The foundation for the stove Modern stoves for the baths are distinguished by high performance and compact dimensions, but they are far from always installed in baths and cottages. After all, many owners of such structures wish to have ancient stoves made of baked bricks and tiled.

After all, such an oven will not only provide an optimal temperature regime in the room and create a sufficient amount of steam, but also has a high performance. But the mass of the furnace from the brick is large, as are the dimensions, so you cannot do without a special foundation.

The foundation for the furnace was not made in ancient times, because the material of the furnace was often made of wood, less often made of clay, so it was enough to strengthen the floor of the building. Now stoves are built from bricks, revetted and decorated with decors.

They can make a barbecue compartment, provide a fireplace, create a completely homely atmosphere in the house. In addition, such a stove is capable of heating large areas if you correctly think over the ventilation and heating system, and make the fireplace open and protected.

Calculation of the foundation for the furnace

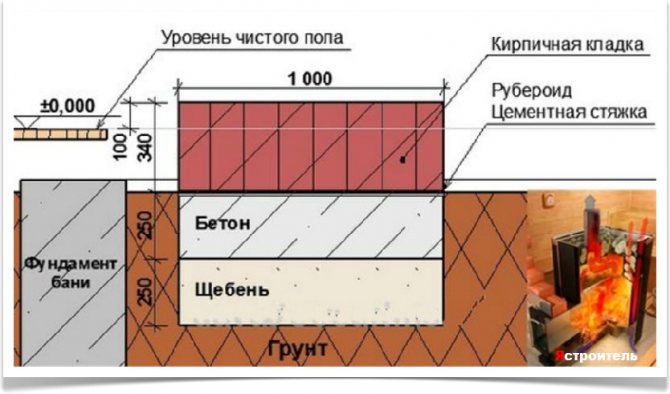

Foundation diagram for a metal bath stove

Considering that modern furnaces are built from fired bricks, their weight will be taken into account in the calculations. Wood and clay structures weigh less. So, the dimensions of the foundation depend on the dimensions of the furnace and its weight. For example, one cubic meter of brickwork weighs 1350 kg with mortar.

If you calculate the volume of the future structure, then it will not be difficult to calculate the mass. Therefore, if the weight does not exceed 750 kg, then the existing foundation will withstand the load, but if it is more, you need to equip a separate base. And here a lot depends on the type of soil on which the stove will stand, because this is an ordinary structure and calculation norms are accepted as for a building.

Also taken into account are the parameters of the mass of the barbecue and fireplace, which are made from refractory bricks and lined with asbestos or steel, as well as the depth of soil freezing. The sole of the base should always rest on solid soil layers below the freezing depth, then the influence of seasonal soil movements will be minimized.

Construction of the foundation for a metal furnace

If you decide to build a foundation for an iron furnace, then you should not think about the need for a foundation, even if you use thin ultra-light steel in your work. If the future structure will weigh about 150 kg or less, then first you should prepare a pit and fill it with rubble. The layer is well compacted, in the end its thickness should be equal to 30 cm. A solution of medium fluidity cement should be poured on top and left for a day to harden.

The ratio of ingredients should be as follows: one part of cement, four parts of sand and liquid "by eye". From this solution, the base of the foundation should be poured. On the dried layer, pieces of roofing material are laid to exclude the effect of water, and after that the pit is filled with a mixture prepared in the following proportion: one part of cement, fine gravel in the amount of four parts, 2.5 parts of sand and water. With the help of a level, the master must check the horizontality of the base.

Choice of dimensions and location for installation

The foundation for a stove in a wooden house

At first glance, there is nothing special here, but this is only at first glance. For example, the size of the stove is influenced by the installation of additional equipment, such as a barbecue and a separate fireplace.

It is clear that they only increase the dimensions of the upper part of the structure, but at the same time the total mass of the load-bearing walls also increases. Therefore, the typical size of the foundation should be 50 cm greater than the thickness of the load-bearing walls.

Then you need to decide on the location of the chimney. It is a brick hollow pipe of small inner and large outer diameter, steel pipes are not practiced through their aesthetics. Therefore, it is necessary to clearly determine the size of the stove so that the chimney does not rest against the upper part of the supporting structure of the house.

It is clear that when modernizing a house, it is problematic to get around the problem of limited space for construction, therefore they practice vertical installation of barbecue and remote location of fireplaces connected to the main burner by a pipe communications system.

As a result, all this will lead to an increase in financial costs, but at the same time, the foundation for the furnace can be made as needed with your own hands.

The process of correctly installing the stove in the bath with your own hands

A bath stove can be purchased ready-made, while you need to carefully study installation instructions and follow it clearly. If you are building a sauna stove yourself, you must adhere to the rules for performing work so that the design is safe and efficient.

