Opinion of the owners of country houses about the system

According to most owners of suburban real estate, this scheme is really very effective - the Tichelman loop. This system has earned excellent reviews. A very comfortable microclimate is established in a house with its correct design and assembly. At the same time, the equipment of the system itself rarely breaks down and serves for a long time.

Not only the owners of residential buildings, but also the owners of summer cottages speak well of the Tichelman loop. The heating system in such buildings is often used irregularly during the cold season. If the wiring is done according to a dead-end scheme, when the boiler is turned on, the rooms warm up extremely unevenly. Of course, there are no such problems with a passing system. But the cost of assembling heating according to such a scheme is really more expensive than according to a dead-end one.

Myths around the device

If you ever have to face the need to make a choice between such systems for heating a house as a passing and a dead end, you will surely notice how controversial reviews and myths regarding the first option fill the network space. Meanwhile, practice shows that the lion's share of publications by pseudo-professionals have no practical basis and are built exclusively on a hypothetical plane. So, experts identify three most common myths that tarnish the glory of heating with a passing movement of the coolant:

- There is no need to balance such a system, and therefore it is not necessary to install balancing type valves on a heating device in its design;

- In this design, both the diameter and the length of the pipeline can be deliberately reduced.

- Each circulating ring has the same hydraulic resistance.

It is worth noting that there are certain state standards, as well as special textbooks, by turning to which you can quickly make sure that the myths presented above are false.

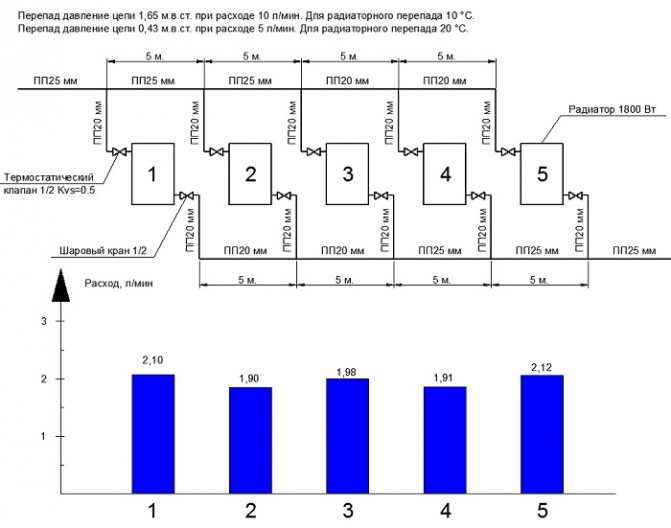

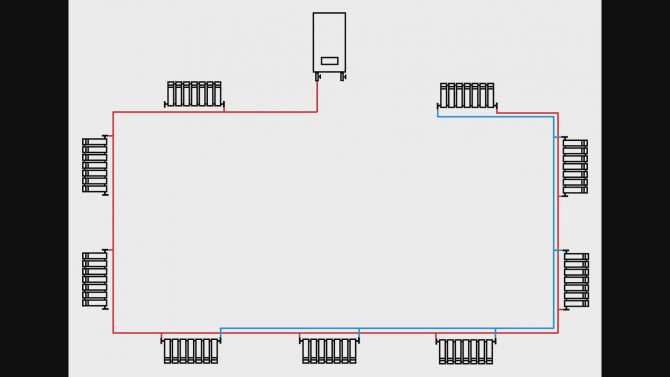

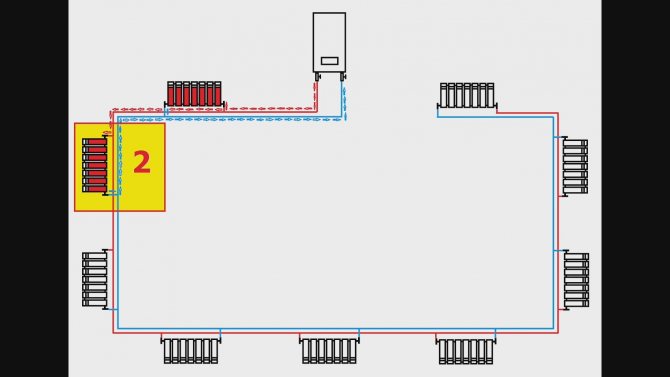

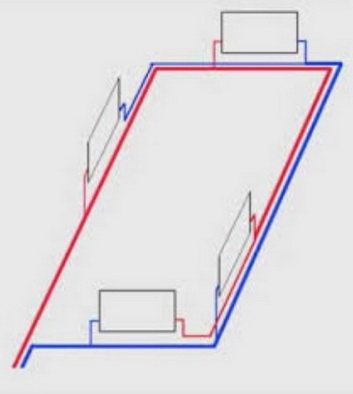

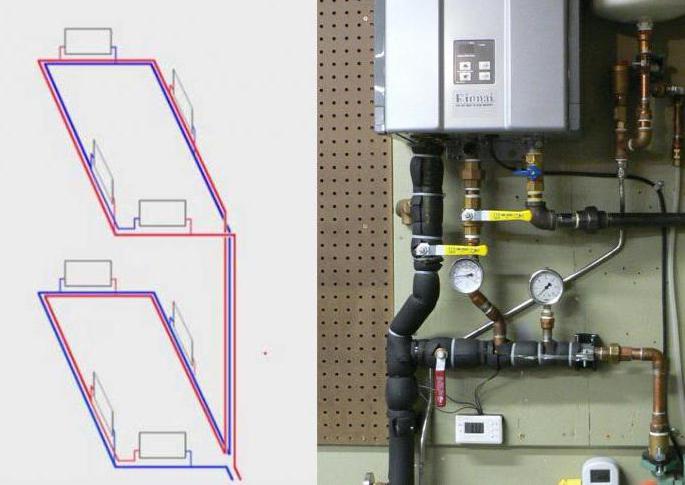

Example of a "loop" scheme

Installation procedure

The work consists of the following operations:

- Boiler installation. The required minimum height of the room for its placement is 2.5 m, the permissible volume of the room is 8 cubic meters. m. The required power of the equipment is determined by calculation (examples are given in special reference books). Approximately for heating 10 sq. m requires a power of 1 kW.

