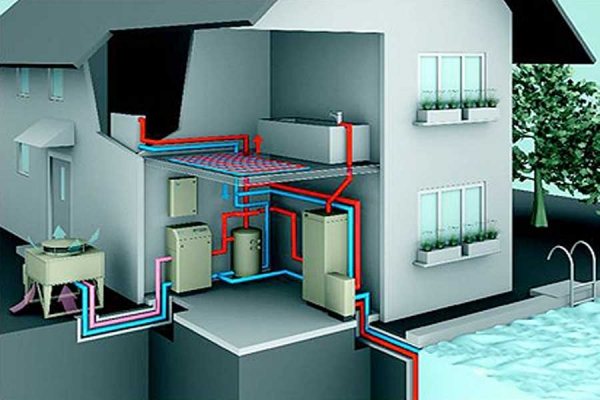

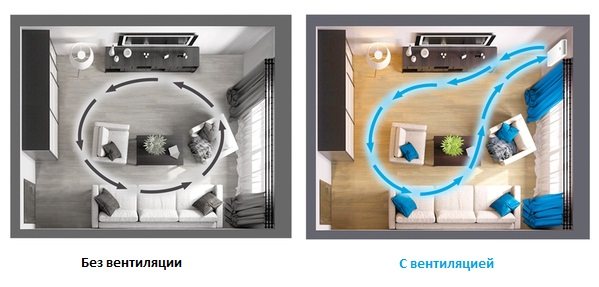

The most forward-thinking homeowners design two ventilation systems in their buildings at once: gravitational (natural) and mechanical with heat recovery (forced). In this case, the natural ventilation system is emergency and serves in case of malfunctions in the operation of the air handling unit and is used mainly in an unheated period. It should be remembered that during the operation of the mechanical ventilation system, the gravity ventilation ducts must be tightly closed. Otherwise, the effectiveness of the forced ventilation will be lost.

Types of heat recovery units

Heat recovery in the supply ventilation system is a relatively new phenomenon and is not yet widespread. There are several types of devices and a large selection of models for each type. Supply and exhaust ventilation with air heating and recuperation performs the following functions:

- Heat recovery;

- Fuel economy;

- Reducing the cost of equipment;

- Ensuring environmental standards;

- Reducing transportation costs;

- Reducing the cost of gas cleaning;

- Reducing the cost of the heating system.

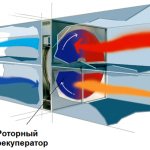

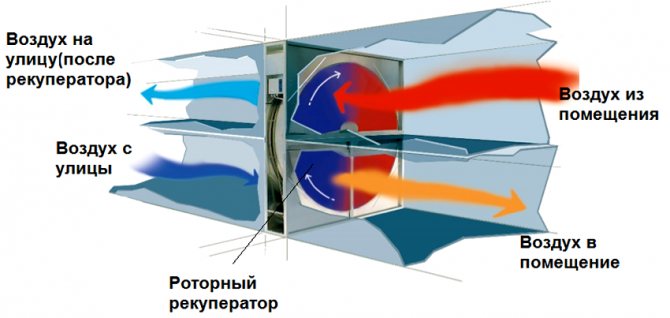

Rotary (drum)

The heat exchanger is suitable for areas with harsh climates. The drum is made of aluminum foil. By progressive movements, the heat is transferred from the extracted air to the supplied air:

- Heat is transferred to the supplied air;

- Mixing streams is less than 0.1%;

- Warm and humidified air returns.

Rooms dry out less. The net power is 92%.