It is best to plan a site for the stove during the construction phase of the premises, taking into account its dimensions. It is possible to make adjustments in the already built bathhouse, but it is longer and more difficult.

What tools will come in handy

So that you can get the job done, you need to have such tools:

- Bulgarian;

- welding machine;

- electrodes;

- measuring instruments;

- building level;

- bucket;

- spatula and trowel;

- protective mask, overalls, gloves.

Whole tool prepares in advance, this will not only simplify, but also speed up the installation process. To create and install a stove in a bath, it is better to use new rather than used metal. It will be easier if you choose square or rectangular designs.

Seat selection

The place for the stove in the bath is chosen during its design. If a ready-made room is being converted into a bath, then the position of the oven must be correctly determined.

The metal stove should not be closer than 1.5 m to flammable structures. To protect them, it is envisaged to install special screens.

It is especially necessary to carefully choose the location of the stove in a wooden building. To make it convenient to throw up firewood and remove ashes, there should be a 1.2-1.5 meters of free space.

Important! When designing a furnace, the optimal placement option will be when it is heated at the same time steam room, dressing room and rest room.

Usually they choose the option when a stove with a heater is located in the steam room, and her the firebox is in the rest room. This allows you to heat both rooms, the heating process is carried out outside the steam room, so smoke will not get there. This option is suitable for both brick and metal structures.

An electric stove is installed in the steam room, and in the rest room and dressing room it is used warm floor.

Site preparation

The preparation process consists in creating a base for the stove. If possible, it is better to do high-quality and reliable concrete foundation:

- next to the dressing room they make a hole that is larger than the stove on 10-15 cm;

- the bottom is rammed and covered with sand, and then with rubble;

- a layer of film is laid, which serves for waterproofing;

- the frame is laid from reinforcement or from a mesh;

- concrete is poured.

Photo 1. The process of creating the foundation for the sauna stove: a hole was dug for the device, piles were installed, which will serve as a support for the stove.

The foundation should get stronger, so further work is carried out in 3-4 days... Roofing material is used as an insulating material.

Reference. The foundation is made either flush with the floor or on 10 cm above it, which improves the aesthetic appearance of the stove.

If the stove is metal, then the foundation can be omitted, and at the place of its installation, a base is created from a non-combustible material. If the floor is covered with tiles, then it does not require additional arrangement. A sheet of metal is placed on a wooden surface, its size 2 times the area of the stove... Ceramic tiles or asbestos-cement slabs are laid on top. You can make a base of refractory bricks, its laying is done on clay.

How to install a brick oven correctly

After the place for the furnace has been chosen, as well as the foundation has been prepared, and it has gained sufficient strength, you can proceed to the installation:

Preparation of masonry mortar. It must be made of clay.

Experienced craftsmen know the necessary proportions, and if you are a novice stove maker, it is better to purchase a ready-made dry mixture. The brick used for masonry must be able to withstand high temperatures.

Masonry... According to the developed or chosen design of the stove, they begin to lay it. The location of the smoke shafts is observed, it is imperative to control the installation process using a level and a plumb line. Different models of stoves have their own differences, but they all have a blower, a combustion chamber, a stove and a chimney.

Fire safety. Since the walls of the stove are thick, they do not heat up very much, but in order not to provoke a fire, the place in front of the firebox is fenced off with a metal sheet.

Chimney. During the creation of the chimney, the pipe must be well insulated.

Finishing. After laying the stove, its walls are processed with sandpaper, after which ceramic tiles can be laid.

How to put a metal stove

Keep in mind that a metal stove has a fire hazard class much higher than a brick one. You can buy a ready-made stove or make it yourself, there are many different designs for this. The installation process consists of the following steps:

- Surface preparation. Since the weight of the device is small, a base made of brickwork with a height 10-20 cm or a metal sheet covered with an asbestos board.

- Wall protection. The metal surface is very hot, so the walls nearby must be protected. For this, brickwork, porcelain stoneware, which are covered with heat-insulating material, are used. Be sure to install heat-reflecting screens.

- Furnace installation. It is carried out on a prepared base, the stove is filled with stones.

- Security. The floor around the firebox is covered with a sheet of metal, which is laid on a heat-insulating material.

Photo 2. The process of installing a metal stove in a bath. For fire safety purposes, the area around the device is covered with metal sheets.

- Chimney installation. It also has its own requirements: above the roof, the pipe must protrude at least 50 cm, from the ridge - 1.5 m, not lower than the height of the gable roof. The part that is in the room is made of metal with a thickness 5 mm, and the one that takes place in the attic and on the street is thermally insulated. The contact points of the chimney with the wooden ceiling and roof are also reliably insulated.

Attention! When choosing a metal stove for a bath, you need to pay attention to its power, which should correspond to the area of the room.