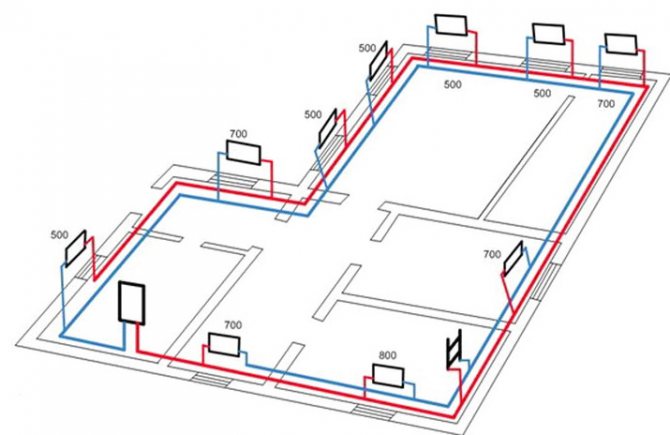

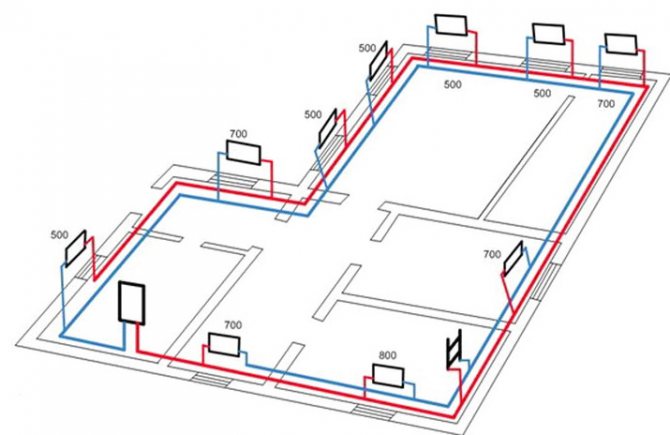

- Mounting of radiator sections. The use of biometric products in private homes is recommended. After selecting the required number of radiators, their location is marked (as a rule, under window openings) and fastened using special brackets.

- Pulling the line of the associated heating system. It is optimal to use metal-plastic pipes that successfully withstand high temperature conditions, which are distinguished by their durability and ease of installation. The main pipelines (supply and "return") from 20 to 26 mm and 16 mm for connecting radiators.

- Installation of a circulation pump. It is mounted on the return pipe near the boiler. The tie-in is carried out through a bypass with 3 taps. A special filter must be installed in front of the pump, which will significantly increase the life of the device.

- Installation of an expansion tank and elements that ensure the safety of the equipment. For a heating system with a passing flow of the heating medium, only membrane expansion tanks are selected. The elements of the safety group are supplied complete with the boiler.

For tracing the main line of doorways in utility rooms and utility rooms, it is allowed to mount pipes directly above the door. In this place, in order to exclude the accumulation of air, automatic air vents are necessarily installed. In residential areas, pipes can be laid under a door in the floor body or bypassing an obstacle using a third pipe.

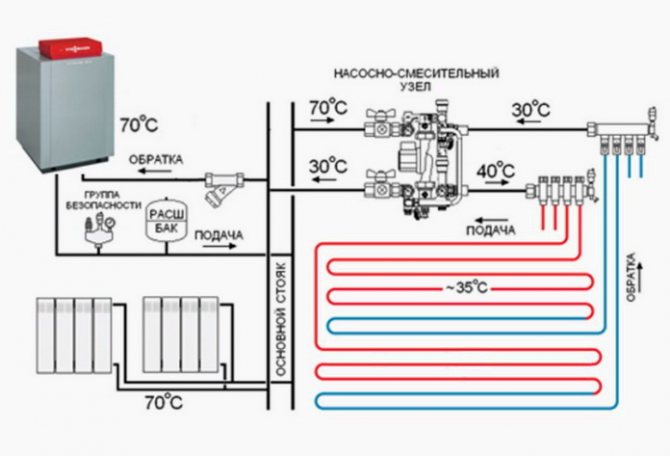

Tichelman's scheme for two-story houses provides for a certain technology. Piping is performed with the tying of the entire building as a whole, and not each floor separately. It is recommended to install one circulation pump on each floor while maintaining equal lengths of return and supply pipelines for each radiator separately in accordance with the basic conditions of the associated two-pipe heating system. If you install one pump, which is quite acceptable, then if it fails, the heating system in the entire building will turn off.

Many experts consider it advisable to install a common riser on two floors with separate piping on each floor. This will allow taking into account the difference in heat loss on each floor with the selection of pipe diameters and the number of required sections in radiator batteries.

A separate passing heating scheme on the floors will greatly simplify the setup of the system and will allow for optimal balancing of the heating of the entire building. But in order to obtain the desired effect, it is imperative that a tie-in into the loop of the balancing crane is required for each of the two floors. The taps can be placed side by side directly next to the boiler.

Tichelman loop - reliable heating for large houses, how to make

Gone are the days when gravity and single-pipe systems were installed using large diameter steel pipes. Now such options would be too expensive compared to modern two-pipe, as well as less efficient and stable.

The Tichelman loop is one of the most widely used heating schemes in private houses. It is characterized by stability of operation and uniform heating of all radiators - the main requirements for heating systems in private houses are met.

