Industrial production is characterized by specific working conditions, among which there may be toxic, gas, thermal emissions from technological equipment into the environment. To eliminate such negative factors, industrial ventilation is organized inside the industrial workshop - a complex, multi-level system for normalizing microclimatic indicators. Designed to remove hazardous heat and gas emissions from industrial equipment from the working area of personnel.

Types of industrial ventilation

Air exchange in industrial locations can be done in different ways. Depending on the organization of the device, there are three types of industrial ventilation:

- Natural

- Mechanical (artificial)

- Mixed

Each type has its own characteristics and disadvantages, which should be considered when organizing the system in production.

Flexible pricing policy

Industrial ventilation and air conditioning systems from our company are always excellent quality indicators and a long service life. We work in almost all regions and regions of Russia.

Our advantages are democratic, affordable prices while maintaining the high quality of work. This is due to the fact that the company is constantly establishing direct business ties directly with manufacturing plants, as well as with an integral part of the company's activities - a flexible pricing policy.

Any interested client can purchase ventilation systems and air conditioning in Moscow: both a legal entity and an individual, regardless of where it will be necessary to deliver products, install and install them. Our prices for its design and installation are affordable for many business partners, as well as regular customers.

Natural ventilation in production

The natural system functions due to the physical properties of pressure and temperature fluctuations in the room and outside.

It differs in turn:

- Organized

- Unorganized

Disorganized is considered when the air enters the room through leaking gaps in the building structure,

if there are no equipped ventilation devices.

Organized ventilation system for industrial premises performed by means of exhaust shafts, channels, vents, etc.,

with which you can control the amount and strength of the incoming air flow. An umbrella or a special device - a deflector - is often installed over the shafts of ventilation systems to increase traction.

Ventilation of industrial premises

Ventilation of industrial premises is one of the main components, which is included in the complex of measures to create favorable air conditions for humans in the room. The ventilation system must not only meet all sanitary standards, but also fully comply with the building's construction requirements. It must also support the meteorological parameters of different rooms - this must be taken into account when installing industrial ventilation. Proper ventilation is the main prerequisite for creating a comfortable indoor atmosphere.

The requirements for different ventilation systems are also different. For example, in a country house and in a city apartment, they will be completely different. In an apartment, the main factor is high-quality cleaning of the outside air, while for a country house, the noise level is more important.Therefore, cottage owners choose ventilation systems that make as little noise as possible during operation. The air outside the city is much cleaner than the city air, therefore, the requirements for the quality of filters in the city are stricter. Therefore, it is better to design a ventilation system even at the construction stage.

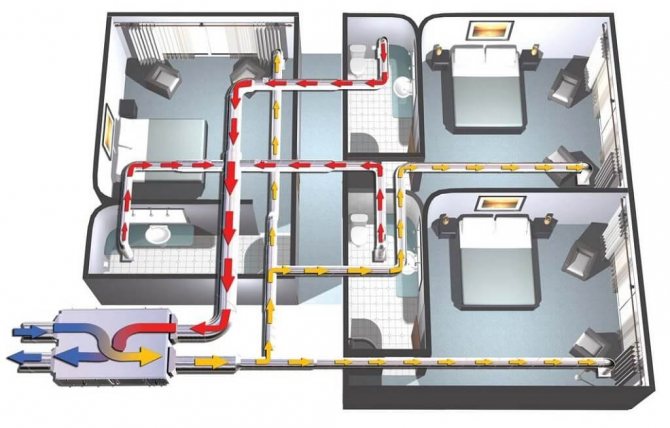

Each ventilation system must take into account the flow of air from the street and its return. For its balance in the house, they must be carried out synchronously.

Ventilation created artificially (mechanical) in production

This type provides the intake and removal of air flows using fans. The organization of a mechanical system requires an investment of large energy resources and economic costs. Despite this, it has a number of advantages:

- Allows air intake from the required location

- It is possible to influence the physical properties: cool or heat the air flow, increase or decrease the humidity level

- It is possible to supply air directly to the workplace or exhaust with subsequent filtration

Purification of polluted air from premises is a prerequisite for production. This factor is strictly controlled by environmental organizations.

A mechanical system, depending on the design, goals, and tasks assigned to it, differs:

- Supply

- Exhaust

- Supply and exhaust

At production sites, the air system is selected based on the needs and specifics of the site of operation.

Supply ventilation in production

Designed to supply the production area with clean air. Installed mainly in places with high operating temperatures and low concentration of harmful substances.

Unclean air is removed through natural ventilation outlets (transoms, ventilation shafts), additionally supported by the air flow of supply ventilation.