What is the best foundation for the oven

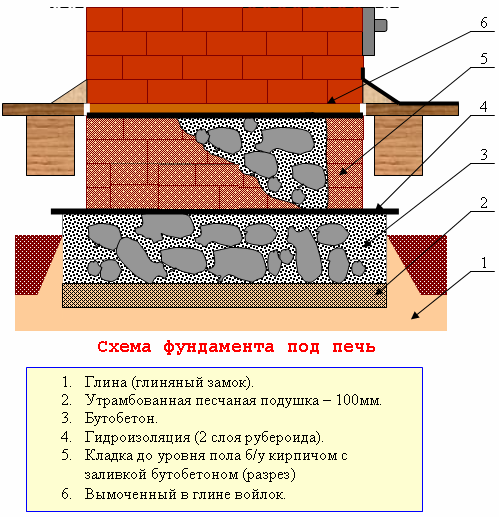

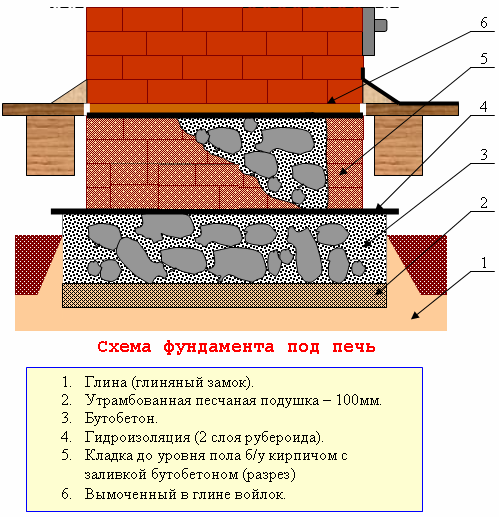

Furnace foundation diagram

When choosing the type of foundation, there are a number of rules that must be followed. It is also recommended to initially make a sketch of the project of the future structure, taking into account the installation sites of the barbecue, fireplace, ventilation pipe and other communications, because their sealing is an additional mass for the outer walls of the stove. So, how to choose the best foundation for your oven?

- Detailed surveying and soil type analysis.If it is sandy or clayey with a large freezing depth, then pile-grillage or columnar structures cannot be dispensed with. If the soil is dense, then a monolithic concrete or precast block foundation can be used.

- The mass of the future structure. It takes into account: the material of the walls, internal and external cladding, the presence of a barbecue and a brick fireplace. The greater the mass of the structure, the more powerful the base has to be erected, therefore, even for small concrete furnaces, a monolithic base or a prefabricated structure on piles is better suited. You can check all the dimensions and calculate the mass of the future structure with your own hands, no special knowledge is needed here.

- Financial component. Considering that furnaces are always erected independently of the existing foundation, always with their own hands, then the design must be carried out comprehensively. Accordingly, if the bathhouse is built on piles, then the stove can also be built on a monolithic or pile foundation, and the dimensions can be quite compact. The main thing here is to make reliable thermal insulation and waterproofing of the floor of the house, so it is recommended to build the foundation for the stove under the already existing structure in the house.

Requirements for the base for a cast iron stove

Cast iron stoves weigh at least 200 kg, and together with stones and a chimney, the total weight will be approximately 400 kg. So the question - do you need a foundation for a stove in a bathhouse - is purely rhetorical: of course, you do.

The foundation for a cast-iron stove in a bath can be provided even at the stage of erecting the foundation of the main structure. It is being built, as well as under a brick stove.

It's another matter if the thought of buying a cast iron came into your head when the construction is completed, and even the floor in the steam room is laid. How to make a foundation for a stove in a bath in this case?

An acceptable solution in this situation is to install the heater directly on the floor. To strengthen it under the beams (logs), you can put additional supports in the form of brick posts, screw piles, etc.

The place of installation of the stove is laid out with bricks or lined with refractory sheet material.

Video about the foundation for the stove in the bath.

The small mass of the iron unit does not excuse the need for laying the foundation. Even small shifts and distortions negatively affect the overall service life and wear. A well-made foundation is a guarantee of durable use.

The process of arranging the foundation for an iron sauna stove does not take much time and effort. The erection is performed according to the algorithm below:

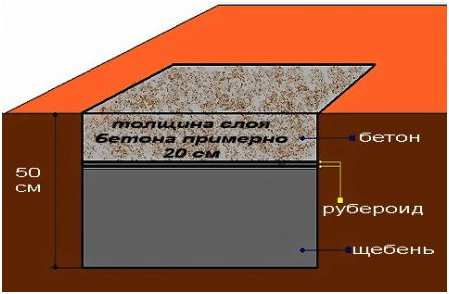

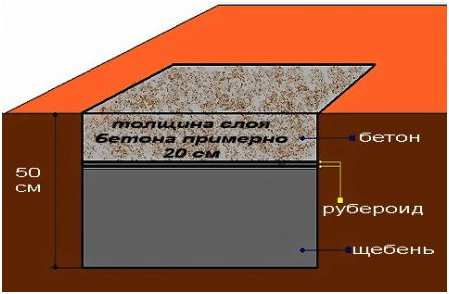

- Taking into account the type of soil and climatic features of the area, a pit of appropriate size and depth is dug.