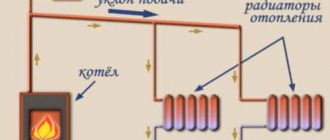

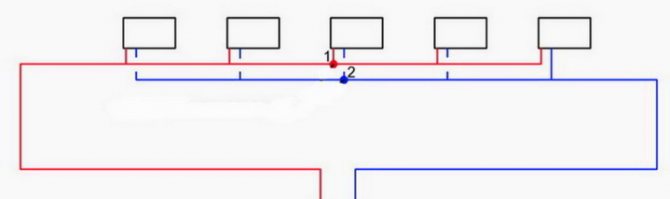

Tichelman loop diagram

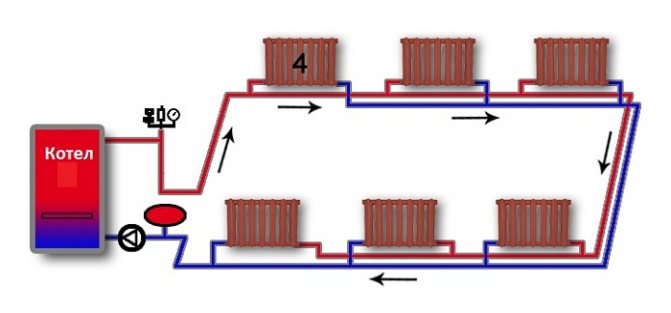

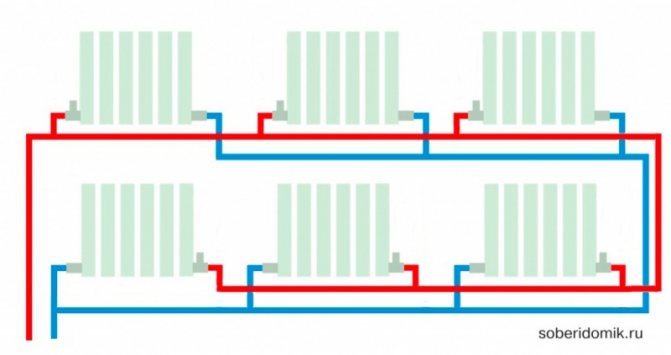

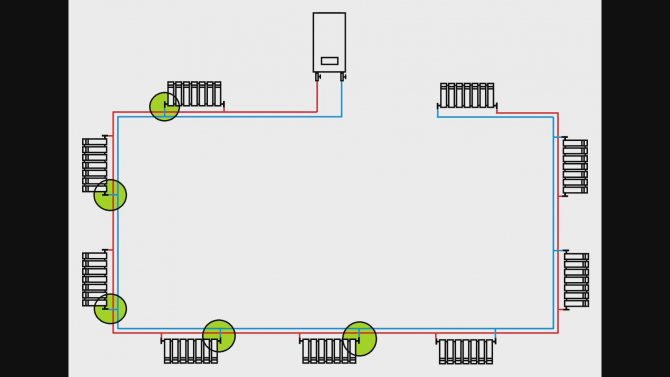

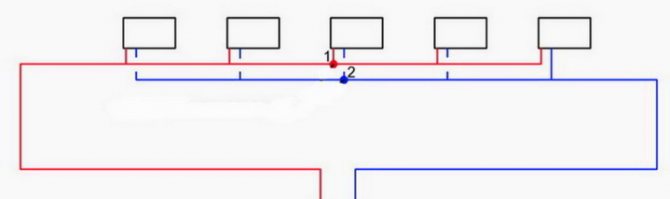

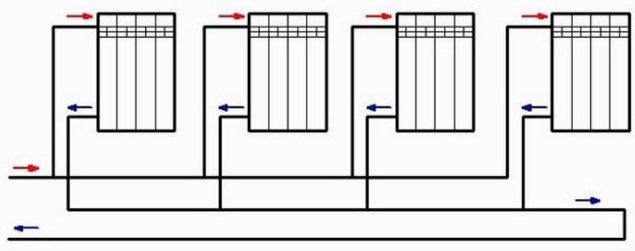

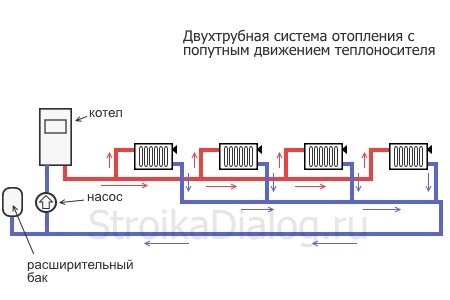

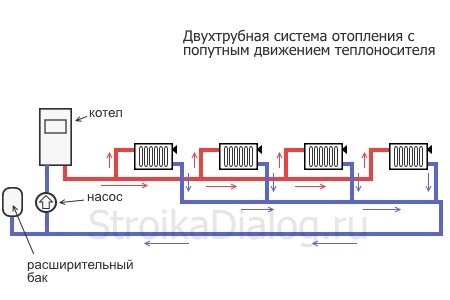

This scheme for connecting heating devices is also called passing. It provides the following:

- For each radiator, the sum of the lengths of supply and return is the same.

- The hydraulic conditions for each radiator in the system are the same.

If the hydraulic resistances of the radiators are equal, then an equal amount of coolant with the same temperature will pass through them, respectively, their thermal power will be approximately equal.

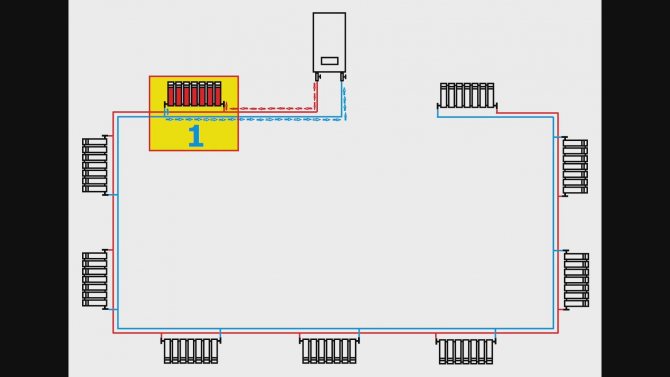

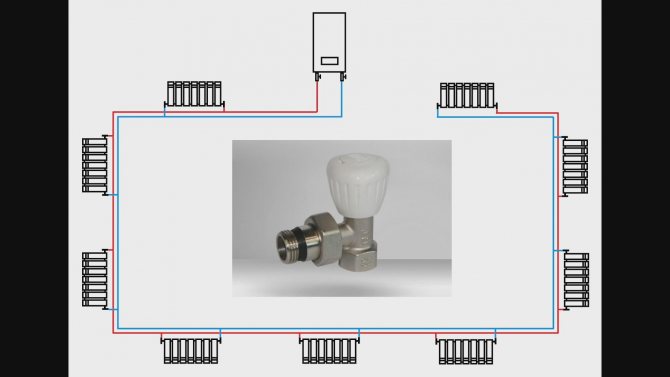

The operating modes of radiators that are not the same, either installed at a distance from the mains, or installed above / below, in niches ... can be adjusted using balancing valves at the outlets.

The flow ends at the last radiator, the return flow starts from the first radiator.

