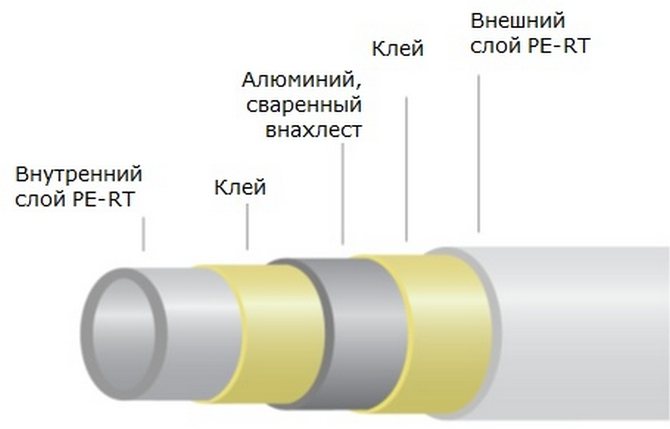

Recently, communications made of cross-linked polyethylene are gaining great popularity, since this material is relatively inexpensive and has a number of significant advantages: the optimal combination of strength and flexibility, resistance to high temperatures, chemical compounds and destruction. A decisive role in the long period of operation is played by high-quality work to fasten all the constituent elements. The assembly of such structures is a rather simple process, however, it has certain features and important points, the knowledge of which will make it possible to carry out the installation of cross-linked polyethylene pipes with your own hands without any particular difficulties.

Modern stores present to the eyes of buyers a huge selection of products designed for equipping communication systems in private houses and apartments. However, pipes of the Rehau brand occupy a leading position in this market segment. With vast experience, German suppliers have been specializing in the manufacture of high quality consumables for quite some time, which has allowed them to acquire a solid reputation.

Find out the cost of heating

Features of joining products

The named manufacturer chose thermoplastic polymers with a linear molecular structure as the basis for such pipes. The only difference from the products of competing companies is the optimal elasticity of the elements, which gives the joints the required tightness. However, in order to perform a high-quality installation of Rehau pipes, the use of welding machines operating at extremely high temperatures will be required.

Repair of heating systems

The price of laying pipes Rehau (Rehau) from cross-linked polyethylene

| Name of works: | Unit rev. | Price |

| Laying Rehau pipes | point (water outlet) | from 1550 to 2440 rubles. |

* We offer a free visit of the master to evaluate the work. The customer will find out the cost "before the ruble" only at the place of work. (No other way)

If you have decided to upgrade an old system or install a new one to ensure normal operation and trouble-free service for decades, call us!

Still have questions? We can call you back ...

Free call

We will provide for free

estimate

Call an engineer for measurements

Mounting types

The connection of polyethylene pipes is carried out in three ways:

- Compression fitting. This type is the simplest and requires common tools. It finds its application in the arrangement of both hot and cold communications, and also provides the ability to quickly dismantle the structure in case of unforeseen situations.

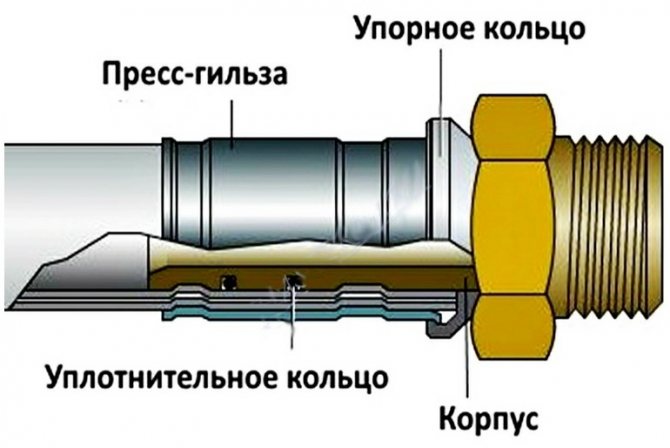

- Press fitting. The named type of fastening allows you to obtain an integral and reliable connection when joining several pipes. In this embodiment, the emphasis is on the regenerative property of cross-linked polyethylene, which allows it to return to its original shape after pressing. The polymers included in the composition fill all gaps and ensure tight contact.

