Varieties of muffle furnaces

By design features, the devices are divided into:

- tubular or cylindrical;

- horizontal or vertical.

By the type of heat treatment composition:

- air;

- vacuum;

- based on inert gas.

Only an air muffle furnace can be made at home, therefore it is about it that will be discussed in the article.

By the features of the thermoelectric heater:

- gas;

- electrical.

Of course, a gas furnace will bypass in operation 3-4 times cheaper than an electric one, due to fuel economy, but such a furnace, firstly, is prohibited by law to manufacture and use, and secondly, it is technically extremely difficult to make a muffle furnace using gas with your own hands.

Due to simple materials, the stove can be made in any convenient form, including one that ideally suits the interior of the room.

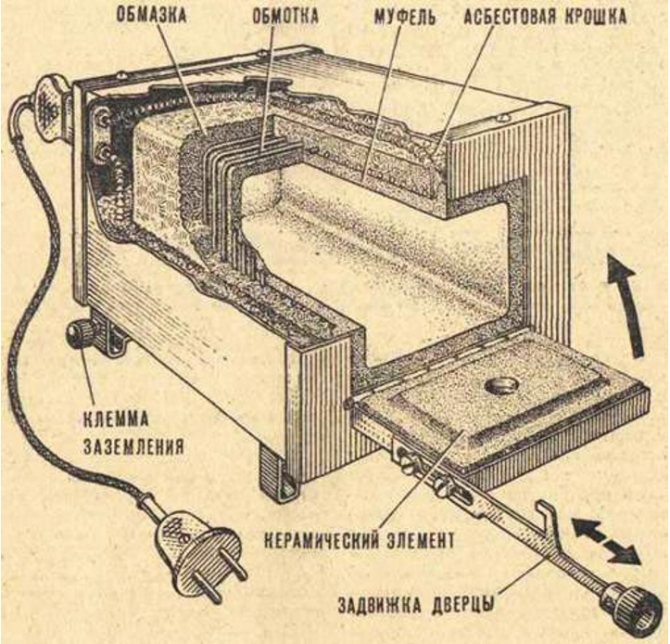

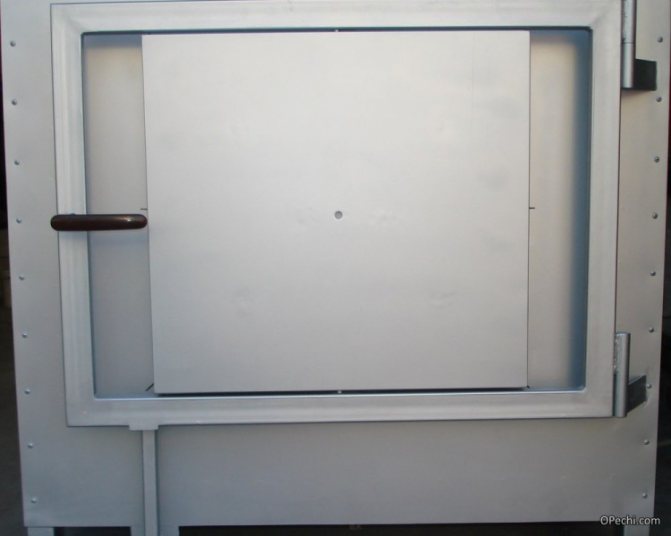

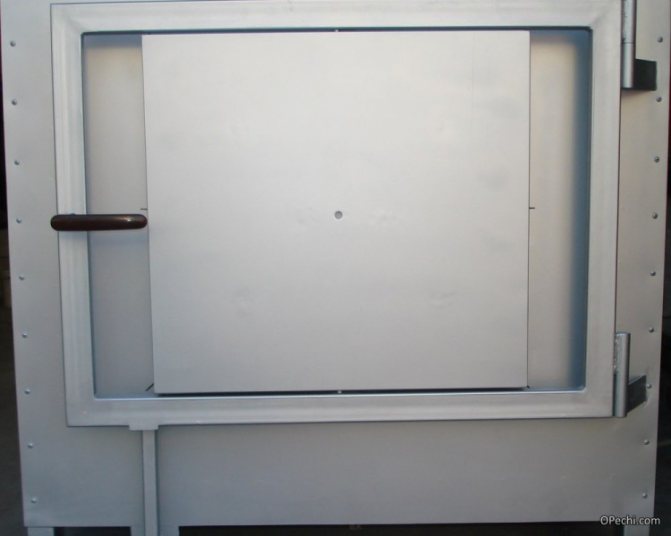

Photo 2 Scheme of an industrial muffle furnace

Manufacturing the device

In this case, we will tell you how to make a vertical muffle furnace for firing ceramics with your own hands.

To do this, you need the following tools:

- angle grinder (grinder) and 1-2 circles;

- electric arc welding and electrodes;

- locksmith tools, including nippers;

- 2mm nichrome wire.

and materials:

- 2.5 mm steel sheet or used oven body;

- corner;

- fittings;

- basalt wool;

- refractory fireclay bricks;

- refractory mortar;

- silicone sealant.

Main elements

Housing

Ideally, the body of an electric oven or miracle oven is suitable as the basis for a homemade muffle furnace for fusing or cupelling, since it already has all the necessary insulation. All you need to do is remove or remove all plastic elements.

Photo 3 Old oven in the form of a muffle furnace body

If it was not possible to find such an oven, the body can be welded from a sheet previously cut into blanks. Weld all the sidewalls, clean the seams with a metal brush or grinder and cover with a primer.