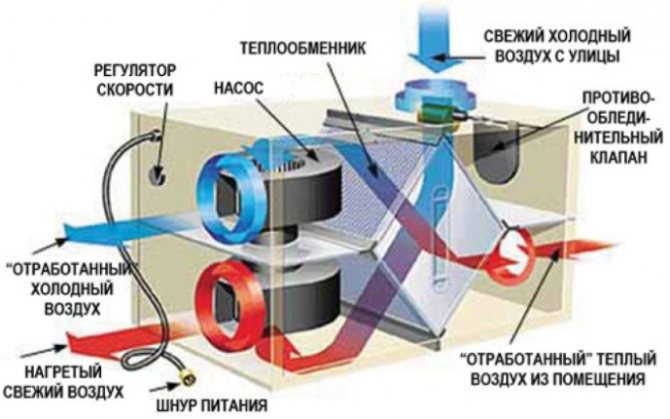

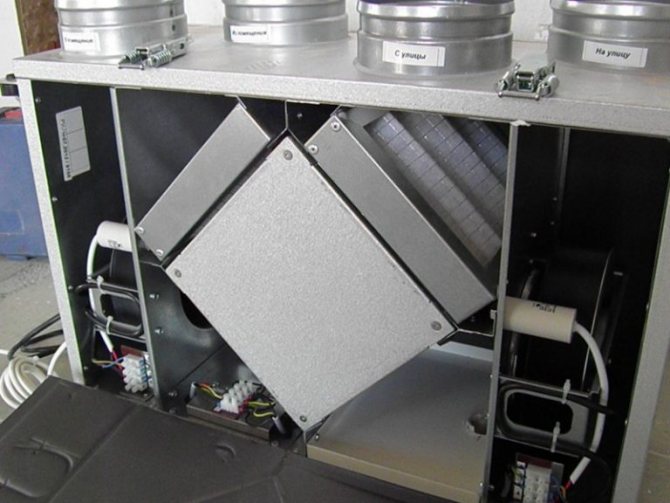

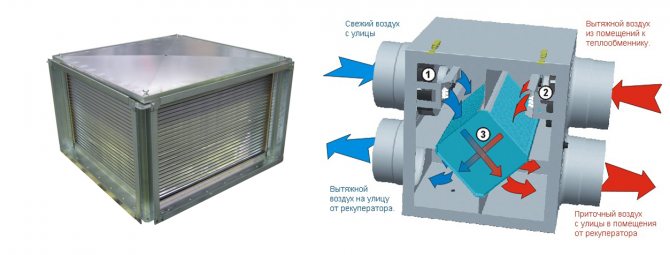

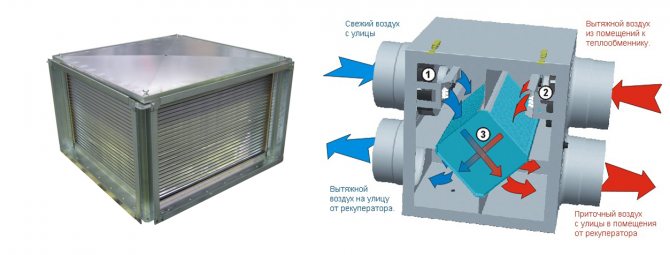

Lamellar cross recuperator

Designed for areas with mild weather conditions. The counter currents of the plate recuperator are separated by aluminum foil.

- Heat is transferred to the supplied air;

- Condensation is forming;

- Water drainage required.

The heat of the exhaust air heats the supplied air through the aluminum fins. Moisture condenses on the plates of the heat exchanger, which comes from the premises.

During warming up, the efficiency of the heat exchanger is zero, heat recovery does not occur. The overall efficiency of the air handling unit drops. The system returns up to 95% of heat.

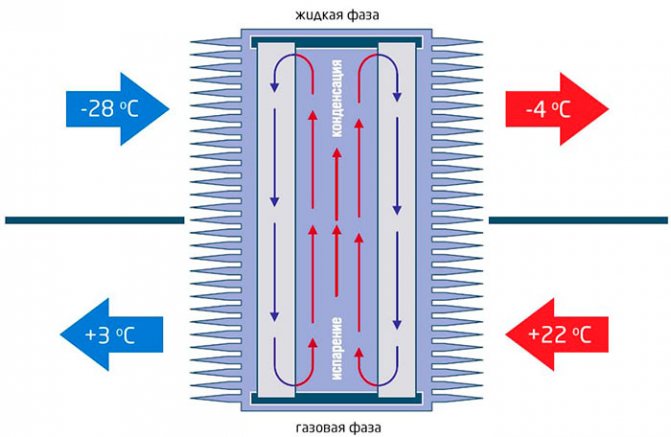

Heat pipes

This type is produced as a hermetically sealed tube from a material with good thermal conductivity. Freon is poured inside. The recuperator is placed vertically in the duct (it is permissible to install it at a small degree). The lower end is placed in the hood, the upper end in the supply ventilation.

Warm air flows through the lower duct at the bottom of the tube. Freon boils, vapors enter the upper part and meet the supply air, taking heat from the freon. The condensate settles to the bottom of the tube and the cycle repeats. Advantage: no moving parts. Disadvantage: poor performance, the system runs on freon.