Where is applied

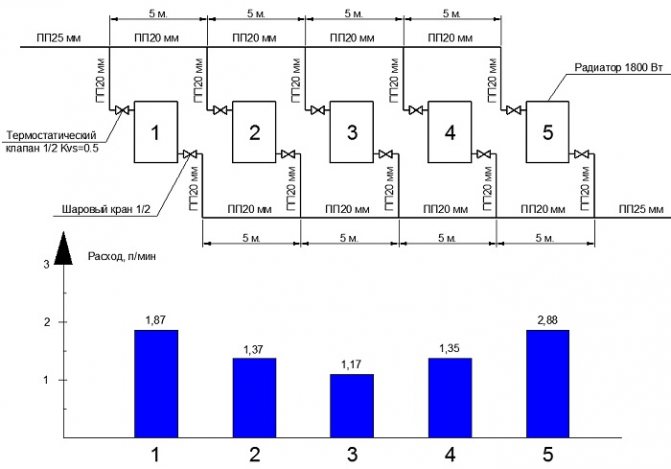

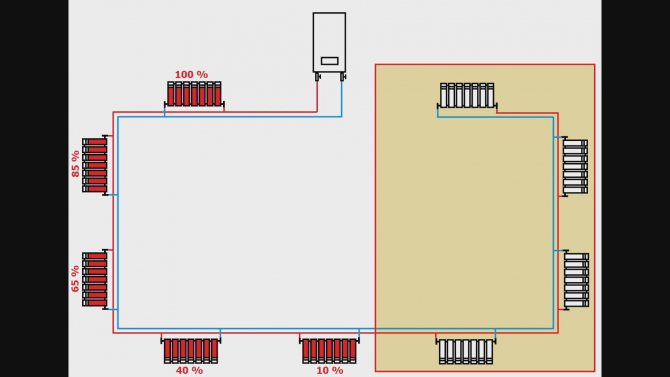

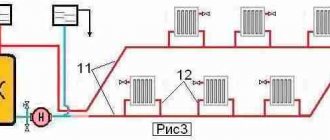

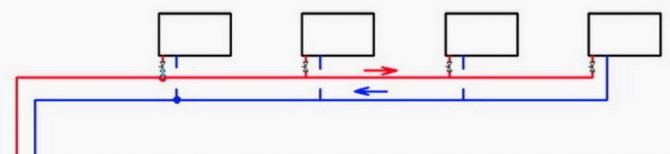

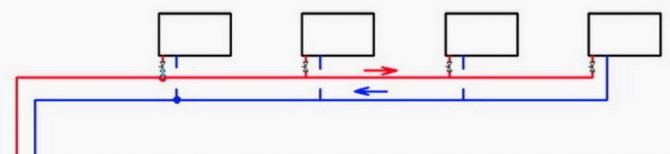

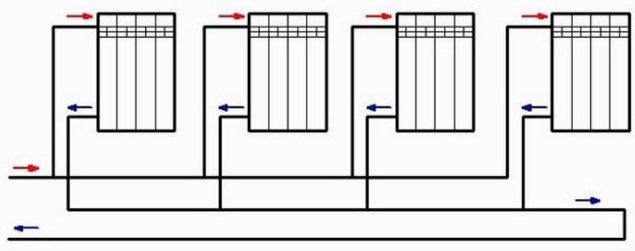

Another widespread heating scheme is dead-end. In it, the radiator closest to the boiler will warm up more, and the last radiator at a dead end will receive the coolant less than others. The dead-end scheme is shown in the figure.

For a dead-end scheme, the number of radiators in each arm is limited.

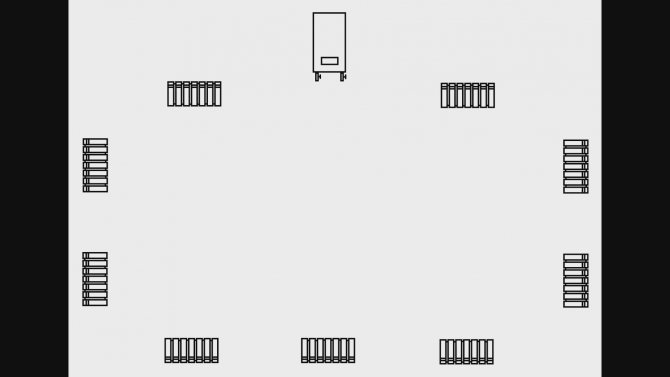

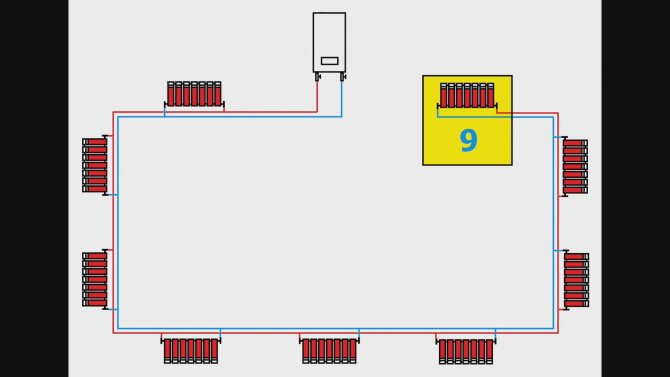

A Tichelmann loop can include a significantly larger number of radiators than an arm (or two arms) of a dead-end circuit. And it can be used for heating large areas.

In fact, the Tichelman loop can also be used to heat the largest area of one floor of a private house.

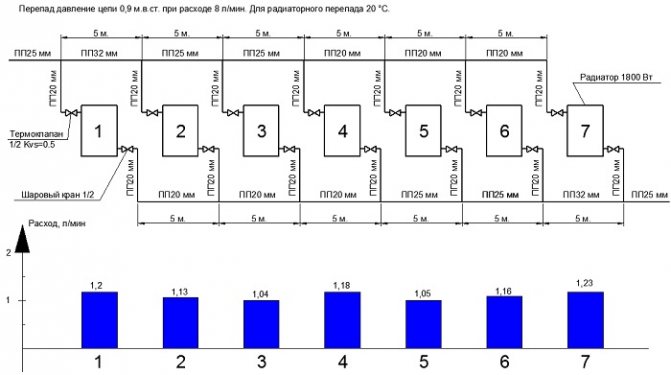

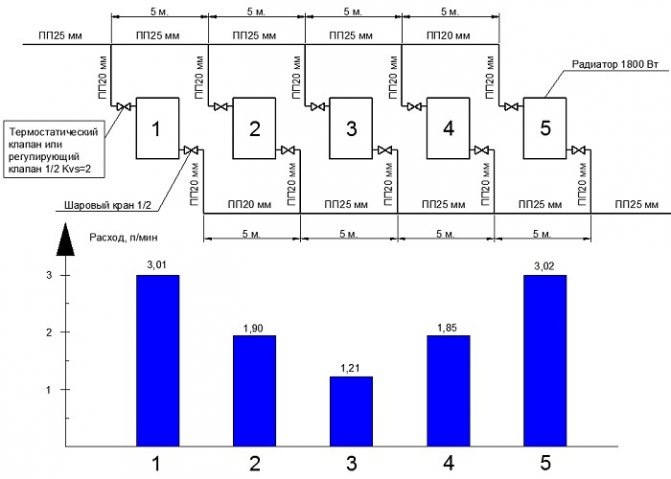

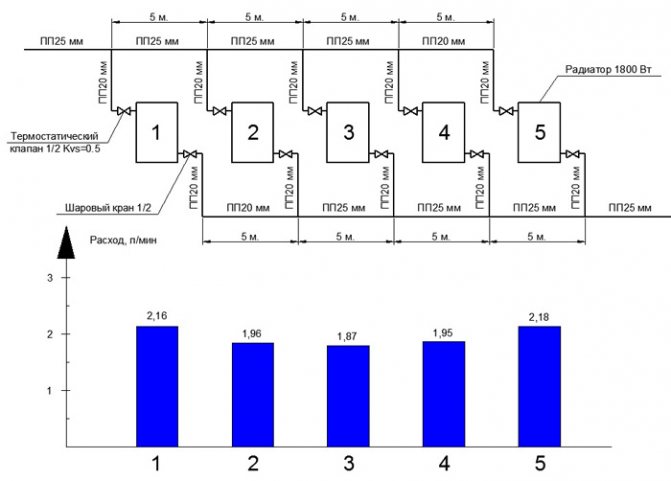

As you know, the dead-end circuit is balanced without any problems, and it works satisfactorily (the difference in the power of the radiators without balancing does not exceed 10%) if the number of radiators in the arm does not exceed 5 pcs. Accordingly, for 2 shoulders - up to 10 pcs.Above this amount - the scope of the passing scheme.

