle is turned to the “closed” position, the wedge is tightly pressed against the seat in horizontal planes parallel to the direction of the flow, which at this moment is forced to bend twice at right angles.

Suberic

With a plug valve, the flow is shut off with a cone-shaped plug attached to the stem. Under the influence of the handle, the stem is lowered and the plug enters the through hole, tightly blocking it.

Worm

The elastomer gasket is tightly pressed against the seat by a worm-type mechanism, which is driven by a handwheel handle.

In the open position of the valve, the stem with the gasket is lifted and the water passage is opened.

Ceramic

Inside the body of such a valve, there are two plates with oblong holes. One of them is fixed motionless in the body cavity, the other is attached to the spindle. When you turn the handle, the movable plate is displaced until their holes coincide and the passage for the movement of water flow opens.

Electrically operated valves

Shut-off valves equipped with an electric drive are installed mainly on large-diameter main pipelines.

They are controlled in automatic mode remotely, they can also be configured for manual control using the steering wheel. The electric drive consists of two main units - a motor and a gearbox, for remote control it is equipped with indicators and position sensors of the shut-off element, to prevent overloads - with special limiters. For fastening to the valve, a flange or coupling type of connection is used.

What is a gate valve?

Under gate valve

it is customary to understand a shut-off mechanism on a pipeline, which involves shutting off the flow of liquid or gas by means of a baffle. It can move across the pipe up and down or left and right. The valve in many cases also allows you to adjust the flow rate of the liquid or gas. For example, if the baffle of a valve is half-shifted, the flow rate is reduced by 50%. As it moves higher or to the left (or lower or to the right - depending on its original position), the flow intensity can increase or decrease.

The baffle on the valve is most often made in the form of a disk, sometimes a wedge or a sheet. There are valves in which the partition consists of one element, but in some cases it is represented by several details. For example, if there are two of them - an increase in intensity, or an opening of a stream, it can be carried out by means of their expansion.Reducing the dynamics, or closing the flow, on the contrary, is carried out by closing the components of the valve baffle.

The main advantage of the gate valve is the ability to open or close the flow relatively quickly and at relatively low energy consumption (or set the required flow rate).

Gate valves can be installed on high pressure pipelines - for example, heating, plumbing. They are among the most sealed shut-off elements.

With frequent use, the valve can wear out rather quickly - this is due in many cases to a rather large frictional force between the edges of the partition and the block, in which it moves left-right or up-down.

Another drawback of the valve is the need to allocate additional space outside the pipeline cross-section in order to temporarily place the moving part of the partition. Installation, maintenance and repair of the shut-off element in question can also be quite labor-intensive.

Thus, taking into account the noted advantages and disadvantages, the valve is most often used not as a regulating element, but as a shut-off element, which is supposed to be placed in the "open", "closed" position or in another static position for quite a long time. In order, in turn, to frequently adjust the flow of liquid or gas on pipelines, another shut-off device, a tap, can be successfully used. Let's consider its features.

Mounting methods

Water supply valves can be connected to the process in different ways: fixed with special elements or mounted by welding.

Flange connection

This type of connection uses a special metal flange with a rubber gasket.

Free flanges are put on the end of the pipe and the valve branch pipe, a gasket is installed between them, then the entire assembly is tightened with bolts.

Coupling fittings

The connecting branch pipe has an internal thread with a fine pitch, and the outside is designed in the form of a hexagon for the convenience of working with a wrench. The coupling is screwed onto the thread with a linen strand seal or FUM tape.

Tsapkovaya

This mounting method is characterized by the presence of an external thread at the end of the connecting pipe and a shoulder at the end of the pipeline.

The end piece of the valve is pressed against the pipe and fixed in this position with the help of a union nut. The tightness of the connection is ensured by a metal gasket and special lubricants.

Choke

The nipple is a short length of pipe (sleeve) with female threads at both ends. With this type of connection, the connecting ends of the fittings are screwed onto the pipe and fixed with a union nut.

For welding

This is a one-piece type of connection, the tightness of which is ensured by welding.

Manufacturing technology and materials

Different materials are used for the manufacture of the valve:

- Brass. The brass product is characterized by small dimensions, low weight, corrosion resistance and long service life. It can be installed in both cold and hot water supply systems made of steel and plastic pipes. The disadvantage is the high cost of such products.

- Cast iron. Cast iron valves have a rather large mass, but are reliable, capable of withstanding an increased level of pressure, resistant to various kinds of deformations. They have a low price, therefore they are often used for the construction of a water supply system in private and apartment buildings, country houses and garages.

- Steel. In steel products, instead of a handle, a wheel is installed on the body, turning which you can adjust the pressure level or stop the pressure of the moving medium.They are lighter than cast iron, have a simple design, maintainable, can be used in heating systems with a higher operating temperature and pressure, as well as in networks where there is a risk of water hammer.

What kind of taps / faucets are there?

Depending on the purpose, there are 4 main types of water taps: valve, single-lever, with a thermostat and sensor.

Valve

These mixers are considered to be the most common appliances.

They are of two types:

- with one valve. These mixers can supply only one type of water - cold or hot. It is mainly used for installation in the kitchen or washbasin. The single valve body is made of copper or brass alloy. The locking mechanism - in the form of a ceramic or worm-gear valve - the axlebox is driven by a valve;

- with two valves. Their device includes a chrome-plated brass body, two valves that control the cartridges (valve - axle box).