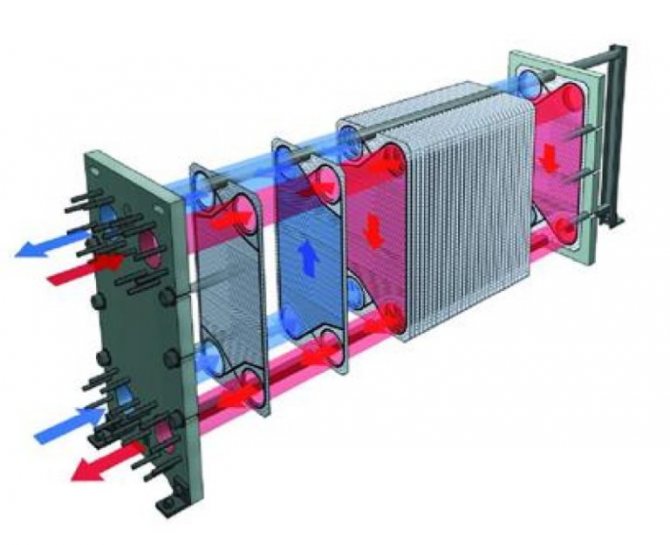

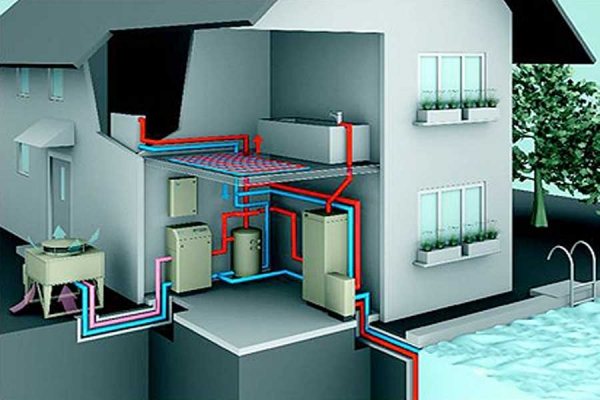

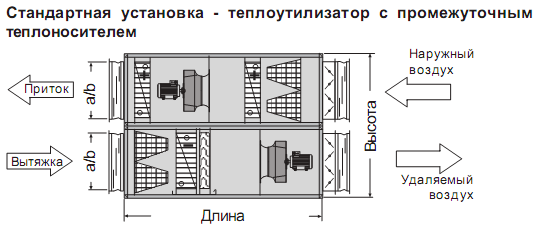

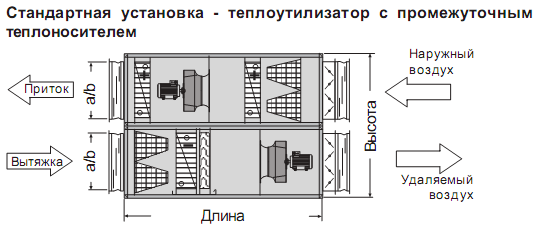

Intermediate heat carrier device

Water or a special solution is used as a heat carrier.

- Two heat exchangers are interconnected by pipelines;

- One of them is in the channel that draws air and receives heat;

- The heat passes through the coolant to the second heat exchanger, located in the supply air channel, where heating takes place.

The streams do not mix with each other, but the intermediate heat carrier reduces the efficiency by up to 50%. Additionally, the efficiency can be increased with a pump. The advantage of intermediate heat transfer fluids is that the heat exchangers can be installed at a distance from each other.Installation is carried out vertically and horizontally.