- The bottom of the pit is covered with a crushed stone sole. Its thickness in the rammed state must be at least 30 cm.

- A layer of crushed stone is covered with cement mortar, on which waterproofing is laid after drying.

- A layer of concrete is poured onto the resulting structure, and its surface is neatly leveled. If desired, this building material can be replaced with brick.

A similar version of the foundation for a stove in a bath is simple to design. It will delight you with its durability at a relatively low cost.

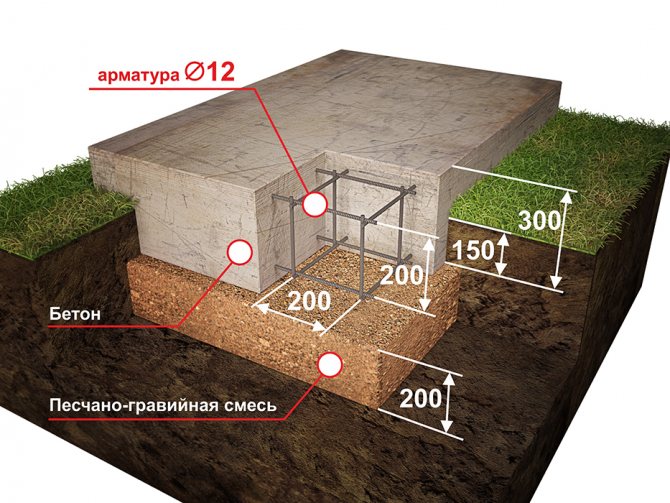

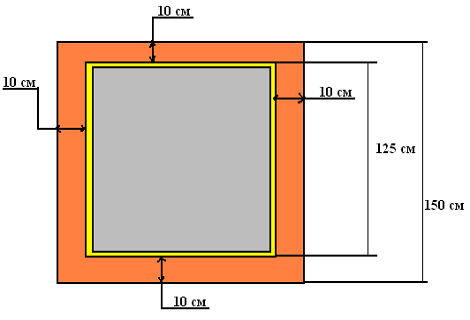

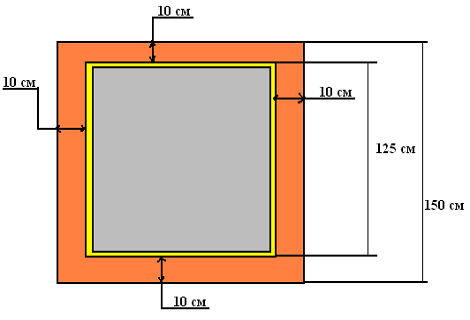

The conventional dimensions of a brick bath heating device are 1.5x1.25 m (LxB). The foundation is laid according to the following scheme:

- The pit must be dug 70 cm below the soil freezing line in winter. To exclude the influence of ground movements on the base for a brick oven, the foundation pit is made about 10 cm wider on both sides.

- The bottom of the resulting pit is covered with a layer of sand 15 cm thick. Then it is filled with water. After the liquid is absorbed, it is necessary to fill up the sedimentary rock to the desired level. The procedure is repeated 2-3 times, then a 20-centimeter layer of crushed stone or broken brick is laid and tamped onto the resulting base. After that, water is again poured and sand is poured.Such manipulations are repeated until the rock ceases to settle.

- A layer of crushed stone 10 cm thick is poured on top of the sand pillow. After it is tamped, formwork is made inside the pit. At the same time, a space of 10 cm remains empty between the walls of the recess and the wooden form.

- The inner part of the formwork is reinforced with a reinforced frame.

When building a bath on clay and loamy soils, additional financial costs cannot be avoided. After all, the construction of inexpensive slab and strip foundations does not protect the earth from heaving at low temperatures. Similar ground movements are possible on some types of sandy soils. In order to ensure the safety of the entire structure and extend its service life, a pile foundation is being erected for the bath stove.

Pits with a diameter of 20 cm are drilled with a hand drill to the depth of freezing, which are half filled with rubble, then tamped. A kind of tubes are rolled up from roofing material, acting as a formwork. They are inserted into the recess and poured to the desired level with concrete. After 10 days, when the building material is gaining the necessary strength, it is required to start making a foundation slab for the furnace.

