Heat dissipation is an important characteristic of radiators, which shows how much heat a given device gives off. There are many types of heating devices that have a certain heat transfer and parameters. Therefore, many people compare different types of batteries in terms of thermal characteristics and calculate which ones are the most efficient in heat transfer. In order to specifically solve this issue, it is necessary to carry out certain calculations of the power for various heating devices and compare each radiator in heat transfer. Because customers often have a problem with choosing the right radiator. It is this calculation and comparison that will help the buyer to easily solve this problem.

Heat dissipation of the radiator section

Thermal output is the main metric for radiators, but there are also a bunch of other metrics that are very important. Therefore, you should not choose a heating device, relying only on the heat flow. It is worth considering the conditions under which a certain radiator will produce the required heat flow, as well as how long it is able to work in the heating structure of the house. That is why, it would be more logical to look at the technical indicators of sectional types of heaters, namely:

- Bimetallic;

- Cast iron;

- Aluminum;

Let's carry out some kind of comparison of radiators, based on certain indicators, which are of great importance when choosing them:

- What thermal power does it have;

- What is the spaciousness;

- What test pressure withstands;

- What working pressure withstands;

- What is the mass.

Comment. You should not pay attention to the maximum heating level, because, in batteries of any type, it is very large, which allows you to use them in buildings for housing according to a certain property.

One of the most important indicators: working and test pressure, when choosing a suitable battery, applied to various heating systems. It is also worth remembering about water hammering, which is a frequent occurrence when the central network begins to carry out work activities. Because of this, not all types of heaters are suitable for central heating. It is most correct to compare heat transfer, taking into account the characteristics that show the reliability of the device. The mass and capacity of heating structures is important in private housing. Knowing what capacity a given radiator has, you can calculate the amount of water in the system and make an estimate of how much heat energy will be consumed to heat it. To find out how to attach to the outer wall, for example, made of a porous material or using the frame method, you need to know the weight of the device. To get acquainted with the main technical indicators, we made a special table with data from a popular manufacturer of bimetal and aluminum radiators from a company called RIFAR, plus the characteristics of MC-140 cast iron batteries.

Radiator power

Is the heat energy of the heat sink, usually measured in Watts (W)

There is a direct relationship between the heat loss of a room and the power of the radiator. That is, if your room has a heat loss of 1500 W, then the radiator must accordingly be selected with the same power of 1500 W. But not everything is so simple, because the temperature of the radiator can be in the range from 45-95 ° C and, accordingly, the power of the radiator will be different at different temperatures.

But, unfortunately, many do not understand how to find out the heat loss of a building ... There are simple calculations to determine the heat loss of a room. It will be written about them later.

And at what temperature will the radiator warm up?

If you have a private house with plastic pipes, then the temperature of the radiators will range from 45-80 degrees. The average temperature is 60 degrees. The maximum temperature is 80 degrees.

If you have an apartment with central heating, then from 45-95 degrees. The maximum temperature is 95 degrees. The central heating temperature is now weather-dependent. This means that the temperature of the central heating medium depends on the outside temperature. If it gets colder outside, then the temperature of the coolant is higher and vice versa. The power of the radiators according to SNiP is calculated at ∆70 degrees. But this does not mean that you need to choose this way. Designers plan the power in such a way as to heat your apartment less and save money on heat energy, and to withdraw money from the rent as usual. To date, changing a radiator to a more powerful one is not prohibited. But if your radiator takes away heat strongly and there are complaints about the system, then measures will be taken against you.

Suppose that you have decided on the temperature of the coolant and the power of the radiator

Given:

Average heatsink temperature 60 degrees

Radiator power 1500 W

Room temperature 20 degrees.

Decision

When you search, ask for a 1500 W radiator, you will be offered a 1500 W radiator with a temperature difference of ∆70 ° C. Or ∆50, ∆30 ...

What is the temperature head of a radiator?

Temperature head

Is the temperature difference between the temperature of the radiator (heat carrier) and the temperature of the room (air)

The radiator temperature is conventionally the average temperature of the coolant. I.e

Let us assume that there is a series of radiators of certain capacities with a temperature head of ∆70 ° C.

Model 1, 1500 W

Model 2, 2000 W

Model 3, 2500 W

Model 4, 3000 W

Model 5, 3500 W

It is necessary to select a radiator model with an average coolant temperature of 60 degrees.

In this case, the temperature head will be 60-20 = 40 degrees.

There is a formula for recalculating the power of radiators:

Uph - actual temperature head

Uн - standard temperature head

More about the formula: Calculation of the power of radiators. Standards EN 442 and DIN 4704

Decision

Answer:

Model 5, 3500 W

| Like |

| Share this |

| Comments (1) (+) [Read / Add] |

A series of video tutorials on a private house

Part 1. Where to drill a well? Part 2. Arrangement of a well for water Part 3. Laying a pipeline from a well to a house Part 4. Automatic water supply

Water supply

Private house water supply. Principle of operation. Connection diagram Self-priming surface pumps. Principle of operation. Connection diagram Calculation of a self-priming pump Calculation of diameters from a central water supply Pumping station of water supply How to choose a pump for a well? Setting the pressure switch Pressure switch electrical circuit Principle of operation of the accumulator Sewerage slope for 1 meter SNIP Connecting a heated towel rail

Heating schemes

Hydraulic calculation of a two-pipe heating system Hydraulic calculation of a two-pipe associated heating system Tichelman loop Hydraulic calculation of a single-pipe heating system Hydraulic calculation of a radial distribution of a heating system Diagram with a heat pump and a solid fuel boiler - logic of operation Three-way valve from valtec + thermal head with a remote sensor Why does the heating radiator in a multi-apartment building do not heat well? home How to connect a boiler to a boiler? Connection options and diagrams DHW recirculation.Principle of operation and calculation You do not correctly calculate the hydraulic arrow and collectors Manual hydraulic calculation of heating Calculation of a warm water floor and mixing units Three-way valve with a servo drive for DHW Calculations of DHW, BKN. We find the volume, power of the snake, warm-up time, etc.

Water supply and heating constructor

Bernoulli's equation Calculation of water supply for apartment buildings

Automation

How servos and three-way valves work Three-way valve to redirect the flow of the heating medium

Heating

Calculation of the heat output of heating radiators Radiator section Overgrowth and deposits in pipes worsen the operation of the water supply and heating system New pumps work differently ... connect an expansion tank in the heating system? Boiler resistance Tichelman loop pipe diameter How to choose a pipe diameter for heating Heat transfer of a pipe Gravitational heating from a polypropylene pipe Why do they not like single-pipe heating? How to love her?