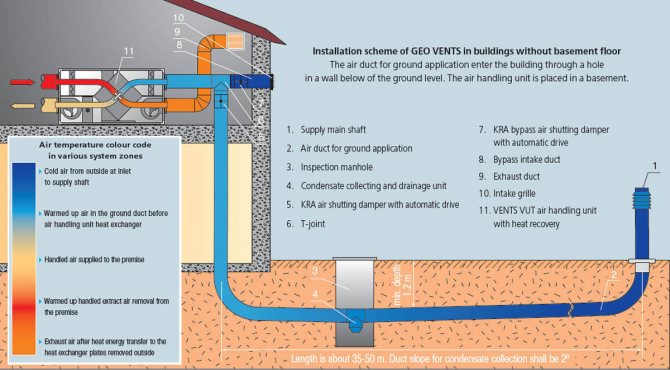

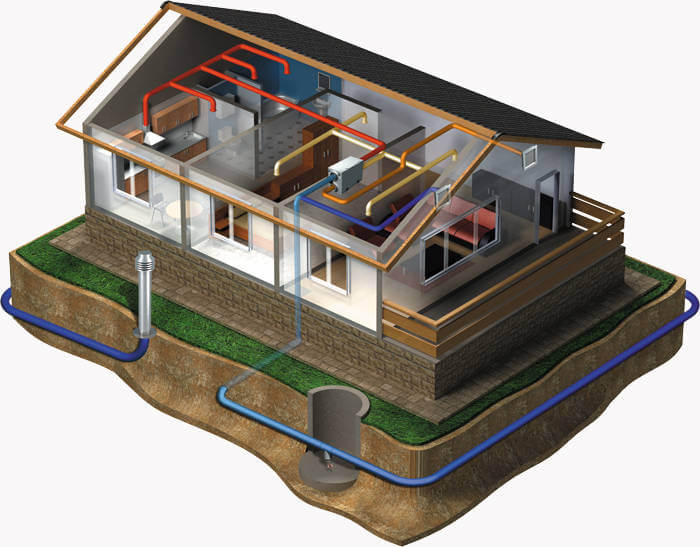

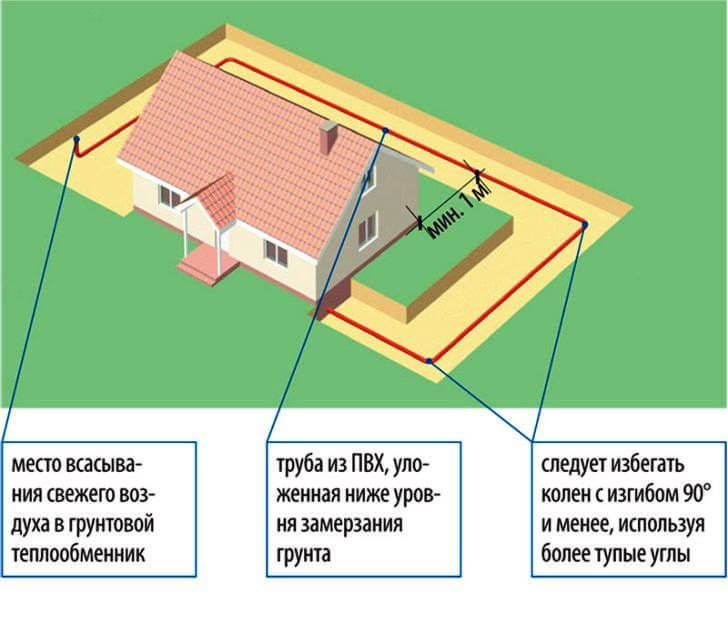

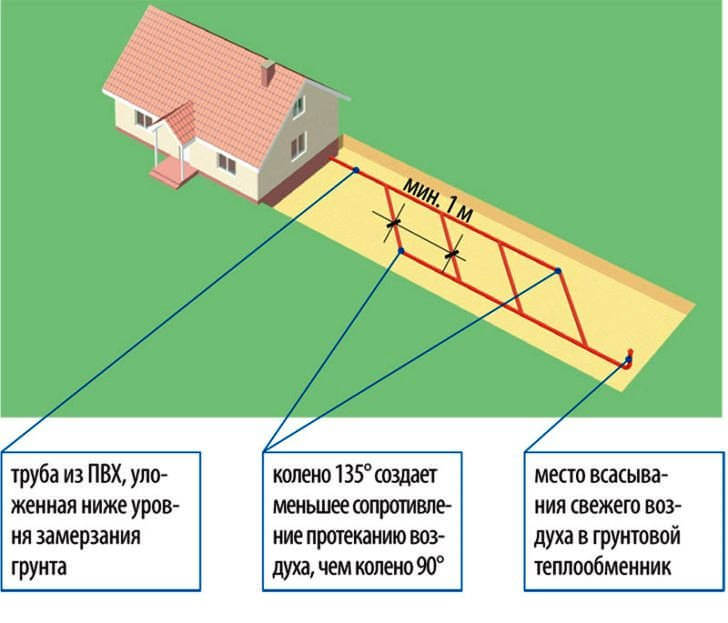

Ground heat exchanger

The cost of operating the system is reduced by 5-10%. If there is no ground heat exchanger, the air entering the recuperation system enters directly from the street. A pipe is laid with a ground heat exchanger at a depth of about two meters in the ground. The air temperature below freezing of the soil always remains stable in the region of + 10 ° C.

The air travels through the pipe in the ground and enters the heat recovery. It is much easier to compensate for temperature differences. The heating elements turn on less often, the heat saving becomes greater.

The ground heat exchanger must be made according to the project. Depending on the area of the house, a recuperation system is selected, which takes a certain volume of air from the street and, passing it through the entire ground heat exchanger, heats it up. It is important to consult an experienced designer. It is he who will be able to calculate the length and depth of the channel.

Conditions and features of operation

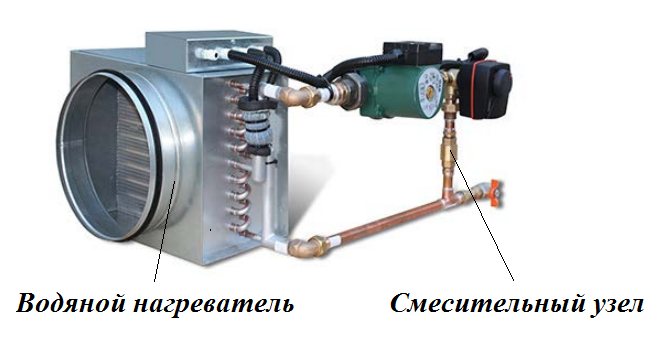

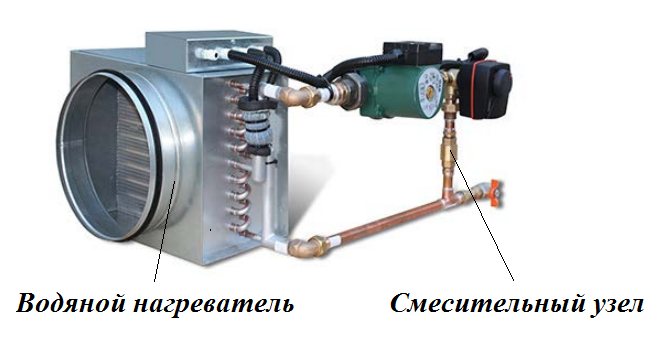

The water heater is connected to the DHW pipe and return

The principle of operation of a water heater for heating equipped with a fan is based on the heat exchange of two working media. Hot water is used as the primary heat carrier, and air is used as the secondary one. Heating of air masses is performed by transferring heat from hot water to a cold air flow. The efficiency of heat transfer depends on the temperature difference - it must be large.