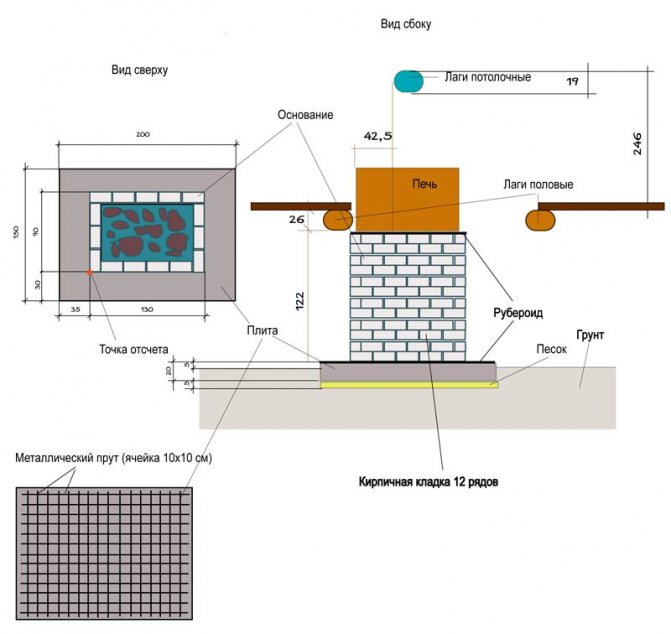

Regardless of the type of base chosen, it is necessary to ensure thorough waterproofing along the upper edge. To do this, two layers of roofing material, coated with bitumen, are laid on the foundation.

This design is optimal for even distribution of the oven weight.

It should be noted that the foundation for the furnace is needed even when it is made of thin ultra-light steel, and was purchased under a well-known brand in a special hardware store. Since if it turns out to be slightly skewed at the time of work, even if it is almost imperceptible to the eyes, then nothing good will come of it at all.

Thus, for a furnace made of sheet steel, the weight of which is not more than 150 kg, the foundation must be made as follows:

- Stage one. It is necessary to dig a pit and fill it well with rubble, and then tamp it thoroughly. Already tamped, this layer should be at least 30 cm.

- Stage two. It is necessary to pour a solution of ordinary cement of medium consistency onto the tamped crushed stone and leave it all like this for a day - in order to freeze. The ratio is approximately the following: a part of cement, four parts of sand, and also water by eye. This is the so-called sole of the foundation.

- Stage three. On well-dried cement, several pieces of roofing material should be placed for full waterproofing.

- Stage four. Now the pit must be filled with concrete, which is made in the following proportion: a part of cement, four of fine gravel, as well as 2.5 parts of sand and a little water.

- Stage five. After the work done, it is necessary to check the horizontal level of the base of the foundation made with a level.

Many friends and acquaintances often ask: do you need a foundation for a metal stove. I will say unequivocally from my practice - no. Although many argue, referring to information on the Internet. Well, please, you want - do it. But from my experience (the third decade has gone) I will say: I will never "warm my head" about the foundation for a metal furnace.

Furnace foundation diagram

It is enough for her to make a good base of the floor. A weight of 200-300 kilograms is not so much. Good underfloor joists can handle this local load with confidence. Usually, instead of veins for the floor, I lay a metal channel with a height of 14-16 cm. Two “sticks” of the channel, laid on the edge under the stove, create a reliable support. It is practically impossible to bend and deform such beams.

A corresponding bar is laid inside the channel, and a wooden floor is fixed with self-tapping screws at an angle to this bar. Just do not put the boards on "bare metal".It is best to spread two layers of roofing material on it. This will save the tree from rotting.

Directly under the oven, on the channel, you can lay a sheet of metal, and then put the "heart of the steam room" on it. That is, it is not worth laying a wooden floor under the stove, since it will still have to be changed over time and the "iron stove" in this case will not interfere with this. Do not forget about fire safety. If the floor is wooden near the stove, a sheet of metal must be spread over it, so that accidentally dropped coals do not do "miracles".

I think my point is clear. If you have a small metal stove, then don't worry about a separate base for it. Good underfloor beams and that's it. It's another matter if the stove is large and heavy (there are models and stones weigh 200 kg as much), and even more so a brick one. Here, one cannot do without a solid foundation.

Although, in my house, which was built back in 95, a brick oven is on the floor. The supporting beams are made of rails. The stove is large, five-turn, with an oven and a water tank. The chimney is also made of bricks, 7.5 meters high. The weight of the whole structure is decent. Until now, there are no cracks on the plaster and there are no cracks in the walk-through ceiling opening. They usually form there due to the different winter movement of the foundations of the house and the stove.

All neighbors suffer from this very problem (the stove cracks and "moves away from the ceiling"). After looking at these "troubles" and analyzing them, you come to the conclusion: continuous errors in the arrangement of both foundations (house and stove). Moreover, in our Siberian conditions, and even on marshy soils. You should not commit them in order to then solve the problems created by yourself.

