Advantages of polypropylene pipes

Of the many advantages of polypropylene elements, the following can be distinguished:

- No reaction with the coolant and no oxidation inside the pipe.

- Trouble-free operation for a long time, provided that the system is correctly installed.

- Easy repair and improvement.

- The ability to install heating from polypropylene pipes even by novice craftsmen.

- Low cost of material compared to metal products.

- Assembling the system without using complex equipment.

It is possible to lay polypropylene pipes without professional knowledge in this area.

Preparatory work for the installation of heating

The first step in the process of arranging a heating system is drawing up a project plan. In this case, the total length of the pipes should be taken into account, as well as the installation scheme for heating from polypropylene pipes.

In addition, the following points are taken into account:

- What type of connecting parts will be used when connected to a common circuit: welded, combined or threaded, allowing you to connect polypropylene and metal pipes.

- Are there difficult places where there are no conditions for performing pipe welding. If available, it is necessary to first connect the heating system elements.

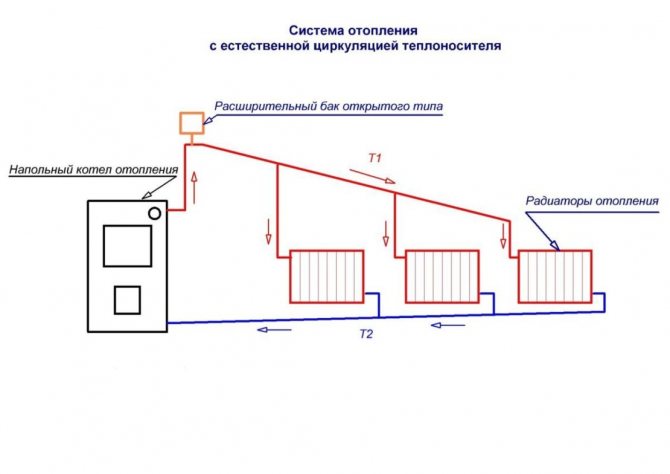

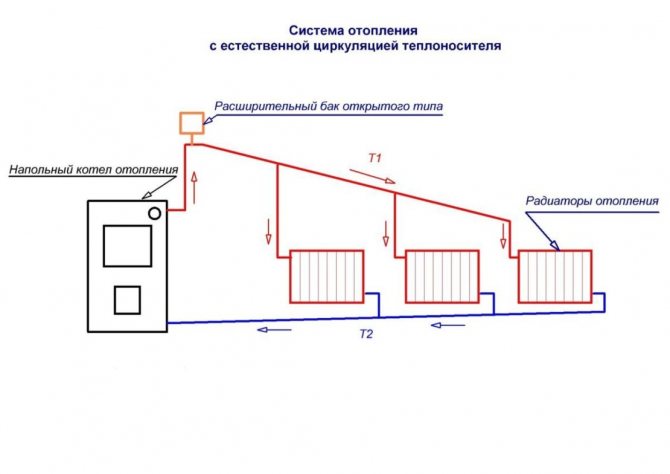

- Type of installed system: gravity circulation or forced movement of the coolant. There is a specific installation for each type.

- At what pressure will the system work, and what temperature the coolant will have.

It is not recommended to install a heating system from polypropylene pipes in rooms with a predominance of low air temperatures, as this increases the risk of deformation of polypropylene products.

To reduce the costs associated with the assembly of heating from polypropylene pipes, you can carry out the installation yourself. To do this, it is enough to have initial knowledge of working with tools and follow all stages of assembly.

Advantages and Disadvantages of the Gravity System

The heating system of a one-story house with natural circulation has the following advantages:

- Networks are easy to install and operate. There is no need to invite specialists to service them.

- A circulation pump and a safety group are not installed in the circuit. The absence of pumping equipment ensures quiet operation.

- Since no electrical appliances are used, the system is considered non-volatile and can operate even during a power outage.

Heating by gravity is not used in a multi-storey building and buildings with a large area. In such structures, it will not be possible to achieve effective heating and a comfortable temperature in the premises due to the fact that the coolant moves at a low speed.

Equipment for installation work

Self-assembly of the heating system is performed using a soldering iron for polypropylene pipes, in another way it is also called "iron". It is great for this type of work, but when choosing such a tool, some nuances should be taken into account:

- Inexpensive models of soldering irons for polypropylene pipes are supplied with Teflon-coated metal nozzles. More expensive soldering irons are equipped with copper tips.

- Large temperature range and high power make the device more convenient to operate.Observing the temperature and time parameters of the soldering, it is possible to efficiently assemble the heating system.

- Cheap soldering irons are not designed to last long.

- The shape of the "ironing" is of great importance. Tube-shaped devices cost several items more than hammer-shaped soldering irons. However, the first option simplifies the soldering of counter-joints and the welding of pipes with corner fittings in difficult places.

Professional equipment has a rich set, but it is not worth buying for this reason. Soldering iron tips are always available from specialized stores.

Installation of heating from PP pipes must be carried out according to certain rules, which state that the diameter of the nozzle must correspond to the diameter of the welded element. However, it should be borne in mind that nozzles of a different type can be used on tubular soldering irons, and hammer-like "irons" work only with their component parts.

Welding machines of a mechanical type are used on a professional level. When working with pipes of large diameter, the alignment of the joints is performed by a special hydraulic drive. Such a device provides comfortable conditions for welding pipe elements, the diameter of which exceeds 4 cm. The device is characterized by a minimum temperature error and high reliability. To carry out the installation of a heating system with such a device, you must have special skills and experience.

It is forbidden to operate any equipment used for welding polypropylene pipes without a reliable stand, which is most often one of the accessory parts. In addition, brazing of wet, wet or dirty pipes inside the PP is not allowed. All these factors adversely affect the tightness of the seams.

Possible heating main installation schemes

As for the number of pipelines, there are two usual options here:

- One-pipe wiring, when the coolant is sequentially supplied to the radiators - from one to the other. The disadvantage of this scheme is the cooling of the coolant along the path of movement, leading to uneven heating of the premises. Therefore, this option is used in small houses with no more than three radiators.

- Two-pipe wiring, when the coolant is simultaneously supplied to all radiators using the supply pipeline. The diversion is carried out via the return line. In this case, the heating of all radiators is the same and can be regulated. In addition, this option allows you to turn off any device for repair without shutting down the system.

The coolant supply can also be carried out according to two schemes:

- Bottom connection - the supply and return pipelines are located at the bottom - in the floor or under the ceiling of the basement. This allows for uniform heating of all radiators and saves on materials. But this option provides for the mandatory presence of a circulation pump.

- Top piping - the supply piping is located on top (under the ceiling of the upper floor of the house or in the attic). The return line is mounted under the floor or in the basement. The radiators are powered through vertical risers. This option can be operated without a pump, so it is relevant for those areas where power outages are possible.

The number of supply risers also provides various options:

- Single riser scheme - used in compact houses with two or three floors, when the area of each floor is relatively small. The coolant is supplied through the floors through one riser, from which wiring is done in all rooms.

- Scheme with several risers - provides for the installation of several risers feeding one heating device on each floor. This option is good for buildings with a large area.

In this case, the risers are connected to the boiler through separate lines.The autonomy of each riser allows you to disconnect them separately if necessary.

Types of polypropylene pipes

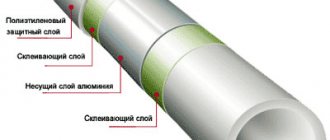

PP pipes are produced in two types:

- Reinforced.

- Unreinforced.

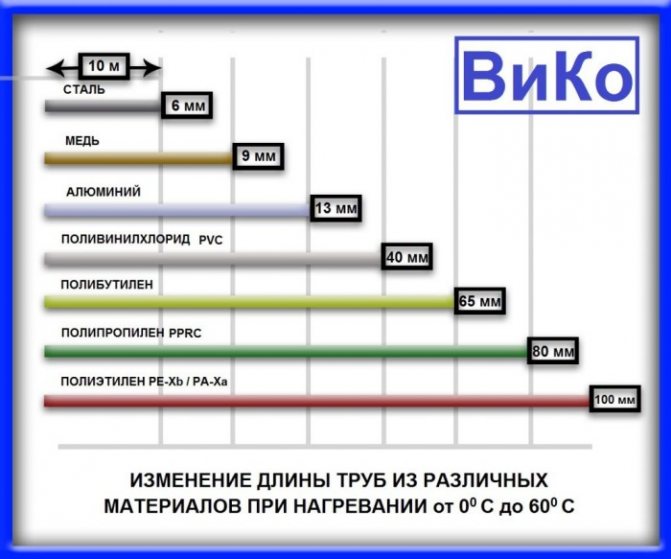

The first option is recommended for use on pipelines where the working medium has high pressures and temperatures. They belong to the category of "stabilized" ones, since they are characterized by the minimum coefficient of thermal deformation.

The second type of pipes is used in industrial systems where liquid heating is not provided, as well as when installing cold water supply systems, which can be easily done by hand.

For each type of work, pipes with a specific marking are used. For example, a pipe with the PN10 index has a working pressure of 10 atmospheres, and the temperature of the medium in such a pipe cannot exceed 450C. Such material is used for the installation of low-temperature plumbing systems. Pipes with the PN25 index (pressure 25 atmospheres and temperature 950C) are used in hot water supply systems and in heating.

Pipes marked with the PPR index have a strictly industrial purpose; the manufacturer does not recommend the use of such materials for the transportation of drinking water.

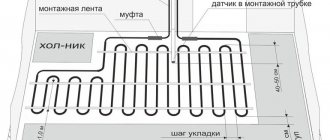

Installation of the underfloor heating system is carried out using specialized polypropylene pipes. Such material is supplied in coils, since the system does not imply welding of elements. In this case, the docking with the coolant collector is carried out using crimp couplings, the fixation of which is performed with special pliers. The cost of this tool is quite high, so it is more profitable to rent it for the duration of installation or repair work.

Pipe elements can be laid in two ways: “snail” or “along the contour”. In both cases, it should be taken into account that polypropylene pipes do not have the ability to bend strongly, this can lead to irreversible damage to the pipe.

The underfloor heating system made of polypropylene pipes must be laid on a prepared base. In most cases, the base is polyurethane foam insulation with an additional foil layer.

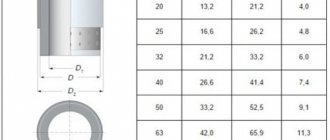

Criteria for selecting the optimal pipe diameter

In order to choose the right pipe size, you need to adhere to the following rules:

- The diameter of the heating pipeline must be constant along its entire length, excluding the branches to the heating radiators.

- The size of the diameter is in direct proportion to the total length of the line - the longer the length, the larger the diameter should be.

- The inclusion of a circulation pump in the heating system is the only condition for reducing the diameter of the pipes.

Professionals recommend focusing on the following indicators:

- If the line length is no more than 50 m and the system has a circulation pump, then the best option is to use PN-25 pipes with an inner diameter of 20 to 30 mm. If there is no pump, then the diameter must be at least 25-35 mm.

- If the length of the pipeline is more than 50 m, then you need to adhere to the following rule: every 10 extra meters of the line require an increase in diameter by 2 mm. As connections to heating devices, you can use pipes, the diameter of which is a quarter less than the diameter of the main wiring.

- In the event that a two-pipe system is being laid, the return line can be installed from PN-20 pipes.

Considering that the temperature at the outlet of the boiler unit can exceed 100 degrees, to connect polypropylene pipes to it, it is necessary to use pieces of metal pipe with a length of at least 500 mm.

Soldering rules for polypropylene pipes

To obtain a high-quality result, it is necessary to follow certain rules for installing heating from polypropylene pipes.

At the first stage, it is necessary to prepare tools for performing installation work. The main steps in the soldering process are performed using a soldering iron. It is best to cut polypropylene pipes selected for the heating system with special scissors. This tool consists of two parts, one of which is a concave lodgment for laying the pipe, the other part is a guillotine knife with a unit for stepped transmission of forces.

A few words at the end

- Before choosing pipes for heating, we will determine the main criteria and type of heating system.

- It can be forced and self-flowing.

- Next, we determine the method of bookmarking, this includes the external and internal method.

- Now you need to determine the pressure and temperature conditions.

What material should you give preference to?

We determine which pipes for heating are better:

- According to experts, it is copper or stainless steel. But these are expensive models.

- For users who want to save money, but get a relative quality, plastic pipes are suitable that can cope with the loads of the heating system.

Basic parameters of PP pipe welding

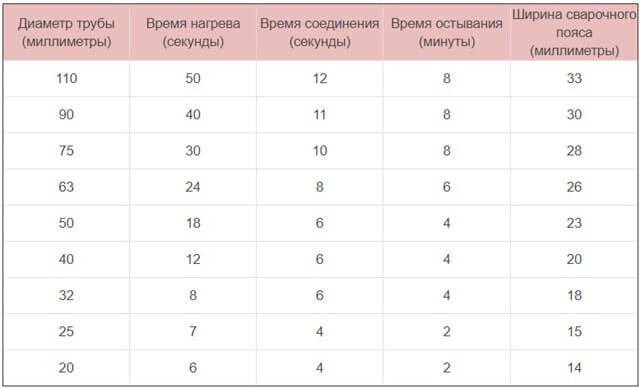

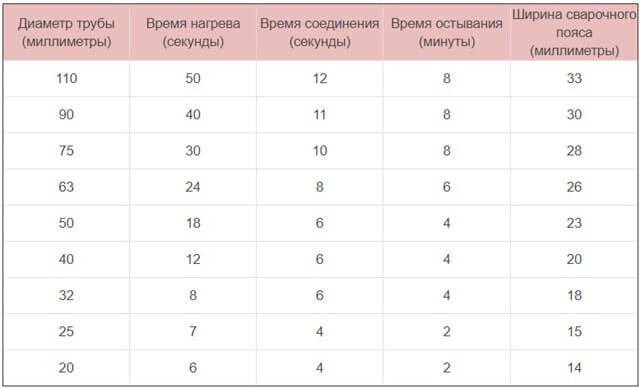

The heating time of polypropylene pipes during the welding process does not have a linear relationship. The complete set of equipment for welding can be supplemented with a sample table from the manufacturer. It indicates the values of the temperature regime of the apparatus for soldering polypropylene pipes and the time during which the pipes are fixed in the nozzle.

The main condition for ensuring the high-quality performance of welded seams is the simultaneous heating of the elements to be joined. If this condition cannot be met, then alternate heating of the parts is allowed. In this case, more time should be spent on the first part so that it does not have time to cool down while the second part heats up.

Using an ordinary tape measure, measure the required length of the material and put a marker on the place where the pipe will be cut. Using the building level, you can easily check the correct assembly of the heating system.

When marking the cut line, it is important to take into account that part of the tubular element will be hidden by the coupling or fitting. Sometimes, on a two-meter straight section of the pipe, several couplings can be seen. The actions performed by the novice wizard lead to this result. Therefore, it should be remembered that it is better to entrust the installation of the heating system to more experienced specialists.

The room in which work is carried out to assemble any system of polypropylene pipes must be well ventilated. Careful and careful handling will prevent burns or injury. Correct calculations of the material and component parts will not allow unnecessary costs for the installation of the heating system.

Self-installation of heating from polypropylene pipes does not exclude the commission of incorrect actions. Due to the low material cost, mistakes can be corrected at any time. The experience gained will help in the future to perform flawlessly installation of plumbing and heating systems.

Material requirements: the main points of the choice

Each type of model has its positive and negative sides. Having considered all the nuances, it will not be difficult to choose exactly that suitable option for yourself. It is necessary to proceed from the rules of what material the model is made of and which pipes are suitable for your heating system.

Basic requirements for material selection for the system

Let's consider the main points that need to be foreseen:

- At what power does the pressure in the circuit work.

- The level of complexity of the design.

- Which installation will be done: external or internal.

- Temperature regime of water.

- Heating type: gravity or forced.