Heat regulators

Room thermostat - how it works

Mixing unit

What is a mixing unit? Types of mixing units for heating

System characteristics and parameters

Local hydraulic resistance. What is CCM? Throughput Kvs. What it is? Boiling water under pressure - what will happen? What is hysteresis in temperatures and pressures? What is infiltration? What are DN, DN and PN? Plumbers and engineers need to know these parameters! Hydraulic meanings, concepts and calculation of heating systems circuits Flow coefficient in a one-pipe heating system

Video

Heating Automatic temperature control Simple top-up of the heating system Heating technology. Walling. Underfloor heating Combimix pump and mixing unit Why choose underfloor heating? Water heat-insulated floor VALTEC. Video seminar Pipe for underfloor heating - what to choose? Warm water floor - theory, advantages and disadvantages Laying a warm water floor - theory and rules Warm floors in a wooden house. Dry warm floor. Warm Water Floor Pie - Theory and Calculation News to Plumbers and Plumbing Engineers Are you still doing the hack? First results of the development of a new program with realistic three-dimensional graphics Thermal calculation program. The second result of the development of Teplo-Raschet 3D Program for thermal calculation of a house through enclosing structures Results of the development of a new program for hydraulic calculation Primary secondary rings of the heating system One pump for radiators and underfloor heating Calculation of heat loss at home - orientation of the wall?

Regulations

Regulatory requirements for the design of boiler rooms Abbreviated designations

Terms and Definitions

Basement, basement, floor Boiler rooms

Documentary water supply

Sources of water supply Physical properties of natural water Chemical composition of natural water Bacterial water pollution Requirements for water quality

Collection of questions

Is it possible to place a gas boiler room in the basement of a residential building? Is it possible to attach a boiler room to a residential building? Is it possible to place a gas boiler room on the roof of a residential building? How are boiler rooms divided according to their location?

Personal experiences of hydraulics and heat engineering

Introduction and acquaintance. Part 1 Hydraulic resistance of the thermostatic valve Hydraulic resistance of the filter flask

Video course Calculation programs

Technotronic8 - Hydraulic and thermal calculation software Auto-Snab 3D - Hydraulic calculation in 3D space

Useful materials Useful literature

Hydrostatics and hydrodynamics

Hydraulic Calculation Tasks

Head loss in a straight pipe section How does head loss affect flow rate?

Miscellaneous

Do-it-yourself water supply of a private house Autonomous water supply Autonomous water supply scheme Automatic water supply scheme Private house water supply scheme

Privacy Policy

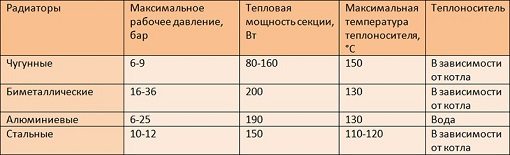

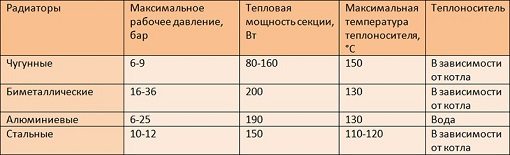

Bimetallic radiators

Based on the indicators of this table for comparing the heat transfer of various radiators, the type of bimetallic batteries is more powerful. Outside, they have a finned body made of aluminum, and inside a frame with high strength and metal pipes so that there is a coolant flow. Based on all indicators, these radiators are widely used in the heating network of a multi-storey building or in a private cottage. But the only drawback of bimetallic heaters is the high price.

Aluminum radiators

Aluminum batteries do not have the same heat dissipation as bimetallic batteries. But still, aluminum heaters have not gone far from bimetallic radiators in terms of parameters. They are used most often in separate systems, because they are not often able to withstand the required volume of working pressure. Yes, this type of heating devices is used for operation in the central network, but only taking into account certain factors. One such condition involves the installation of a special boiler room with a pipeline. Then, aluminum heaters can be operated in this system. Nevertheless, it is recommended to use them in separate systems in order to avoid unnecessary consequences. It is worth noting that aluminum heaters are cheaper than previous batteries, which is a certain advantage of this type.

Low-temperature heating: what is it

Low-temperature heating systems are those in which the temperature of the coolant "at the inlet" is less than 60 ° C, and the "outlet" is about 30 ... 40 ° C, while the temperature in the room is taken as 20 ° C. It is clear that with such input data, heating devices will not heat up as much as traditional radiators designed for 80/60 mode. So for low-temperature heating, the following devices and their combinations are most often used:

Water heat-insulated floor - the most common low-temperature heating device. Even according to SNiP, it should not heat up above + 31 ° C in residential premises.

Convectors with forced convection. It is carried out by a built-in fan and is necessary to ensure greater heat transfer. These devices can be wall-mounted, floor-standing, built-in floor-standing, etc. To operate the fan, they need an electrical connection.

Radiators specially designed for low temperature systems. They have an increased surface area and are most often made of aluminum. This metal has high thermal conductivity and low thermal interference, that is, it provides maximum heat transfer and heats up quickly. It is also possible to use steel radiators with strong fins and similar constructive solutions, due to which the surface area that gives off heat is increased.

"Warm skirting boards", or thermal skirting boards - compact modular radiators that are installed along the walls like a regular skirting board.

According to the current edition of SanPiN 2.1.2.2645-10 "Sanitary and Epidemiological Requirements for Living Conditions in Residential Buildings and Premises", the following air temperature is considered optimal in winter:

- living quarters 20-22 ° С

- kitchen 19-21 ° С

- corridors, flights of stairs 16-18 ° С

- toilet 19-21 ° C

- bathroom and / or combined bathroom 24-26 ° С

Water heat-insulated floor

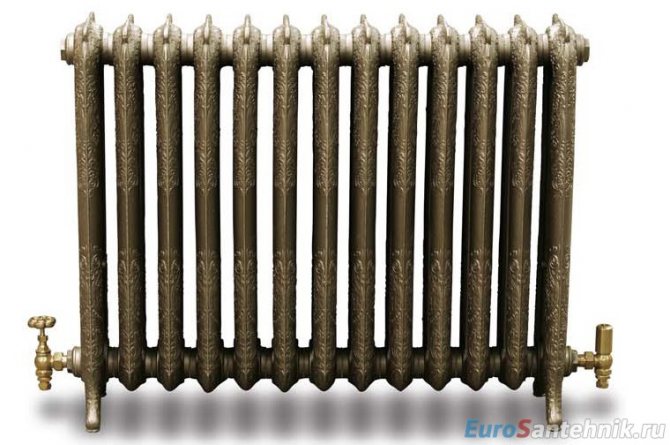

Cast iron batteries

The cast-iron type of heaters has many differences from the previous, above-described radiators. The heat transfer of the type of radiator under consideration will be very low if the mass of the sections and their capacity are too large. At first glance, these devices seem completely useless in modern heating systems.But at the same time, the classic "accordions" MS-140 are still in high demand, since they are highly resistant to corrosion and can last a very long time. In fact, the MC-140 can really last more than 50 years without any problems. Plus, it doesn't matter what the coolant is. Also, simple batteries made of cast iron material have the highest thermal inertia due to their enormous mass and spaciousness. This means that if you turn off the boiler, the radiator will still remain warm for a long time. But at the same time, cast iron heaters do not have strength at the proper operating pressure. Therefore, it is better not to use them for networks with high water pressure, as this can entail huge risks.

Heat dissipation of radiators - choosing radiators for your home

In the passport of any radiator, you can find manufacturer's data on heat transfer. Figures are often quoted in the range of 180 - 240 W per section. These values are partly a publicity stunt, as they are unattainable under real operating conditions. And the consumer often immediately chooses the one with the higher number.

- Under the power numbers there is always an inscription about the conditions under which it was achieved, often in small print, for example, “at DT 50 degrees C”.

This is the condition that completely crosses the consumer's hopes for miraculous heating at home from a conventional radiator. Let's figure out what kind of heat transfer from radiators will actually be in the home heating network, what to look for when choosing radiators and installing them ...

What is DT, DT, dt, Δt in the characteristics of radiators

DT, dt, Δt - different designations of the same - the so-called temperature head. This is the difference between the average temperature of the radiator itself and the temperature of the air in the room where it is installed.

The real heat transfer will depend on this difference.

- The hotter the radiator, the more heat it will give to the air. The warmer the air in the room, the less heat transfer from the radiator.

- What is the average temperature of a heatsink? Is the average value between the supply and return temperature of the heating medium. For example, supply 70 degrees, return 50 degrees, then the average temperature of the radiator is 60 degrees.

At an air temperature in the room of 20 degrees, the difference with a radiator with an average temperature of 60 degrees will be 40 degrees. Those. DT, dt, Δt = 40 deg C.

Manufacturers more often indicate the heat output of one section of the radiator at a thermal head of Δt = 50 degrees C. Or they simply write: "when supplying 80 degrees, return flow 60 degrees, air in the room 20 degrees", which corresponds to dt 50 degrees.

What is the real temperature of the radiator

As you can see, even Δt = 50 degrees C turns out to be an almost unattainable result at home. Automated boilers turn off when the temperature in the heat exchanger reaches 80 degrees, while the supply of radiators is at best 74 degrees. More often, they are operated up to 70 degrees at the supply. The return temperature can fluctuate depending on the air temperature in the house, the power of the heat generator, the boiler settings ... But more often it is less from the supply by 20 degrees.

Thus, we take the typical average temperature of the radiator as 60 degrees. (supply 70, return 50). At a room temperature of 20 degrees, - Δt turns out to be equal to 40 degrees C. And if the air in the room warms up to 25 degrees, then Δt = 35 degrees C.

What is the heat transfer of the radiator during operation

What is the cardinality of one section?

- If the manufacturer specifies Δt = 50 degrees, then the value, usually presented as 170 - 180 W, should be divided by 1.3.

- If it is indicated "at a supply temperature of 90 degrees" (ie Δt = 60 degrees), then the value (usually 200 W) must be divided by 1.5.

In any case, for a standard aluminum radiator with a center distance of 500 mm, approximately 130 watts per section is obtained. This should be accepted, in general, but there are a few more conditions ...

What to do if the specified section heat dissipation is more than 200 W

It is often written that the power of the radiator (of one standard section) is 240 or even more watts, but they indicate that Δt = 70 degrees. Those.the manufacturer accepts completely fantastic operating conditions, when, at a room temperature of 20 degrees, the supply will be 100 degrees, and the return flow will be 80. Then the average temperature of the radiator will be 90 degrees.

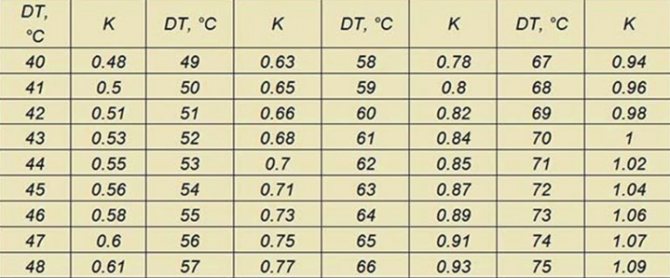

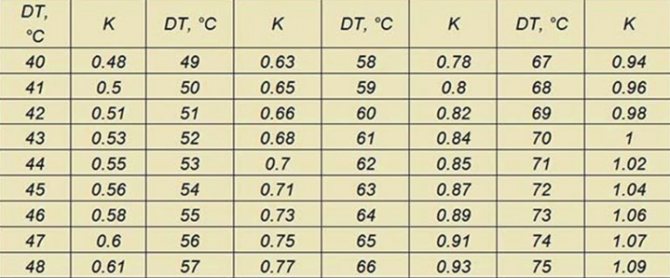

It is clear that in no home heating systems 100 degrees on the supply, except for an emergency with a solid fuel boiler, are not achievable. However, manufacturers quote these numbers in order to "flash" the biggest ad to entice a buyer. For such cases, when Δt = 70 degrees is indicated, a table with coefficients for determining the real power has even been developed.

We translate 240W into Δt = 40 degrees, we get about 120W ...

What power of radiators to take, what else to consider

Ultimately, we are interested in how many sections should be put in one or another room of a radiator of standard dimensions (depth, width, height) with a center distance of usually 500 mm, or what size of a steel radiator panel to accept ... To do this, you need to know the real heat transfer of one section.

What we have calculated here for the standard size of an aluminum (bimetallic, cast-iron MS-140) radiator - the section power is 130 W, when the boiler is heated "for the whole" (74 degrees at the output) - is still not quite suitable for real conditions ... A power reserve for heating devices is often needed. Those. it is advisable to install radiators with a margin of size.