Why arrange a foundation in a bathhouse for installing a heating unit? A properly made base performs the following functions:

- absorbs mass loads, ensuring stability. Installing a massive structure on an ordinary bath floor will provide an uneven transfer of forces from the mass of the unit to the base of the structure, causing it to shrink and skew;

- makes it difficult to freeze the soil under the heating device. With significant freezing of the soil in the periodically heated room of the bath, there is a high probability of cracks in the brick structure;

- protects the floor covering from overheating, prevents fire hazardous situations, perceiving an increased temperature when heated. Installing the heating device on a wooden floor can cause the wood to self-ignite.

Before starting earth and construction activities, decide on the future design of the bathhouse foundation, which can be from the following materials:

- Brick. The total weight can be from 400 kg to 10 tons.

- Sheet steel. The total weight of the structure is 150 kg and more.

The type of foundation for the stove in the bath depends on the weight of the building and the properties of the soil

A conventional heating device made of metal, weighing about 200-250 kg, can be installed on a solid floor of a room without the need for a separate support surface. However, in order to comply with fire safety requirements, it is advisable to prepare a separate site made of asbestos and a steel sheet laid on top.

Erecting a classic base for a barbecue stove with your own hands

It is advisable to make the foundation for the furnace simultaneously with the general foundation.

- First, you need to carry out detailed calculations of the dimensions of the future structure, take into account its location in the house and outline the boundary angles of the pit location.

- Now you can start digging a pit for a monolithic structure or separate indentations for pillars. Considering that concrete is not used in the construction of wooden baths in rural areas, then the masonry is made from brick or natural stone.

- A sand and gravel cushion is laid at the bottom of the trench and pressed. Then it needs to be poured with liquid concrete.

- Brick is started to be laid according to the ready-made mortar.Here it is desirable to obtain horizontal and vertical masonry surfaces, so that then a minimum of time and money would be spent on leveling the base under the waterproofing layer.

- After laying all layers of bricks, thermal insulation and waterproofing works are carried out. The erection of the brick foundation can be considered complete, and the stove in the house can be erected in a few days.

Soil types

A strong and high-quality base for the stove is the key to its long service, since any movement of the ground can cause serious damage to any structure. This is especially true for stoves made of brick or other stone. The question often arises, do you need a foundation for a furnace that is relatively light, weighing up to 750 kilograms? This type of stove is really an exception to the rule and only needs a solid floor structure.

In the conditions of the Russian climate, winters are accompanied by frosts, the result of which is the freezing of the soil to a considerable depth. Therefore, when building foundations in our strip, it is recommended to lay the foundation at least to the depth to which the soil freezes in a particular area. It is important to take into account the type of soil itself.

All soils found in Russia can be divided into four types:

- Sedimentary and alluvial soils They form in places where in the past there were seas, lakes and rivers. The density of such soil is sufficient to erect any foundation on it for a bath stove. As an exception, porous clay and loess soils. Porous clay, absorbing moisture, is capable of significantly swelling and expanding even more when frozen. Loess soils, when saturated with moisture, completely lose their strength, turning into slurry. When equipping the foundation in conditions of porous clay, it is necessary to pull out a pit below the depth of soil freezing. As a basis for it, stone rubble is tamped and a sand cushion of 50-100 centimeters is arranged. The masonry itself is best done from rubble stone or using it.

- Continental soils Continental soils are gravel-sandy soil formed as a result of the destruction of rocks for natural reasons. They are rightfully considered one of the most successful types of soil for the construction of a foundation, since they are least susceptible to the influence of weather conditions.

- Filled soils Fill soils are formed at the sites of construction sites, as well as at sites where a building previously stood. Sands mixed with gravel or crushed stone, and caked for at least three years, can serve as an excellent foundation for a foundation without special preparation. If the bulk layer is less than three years old, and it is not possible to get rid of it, you can tamp it together with the rubble layer.

- Permafrost A significant part of the territory of Russia is covered by permafrost. The foundation for a stove in a bathhouse on such soil should not only serve as a reliable support and protect against frost heaving, but also act as thermal insulation between the surface of the earth and the stove itself.