When operating devices, several requirements must be observed:

- Performance figures are calculated prior to installation in a large room.

- Household models are compact, compatible with steam or water heating.

- The use of water with a temperature of more than 180 degrees in the mains is unacceptable - the heater will fail.

- For large rooms, a power control system for the heater is used in the form of a mixer with a three- or two-way valve.

- The maximum density of aggressive impurities in the air during the operation of the device is specified in GN 2.2.5.686-98 and GOST 12.1.007-76.

- The energy efficiency of the heater depends on the heat transfer coefficient. The value is indicated in the passport.

- Before installation in a home workshop or garage, it is required to install filters to remove chemical impurities.

- Three-row models are suitable for ventilation systems that supply outside air at temperatures from 0 to -40 degrees.

- Four-row modifications are launched in winter only when the temperature increases to 30 degrees per hour.

- The units are not suitable for forced or artificial ventilation - they pump air through duct elements.

Specifications to pay attention to when choosing

- Metal devices are effective in operation down to -10 ° C. At low temperatures, performance is noticeably reduced. As a result, electric pre-heating elements are used;

- When choosing, you should study the thickness of the case, the material of the cold bridges. The thickness of 3 cm is subject to additional insulation when the outside temperature drops below -5 ° C. You will have to double the use of insulating material if the frame is made of aluminum;

- Pay particular attention to the free flow values of the fans. It may happen that the head may be completely absent at 500 m3. Consumers find out about this, as a rule, when the recuperator fails;

- A big plus when additional functions can be connected to the automatic system. Thanks to improved automation, operating costs are reduced and the operation of the entire device is increased;

- The main indicator for deciding on which recuperator to choose is the ventilation pressure and power.A preliminary calculation is made of how much air should enter the house in one hour.

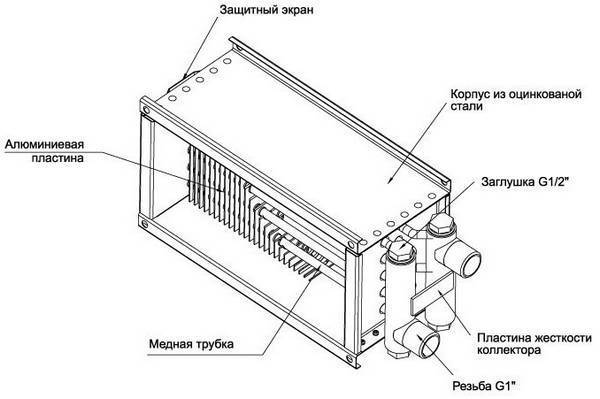

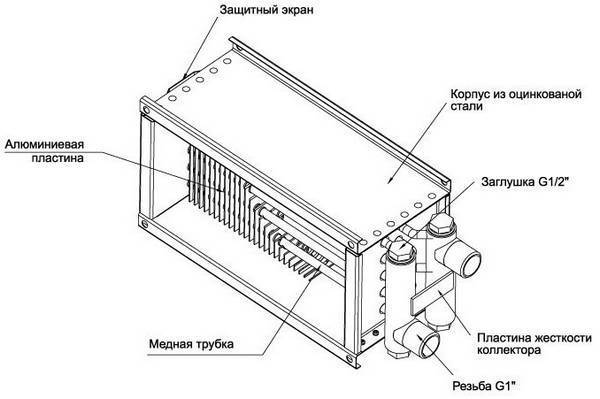

The principle of operation and design of a water heater

Universal devices operating on water are installed in places with a well-established heating system. A simple but quite effective design solution allows you to heat air in the range from + 70 ° C to + 100 ° C and is relevant for hangars, gyms, supermarkets, greenhouses, warehouses, large pavilions - that is, large rooms that require additional heating.

If you have ever used a household heat exchanger, you will easily understand the principle of operation of a water device. It also heats the air, but the role of an electric spiral enclosed in a small case is played by a set of metal tubes through which the heated coolant circulates.

The heating process is as follows:

- hot water heated to the required temperature (on average from + 80? C to + 180? C) from the heating pipes enters the heat exchanger, consisting of small aluminum, steel, bimetallic or copper pipes;

- the tubes heat the air passing through the device;

- the built-in fan circulates the heated air throughout the room and stimulates its movement in the opposite direction - to the device.