- Electrofusion fitting. The presented type is quite rare in practice due to the fact that it requires special welding machines and special skills. However, it is the most effective of all these methods.

An important point in determining the optimal type of connection is taking into account the pressure of the future communication system, since the first type of attachment can withstand up to 2.5 atm, the second - no more than 6 atm, and the third is practically unlimited.

Water supply systems

Execution order

Each type of connection has its own characteristics and a slightly different procedure:

- The crimp type provides for reliable fixation of the compression nut on the cut of the pipe, while its thread should look towards the future connection. Then it is necessary to tighten and secure the split ring in such a way that the end of the pipe is at a distance of no more than 1 mm. Next, on the fitting of the fastening device by pulling the cut of the pipe with the elements prepared on it. Finally, with wrenches, we tighten the compression nut until it fits snugly.

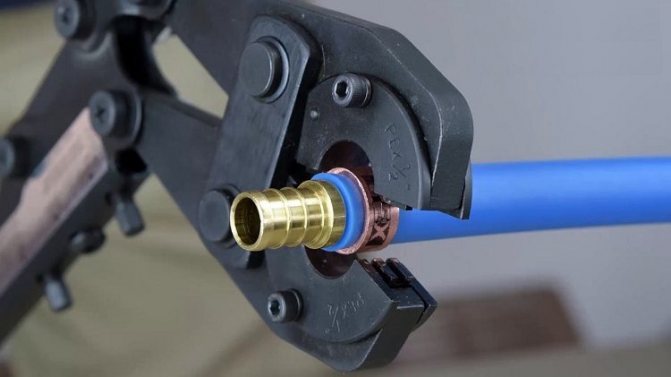

- In the press type, the clamping sleeve must first be securely fixed to the pipe cut. Then, using the expander, we pull the connecting pipe onto the fitting of the fitting device and hold it in this position for several minutes. Subsequently, due to the completion of the last point, the pipe segment will press itself as tightly as possible.

- The electric welding connection is carried out by fixing a special coupling on the pipe cut. Then, by means of welding equipment, the end of the inner spiral of the fitting device should be heated. As a result, the heated polyethylene ideally takes the shape of a fitting and cools, while ensuring the most tight contact.

Do-it-yourself pipe installation

The principle of joining polyethylene products differs depending on which method is used. Not only the instructions for performing the work change, but a different tool is required in most cases. Do-it-yourself installation of XLPE pipes is easiest to do using compression or press fittings.

Training

They clean the room: it is necessary to avoid the deposition of dust on the end of the pipes, since any contamination can negatively affect the quality of the connection. To avoid the appearance of condensation, it is recommended to protect communications using heat-insulating material. Common options: corrugation, special insulation in the form of a cylinder (hollow inside). Additionally, it is recommended to fix the pipes on the intended section of the wall, since they tend to change somewhat due to plasticity. For this purpose, staples are used.

Required tools and materials

To work you will need:

- pruning knife;

- spanners;

- expanders;

- roulette;

- building level.

The set of tools may vary slightly depending on the pipe joining technology used. For example, to work with compression fittings, you need to additionally prepare a press (hydraulic, manual).

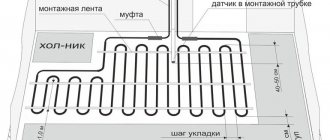

Drawing and diagrams

When working with products made of cross-linked polyethylene, they draw up a project for a communication system. At home, a sketch is enough with the designation of the main parameters: the diameter of the pipes, their length, the locations of the fittings.

Work order

Compression method:

- A compression nut is placed on a XLPE pipe for heating or water supply.

- Install the split ring. Its edge should be 1 mm from the edge.

- Then the communication sections are connected, tighten the crimp nut with a wrench.

Application of the electrowelded method:

- A fitting is put on the end of the polyethylene product.

- To ensure sufficient heating intensity, a welding machine is connected to the connecting element. For this purpose, terminals are used. Under the influence of stress, the part of the product covered by the fitting will start to melt.

Press-on method:

- The pipes are joined using a clamping press sleeve. It is put on one section of the product.

- With the help of an expander, the inner diameter of the pipe is increased. Then it is pushed onto the fitting spigot.

- It is recommended to hold the product in this position for several minutes. At the end of the time, the assembly of the pipes ends, since they take their original shape. Considering that a fitting is installed at the end, the material will fit snugly against it.

Installation features

A diagram of a water supply or heating system is drawn up not only to determine the installation points of fittings, but also to calculate the material. According to the sketch, the length of the pipeline is calculated, the number of connecting elements that are planned to be mounted. Before starting work, it is necessary to arrange all sections of communications and fittings on the floor in the required sequence. This will avoid mistakes during the installation process. Do not allow distortions when joining elements.

Heating water supply boiler room

8(495)744-67-74

Heating repair

Water supply repair

Calculating the cost of heating

Heating system repair cost

Water supply installation cost

Engineering systems: heating water supply:

- XLPE pipes and fittings Rehau XLPE pipes and Rautitan fittings system Royal Thermo AXIOpress piping system Heating water supply boiler room ...

- Uponor XLPE PE-Xa Pipes Uponor XLPE PE-Xa pipes have a unique set of qualities that make them ideal for potable water applications. In addition to outstanding mechanical strength, the main advantage of these pipes is their exceptional resistance to temperature influences, which allows the use of PE-Hat pipes also for hot water pipelines. All this…

- Uponor Aqua Pipe made of cross-linked polyethylene PE-Xa Uponor Aqua Pipe made of cross-linked polyethylene PE-Xa series S3,2 PN10 in coils The pipes are intended for hot and cold water supply systems. They are made of cross-linked polyethylene PE-Xa according to the Engel method, in accordance with EN ISO 15875 and GOST 52134. Maximum temperature: ...

- Uponor evalPEX pipes made of cross-linked polyethylene PE-Xa Uponor evalPEX pipes made of cross-linked polyethylene PE-Xa series S3,2 PN10 in coils Uponor evalPEX pipes are intended for floor heating, radiator heating and cooling systems. They are made of cross-linked polyethylene PE-Xa according to the Engel method, in accordance with EN ISO 15875 and GO STR 52134, series ...

- Uponor XLPE pipes and fittings PE-Xa Uponor XLPE pipes PE-Xa Uponor Quick & Easy connection system Uponor PE-Xa Quick & Easy fittings for radiator connections Uponor clamp fittings Uponor accessories PE-Xa Uponor XLPE pipes PE- Ha have a unique set of qualities that make them perfect ...

- Fittings for cross-linked polyethylene and their types Table of contents: [hide] Types of existing fittings General installation technology Features of fitting fittings Have you decided to change pipes and chose a simple and reliable version of cross-linked polyethylene pipes? No wonder, because products made of such a material can withstand a wide range of temperatures, are not subject to corrosion, are non-toxic, ...

- XLPE pipes XLPE pipes. For more than 30 years, XLPE pipes for heating have been successfully used in America and many European countries. Now this trend has reached us. And now the most popular material for the manufacture of pipelines in the heating system and ...

- Uponor Combi Pipe made of cross-linked polyethylene PE-Xa Uponor Combi Pipe made of cross-linked polyethylene PE-Xa series S3,2 PN10 in coils Uponor Combi Pipe is intended for underfloor heating, radiator heating, cooling, cold and hot water systems. Made of cross-linked polyethylene PE-Xa according to the Engel method, in accordance with EN ISO 15875 ...

- Universal pipe made of cross-linked polyethylene Elsen PE-Xa Elspipe 20 x 2.2 Installation of heating systems, water supply, boiler units EPU20.2211-120 DESIGN PRESTIGE LLC works around the clock, departure in Moscow and the Moscow region Elsen Size,: 20 x 2.2 Packing,: 120 Country production,: Czech RepublicPurpose,: Heating + water supplyMaterial,: Cross-linked polyethyleneWorking environment,: Water + heat carrier Pipes ...

- Universal pipe made of cross-linked polyethylene Elsen PE-Xa Elspipe 32 x 4.4 Installation of heating systems, water supply, boiler units EPU32.2211-50 DESIGN PRESTIGE LLC works around the clock, departure in Moscow and the Moscow region Elsen Size,: 32 x 4.4 Packing,: 50 Country production,: Czech RepublicPurpose,: Heating + water supplyMaterial,: Cross-linked polyethyleneWorking environment,: Water + heat carrier Pipes ...