Back to content

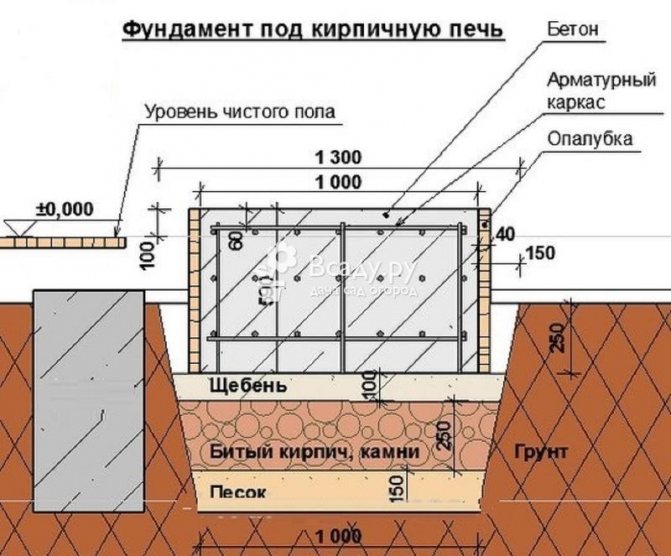

Furnace foundation device

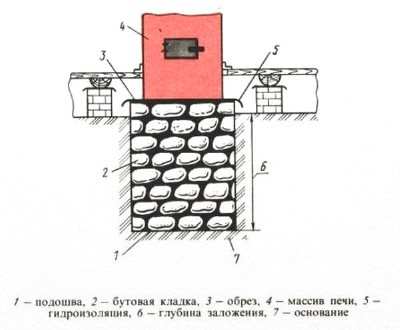

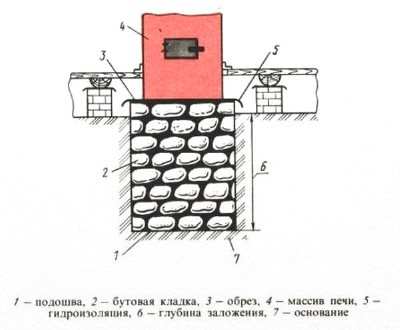

If it is decided to build a classic massive brick stove in the bathhouse, then the foundation must be designed so that a space of 40-50 centimeters remains between the planned stove and the walls of the building. Its dimensions must be made 5-6 centimeters larger than the oven installed on it.

Since the weight of the kiln is critical in choosing the type of foundation, it makes sense to calculate the total mass of bricks going into the building. The calculation is easy to carry out, taking the figure of 3.5-3.6 kg for the standard weight of a red brick. Stoves-heaters are rarely lighter than 1200 kilograms, therefore, they require such a massive base, with which only the foundation for a Russian stove can be compared.

On clayey soils with groundwater close to the surface, the foundation for such a furnace is best arranged on piles (a metal frame or a slab of reinforced concrete is installed on top of the pillars dug to the depth of freezing of the soil). The foundation for the furnace must be arranged separately from the foundation of the walls, leaving a gap of at least 3-5 centimeters between them, thereby ensuring a free settlement of each structure. It is best to fill the gap between them with dry sand, insulated on both sides with roofing felt.

Between the proposed floor of the bath and the site of the stove foundation, it is necessary to leave 15-20 centimeters, that is, the distance for 2-3 rows of brickwork. After laying the foundation, its surface should be covered with a cement screed (a layer of cement mortar) a couple of centimeters thick and leveled to ensure a completely horizontal surface. The first row of the brick base of the stove should be laid out on top of the waterproofing, which reliably protects the brick from dampness. Moisture has a destructive effect on this material. In addition, the damp bottom row of bricks can create dampness in the bath room and, as a result, mold and mildew.

If you are lucky enough to start construction on dense rocky or sandy soil, the foundation for the stove can be laid to a depth of 30-40 centimeters. To do this, it is enough to remove the fertile, vegetative layer of the earth and carry out work on top of the indigenous soil. For this, both brick and reinforced concrete or rubble stone are suitable.

Back to content

How a pile foundation is installed

Screw pile foundation for the furnace

- First, in strictly marked places, you need to drill deep cylindrical holes, their diameter is about 20 cm. Instead of drilling, you can use rectangular or square depressions for pillars of the corresponding shape.

- Pour a layer of sand and gravel cushion on the bottom of the hole and compact.

- Install asbestos pipes into the prepared holes or start laying with bricks up to the required height of the supporting grillage.

- Install vertical reinforcement with horizontal straps in the pipes, then pour everything with concrete.

- After the concrete gains its grade strength, align the upper cut horizontally, install the grillage and secure it.

Recommendation. After installing and fixing the pillars, you need to additionally cover the upper open part of the columnar foundation with waterproofing and install a blind area. It is also recommended to leave a free gap between the base and the ground, which is then eliminated by free shrinkage of the base.

If a hanging grillage is used, then the subfloor is additionally covered with a layer of thermal insulation, and the shallow foundation - with several layers of bitumen or waterproofing.

The foundation for a stove made of natural stone

Foundation scheme for a furnace made of concrete and rubble stone

- The pit is being marked, the alignment marks should recede from the load-bearing walls at a distance of up to 15 cm.

- Then a layer of rubble 15 cm thick is poured onto the bottom of the pit and rammed manually or by a mechanized method.

- A wooden rigid formwork is formed along the outer perimeter of the base, which can be double along the inner contour. But in terms of cost, such a design will turn out to be a little more expensive and time-consuming.

- The walls of the formwork are covered from the inside with a layer of roofing material for waterproofing.