- There are days with peak frosts when it would be desirable to flood better ...

- Many people want a higher temperature - all 25 degrees, and in some places 27 degrees ...

- The room can be poorly insulated, during construction it is necessary to realistically assess whether the thermal insulation and ventilation in the dwelling is "satisfactory" or not ...

- Low temperature heating is recommended by many as it generates less dust.

Considering these circumstances, it is possible to recommend installing radiators on the basis that the power of a standard section with a center-to-center distance is only 110 W. In this case, the boiler can operate most of the time in a lower temperature mode - 55 - 60 degrees (but above the dew point on the heat exchanger).

- If the house has underfloor heating and their reliability is estimated to be close to 100%, then many experts believe that it is possible to save and install 50% of the power of radiators or floor convectors for the sake of design ... savings ...

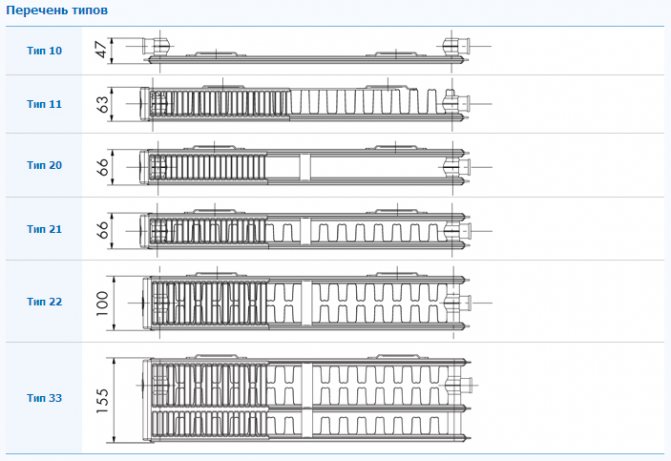

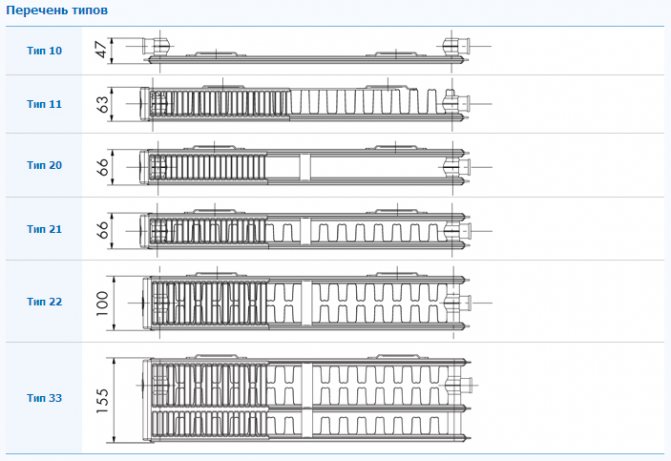

Steel batteries

The heat dissipation of steel radiators depends on several factors. Unlike other devices, steel ones are more often represented by monolithic solutions. Therefore, their heat transfer depends on:

- Device size (width, depth, height);

- Battery type (type 11, 22, 33);

- Finning degrees inside the device

Steel batteries are not suitable for heating in the central network, but they have proven themselves ideally in private housing construction.

Types of steel radiators

To choose a suitable device for heat transfer, first determine the height of the device and the type of connection. Further, according to the manufacturer's table, select the device by length, considering type 11. If you found a suitable one in terms of power, then great. If not, then you start looking at type 22.

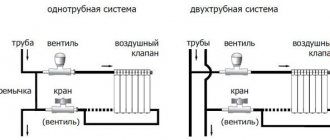

Understanding the efficiency of different types of batteries

Most modern batteries are produced in section, so that by changing their number, it is possible to ensure that the heat output of heating radiators meets the needs. It should be borne in mind that the efficiency of the battery will depend on the temperature of the coolant, as well as on its surface area.

What determines the efficiency of heat transfer

The efficiency of a heating radiator depends on several parameters:

- on the temperature of the coolant;

Note! In the documentation for the heater, the manufacturer usually indicates the amount of heat output, but this value is indicated for normal temperatures (90 ° C at the supply and 70 ° C at the exit).When using low temperature heating systems, manual calculation is required.