Making a case from sheets, although a little more complicated, allows you to make the design that fits in size for a particular room.

A heating element

A key component of the device, since it is on it that the temperature in the oven and the heating rate depend. You will also need to make a thermostat for a muffle furnace with your own hands, or purchase a ready-made one. A nichrome wire will act as a heating element, the diameter of which is selected depending on the maximum temperature. The minimum and most consumable diameter is 1.5-2 mm.

Nichrome on a standard spiral can withstand 1100 degrees, but it is necessary to exclude the ingress of air, otherwise it will burn out. Fechral is best suited for a muffle furnace - its working temperature is 1300 degrees, and it is “friendly” with air.

Photo 4 Heating element

Any electric muffle furnace, even the smallest one, made by hand, when heated to 1000 degrees, spends about 4 kW. Check all wiring and set the auto-stabilizer to 25A before use.

Thermal insulation

The most important aspect of work, which is responsible for the integrity and efficiency of the entire structure. Inside the muffle furnace, fireclay bricks are installed on fire-resistant glue. To the size of the oven, it is cut off with a grinder. Basalt wool is used on top.

Photo 5 Fire-resistant glue Terracotta

Some forums for the manufacture of muffle furnaces recommend using asbestos for masonry. This is really a fire-resistant material, but already at a temperature of 650 degrees + it begins to release carcinogens.

Making a homemade muffle furnace

The first point can be skipped for those who use an old oven as a body.

Self-production

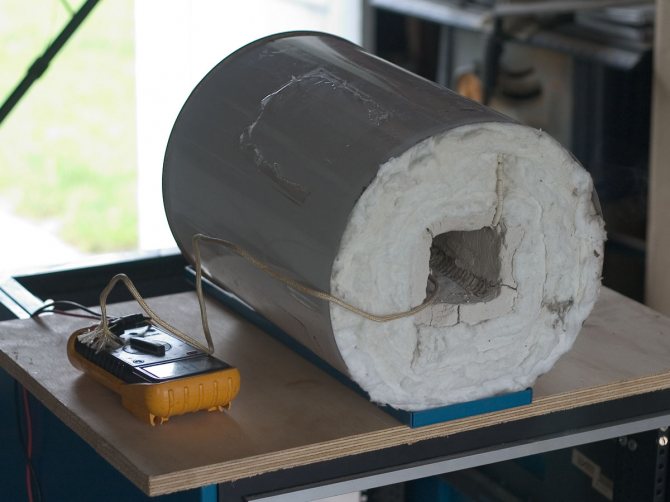

If there is no way to find an old oven, then you will have to use sheet metal and electric welding. According to the required dimensions, using a grinder, the walls of our future product are cut from a sheet of metal. To simplify the process, the oven is made in a cylindrical shape. Then the strip of metal is rolled up into a cylinder and welded with one seam.