- A layer of large stones is laid on the base, which must be poured with liquid concrete. This is how each individual layers are erected as the height of the base increases. Each layer must dry for a while to be durable enough.

- Pouring with concrete must be stopped when the height of the base reaches a mark of 10 cm from the level of the finished floor. Then the surface is checked with a building level, if necessary, trimmed with liquid concrete.

- The finished leveled surface must be covered with plastic wrap and left to dry for several days.

- After dismantling the formwork, a small gap will remain between the walls of the pit and the foundation. It must be covered with sand, having previously covered the walls of the base with tar or roofing material in several layers.

The foundation for the oven - warnings, advice on choosing, instructions for work Video

Zero cycle works traditionally “eat up” 25-30% of the total construction budget. A lot, right? But saving is not appropriate here, since a healthy "root" is the key to the integrity of the whole "plant".

The foundation for the furnace is made in the form of a solid base plate, and it should not be connected to the base of the building itself. But its depth depends on three main factors:

- the height of the aquifer;

- type of soil;

- the level of soil freezing.

All these data are obtained during geological exploration of the site, when specialists, by drilling control wells, obtain soil and water samples and make appropriate analyzes. The procedure is paid (from $ 50), so many homemade products run the risk of building "by eye" or are guided by folk methods (for example, a willow frame). It is not always possible to guess, therefore, a weak foundation for the stove shows its "dissatisfaction" with such symptoms:

- Through cracks in the body.

- Partial destruction of individual parts of the masonry.

- Violation of the integrity of the chimney.

The main feature of the listed defects is that the breakdown cannot be repaired. After the restoration of the furnace, cracks and collapses are repeated, which directly indicates an incorrectly laid foundation. Here you remember with a "kind" word about your pseudo-economy - but it's too late. It is impossible to carry out "sparing" repair of brick stoves with a weak foundation. We'll have to completely demolish the unit and redo it again.

For those who are afraid of the complexity of zero-cycle work, it is useful to remember how hard our ancestors worked on this stage: they prepared massive logs and manually adjusted them to each other in order to achieve the correct support for their “wet nurse”.

Now in the homemade arsenal there are two available ways to get a strong foundation for a brick oven:

- Assembly of the slab. Small reinforced concrete blocks or ceramic bricks are used as building materials.

- Pouring the slab. The base is formed from concrete mortar, into which a rigid frame made of river rubble or iron reinforcement is introduced.

The monolith also has disadvantages: the slab must stand at rest for at least three weeks. In principle, such a delay in construction is not a problem. For example, if the foundation for a sauna stove is being set up, then during a technical break, the builders are engaged in finishing work in the steam room.

To describe the progress of the work, we chose a monolithic furnace foundation, reinforced with reinforcing rods, since this type of base is the most popular among homemade people. Remember, the base plate should be 5 cm wider than the stove body.

- We are preparing a pit for the foundation. The dimensions of the pit are additionally increased by another 15-20 cm. This margin is needed for the correct laying of the formwork and the filtering side layer of crushed stone, bricks and sand. The depth of the pit is calculated according to geo-prospecting (an allowance for filtering "cushions" is added).

- We lay the sand "pillow" under the foundation. A 15-centimeter layer of sand is poured into the bottom of the pit, which is carefully tamped. To prevent shrinkage, it is spilled with water until the level of the backfill stops dropping. In the process of tamping, sand should be poured to the desired level.

- We lay the crushed stone filter for the foundation. A 20-centimeter layer of rubble is poured onto the compacted sand, mixed with brick fighting and medium-sized stones. The stone "carpet" is lightly sprinkled with a sand mixture to fill the voids formed in it. For better sand penetration, water is also needed.Then lay out a 10-cm layer of finer gravel and cover the resulting filtering "pillow" with a double layer of roofing material.

- Formwork installation. A solid plywood (or plank) "fence" is installed along the perimeter of the pit, which is reinforced with a support every 50 cm. There must be at least 10 cm of free space between the edge of the pit and the formwork.

- Reinforcement mesh tab. The bottom of the pit is poured with concrete (starting layer 4-5 cm), which will serve as a support for the "skeleton" of the foundation. As soon as it grabs, pre-connected reinforcement meshes are placed in the pit (there are ready-made sets on sale).

- Pouring solution. Concrete is prepared according to the following proven proportion: cement - 1, sand - 3, crushed stone - 5 and water. Before pouring the solution, the formwork is thoroughly moistened in order to prevent the absorption of water from the concrete by the tree. The working mixture is poured in layers (20 cm each), gradually reaching the zero mark of the plate. Each layer is carefully knocked out with a hoe to expel air bubbles from the solution. The top of the slab is carefully leveled and, after the first setting, is covered with a tarpaulin (roofing felt).

During all three weeks, the stove foundation should be hidden from the sun and periodically moistened.