Due to the work of the cartridges, the pressure and temperature of the water are regulated. The spout, depending on the modification of the mixer, can be integral with the body (not swivel) or freely rotate in different directions. Two-valve mixers are intended for mixing hot and cold water;

Single-lever

The single-lever mixer has only one handle (lever), with which the intensity of the supply of cold and hot water is regulated. The pressure can be increased by lifting the handle up.

The temperature is adjusted by turning the lever to the left or to the right; to completely block the water, the handle must be lowered down.

With thermostat

This is an innovative type of device. Adjustment of the temperature and intensity of water intake occurs when a certain indicator is set on a special thermostat scale.

Contactless

The device of such mixers includes special sensors, the principle of which is based on the reaction of infrared rays to heat and movement.

Therefore, as soon as hands are brought close to this mixer, it immediately works. Most often they can be seen in public places: toilets of airports, train stations, entertainment centers, healthcare institutions, etc.

Which one is better to choose?

Choosing a mixer can be tricky. After all, I want it to be compact, reliable, firmly "sit" in the workplace, fit the style of the room and not fail for a long time.

- For the kitchen, it is advisable to choose a valve faucet made of brass, bronze, copper with chrome or gold plating, on which grease does not retain and dirt is easily washed off. These faucets are durable and expensive, they are not susceptible to oxidation and rust. The faucet should also have a swivel spout with a gooseneck height convenient for washing dishes. The price of a quality product starts from 5 thousand rubles.

- For a bathroom - the body and spout of the faucet must be made of brass, preferably a replaceable cartridge. It can be a ball mixer equipped with a single lever handle or a two-valve valve. Many people prefer a ceramic faucet, i.e. with ceramic cartridge. In it, the sealing element is a ceramic ring. Such products better withstand the effects of hot water, regulate more smoothly than taps with a rubber seal, serve for a long time, and require less repair and maintenance. Of course, with such characteristics, a ceramic faucet has a considerable price - from 4.0 to 35.0 thousand rubles (depending on the manufacturer).

- For other situations. In the back rooms, the garage, an inexpensive single-valve crane will be enough. The price of such products varies from 1.5 to 3.5 thousand rubles.

How to install it yourself?

Correct installation of the water valve is essential for safe operation and a longer service life. In principle, the installation itself proceeds according to the following scheme:

- Shut off the water supply system.

- Open all taps to drain the remaining water from the pipes.

- Dismantle the worn out device. The choice of dismantling method depends on the type of connection of the old product:

- tsapkovy - loosen the union nut with a key;

- clutch - by dismantling the clutch;

- flanged - loosen the bolts used to fix the mounting flanges;

- welded - cut a section of the pipe using a welding machine.

- Clean the pipe at the installation site from the remnants of the sealant and rust;

- A new valve is installed, sealing the threaded part of the fum connection with tape or Tangit Unilok thread. For a flanged valve, no sealing material is required. Unlike fittings with a collapsible type of connection, a special apparatus for soldering pipes is required for mounting a welded device.

However, there are a number of nuances that should be taken into account when working:

- choosing a convenient place for installing the product so that there is no interference with the movement of the lever - handle;

- the thread may need to be lengthened. If the valve is being replaced, then after dismantling the old device, you need to clean the thread of the branch pipe from the remnants of the sealing material and try to screw a new product onto it. Quite often, during operation, corrosion destroys the metal on two or three turns of the threaded part, therefore, it is required to cut the missing turns;

- it is necessary to install the product taking into account the direction of flow of the working medium indicated on the body of this type of shut-off valve.

Ball valve and valve difference and product features

What is better to buy: a tap or a device such as a valve? It is actually unrealistic to answer such a question exactly. Indeed, in some situations it is necessary to use a ball valve, but in others - a special valve. Additionally, it is recommended to note here the fact that the crane is considered a more convenient device to use. In this situation, the handle can be rotated all 90 degrees. Due to this, the incoming water is shut off. But the shut-off valve present in the valve must be turned in order to close or open the water supply.

Additionally, there are special valves with gaskets on the valve. When worn out, it is enough to simply change them to a new version. It is also recommended to periodically replace the oil seal itself. But with a ball valve, such problems do not really exist. Only constant and thorough care of the surface itself is recommended here. She should always be in the most perfect condition.

In general, if enough hard water is supplied to the room, then the installation of a valve is recommended. After all, such a product is subject to, albeit partial, but still repaired. In a situation where the crane is damaged for some reason, then you cannot do without its full replacement.

With all this, the valve can most often be purchased at a lower cost, if taken in comparison with the second type of product. Such a not too high price is primarily due precisely to the fact that the device has a simple design of such an element as a shut-off valve.

In any situation, a shut-off type of fittings in modern times is used to create a variety of sewer and gas pipeline systems. It is also commonly found in general purpose pipelines. The device is designed to shut off a gas or water flow. For this purpose, it is possible to install not only valves and gate valves, but also such devices as taps and valves. All of them have a huge number of advantages, and some negative characteristics. It all depends on the situation.

Thus, the difference between a valve and a tap initially lies in the fact that with the use of a tap it is impossible to regulate the pressure of the working flow. But the second product allows for such an action.

Bookmark this site

- Views

- Choice

- Installation

- Finishing

- Repairs

- Installation

- Device

- Cleaning