The metal circle will serve as one end, and on the other side a door will be installed a little later. The structure must be strengthened, and for this it will be necessary to weld several corners at the junction of the walls of the cylinder and the circle.

We bend a sheet of metal into a cylinder

From the inside, the walls of the resulting cylinder are sheathed with basalt wool. This material was not chosen by chance. The limiting temperature in contact with an open fire is 1114 ° C degrees, the material has poor thermal conductivity, which we just need in these conditions, and is also safe for human health even at critical temperatures.

The edges of fireclay bricks are processed with a grinder in such a way that in cross section it is a trapezoid. From such elements, you can make a kind of refractory ring.

Making a refractory ring

Since the edges will turn out at different angles, and you will have to disassemble the structure, it is recommended to put a serial number on each brick. Having laid the bricks on a flat surface so that the inner edges "looked" up, make shallow slots at a slight angle, a spiral will be inserted into these slots. The grooves must isolate the spiral turns from each other and ensure the distribution of the heating element throughout the entire core. Now again you need to assemble the bricks into a ring and pull them together with a wire or a clamp.

The prepared spiral is placed in the groove, and its ends are brought out, where the connecting terminals will be mounted. The spiral ring represents the heating element of the oven.

Spiral laying

A cylinder with basalt wool is installed with its end on a horizontal plane. Fireclay bricks are placed at the bottom to protect the round wall from high temperatures. A heating element is inserted inside, and all voids are filled with heat-resistant glue. It will take several days for the device to dry. During this time, you can come up with and make a door for the oven. The tighter it closes the firebox, the longer the homemade spiral will serve. A self-built muffle furnace is capable of melting precious metals, baking clay, melting some metals.

Good to know: How is a baby brick oven built, from foundation to masonry

In order to burn small-sized clay products at home, you can make a simpler version of the furnace. It consists of a hotplate with an open heating element and a suitable sized ceramic pot. It is impossible to put the part directly on the spirals, therefore, fireclay bricks are placed under it and covered with a pot on top.

Furnace materials

DIY muffle furnace

At home, you can assemble a simple oven design with your own hands. At the same time, a "do-it-yourself" muffle furnace will run on electricity. The main element - a muffle - can be made of clay or folded from fireclay bricks.

For a clay muffle, a blank is made of cardboard or plywood.The resulting box is covered with a layer of clay with a thickness of 1 cm, dried until it hardens (3-5 days) and fired in a coal oven. The firing temperature is 700-800ºC. This is sufficient to vitrify the clay structure and create a strong inner chamber.

DIY muffle furnace

The resulting ceramic muffle is wrapped with wire (nichrome or fechral, 1 mm in diameter) - it will work as a heating element. In order to secure the wire to the casing, it is covered with a second layer of clay (which is also dried and fired in a coal oven). The ends of the wire are left open for further connection to the mains.

To fold the fireclay muffle, grooves are made in each brick (for the location of the heating coils). After folding the bricks, a spiral wire is placed in the grooves. To fix it in the grooves, the spiral is coated with clay or reinforced with wire.

The finished inner chamber is placed in a metal case. It is welded from steel sheets with a thickness of 2 mm or more. Holes are left in the housing for connection to the heating wire.

A finished muffle is placed inside the casing, the contacts are connected and thermal insulation is made. Basalt wool or asbestos chips are used as an insulating material (asbestos is a more harmful option, carcinogens are released when it is heated).

Note: Such a do-it-yourself muffle furnace allows you to burn ceramic products. For metallurgical annealing or remelting of non-ferrous alloys, an industrial furnace is required.

Self-made muffle furnace

Preparation for work

Any work should begin with a certain preparatory stage. Even if an action plan is approved, it is necessary to prepare tools and materials, otherwise long breaks may occur in the work, which will negatively affect the master's performance and the quality of the constructed structure.