- Universal pipe made of cross-linked polyethylene Elsen PE-Xa Elspipe 16 x 2.2 Installation of heating systems, water supply, boiler units EPU16.2211-120 DESIGN PRESTIGE LLC works around the clock, departure in Moscow and the Moscow region Elsen Size,: 16 x 2.2 Packing,: 120 Country production,: Czech Republic Purpose,: Heating + water supplyMaterial,: Cross-linked polyethyleneWorking environment,: Water + heat carrier Pipes ...

- Installation of cross-linked polyethylene pipes Installation of cross-linked polyethylene pipes Currently, in the installation of water supply and heating systems, pipes made of cross-linked polyethylene from Rehau (Germany) and Uponor (Sweden) are widely used. Externally resembling metal-plastic pipes, unlike polypropylene, copper, metal and metal-plastic pipes, pipes ...

- About the Code of Rules "Design and installation of underground hot water supply networks from PE-S pipes (cross-linked polyethylene) with thermal insulation from polyurethane foam in a polyethylene sheath" Services for the installation of heating water supply DESIGN PRESTIGE LLC 8 (495) 744-67-74 In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our page on heating> resant.ru/otoplenie-doma.html

- Rehau fire protection collar for XLPE pipes The fire protection collar is designed for use with Rautitan flex, Rautitan his, Rautitan pink, Raupex and Rautherm S pipes. In the event of fire, according to DIN 4102 Part 11, Edition 12/85, the fire protection collar retains smoke and fire from the side of combustion, not allowing it to enter other rooms. The fire cuff can be installed ...

- Compress. fitting for pipes made of polyethylene and cross-linked polyethylene, 3/4 ″ EK thread, size 20 x 2.0 Water supply heating installation services DESIGN PRESTIGE LLC In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our page on heating> resant.ru/otoplenie-doma.html

- Compress. fitting for pipes made of p / p and cross-linked polyethylene, 3/4 ″ EK thread, size 16 x 2.0 Water supply heating installation services DESIGN PRESTIGE LLC In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our page on heating> resant.ru/otoplenie-doma.html

- Compress. fitting for pipes made of polyethylene and cross-linked polyethylene, thread 3/4 ″ EK, size 16 x 2.2 Installation services for heating water supply DESIGN PRESTIGE LLC In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our page on heating> resant.ru/otoplenie-doma.html

- Fixing gutter Rehau 40 for pipes made of cross-linked polyethylene 11380731001 Installation of heating systems, water supply, boiler units 11380731001 DESIGN PRESTIGE LLC works around the clock, departure in Moscow and the Moscow region Rehau Size, mm: 40 Quantity in a package: 3 m gutter Buy 456.02 РТruitan with this product Flex 40 x 5.5 = Rehau accessories ...

- Fixing gutter Rehau 63 for pipes made of cross-linked polyethylene 11380931001 Installation of heating systems, water supply, boiler units 11380931001 DESIGN PRESTIGE LLC works around the clock, departure in Moscow and the Moscow region Rehau Size, mm: 63 Quantity in a package,: 3 m gutter Buy with this product Rehau 885.74 Flex 63 x 8.6 = Rehau accessories ...

- Fixing gutter Rehau 50 for pipes made of cross-linked polyethylene 11380831001 Installation of heating systems, water supply, boiler units 11380831001 DESIGN PRESTIGE LLC works around the clock, departure in Moscow and the Moscow region Rehau Size, mm: 50 Quantity in a package,: 3 m gutter Buy 600.22 RTruitan with this product Flex 50 x 6.9 = Rehau accessories ...

Previous post How to cut ceramic tiles

Next post Do it yourself well

Polypropylene pipes.

Polypropylene pipes.

Polypropylene pipes are hygienic and safe for humans. Resistant to corrosion, pressure up to 25 atm., Temperature up to + 95 ° C. Polypropylene is not subject to rotting and contamination during operation. Its service life in the cold water supply system reaches 50 years, and in the hot water supply system - up to 25 years.

Unlike metal-plastic and metal pipes, polypropylene pipes are much quieter in operation, since they have excellent sound insulation. They are not covered with condensation due to the extremely low thermal conductivity of polypropylene. It is equal to 0.24 W / M * K. For example, for copper, this coefficient is 400 W / M * K.