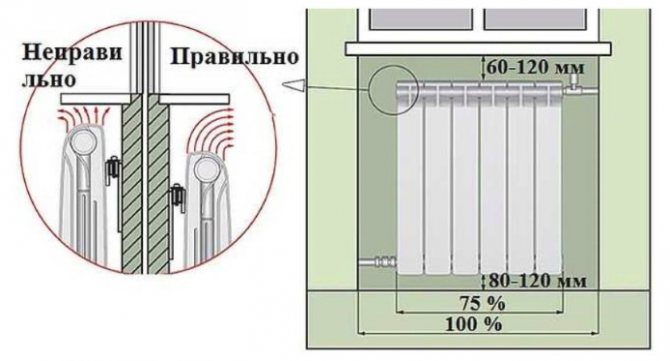

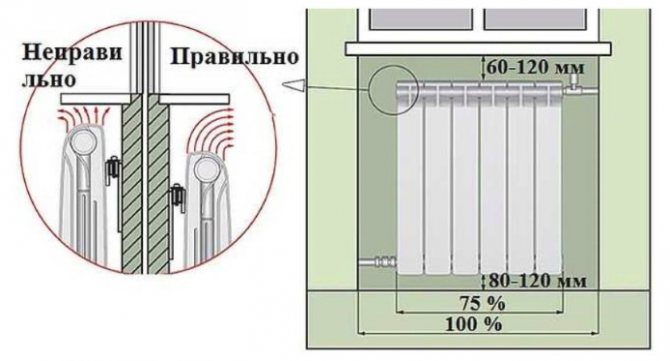

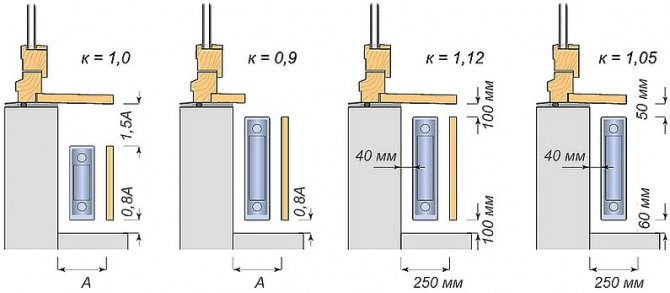

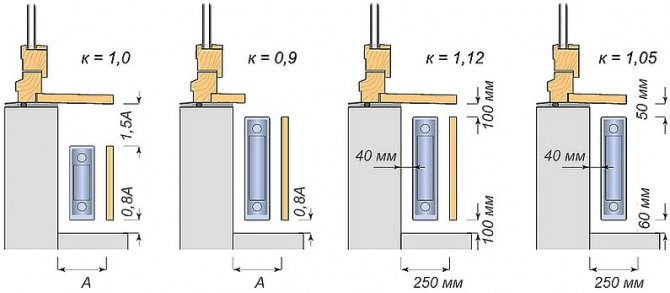

- from the installation method - sometimes the owners, in pursuit of the beauty of the interior, cover the batteries with decorative grilles, if the heat flow of heating radiators stumbles upon an obstacle in its face, then the heating efficiency will slightly decrease;

Dependence of heat transfer on the installation method

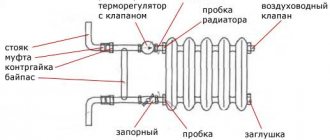

- from the connection method. With a diagonal connection (the supply pipe is connected from the top), and the outlet pipe is connected from the bottom on the other side, almost ideal battery operation is ensured. All sections will warm up evenly.

The photo shows an ideal example of connecting a radiator

It is advisable not to be lazy and independently calculate the required power of the radiator, while it is better to choose a heater with a certain margin. A spare heat watts of the radiator will not be superfluous, and if necessary, you can always install a thermostat and change the temperature of each individual heater.

Methods for calculating the required power

The calculation of the thermal power of heating radiators can be carried out according to several methods:

- simplified - the average figure is used for a room with 1 door and 1 window. In order to roughly estimate the number of radiator sections, it is enough to simply calculate the area of the room and multiply the resulting number by 0.1. The result will be approximately equal to the required thermal power of the heater, for insurance, the resulting number is increased by 15%

Note! If the room has 2 windows or it is corner, then the result should be increased by another 15%.

- by the volume of the room. There is another dependence, according to which a 200-watt section of a radiator is a way to heat 5m3 of space in a room, the result is rather inaccurate, the error can reach 20%;

Dependence of the required power of the heater on the characteristics of the room

- with your own hands, you can perform a more accurate volumetric calculation. A dependency of the form

Q = S ∙ h ∙ 41,

the following designations are adopted: S - the area of the room, h - the height of the ceiling, 41 - the number of watts for heating 1 cube of air.

But you can also perform a more detailed calculation, taking into account the method of installing the radiator, the method of connecting it, as well as the real temperature of the coolant in the pipes.

In this case, the calculation instructions will look like this:

- first, the temperature head ΔT is calculated, a dependence of the form ∆T = ((T_pod-T_rev)) / 2-T_room is used

in the formula Тпод - water temperature at the inlet to the radiator, Тobr - outlet temperature, Тroom - temperature in the room.

- then calculate the required power of the heater Q = k ∙ A ∙ ΔT,

where k is the heat transfer coefficient, Q is the radiator power, A is the battery surface area.

- the documentation usually indicates the information heatsinks-heatwatt-manufacturer, so that Q is known and the corresponding temperature head. So you can determine the value of k ∙ A (this value is a constant for any temperature difference);

- further, knowing the product of k ∙ A and the real temperature head, one can calculate the power of the radiator for any operating conditions.

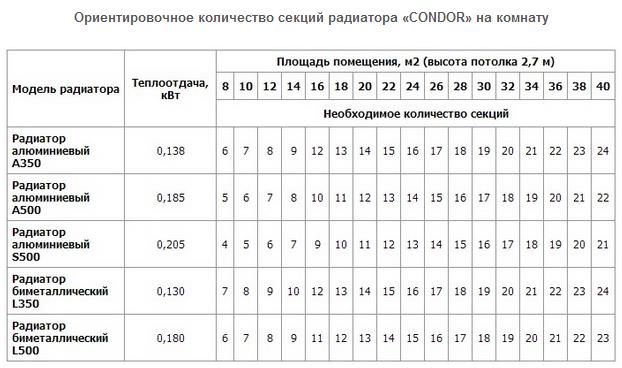

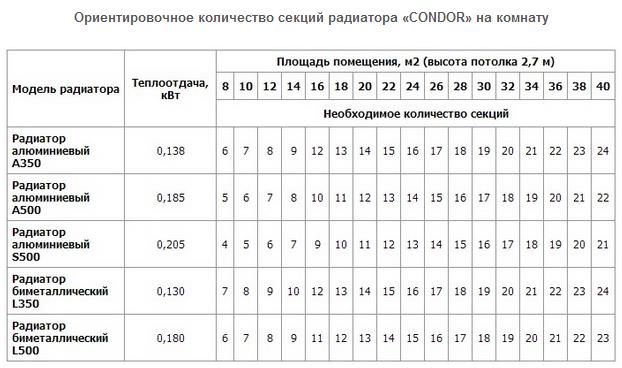

Or you can do it even easier and use ready-made tables with the recommended number of radiator sections for a certain footage. For example, the table of heat output of cast iron heating radiators allows you to select the required battery size without calculation. There are also online calculators for easy calculation.

Data for the selection of a heater for the home

Radiator selection

In terms of heat transfer, bimetallic heating radiators can be considered the undisputed leader. The table of thermal power of heating radiators clearly shows that the heat transfer of such a structure is approximately 2 times higher than that of cast iron.

Comparison of heat dissipation of different types of batteries

But you need to take into account a lot of other details:

- the cost - classic cast iron radiators will cost at least 2 times cheaper than bimetallic ones;

- cast iron does not tolerate water hammer, and in general - a rather fragile material;

- it is worth thinking about the appearance... At an exorbitant price, you can purchase cast iron radiators with a beautiful pattern on the surface. Such a heater itself is a decoration of the room.

Real room decoration

With regard to cost and efficiency, it is worth introducing such a concept as the heatwatt of bimetallic radiators (or cast iron, steel). If we take into account the cost of the battery and its efficiency, it may turn out that the cost of a heat-watt of a cast-iron radiator will be lower than that of a bimetallic structure.

So do not discount the good old cast iron heaters. The thermal power of cast-iron heating radiators allows them to be used to heat houses, and with careful operation they can last for more than a dozen years.