Before the direct construction begins, you will have to immediately prepare a grinder for cutting sheet metal and processing fireclay bricks. Grinder circles must be appropriate. The list will be supplemented by electric welding with consumables and other locksmith tools for everyday use.

Good to know: How is a convection oven used to heat a house, what is it like

The material includes nichrome or fechral wire, basalt wool, fireclay bricks and sheet iron with a thickness of at least 2 mm. Depending on how the structure is made, some tools or materials may not be useful, and additional ones will be purchased in the process.

Handicraft oven

Types of muffle furnaces

Muffle furnaces are classified according to several criteria. They are divided according to the heating method:

- electrical;

Electric muffle furnace

- gas.

Gas muffle furnace

By the type of protective atmosphere:

- Air (the muffle limits the mixing of air between the workspace and the heaters).

- Vacuum (inside the muffle they create a rarefied space - a vacuum).

- Furnaces with a special atmosphere - the space inside the muffle is filled with a special gas (inert, nitriding, reducing, etc.).

The working temperature inside the oven can vary from + 400ºC to 2500ºC. On this basis, muffle furnaces are classified into types:

- For moderate heat up to 500ºC.

- For medium temperatures up to 900ºC.

- For high temperatures up to 1400ºC.

- For extremely high temperatures - up to 2000-2500ºC.

Note: The heating temperature determines the price of the oven. The more the furnace heats up, the higher its cost. In addition, the prices of muffles depend on the size and functional equipment (thermocouples, type of heaters, automation).

Useful video

Check out the video that shows how to start making a muffle furnace: what materials and tools are required, what needs to be done first, and what actions are not recommended.

Cover making

- Cut a circle out of steel that is identical in diameter to the already fully assembled structure.

- On top of the glue "plant" fireclay brick - it will provide sufficient sealing.

Weld on the sides of the handles so that it is convenient to lift and remove the lid and latch for closing.

Cover the edge with fireproof silicone, before that the surface must be degreased (even White Spirit will do).

As a reminder, when the oven is running, it must be closed. Excessive air ingress will lead to rapid wear of the nichrome.

Materials and elements for work

A muffle furnace for melting aluminum with your own hands or hardening steel parts - we prepare a full range of materials for production. We will need:

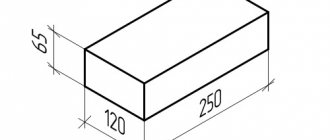

- fireclay brick;

- thermal insulation;

- sheet metal or any material at hand. If you have an old safe with an inner layer of sand, then you are in luck. Such a furnace will last a long time and will save on the outer layer of thermal insulation;

- refractory clay, sand or ready mix for brickwork. To seal cracks and voids, you can purchase a fire-resistant sealant or use a solution;

- electric cable, ceramic insulators, automatic connection in the dashboard.

Materials for the manufacture of muffle and furnace lid

We use the most modern materials for the manufacture of ovens. For the working layer of the lining (muffle and furnace lid), we use lightweight refractory bricks, which we bring from Germany. This brick has excellent thermal characteristics, namely, it has low thermal conductivity, high thermal and heat resistance. The classification temperature for this brick is 1430 ° C. With all this, the brick is quite lightweight due to its low density and is well processed mechanically. This allows you to mill grooves in bricks for the installation of heating elements. Milling ensures the highest precision of the spiral grooves.

Lightweight refractory brick

Lightweight refractory brick

Lightweight refractory brick

Oven cover

The furnace cover is made of two layers of refractory bricks. In this case, the second layer overlaps the seams of the first layer, which increases the strength of the lid. Most stoves of Western and Russian production have only one layer of bricks.

Also, the bricks are chamfered, which prevents the bricks from chipping when the material expands (heats up).

In the outer layers of the muffle and the furnace lid, we use additional insulating refractory layers, which have an even lower thermal conductivity with a significantly lower weight.

Refractory mats made of ceramic fiber, mullite-silica cardboard (MKRKG), etc. can be used as such materials.