There is no need to specially heat the water, since it is part of the heating system, therefore, significant cost savings occur.

A standard water heater circuit is a hybrid of a heat exchanger, fan and convector. It is effective for heating large industrial premises, and when choosing the right piping - for cottages with a well-established ventilation system.

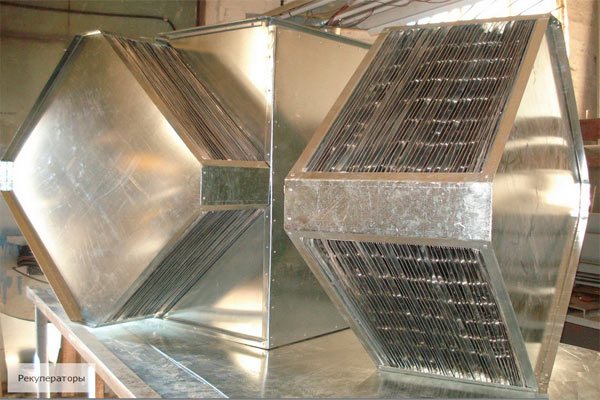

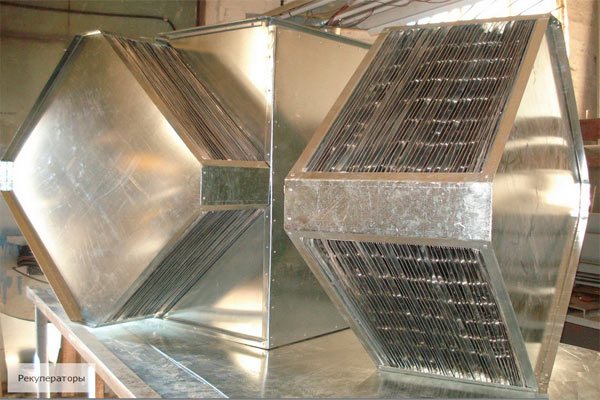

Rooftop recuperators

These ventilation units are used in facilities with a large working space. They filter, heat and supply air to the building. The air temperature is regulated by a duct heater or cooler. Its inflow is carried out partially or in full through the plate structure of the recuperator.

Characteristic

Such supply and exhaust ventilation systems are installed on the roof ceilings of buildings through holes made in them. The recuperators extract the used air collected from the ceiling and release it into the atmosphere, and its heat is transferred to the powerful incoming jet. The air supply is directed directly to the ceiling or directed to the work area. The recuperator can be an integral unit in the overall ventilation scheme of the entire facility. The device is easy to operate.

Design

Models of units are made of different power, which is measured by the volume of passing air in cubic meters per hour. The base of the device is a frame-panel construction made of aluminum profiles. The optimum thickness of the heat exchanger sheets is about 0.2 mm. For sound and thermal insulation, the walls of the case are laid with mineral wool. Recuperators are equipped with electric, water and gas sections for heating. The achieved efficiency is about 65%. Installation of supply and exhaust ventilation does not cause any difficulties. To do this, it is necessary to make a window in the roof and strengthen the structure - "glass" for the correct distribution of the load. Installing the recuperator on the roof does not take up the useful volume of the building.

Recuperator with water circulation

Characteristic

The thermal energy carrier is water or antifreeze supplied to the supply unit from a separately located exhaust heat exchanger. The operation of a water circulation recuperator is similar to that of a water heating. The efficiency of the action of the plate heat exchanger with water circulation reaches 50-65%. Supply and exhaust ventilation with recuperators of this type is rarely used when it is possible to assemble a heat exchange line. The operation of this system requires frequent monitoring.The weak point is the presence of a pump that circulates the heat exchanger. As well as additional nodes that regulate the operation of the system. They increase energy consumption. With a large distance between the supply and exhaust heat exchangers, it is impractical to use this option. The recuperator performs only the function of heat exchange without moisture transformation.

Design

The main units of the supply and exhaust ventilation system with heat recovery are two heat exchangers. They are installed separately in the supply and extract air ducts. Connect them with an insulated flexible pipe. It allows for an easier choice of the location of the nodes and the installation of the system. The recuperator with water circulation is equipped with a pump, expansion tank, controller, pressure indicator. Temperature sensors. Air, safety and control valves. When installing a single recuperation system, it is possible to connect several heat carriers. Different air exhaust and air flow paths ensure that the recuperator operates without the formation of traces of icing. The transfer of contaminants by the outgoing air to the inlet stream is excluded.