Calculation of heat output

To design a heating system, you need to know the heat load required for this process. Then already carry out calculations on the heat transfer of the radiator. Determining how much heat is consumed to heat a room can be quite simple. Taking into account the location, the amount of heat is taken for heating 1 m3 of the room, it is equal to 35 W / m3 for the side from the South of the room and 40 W / m3 for the north, respectively. We multiply the actual volume of the building by this amount and calculate the required amount of power.

Important! This method of calculating the power is increased, so the calculations should be taken into account here as a guideline.

To calculate the heat transfer for bimetal or aluminum batteries, you need to proceed from their parameters, which are indicated in the manufacturer's documents. In accordance with the standards, they provide heat transfer from one single section of the heater at DT = 70. This clearly shows that a single section with the supply of a carrier temperature equal to 105 C from the return pipe of 70 C will give the specified heat flux. The temperature inside with all this is equal to 18 C.

Taking into account the data of the given table, it can be noted that the heat transfer of one single section of the radiator made of bimetal, in which the center-to-center dimension is 500 mm, is equal to 204 W. Although this happens when the temperature in the pipeline drops and is equal to 105 oС. Modern specialized structures do not have such a high temperature, which also reduces parallel and power. To calculate the actual heat flux, it is worth first calculating the DT indicator for these conditions using a special formula:

DT = (tpod + tobrk) / 2 - troom, where:

tpod - indicator of the temperature of the water from the supply pipeline;

tobrk - return flow temperature indicator;

troom - an indicator of the temperature from inside the room.

Then the heat transfer, which is indicated in the passport of the heating device, must be multiplied by the correction factor, taken taking into account the DT indicators from the table: (Table 2)

Thus, the heat output of heating devices for certain buildings is calculated, taking into account many different factors.

Calculation and selection of heating radiators.

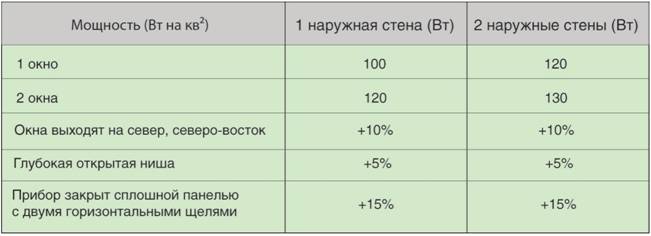

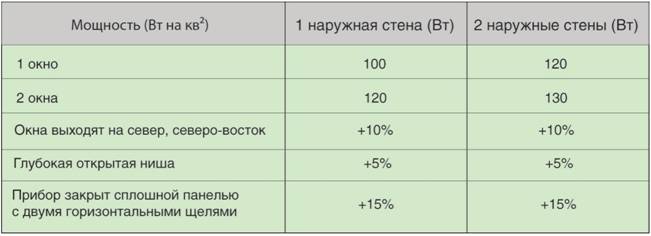

Radiators or convectors are the main elements of the heating system, since their main function is to transfer heat from the coolant to the air in the room or to the surfaces of the room. In this case, the power of the radiators must clearly correspond to the heat losses in the premises. From the previous sections of the series of articles it can be seen that the enlarged power of the radiators can be determined by the specific indicators for the area or volume of the room.

So, for heating a room of 20 m? with one window, on average, it is required to install a heating device with a power of 2 kW, and if we take into account a small margin on the surface of 10-15%, then the radiator power will be approximately 2.2 kW.This method of selecting radiators is rather crude, since it does not take into account many significant features and building characteristics of the building. More accurate is the selection of radiators based on the heat engineering calculation of a residential building, which is carried out by specialized design organizations.

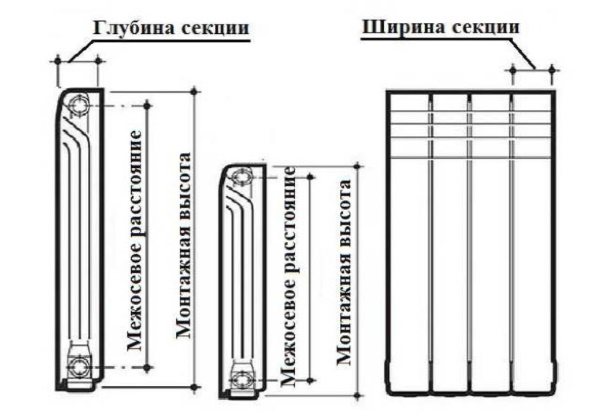

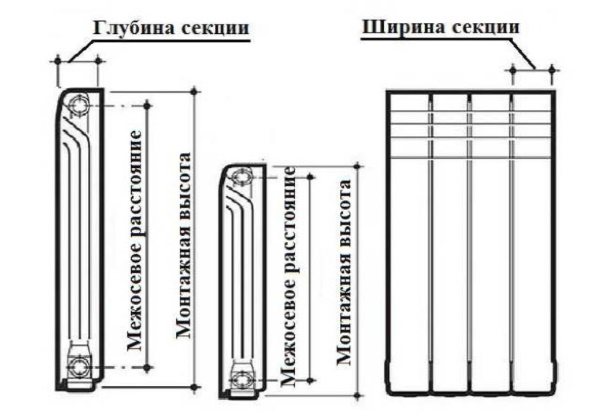

The main parameter for the selection of the standard size of the heating device is its thermal power. And in the case of sectional aluminum or bimetallic radiators, the power of one section is indicated. The most commonly used radiators in heating systems are devices with a center distance of 350 or 500 mm, the choice of which is based primarily on the design of the window and the mark of the window sill relative to the finish floor covering.

| Power of 1 radiator section according to the passport, W | Room area, m2 | ||||||

| 10 | 12 | 14 | 16 | 18 | 20 | 22 | |

| Number of sections | |||||||

| 140 | 8 | 9 | 10 | 12 | 13 | 15 | 16 |

| 150 | 7 | 8 | 10 | 11 | 12 | 14 | 15 |

| 160 | 7 | 8 | 9 | 10 | 12 | 13 | 14 |

| 180 | 6 | 7 | 8 | 9 | 10 | 12 | 13 |

| 190 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 200 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

In the technical passport for heating devices, manufacturers indicate the thermal power in relation to any temperature conditions. The standard parameters are the heat carrier parameters 90-70 ° C, in the case of low-temperature heating, the heat output should be adjusted according to the coefficients specified in the technical documentation.