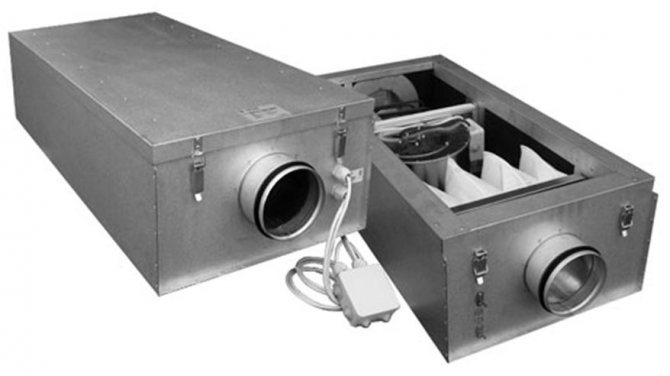

The following air handling units are distinguished by the type of device:

- Monoblock. These devices are easy to operate and maintain, but they are expensive. During installation, the main unit is fixed, to which the air ducts are supplied and the electrical power is connected.

- Typesetting. The devices require special skills to install and are relatively inexpensive in price.

With supply ventilation you can influence the environment

and subject to the necessary processing: heat, dry, humidify, depending on the type of production.

Exhaust ventilation in production

It performs the opposite functions of supply ventilation. Exhaust ventilation system for industrial premises provides air removal.

In production, it is independently used for small movements of the air flow. Depending on the prevalence, exhaust ventilation is distinguished:

- General exchange. Air movement covers the volume of the entire room

- Local. Designed to remove air from a specific workplace

Mainly installed in warehouses, utility rooms, in places where where there is no large concentration of harmful gases and impurities.

In this case, the inflow comes by the infiltration method through the building frame, windows, transoms.

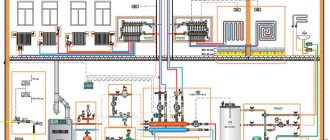

Supply and exhaust ventilation in industrial premises

The main task of the supply and exhaust system is providing production facilities with fresh air flow

and removal of treated, contaminated air. This type of system is the most common in industries with increased requirements for air exchange. It is necessary to correctly calculate when installing flow and exhaust ventilation in factories so that air flows do not enter, unnecessarily, into adjacent rooms and are not removed from there.

Fresh air supply devices are placed on the equipment maintenance side, so that harmful substances or warm vapors do not fall on personnel.

Accurate calculations are required for this type of installation.

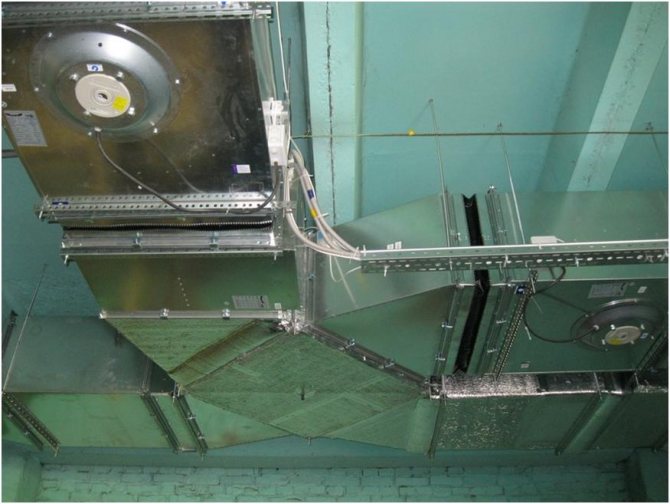

Industrial premises with mechanical ventilation

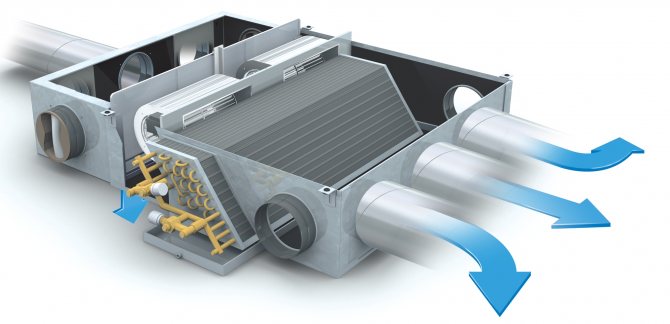

Industrial ventilation, carried out by this method, has a higher productivity in comparison with the natural method. In addition, special equipment is used here, which cleans the air coming from outside from dust and dirt, and the exhaust air emitted into the atmosphere also necessarily passes through a special cleaning system.

These systems are installed in such a way that they do not purify the air, but prevent the emission of harmful dust or vapors directly into the working room itself.

The elements of installations with mechanical ventilation include air intakes. fans, ventilation ducts, filters for air purification from harmful impurities and, of course, a device for the outflow of exhaust air.

The systems are calculated in such a way that the air from the outside is supplied to the place of the highest concentration of harmful substances. Most often the supply ducts are made of ordinary steel. But if aggressive reagents are present in the working shop, for example, alkali vapors, then the installation of the supply ventilation ducts should be carried out only from stainless steel, ceramics or plastic.