Thus, the lower the thermal conductivity of the materials, the better the thermal performance of the furnace.

| Material | Maximum temperature application, ° C | Thermal conductivity, W / m * K | Density of material, kg / m3 |

| Lightweight brick | 1430 | 0.28 at 600 ° C | 770 |

| Ceramic fiber | 1260 | 0.27 at 1000 ° C | 128 |

| MKRKG-400 cardboard | 1150 | 0.11 at 600 ° C | 400 |

The complex application of these materials significantly saves energy resources, as well as saves time for heating and cooling furnaces. Unfortunately, many modern, both Western and Russian manufacturers make kilns for firing from ceramics only with the use of refractory bricks, making the kilns less efficient.

How muffle furnaces work: design

The main structural element of the furnace is the muffle.Parts for heat treatment (or gold for remelting, a medical instrument for heat treatment, ceramics for firing) are loaded into its chamber. The muffle is made from a chemically inert material.

The muffle chamber is located inside the furnace. In this case, the space between the outer casing and the inner chamber is filled with a heat insulator. High-quality thermal insulation determines the efficiency of the device, as well as its safety (it limits the strong heating of the casing and prevents the possibility of getting burned on it).

Muffle furnace chamber

Heating elements are located outside the muffle or in its walls. They heat the inner chamber, which in turn transfers heat to the workspace. The operation of the heating elements is controlled by the regulator. It controls the temperature and heating time, the whole heat treatment process. The level of automatic regulation affects the price of the heating device. The more regulating functions, the more expensive the oven is.

Muffle: construction and materials

The following materials are used for the manufacture of the inner chamber:

- ceramics;

- ceramic fiber;

- corundum;

- refractory (fireclay) brick.

The choice of material for the manufacture of the muffle is determined by the operating conditions and the purpose of the furnace. For example, a refractory fiber muffle is used for heating in a neutral environment. Corundum chambers - can be used in chemical environments. But the ceramic muffle is universal. Due to its inertness, it is used for various tasks (remelting, heat treatment, roasting).

Principle of operation

The device of a muffle furnace can be varied, it all depends on the purpose. The unit operates from the mains, and is used for high-temperature heat treatment of various materials. The temperature regime of heating is limited to 1150 degrees. The power of the heating elements must not exceed the specified temperature.

The muffle should be made of high quality ceramic material, this will ensure a gradual decrease in temperature between the muffle and the heating element. During operation, the furnace consumes a large amount of electricity, the muffle is heavy and has slow heating properties. Due to these properties, the loaded materials do not come into contact with substances that are formed during combustion - gases, soot. This protects metals and chemical samples from extraneous contamination and inclusions.

We recommend: Smokehouse for cold smoking

Materials and tools for the assembly of the structure

Before you start making a muffle furnace with your own hands, you need to acquire a set of tools. Useful for work:

- welding and electrodes;

- Bulgarian;

- nippers and scissors;

- respirator, glasses;

- steel or oven case;

- metal corner;

- galvanized mesh with a mesh of 2 x 2 cm;

- door - ready-made, or homemade;

- fireclay brick;

- refractory mixture;

- heat-resistant silicone;

- perlite or basalt slab (roofing insulation 1 - 2 cm thick);

- nichrome wire 1 mm.

The thickness of the metal for the case should be 2 - 2.5 mm, since the final structure will be very heavy. For the same reason, if thin-walled household appliances are used, they must be reinforced with a steel angle.

Those who are going to burn ceramics do not need temperatures above 800 ° C, so they can make a muffle from any porcelain or earthenware dish or an old flushing cistern.

Refractory masonry

To make a muffle, you will need:

- refractory brick, best of all fireclay, and its light appearance;

- asbestos products (fiber, slabs);

- refractory plates.

If you use a brick as a refractory, then a special refractory mixture for chamotte is required for its masonry. It is purchased dry and diluted with water to the required consistency, the proportions are indicated in the instructions.You can also use mortar, refractory clay, or other refractory masonry mix.

Before laying out the refractory, customized in size to match the parameters of the camera. For this, bricks or slabs are cut with a grinder.

When laying slabs or bricks, it is necessary to lay them very tightly together. In this case, the layer of solution should be sufficiently thin, no more than 5 mm. Before laying out the bricks, they should be put in water for 30 seconds to fill all the pores.