Can Tichelman's loop be used in small houses? It can even be used for one radiator. But most likely it will be problematic and (or) not economical. This scheme has its drawbacks.

disadvantages

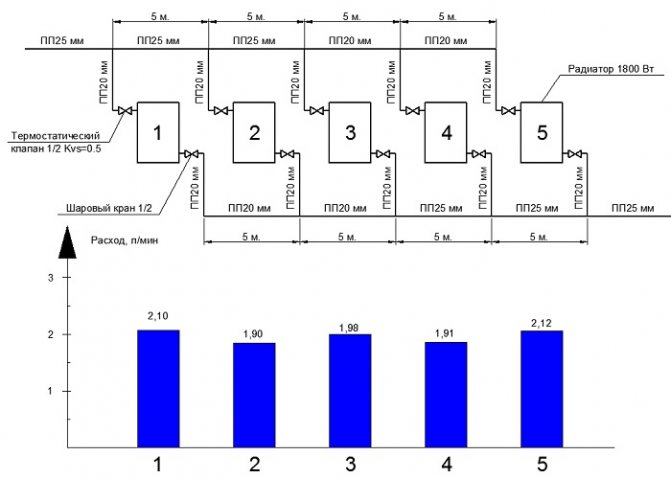

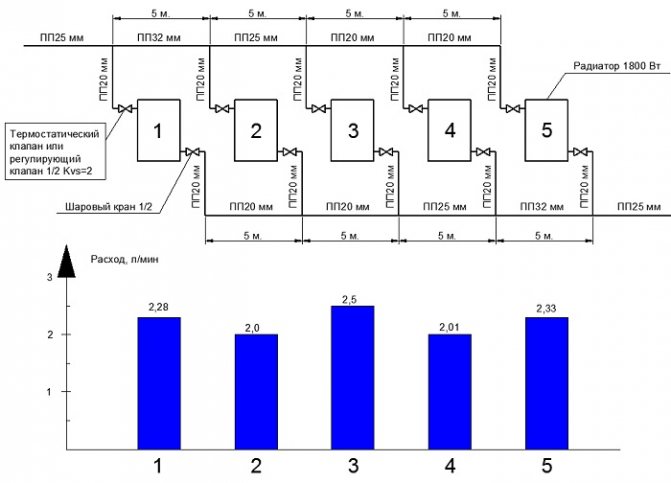

The inclusion of a large number of radiators in the Tichelman Loop ring results in an increase in the diameter of the pipelines.

Large diameter gaskets are cost-intensive. An attempt to reduce the diameters (only at the end sections of the ring the maximum flow is required) is generally not a rewarding exercise. Since the hydraulic conditions for connecting the radiators will vary, the system will be difficult to set up. As a rule, the same large diameter is used along the ring both on the supply and on the return. But in principle, a decrease in pipe diameters towards the middle is possible, provided that the length of sections with the same diameter and supply and return will be approximately equal.

A dead-end scheme, in which the supply and return to the last radiator can be of a minimum diameter, is more profitable.

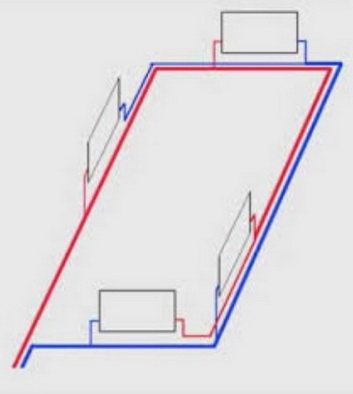

The second main drawback is associated with the need to go around the building with pipes along the perimeter along the outer walls and return to the boiler. Almost everywhere this is not easy to do - doors, high windows, stairways and more interfere.

Return the return line with a large diameter in the back direction, i.e. actually laying three pipes is not profitable.

In houses large in area, where the heating project has not been properly completed, it is necessary to engage in "design", combining various schemes, reverse piping in order to provide all the nooks with high-quality radiator heating.

In small houses, it is generally easier, more profitable to lay pipelines along the walls in a dead-end scheme. Modern projects provide special solutions ...

Tichelmann loop in modern large houses

In the modern design of private houses, it is not uncommon to find additional doors to the terrace, to the garden, to unheated rooms, as well as high windows to the floor. Hanging pipes on walls is considered unacceptable, an element of the interior that does not correspond to modern ideas.

Basically, it is planned to lay the heating pipeline under the flooring in the tunnels, dressed in heat-insulating shells so as not to destroy the structures by overheating.

The floors are made either on logs, or a thick screed is laid (warm floor). Mainly flexible piping is used, elbow fittings are not used.

In modern houses, the Tichelman loop loses its main drawback - the complexity of laying a vicious circle on the distributor. Can be easily used in small and large areas, when installed under the floor.

Recently, floor convectors have been increasingly used under high windows. The Tichelman loop will turn out to be a suitable circuit for connecting convectors, more economical and stable compared to the beam circuit with a large number (more than 4 pieces) of heating devices.

Pipes, pumps for a passing circuit

Private houses are always of a compressed layout, there are no long lines to heating devices, - there is no increased hydraulic resistance in the circuits.

Recommendations to make calculations of the heating system are unnecessary, since the exact heat loss of the building cannot be independently established, and the equipment used is standard, it remains only to choose the appropriate one from a couple of samples.