In the cold season, large air volumes entering the workshops are usually heated using air heaters. At the same time, so that it does not happen in production that due to heating the air becomes too dry, it is passed through special irrigation chambers. Passing through these devices, it is humidified by water or steam.

How to calculate supply and exhaust ventilation

The first step in the design of supply and exhaust ventilation in industrial places is to determine the source of harmful or hazardous substances. Next, it is calculated how much air must be removed from the room and the air flow for the safe work of workers. Ideally, if there is no environmental pollution at the enterprise, then the required air flow is calculated:

L = N x m

Where: L is the amount of air used; N is the number of people working in the room; M is the consumed air per person per hour.

The amount of air consumption per person is regulated by sanitary standards and amounts to: 60 m3 / h per person - unventilated room, 30 m3 / h - ventilated room.

Individual substances have their own concentration standards for production. In order to ensure that the amount of harmful substances does not exceed the permissible values, a clean air flow is supplied to production sites, which is calculated by the formula:

L = Mv / (ypom - yp),

Where: L is the required amount of fresh air to supply m3 / h; Mw - harmful substances entering the room, mg / h; ypom - specific pollution of the entire production area, mg / m3; yп - the amount of this substance in the incoming air flow, mg / m3.

To create the correct air balance, it is necessary to take into account the amount of hazards and local suction in order to accurately calculate how much fresh air should be supplied.

Requirements for the ventilation system in production

Systems are regulated by special sanitary standards, which are disclosed in SNiP "Ventilation of special and industrial buildings". The main provisions that should be highlighted:

- Installation in industrial places should be carried out in any production, regardless of the number of workers and pollution. This is necessary for safety reasons in the event of an accident or fire in order to be able to clean the required place.

- The system itself must not cause contamination. This is excluded in new technologies.Requirements apply to older devices requiring replacement

- The noise of the ventilation unit must comply with the standards and not amplify the noise from production

- With the prevalence of air pollution, the amount of extracted air must be greater than the supply air. If the place is clean, then the situation should be the opposite, the inflow is greater, and the exhaust is less. This is necessary to avoid contaminated air flow into the surrounding areas. In most other cases, it is necessary to maintain a balance of inflow and removal of air.

- According to the norms, not less than 30 m3 / h per person of fresh air, with increased areas of production places, the amount of clean supplied air should be increased

- The amount of incoming clean air per person must be sufficient. Calculations establish the air flow rate and its mass. The following factors are taken into account: humidity, excess heat and environmental pollution. If several or all of the above factors are observed, then the amount of inflow is calculated according to the superior value.

- The structure and type of the system at each production facility are regulated by SNiP. Any system can be installed as long as the design is carried out in compliance with laws and regulations

Emergency ventilation in production

It is an independent installation, which is necessary to ensure safe working conditions in production with the likelihood of the release of harmful and hazardous substances.

The emergency system device works only for the hood. This is necessary to avoid contaminated air getting into different places.

Ventilation of industrial premises is a labor-intensive and energy-consuming process that requires specialized knowledge and skills. Regardless of the type and type of ventilation device in production, two main factors must be observed: correct design and functionality. If these conditions are met, a correct and healthy microclimate is ensured.

Species variety of ventilation systems

Industrial ventilation systems are divided into two main types, namely:

- General exchange, or the so-called supply ventilation system. This system aims to reduce the concentration of harmful substances by mixing indoor air with fresh air coming from outside.

- Local exhaust system. Its peculiarity lies in the fact that such a device fights harmful and hazardous substances in the room by releasing them outside. Thus, only fresh air remains in the building.

Also, it is worth noting that general ventilation copes well even with particularly strong air pollution. The amount of air entering the room with the help of this system is equal to those volumes that will precisely dilute the amount of harmful substances to the permitted levels.

Supply ventilation also has a number of limitations. Thus, if such a system was chosen as a device for protecting workers in a hazardous enterprise, it is important to be aware of the following points:

- Such a system is not able to cleanse the air from all contaminants.

- Does not remove large amounts of dust, gases and metal vapors.

- Not effective in removing intermittent emissions.

- The use of such a system is impractical when working with highly toxic substances.

- Requires large amounts of air for cooling and heating.

Supply and exhaust type of ventilation creates specific conditions in the room, which are set by the parameters. This can be achieved with the help of specific technical designs, including:

- Air curtain. It is a flat stream of air that is dense enough to prevent harmful substances from entering the air of a certain space.

- Ventilation grilles are a special system that can fill a room with fresh air.

- Air distribution grille - is a precisely directed air stream that can be installed next to a work or technical unit.

Any ventilation system has a number of limitations:

- Any ventilation requires maintenance.

- If problems arise, testing is required immediately.

- During long-term operation of the device, contamination is deposited in the ventilation system, which leads to ineffective operation of the system.

- Periodically, it is required to use the services of professionals to determine the effectiveness of the ventilation.