First, the bottom of the structure is laid out, then the walls and the top of the muffle. You need to try so that the seams do not coincide in the vertical plane.

Furnace description

You can smelt in a furnace not only metal, but also ceramics, glass, wax. A wide variety of work that can be performed with this equipment is due to the fact that the operating temperature range inside the furnace is from +20 to +1000 degrees Celsius. The direct process of assembling a muffle furnace with your own hands can be carried out quite quickly, provided that all the necessary components are at hand. However, you will have to give several days for the material to dry, since it is often made from fireclay bricks.

Necessary materials

Materials will be needed directly for the manufacture of the furnace:

- fireclay brick

- one and a half kW spiral

- heat resistant clay or mortar

After its manufacture, it is placed in a casing. It can be welded from 2 or 3 mm steel sheets. Its dimensions are taken based on the dimensions of the oven. Also, in the form of a casing, you can use an old gas or electric oven, having previously removed all plastic parts and elements from it. The space between the oven and the casing is filled with an insulating material such as rock wool.

Top-loading kilns are best suited for firing ceramics. In furnaces where mainly work will be carried out with melting, quenching or other processing of metals, the process of heating the product should be controlled by using a temperature sensor, the workpieces are loaded into such chambers horizontally.

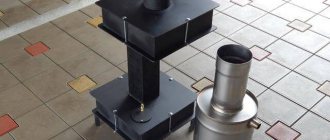

Let's consider step by step an example of a muffle furnace

In this case, an old iron rectangular tank is used for the casing. It should be slightly improved and it will be fully suitable for its role. Cutting off the edge of the tank with a grinder, on which there is a round hole, 5-10 cm wide. Drill holes along the edges for fastening the door to the body on the curtains.

The work should begin with planning: Assemble a brick oven dry, make markings on it from the inside, in those places where you will need to lay a spiral. In the brick, according to the markings made earlier, with the help of a drill, using a victorious drill, recesses should be made. In the illustration below, the drill is set at an angle to the groove, this is how you can optimally achieve the desired result.

We put the prepared brick into the oven; an external frame for it should be made from the corner. We put a spiral into the grooves. We coat the entire structure with a mortar solution on water. All cracks should be covered.

Next, you should make an electronic unit that will control the heating of the spiral. Moreover, it will not be easy to heat up the oven, but it will be stepped heating. For this, a step thermostat is used. A support should be made under the muffle furnace in order to avoid losses at the bottom. The frame from the corner is cut out and welded at the corners, on the sides, legs are welded onto it, also from the corners. A row of plates are welded on top.

We use a special fiberglass heat shrinkage. It serves to protect a thermocouple, the characteristics of which are as follows: chromel-alumel (TXA) diameter 0.5 mm, length 1 m. We also use a ceramic tube with two thermocouple holes. You will need another thick heat shrink to power the spiral.We put on a heat-resistant fiberglass cambric on the thermocouple, insert its tip into a ceramic tube. At the top of the stove, a hole is made with an ordinary drill, and a thermocouple must be inserted there and covered with mortar. Allow to dry.

To connect, you need a special heat-resistant wire for electric ovens. The coated stove is hidden in a casing, its thermal insulation will be provided by basalt wool. At the top of the casing, you need to make a hole for the output of the power wires and the thermocouple to control it. Before the final packing in cotton wool, a test connection of the oven should be made.

The device itself is mounted on an asbestos sheet. The cotton wool should be laid with medical gloves. Control unit for the oven. Next, we proceed to the manufacture of the furnace control unit.

The set of accessories consists of:

- enclosure (taken from a small switchboard)

- electromagnetic contactee (in this case, still "Soviet")

- terminal blocks (one ceramic for connecting the nichrome spiral from the muffle furnace to the power wires, and more made of fire-resistant plastic for the main switching)

- machine for 16A; bolts, nuts, engraver; thick wire and plug

- thermostat Profile-M-1K multistage single-channel

The thermostat can heat up according to a complex schedule; you can set the heating time and temperature during this interval.

This is what the finished device looks like: