General classification of tees

Tees can be classified according to several criteria:

- material of manufacture;

- manufacturing method;

- fastening method;

- operating principle.

The material of manufacture can be different: steel, stainless steel, brass, copper and plastic. So, stainless steel tees are needed to work with aggressive conditions - more often it is the chemical and oil and gas industry. Tees made of steel, brass, copper and plastic are installed in systems for transporting water (hot and cold), steam, for heating systems. Brass tees are used for metal-plastic pipelines.

Tees made of polymer (polyethylene and polypropylene) materials are well suited for cast iron structures. The tee can be used as a connector, branch or fitting.

According to the manufacturing method, tees are divided into welded and stamped. A stamped tee is a part that is hot stamped and machined. A welded tee is a welded nipple design. There can also be stamped-welded tees - i.e. using both welding and stamping.

There can be four fastening methods: coupling, flanged, welded and threaded. The choice of fastening depends on the function of the pipeline, operating conditions and requirements for strength and tightness. Of course, the material from which the tee is made also affects.

There are only two principles of operation - tees can be transitional and equal. Equal tees are elements with three identical holes that are needed to connect pipes of different diameters. The neck of such a part is located perpendicular to the body, there are tees with a different angle of the neck, but they are produced in limited quantities and are used in pipelines with low pressure.

Reducing tees are elements with one hole, which has a smaller diameter. They are used to branch pipes with different diameters and change the pressure in the system.

In metal-plastic pipelines, in addition to threaded and tees for a press sleeve, combined tees are also used, in which the ends are also formed by a crimp method.

Table 1. Technical parameters of tees depending on the manufacturing method

| Index | Alloy and carbon steel | Galvanized Tees | Stamped tees | Stainless steel tees |

| Operating pressure | Up to 16 MPa | Up to 10 MPa | Up to 16 MPa | Up to 16 MPa |

| Temperature | -70 to +450 degrees | -700 to +4500 ° C | -70 to +450 degrees | -70 to +450 degrees |

| Conformity | GOST 17376-2001 and GOST 17380-2001 TU 102-488-95 | |||

| Working diameter | 45-426 mm | 50-300 mm | Up to 462 mm | |

| Features of the | Often used in the Far North and in the oil and gas industry | 10% heavier than steel, resistant to chemicals and corrosion | — | For pipelines of critical areas |

| Material grade | Steel 10, 20, 09G2S, 10G2, 15x5m, 10x17n13m2t, 13khfa, etc. | |||

.

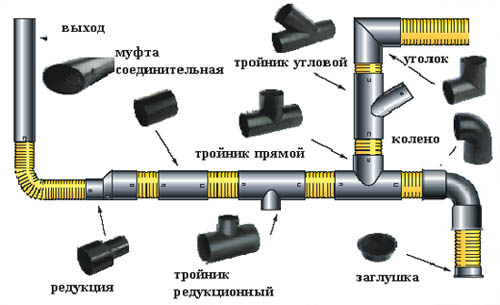

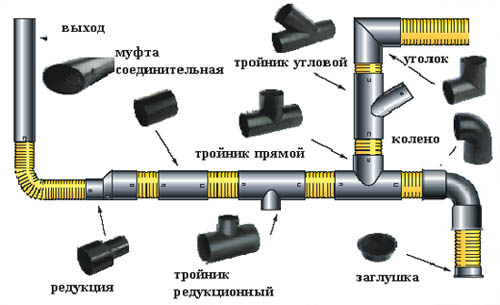

HDPE fittings for water supply

For the assembly of an internal water supply system, the plumbing market offers a wide range of PVC pipes and fittings for water supply.

The name of the HDPE is taken from the manufacturing method, it has nothing to do with the pressure in the pipelines. Therefore, for the arrangement of systems operating at elevated pressure, reinforced products with thickened walls are selected.

Plastic fittings for water pipes have proven themselves well when working with temperature drops, intra-system pressure. Highly resistant to corrosion.

Types of HDPE fittings:

- Compression.During installation, the retaining ring is clamped with a nut. They are used when assembling a metal-plastic pipeline in open areas indoors.

- Welded. A special soldering iron melts the outer surface of the pipe, the inner surface of the fitting, and the parts are joined. After cooling, a monolithic connection is obtained.

- Combined. Welded on one side and threaded on the other. Designed to connect plumbing devices.

- Adhesive. A special adhesive based on dichloroethane is applied to the joints, which dissolves the plastic surface. The details fit together. After solidification, the joint is similar to a welded one.

- Press fittings. The ends of the part are crimped with a special electric or pneumatic tool.

PVC pipe couplings

In a large assortment of PVC fittings, the coupling is one of the most demanded parts. By their purpose, they can be divided into 2 types:

- couplings for connecting pipes;

- protective couplings.