In this case, the power of the heating devices is determined as follows:

Q = A * k *? T, where A is the heat transfer area, m? k is the heat transfer coefficient of the radiator, W / m2 * ° C. ? T - temperature head, ° C

ΔT is the average value between the temperature of the supply and return heat carrier and is determined by the formula:

? T = (Тпод + Тобр) / 2 - troom

The passport data is the radiator power Q and the temperature head determined under standard conditions. The product of the coefficients k * A is a constant value and is determined first for standard conditions, and then can be substituted into the formula to determine the actual power of the radiator, which will operate in the heating system with parameters that differ from the accepted ones.

For a frame house, considered as an example with an insulation thickness of 150 mm, the selection of a radiator for a room with an area of 8.12 m2 will look like this.

Earlier, we determined that the specific heat loss for a corner room, taking into account the infiltration of 125 W / m2, which means that the radiator power should be at least 1,015 W, and with a margin of 15%, 1,167 W.

A 1.4 kW radiator is available for installation with coolant parameters of 90/70 degrees, which corresponds to a temperature head? T = 60 degrees. The planned heating system will operate at water parameters of 80/60 degrees (? T = 50) Therefore, in order to make sure that the radiator can completely cover the heat loss of the room, it is necessary to determine its actual power.

To do this, having determined the value k * A = 1400/60 = 23.3 W / deg, we determine the actual power Qfact = 23.3 * 50 = 1167 W, which fully satisfies the required thermal power of the heating device, which must be installed in this room ...

Video clip on the topic of calculating the power of the radiator:

The best batteries for heat dissipation

Thanks to all the calculations and comparisons carried out, we can safely say that bimetallic radiators are still the best in heat transfer. But they are quite expensive, which is a big disadvantage for bimetallic batteries. Next, they are followed by aluminum batteries. Well, the last in terms of heat transfer are cast iron heaters, which should be used in certain installation conditions. If, nevertheless, to determine a more optimal option, which will not be entirely cheap, but not entirely expensive, as well as very effective, then aluminum batteries will be an excellent solution. But again, you should always consider where you can use them and where you can't. Also, the cheapest, but proven option, remains cast-iron batteries, which can serve for many years, without problems, providing homes with heat, even if not in such quantities as other types can do.

Steel appliances can be classified as convector-type batteries. And in terms of heat transfer, they will be much faster than all of the above devices.

Energy efficiency of steel panel radiators in low temperature systems ...

Home \ Articles \ Energy efficiency of steel panel radiators in low-temperature heating systems

Often, in the pursuit of innovation, we forget about effective solutions developed over the years. Instead of improving on something old, we invent something new, completely forgetting that “new” does not mean “better”. This happened with aluminum radiators, which have been producing for about 15-20 years only for Russia and the post-Soviet space. For comparison, steel panel radiators, for example, Purmo, have been produced for over 80 years and are used in all countries where heating is needed. Why is this happening? Surely all of you have repeatedly heard from manufacturers of steel panel radiators (Purmo, Dianorm (Gas Corporation LLC - dealer), Kermi, etc.) about the unprecedented efficiency of their equipment in modern high-efficiency low-temperature heating systems. But no one bothered to explain - where does this efficiency come from? First, let's consider the question: "What are low-temperature heating systems for?" They are needed in order to be able to use modern highly efficient sources of thermal energy, such as condensing boilers (e.g. Hortek, Rendamax, Ariston and heat pumps. Due to the specificity of this equipment, the temperature of the coolant in these systems ranges from 45-55 ° C. Heat pumps are physically unable to raise the temperature of the heat carrier higher. And condensing boilers are economically impractical to heat above the steam condensation temperature of 55 ° C due to the fact that when this temperature is exceeded, they cease to be condensing boilers and work like traditional boilers with a traditional efficiency of about 90%. In addition, the lower the temperature of the coolant, the longer the polymer pipes will work, because at a temperature of 55 ° C they degrade for 50 years, at a temperature of 75 ° C - 10 years, and at 90 ° C - only three years. In the process of degradation, pipes become brittle and break in loaded places. We decided on the temperature of the coolant. The lower it is (within acceptable limits), the more efficiently energy carriers (gas, electricity) are consumed, and the longer the pipe works. So, the heat from the energy carriers was released, the heat carrier was transferred, it was delivered to the heater, now the heat must be transferred from the heater to the room. As we all know, heat from heating devices enters the room in two ways. The first is thermal radiation. The second is heat conduction, which turns into convection. Let's take a closer look at each method.

Everyone knows that thermal radiation is the process of transferring heat from a more heated body to a less heated body by means of electromagnetic waves, that is, in fact, it is heat transfer by ordinary light, only in the infrared range. This is how the heat from the Sun reaches the Earth. Because thermal radiation is essentially light, the same physical laws apply to it as to light. Namely: solids and steam practically do not transmit radiation, and vacuum and air, on the contrary, are transparent to heat rays. And only the presence of concentrated water vapor or dust in the air reduces the transparency of the air for radiation, and part of the radiant energy is absorbed by the environment. Since the air in our houses contains neither steam nor dense dust, it is obvious that it can be considered absolutely transparent for heat rays. That is, the radiation is not delayed or absorbed by the air. The air is not heated by radiation. Radiant heat transfer continues as long as there is a difference between the temperatures of the emitting and absorbing surfaces. Now let's talk about heat conduction with convection. Thermal conductivity is the transfer of thermal energy from a heated body to a cold body during their direct contact. Convection is a type of heat transfer from heated surfaces due to the movement of air created by Archimedean force.That is, the heated air, becoming lighter, tends upward under the action of the Archimedean force, and cold air takes its place near the heat source. The higher the difference between the temperatures of hot and cold air, the greater the lifting force that pushes the heated air upward. In turn, convection is hampered by various obstacles, such as window sills, curtains. But the most important thing is that the air itself, or rather, its viscosity, interferes with air convection. And if on the scale of the room the air practically does not interfere with convective flows, then, being "squeezed" between the surfaces, it creates significant resistance to mixing. Remember the glass unit. The layer of air between the glasses slows down itself, and we get protection from the outside cold. Well, now that we have figured out the methods of heat transfer and their features, let's look at what processes take place in heating devices under different conditions. At a high temperature of the coolant, all heating devices heat equally well - powerful convection, powerful radiation. However, with a decrease in the temperature of the coolant, everything changes.