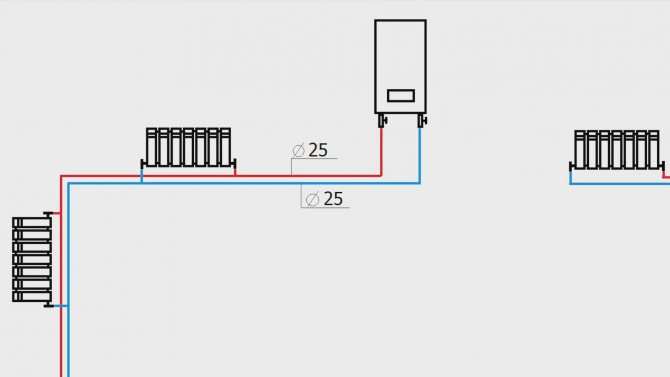

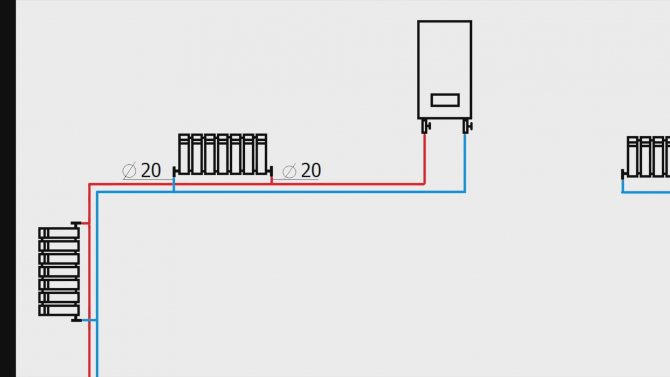

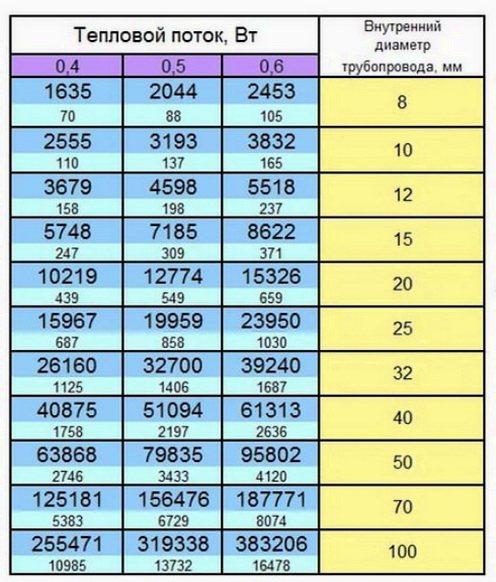

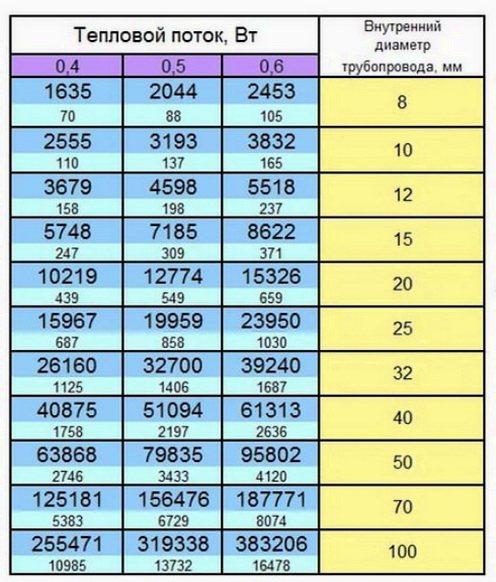

To determine the diameter of the pipes for the Tichelman loop, you can use the tabular data, the dependence of the diameter on the required energy.

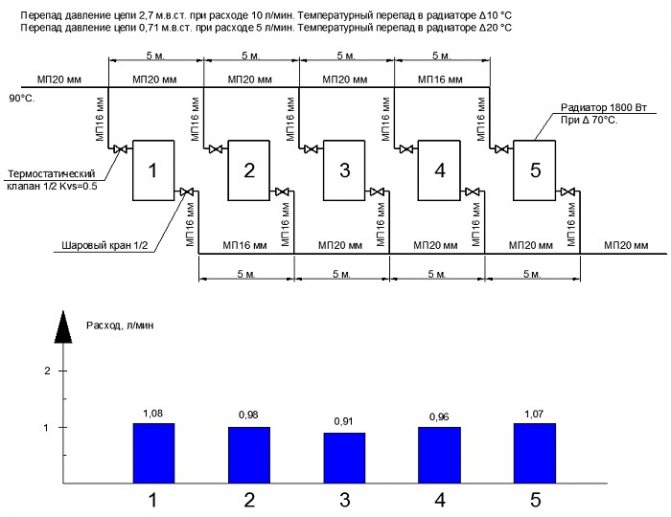

With heat losses of up to 15 kW (150 square meters) of area, pipes with an inner diameter of 20 mm will be suitable.They are also used for the main lines in most cases, up to about 8 radiators in a ring.

With heat losses from 15 to 27 kW (up to 250 sq. M. Area) - it is necessary to use pipes of 25 mm on the highways, so that in the future the pump will work more economically.

The diameter of the piping in the loop can be reduced as calculated. And with the condition indicated above. In any case, a minimum diameter of 16 mm is laid to the last radiator according to the flow.

All radiators are connected by layouts with an inner diameter of 16mm.

For heated areas up to 180 sq. M. you can use a pump 25-40, up to an area of 250 sq. m. - pump 25-60.

The new modern circulation pumps of the Alpha type are perfect for the Tichelman loop, which you can read about HERE

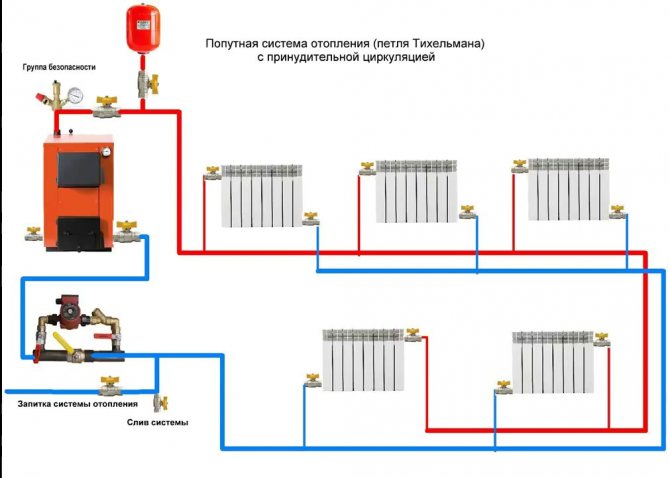

For a two-story house

It is advisable to make a common riser and lay a separate Tichelman loop ring for each floor. It is important to take into account that the energy losses for each floor will differ significantly, in accordance with this, the selection of radiators is made, as well as the diameter of the pipes.

Separate floor plans will allow one floor to be balanced against another and greatly simplify system setup. It is only important not to forget to include a balancing crane in the loop for each floor. If there are 2 floors, then these taps can be located nearby in the boiler room.

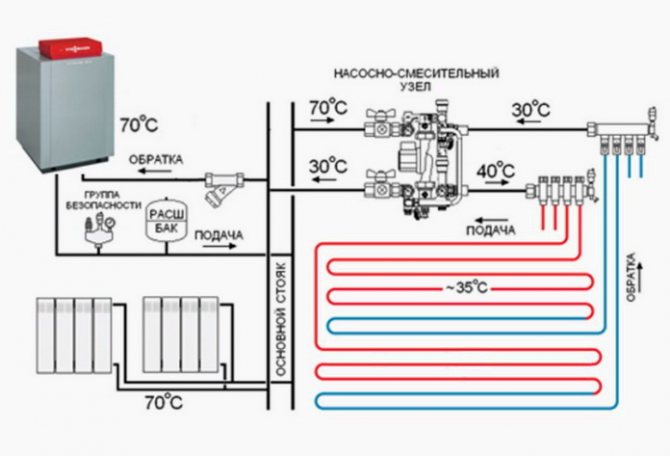

How the warm floor is connected to the Tichelman Loop

The warm floor is connected in parallel to a passing circuit, within each floor. At the same time, the balancing valves of the radiator circuit on each floor should not affect the operation of the warm floor. Those. according to the scheme, the taps should be located farther from the boiler than the inclusion of a warm floor.

The underfloor heating circuit with a mixing unit is necessarily supplied with its own circulation pump. Short circuits with flow limiter adjustment are connected without an additional pump, but must be taken into account in the calculation of the general hydraulic circuit. Since, most likely, a more powerful pump will be needed due to an increase in the total flow.

Do-it-yourself Tichelman loop

When installing the heating system, one must not forget the issues of draining the liquid and the possibility of airing. Therefore, in principle, it is possible to bypass the doorway with the pipeline, but one must not forget to put the air vent at the highest point and ensure the drain from the bottom.

In general, it is not uncommon when longer dead-end circuits are made in order not to get involved with the height differences that the Tichelman Loop forces.

It is also worth doubting the quality of polypropylene soldering, and it is possible to take up metal-plastic, how to make a high-quality connection with metal-plastic, read HERE

When installing, you must not forget the main rules:

- protection of a solid fuel boiler from a cold return - how to do

- installation of a hydraulic accumulator in the heating system, which has to be selected

And also much more.

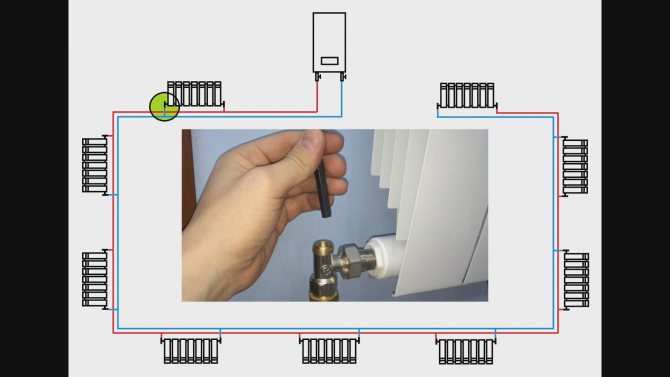

We must not forget that the Tichelman loop is, in general, a "gentle" scheme in terms of the inequality of the hydraulic resistance of the radiators, therefore all radiators are supplied with tuning taps on the return line. For more details about connecting radiators, you can find out how

Tichelmann loop for two floors or more

Most often, such a heating system is installed in large one-story buildings. It is in such houses that she works most effectively. However, sometimes such a system is assembled in two or three-story buildings. When performing wiring in such houses, you should adhere to a certain technology. According to the Tichelman scheme, in this case, not each floor is tied separately, but the entire building as a whole. That is, an equal sum of the lengths of the return and supply pipelines for each radiator of the house is kept.

Thus, the Tichelmann loop for two floors is assembled according to a special scheme.Also, experts believe that using only one circulation pump in this case is impractical. If possible, it is worth installing one such device on each floor in the building. Otherwise, if the only pump breaks down, the heating will be turned off in the whole house at once.

System advantages

This layout has the following advantages:

- no need for complex balancing;

- uniform heating of all rooms in the house;

- work with maximum efficiency.

In dead-end two-pipe systems, the radiators located next to the boiler always heat up more strongly than those installed in remote rooms. In order to remedy the situation, balancing cranes are used in such schemes. With their help, the amount of coolant passing through the batteries located closer to the boiler is limited. But even balancing such systems does not allow all radiators to be used at full capacity. In addition, with such a scheme, you have to install a more powerful pump.

The accompanying circuit of the heating system, the Tichelman loop, is completely devoid of such shortcomings. All batteries in it work in absolutely equal conditions. That is, there is no need to balance it.

Areas of application of the Tichelman hinge

The increased consumption of materials is not always better, therefore, the Tichelman system in a two-story house is rarely used. The exception is the highway with the placement of radiators around the perimeter of the building. The ring system will require significant costs for materials, but the arrangement of the closed ring is carried out only in the absence of interference in the form of doorways, windows "to the floor". We'll have to lay another line to return the coolant to the heating device.

If the loop is lengthened, moved away from the heater, the pipe cross-section is increased, or a powerful circulation pump is selected, otherwise the system will not be able to work at full capacity.

To reduce the flow rate of the coolant in the area where the first batteries are connected, the diameter of the pipeline should be reduced, this will help maintain the water pressure in subsequent sections. Reducing the diameter is carried out only according to preliminary calculations, otherwise the radiators located at a considerable distance from the heating device will not receive the coolant in sufficient volume.

It turns out that it is possible to use two-pipe wiring with a passing water flow only with a total length of the line of 70 meters, on which it is installed from 10 radiators. Otherwise, the associated wiring will not justify the investment.

What is Tichelman's loop

The Tichelman loop (also called a "passing scheme") is a piping diagram of a heating system. Such a scheme combines the advantages of two common schemes at the same time: the Leningrad and two-pipe, while having additional advantages.

When compared with a two-pipe scheme, when using the Tichelman loop, there is no need to install expensive control systems. The heaters work like one large radiator. The coolant flow is the same throughout the heating circuit. There are no pipe constrictions and dead-end radiators, in which the duct is the worst. The disadvantage in comparison with a two-pipe heating scheme is that the entire branch must be made with a large diameter pipe, which can greatly affect the cost of the entire system as a whole.

If we compare it with the Leningrad (one-pipe) scheme, the advantage is that the coolant does not pass through the pipe past the radiator. The Leningrad scheme is very demanding on the scheme design and installation. With a low qualification of performing either the first or the second, it will be impossible to force the water to pass through the heater, it will pass through the pipe by. The radiator will remain slightly warm. In addition, in the Leningrad scheme, the first radiators in terms of water flow will be hotter than the subsequent ones. Since the water reaches them already chilled.The disadvantage of the Tichelman loop in comparison with the "Leningrad" loop is that the pipe consumption is almost doubled.

Of the general advantages, I would like to note that such a scheme is difficult to unbalance. The conditions for the movement of the coolant are almost ideal, which, moreover, is positively reflected in the operation of the heat generator (be it a boiler, solar systems or something else).

The main disadvantage of the associated heating scheme is certain requirements for the room. In practice, it is not always possible to organize the circular movement of the coolant. Doorways, architectural features, etc. may interfere. In addition, it can be used only with horizontal wiring; with a vertical Tichelman loop, it is not applicable.

Do-it-yourself Tichelman loop

Trim for Tichelman loop in the heating system

When self-installing such a structure, you need to pay attention to the following points: the type and size of the pipes used, the selection of the capacities of the components involved and their strapping. It should also be borne in mind that a configuration with height differences (with pipe laying over the doorway) requires air extraction and drainage. Sometimes, instead of arranging such an installation, they make a choice in favor of a dead-end scheme, which has a longer path length.

The feed contains the components responsible for the safety of the system. They include a pressure gauge, a bleed valve and an automatic air release device. The open configuration assumes vertical guidance of the track before the start of the evasion, with the expander placed at the highest point. The backbone is then routed to the remaining components of the network.

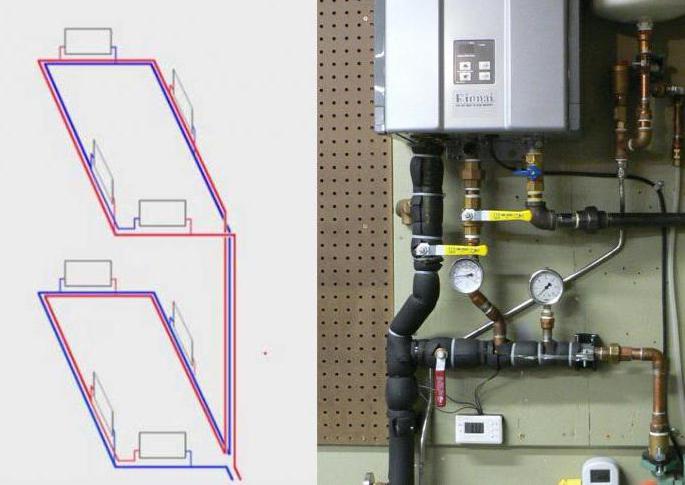

On the way back, a pump is installed, the power of which should be enough to neutralize the resistance of the hydraulics. The piping system for the boiler includes shut-off valves that are mounted next to it on both pipes and in the vicinity of the expansion tank. They are also attached to the sides of the pump and to the feed pipe located near it.

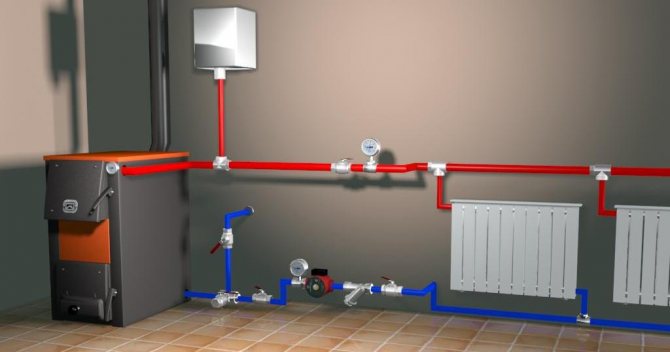

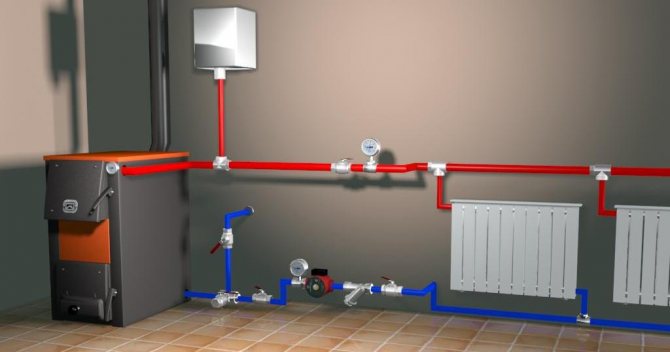

Traditionally used heating schemes

- One-pipe. The circulation of the heat carrier is carried out through one pipe without the use of pumps. On the line, the radiator batteries are connected in series, from the very last through the pipe the cooled medium is returned to the boiler (“return”). The system is simple to implement and economical due to the need for fewer pipes. But the parallel movement of streams leads to a gradual cooling of the water, as a result, to the radiators located at the end of the series chain, the carrier arrives significantly cooled. This effect increases with an increase in the number of radiator sections. Therefore, in rooms located near the boiler, it will be excessively hot, and in remote rooms, it will be cold. To increase heat transfer, the number of sections in the batteries is increased, different pipe diameters are installed, additional control valves are installed, and each radiator is equipped with bypasses.

- Two-pipe. Each radiator battery is connected in parallel to the pipes for the direct supply of the hot coolant and the “return”. That is, each device is supplied with an individual outlet to the "return". With the simultaneous discharge of cooled water into the common circuit, the coolant returns to the boiler for heating. But at the same time, the heating of heating devices also gradually decreases as they move away from sources of heat supply. The radiator, located first in the network, receives the hottest water and is the first to give the carrier to the “return”, while the radiator located at the end receives the coolant as the last one with a lowered heating temperature and also the last to give water to the return circuit. In practice, in the first appliance, the hot water circulation is the best, and in the last one it is the worst. It is worth noting the increased price of such systems in comparison with one-pipe systems.

Both schemes are justified for small areas, but ineffective with long networks.

An improved two-pipe heating scheme is Tichelman. When choosing a specific system, the determining factor is the availability of financial capabilities and the ability to provide the heating system with equipment that has the optimal required characteristics.

Tichelman heating feature

The idea of changing the principle of operation of the "return" was substantiated in 1901 by the German engineer Albert Tichelman, in whose honor it got its name - "Tichelman loop". The second name is “reversible type return system”. Since the movement of the coolant in both circuits, supply and return, is carried out in the same, concurrent direction, the third name is often used - “scheme with concomitant movement of thermal carriers”.

The essence of the idea consists in the presence of the same length of straight and return pipe sections connecting all radiator batteries with a boiler and a pump, which creates the same hydraulic conditions in all heating devices. Circulation loops of equal length create conditions for the hot coolant to pass the same path to the first and last radiators with the same thermal energy being received by them.

Tichelman loop diagram:

Two-pipe associated heating system - Calculation - Tichelman loop

If heating with a Tichelman loop is used for a two-story house with integration into the system of a pump of increased productivity, care must be taken to eliminate noise during the operation of the pump. Tichelman's scheme is quite simple.

In the classic two-pipe scheme, the return heating line starts from the last radiator and ends with the boiler, and the supply starts from the boiler and ends with the last radiator. It turns out that the first radiator from the boiler is the first on the supply and the last on the return, respectively, the last radiator is the last on the supply, but the first on the return.

This is a kind of direct-flow system in which the coolant moves in the same direction in the supply and return heating lines. First of all, we note the balance of the system and the absence of the need to install various adjusting equipment, which is quite expensive. In this case, the flow of the coolant throughout the system is the same, and the operation of the heat-generating equipment is optimal and has a high efficiency.

The disadvantages of the Tichelman scheme include the need to use additional pipes and preferably a large diameter, and this is an additional cost. Moreover, the architectural features of a private house do not always allow the installation of an open heating system with three pipes.

For example, doorways and a number of other architectural forms can interfere with the installation of this type of heating system. Therefore, it is not always possible to organize a circular movement of an intermediate coolant in a two-pipe heating system of a private house.

We also note that in most cases, when installing return heating systems of a reversible type according to the Tichelman scheme, horizontal wiring is used. For the rest of the characteristics and the heating equipment and heat generators used, the Tichelman loop does not differ from its two-pipe counterparts.

Heating systems in which the coolant is transported in a two-pipe passing scheme are called Tichelman's loop. The main features of the schemes are in the absence of balancing work, stability of operation. Consider the technical indicators, the device of the heating main, the possibility of using and shaping it yourself. You should understand the advantages and disadvantages of the heating scheme and calculate the costs before choosing a connection of this type for private mansions.

You are misleading those who are trying to find the correct answers for heating systems on your website.The presented scheme of the Tichelman loop, by definition, is not. The main advantage of the Tichelman loop is that the lengths of the straight and reverse sections for all radiators of the circuit must be the same relative to the boiler and pump, which guarantees equal hydraulic conditions for all radiators. This is NOT in your circuit.

Returning the return pipe with a large diameter towards the back, that is, in fact, laying three pipes is not profitable. In small houses, it is generally easier, more profitable to lay pipelines along the walls in a dead-end scheme. Modern projects provide special solutions…. In the modern design of private houses, it is not uncommon to find additional doors to the terrace, to the garden, to unheated rooms, as well as high windows to the floor.

Hanging pipes on walls is considered unacceptable, an element of the interior that does not correspond to modern ideas.