System installation problems

There are practically no potential problems associated with the use of such equipment. Some are decided by the manufacturer, others become a buyer's headache. The main problems include:

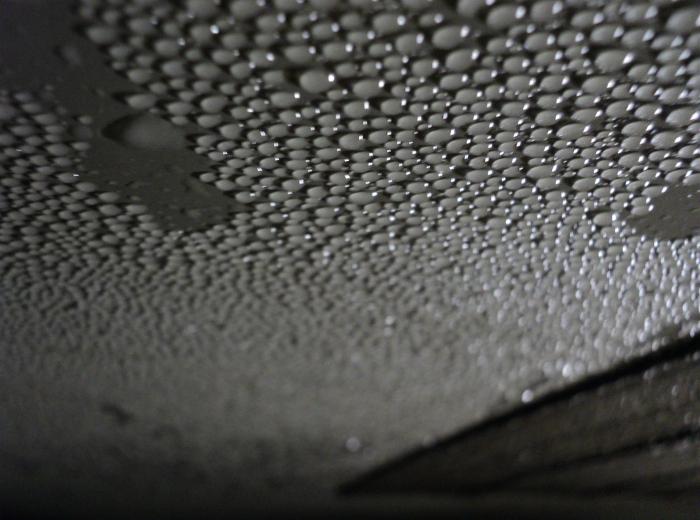

- Condensation formation. The laws of physics dictate that condensation occurs when high-temperature air passes through a cold, enclosed environment. If the ambient temperature is below freezing, then the fins will begin to freeze. All information provided in this paragraph defines a significant decrease in the efficiency of the device.

- Energy efficiency. All ventilation systems working in conjunction with the recuperator are energy dependent. The economic calculation carried out determines that only those recuperator models that will save more energy than spend will be useful.

- Payback period. As previously noted, the device is designed to save energy. An important determining factor is how many years it takes for the purchase and installation of recuperators to pay off. If the indicator under consideration exceeds the 10-year mark, then there is no point in the installation, since during this time other elements of the system will need to be replaced. If the calculations show that the payback period is 20 years, then the possibility of installing the device should not be considered.

The above problems should be taken into account when choosing a heat exchanger, which there are several dozen types.

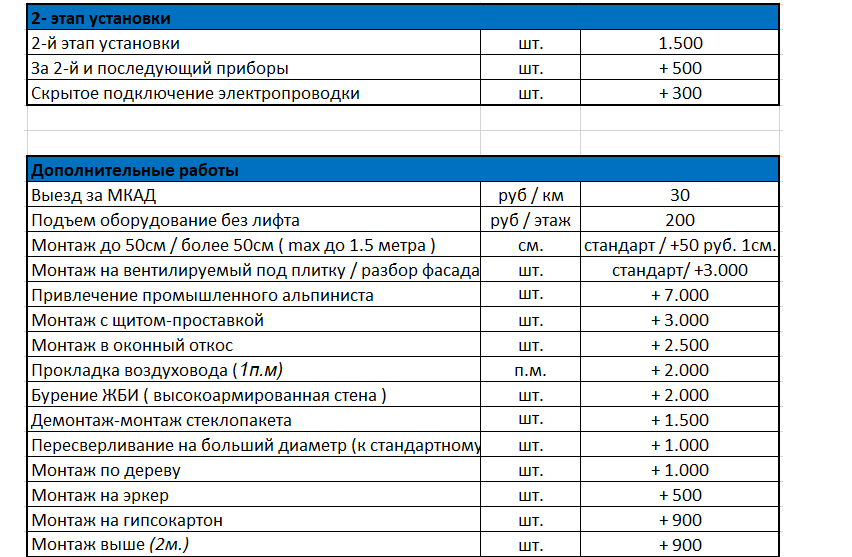

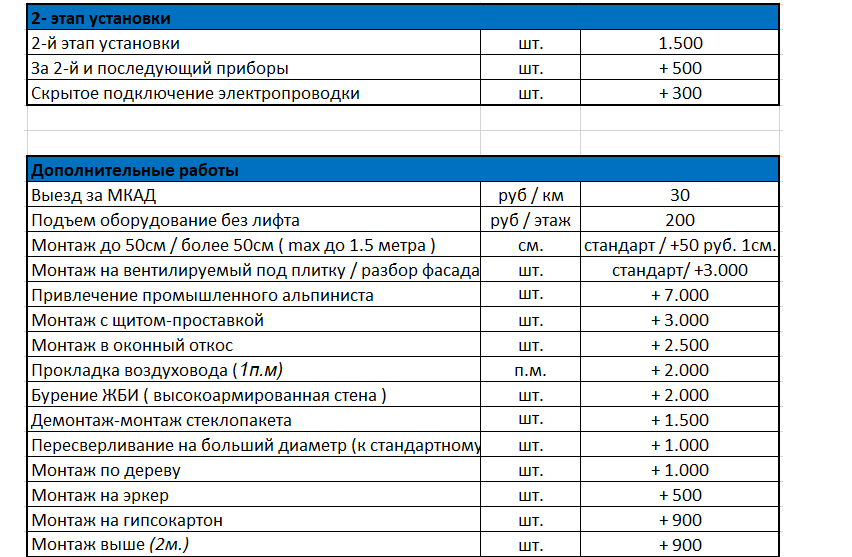

Cost of additional work:

✔

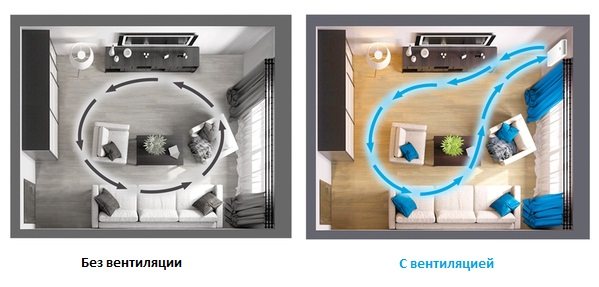

Supply ventilation is the most accessible and least complex type of household aeration device. Its mission is to optimize the microclimate in the room through the migration of internal and external air flows. As a result, the exhaust air, burdened with harmful gases, is discharged into the street and gives way to oxygen-rich air masses. Agree, it is impossible to stay in a stuffy place for a long time. Lack of fresh air negatively affects the level of comfort and the general well-being of people. Therefore, it is important to ensure sufficient air exchange and provide efficient ventilation.

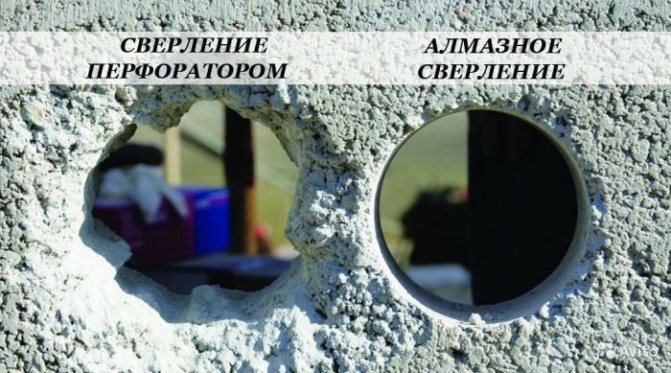

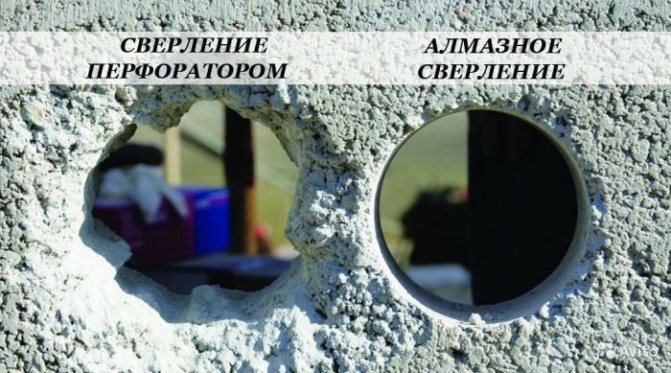

✔ Work on the installation of household ventilation

easier than air conditioning. the main task during installation is to make a hole in the wall, and the installation of the device usually takes about

1 hour

and won't hurt your repair. Installation crews use professional diamond drilling equipment, which is connected to

industrial vacuum cleaner

with water supply for dust wetting. this allows

leave no dirt and dust

after work.It is necessary to inform the consultant in advance about the presence of a ventilation facade.if it is a facing brick, then the installation is no different from the usual. if these are composite sheets, then you only need to choose a place for the device so that the hole does not fall into the profile to which the sheets are attached. if it is porcelain stoneware, then it is possible either to install a pipe under the facade, without outputting it to the outside (in this case, the air quality is the same as on the street), or to drill a ventilation facade, but if the tiles are damaged, its restoration will be at the expense of the client.

- according to current building codes of bore diameter less than 200 mm

no need to reconcile. the hole is covered with a decorative grill from the street, so it does not spoil the appearance of the building, unlike external air conditioner units. this grille can also be painted in the color of the facade.

* There are 3 options if installation on a loggia and balcony:

1. if there are no plastic windows on the loggia or their permanent position in the ventilation mode is allowed, then the breather can be installed so that it draws air directly from the loggia. this does not interfere with the flow of fresh air, neither in summer nor in winter. in addition, in winter, even on an uninsulated loggia, the temperature is higher than outside, which will allow even less energy to be spent on heating the air. this installation option is common in new houses, where the loggias are glazed already at the construction stage.

2. if there are sealed plastic windows and / or a fully insulated loggia on the loggia, then two holes are made: one in the wall between the room and the loggia, the second - directly in the outer wall of the loggia. a flexible duct connects both holes, the air is taken directly from the street. in this case, the device is located in the room in such a way as to minimize the length of the duct.

3. if the loggia is completely insulated and connected to the room, then the hole is made directly on the partition of the loggia and the device is placed on the partition. in this case, it is necessary that the door to the loggia always remains open.