When installing, as well as repairing water mains, couplings with embedded heaters are used. The prepared ends are inserted into the sleeve. A special power transformer is connected to the contacts.

Parts are heated to the melting point. When heated, the mating surfaces are tightly pressed against each other, the unit is welded.

Compression couplings are provided with internal or external threads. The docking elements are secured with a nut cover. The sealing is provided by an O-ring.

What is an American woman and valves for?

American is a two-piece detachable sleeve connection. One half is threaded and the other is a union nut. Both halves of the connecting elements are tightened with a nut. A gasket is placed between them, ensuring the tightness of the connection.

Benefits:

- convenience, ease of installation;

- connection quality;

- the ability to quickly dismantle to clean the contaminated area or replace;

- the ability to repeatedly mount the docking station;

- convenience of connecting additional elements to the water supply system.

There is only one drawback - the high production cost.

American women are available with a flat and tapered connector, can be straight and angled with different angles.

Valves are elements of pipeline shut-off valves. Serve to supply water or disconnect it to the water supply system. They make it possible to control the pressure by opening the valve or damper more or less.

In the event of an emergency, you can stop individual sections for repairs to eliminate defects.

PVC pipe plugs

Plugs are parts of special piping equipment. Their main purpose is to shut off the water supply. By installing the plug in a separate area, you can repair it. The main line will be in operation.

Plugs come in plastic, metal and rubber.

Crosspieces for PVC pipes

When assembling the water supply system, the crosses are installed at the branch points of the pipeline, as well as when pipes are joined at different levels.

The crosses can be of the same diameter and with the transition to other sizes.

PVC pipe contours

There are situations when on the line of the pipeline it becomes necessary to bypass any element. This is done by selecting the necessary fittings - angles, couplings, adapters.

Equal Tee Classification

Equal tees are divided into the following types:

- simple mortise without reinforcement - needed in systems with pressures up to 2.5 MPa, if the pressure is higher than 2.5 MPa, then the pipes must be of small diameter;

- Tees with reinforcement - are used in systems with high pressures up to 4 MPa, where structural reinforcement is required. Such tees are divided into subspecies - with a thickened fitting, with a saddle and with linings.

By the type of manufacture, equal tees are divided into:

- welded - made by welding two parts of the pipe (neck and body). The body is the part that connects the two elements of the main pipe, and the neck is the part of the tee that connects to the branch pipe. Of all welded elements, the most economical simple mortise;

- stamped - made by extrusion on presses. They are distinguished by high strength due to the smooth transition from the body to the neck;

- stamped-welded - in this way tees with a large diameter are made. First, the body and the neck are stamped separately, and only then they are welded together.

Equal tees are made primarily of low alloy or carbon steel. They are used for the transportation of neutral liquids, and if it is an aggressive or food-grade environment, it is made of stainless steel.

You can find out the range of tees and their prices in your city here:

- Astana;

- Almaty;

- Karaganda.

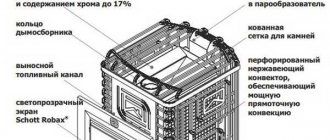

PVC tee design

Externally, a tee is a part of a pipe with a side outlet, to which it is easy to attach an additional pipe and create the desired branching.

The T-piece can also be used for a regular connection without connecting another trunk, but taking into account the fact that in the future it may be necessary. For example, if it is planned to bring out another pipe after some time, then the tee can be installed in advance, and the additional outlet can be closed with a plug for now. Installing a branch pipe when the time comes will be a fairly simple operation: you just need to remove the plug and connect the pipe.

We recommend that you familiarize yourself with: Types and functional features of a flanged check valve

Types of transition tees

Reducing tees are divided into:

- tees that have a crimp nut and a press sleeve;

- tees that have both a compression nut and a threaded end;

- a tee with fastening, their body is fixed to the support using cast brackets, into which self-tapping screws can be inserted. The ends are designed for threaded or crimp connections.

It should be noted that the press sleeves are made of stainless steel, and the seals are made of polymers. For the body, brass is used as the material. Threaded ends are made using taps and dies. To connect metal-plastic pipes using transition tees, both crimping and pressing methods can be used. In the case of a crimp fitting, a collet fitting is taken, in the case of a crimp fitting, a press fitting.

Installation

Installation of fittings is divided into two types - this is a compression connection (quick disconnect) or using welding equipment.

Electric welding connections

They are widely used in industry. The pressure in the system is allowed from 1 to 2.5 MPa.

This connection has an embedded electric heating segment (metal resistance wire). Each product has a barcode with information; required voltage and time for connection. There are automatic devices. The installation process is fast and easy.

During welding, the material becomes homogeneous and airtight.

Weld fittings

Preparation for welding

- Pipe cut angle 90 degrees

- The chamfer is dismantled

- The surfaces are heated with a soldering iron nozzle and fixed.

- After the point has cooled down, the knot is ready.

If the pipe diameter is large and does not require turns, then butt welding is performed.

Fitting the fitting using a press is more difficult. Certain equipment is required. (Press pliers, nozzles, sleeves corresponding to the profile).

This installation has a significant drawback. In case of an accident, the entire segment changes.

Subject to the technology, the pressed fitting will last more than 30 years.

Compression fitting

This type of installation is perfect for self-laying pipes.It is easy to replace the components of the plumbing system. Only hands are needed to assemble.

The disadvantage is a short service life. The rubber tab will last a maximum of 5 years. For this reason, it is not worth monolithing this type of connection.

Note

Polyethylene grades

PE32 - high pressure polyethylene up to PE100 - low pressure. PE80 and PE100 are used for urban cold water supply lines.

Diameter and wall thickness

According to GOST 18599-2001, the outer diameter of a PE pipe cannot be lower than 10 mm with a wall thickness of 2 mm.

PE32 can withstand pressure up to 1MPa.

The maximum parameters are 1200 mm diameter with a thickness of 58.8 mm. Such a pipeline can withstand up to 1.6 MPa (16 atmospheres).

Plastic tees: types and applications

Plastic tees are used for sewer pipes. There are several common types:

- sewer PVC tee 87 or 90 degrees - for connecting vertical risers with horizontal pipes;

- sewer tee made of PVC at 45 degrees - for fastening plastic pipes in a horizontal branch;

- PVC revision is a sleeve with an additional third hole screwed with a special cap. It is needed so that blockages can be dealt with in certain parts of the pipes.

What are the sewer tees?

There are several types of tees for sewage.

- Equal straight lines. Typical solutions for connecting pipes at an angle of 90 degrees. The working passages have the same diameter.

- Straight lines with different passages. Tees that branch off at right angles. The diameter of one hole is different from the other two.

- Tilted at 45 degrees. Fittings for horizontal connections. As in the case of straight tees, they can be equal and multi-bore.

- Revision. Products with control openings. They are used for line maintenance and have a sealed cover.

Bathtubs and toilets, washing machines and dishwashers are connected via tees. With their help, branch lines are organized, pipes of various diameters are connected.

Fitting materials

All connectors for the water supply network are classified according to the materials of manufacture.

They may be:

- Copper fittings for water supply.

Copper fittings

The advantages of using such products:

- When using copper products, the temperature range can be from (-200 ° C) to (+ 250 ° C).

- The ductility and strength of copper do not decrease from exposure to low temperatures, but increase, in contrast to other materials.

- Resistant to the formation of corrosion, the harmful effects of ultraviolet radiation. They are not subject to the destructive actions of many aggressive chemical compounds.

- Easy assembly of copper elements.

- Low roughness coefficient.

- Environmentally friendly material.

- A beautiful appearance allows you not to mask the fittings, but to choose an open gasket, making them design elements.

The disadvantages include:

- High cost.

- Incompatibility with other types of metals, for example: when connected to steel pipes, an electrolytic reaction occurs, which leads to corrosion of the metal.

Tip: To avoid corrosion, special adapters should be used.

- Plastic.

Plastic plumbing installation diagram

The use of plastic products is the best option for the plumbing system, especially if the fittings are compression.

Their advantages:

- Easy installation.

- Relatively low price.

- Corrosion does not form. They react only to alkali and other aggressive chemical reagents.

- They are available in a wide variety of options and modifications, including compression fittings that allow angled connections at joints.

- You can use plastic fittings for drinking water supply, heating, water drainage.

Disadvantages of parts:

- UV-resistant.

- Low resistance to mechanical stress.

- Wastewater disposal is not always possible, especially when the sewerage is located in cold climates.

- Made of polyvinyl chloride - PVC.

PVC Fittings

- Polyethylene - HDPE.

Polyethylene fittings

- Polypropylene - PPR.

Polypropylene accessories

The use of PVC, polyethylene and polypropylene fittings is a very practical solution, in which a reasonable ratio of quality and price compared to products made from other materials.

They are distinguished by a long service life and environmental safety. Withstand high temperatures and large pressure drops within the system.

- Brass.

Brass products

They are used most often by home craftsmen when assembling a variety of pipelines with their own hands. The range of such products outperforms fittings kits made of any other material.

- Cast iron - tees, bends, bends.

Cast iron fittings

Such products are rarely used, but their relative cheapness keeps them on the market for parts for pipelines. These are hard, but rather fragile parts, they are afraid of strong shock loads, especially in systems with water hammer - sudden pressure surges in pipelines with the presence of liquid in them.

- Steel.

Steel elements for pipelines

Their assortment is similar to cast iron parts, but more often the products are made without threads, for welding, including for pipelines made of stainless steel.