Convector.The hottest part of it - the coolant pipe - is located inside the heater. The lamellas are heated from it, and the farther from the pipe, the colder the lamellas. The lamella temperature is practically the same as the ambient temperature. There is no radiation from cold lamellas. Convection at low temperatures interferes with the viscosity of the air. There is very little heat from the convector. To make it warm, you need to either increase the temperature of the coolant, which will immediately reduce the efficiency of the system, or artificially blow warm air out of it, for example, with special fans.

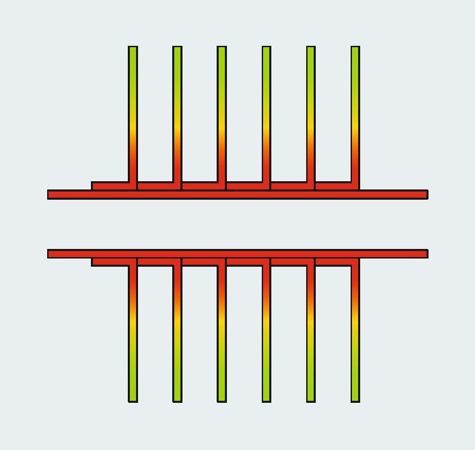

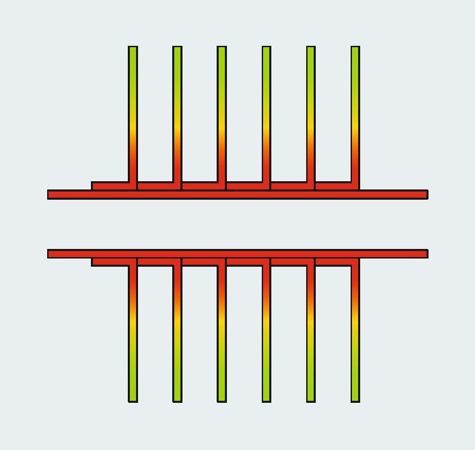

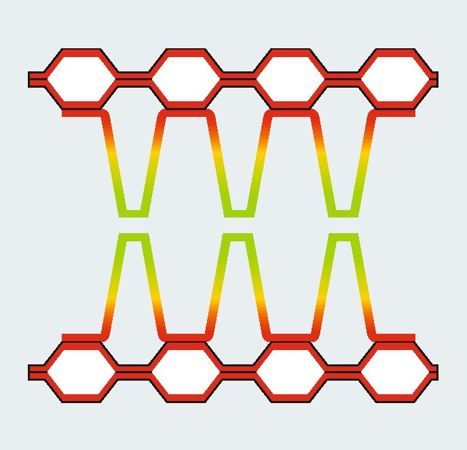

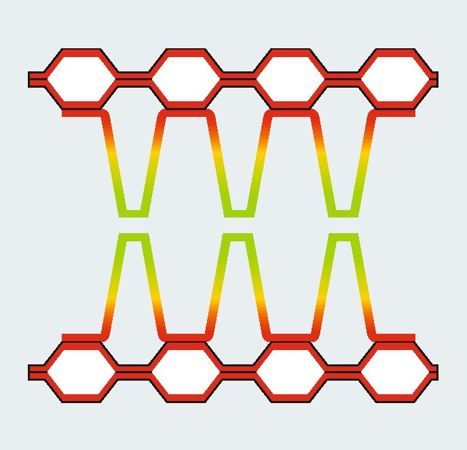

Fig. 1. Convector section.

Aluminum (sectional bimetallic) radiatorstructurally very similar to a convector. The hottest part of it - a collector pipe with a coolant - is located inside the sections of the heater. The lamellas are heated from it, and the farther from the pipe, the colder the lamellas. There is no radiation from cold lamellas. Convection at a temperature of 45-55 ° C interferes with the viscosity of the air. As a result, the heat from such a "radiator" under normal operating conditions is extremely small. To make it warm, you need to increase the temperature of the coolant, but is this justified? Thus, we almost everywhere come across an erroneous calculation of the number of sections in aluminum and bimetallic devices, which are based on the selection "according to the nominal temperature flow", and not on the basis of the actual temperature operating conditions.

Fig. 2. Sectional view of an aluminum radiator.

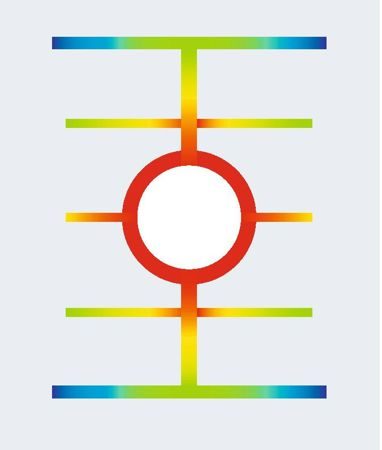

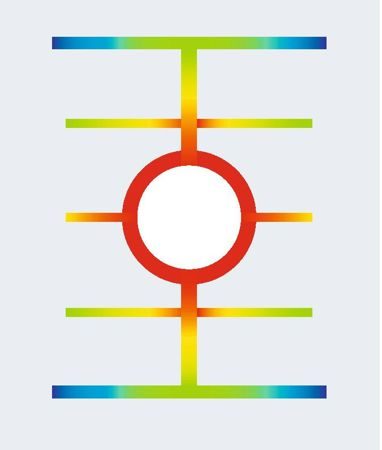

Steel panel radiator.The hottest part of it - the outer panel with the coolant - is located outside the heater. The lamellas are heated from it, and the closer to the center of the radiator, the colder the lamellas. Convection at low temperatures interferes with the viscosity of the air. What about radiation? Radiation from the outer panel lasts as long as there is a difference between the temperatures of the surfaces of the heater and the surrounding objects. That is, always!

Fig. 3. Sectional view of a steel radiator.

⃰ The hottest part of a steel panel radiator - the external heating medium panel - is located outside the heater. The lamellas are heated from it, and the closer to the center of the radiator, the colder the lamellas. And there is always radiation from the outer panel! ⃰

In addition to the radiator, this useful property is also inherent in radiator convectors. In them, the coolant also flows from the outside through rectangular pipes, and the lamellas of the convective element are located inside the device. The use of modern energy efficient heating devices helps to reduce heating costs, and a wide range of standard sizes of panel radiators from leading manufacturers will easily help to implement projects of any complexity.Source: https: //www.c-o-k.ru/articles/energoeffektivnost-stalnyh-panelnyh-radiatorov-v-nizkotemperaturnyh-sistemah-otopleniya This may be useful to you: Our price list Design Contacts