Advantages of self-adhesive insulation

The scope of this material is extensive. It can be used to insulate walls and ceilings, pipes and roofs, doors and windows. Thermal insulation works are carried out in basements, attics and attics.

Advantages of self-adhesive material:

- versatility;

- environmental friendliness;

- fire safety;

- small thickness;

- excellent waterproofing and moisture resistant properties;

- resistance to negative environmental influences;

- wide range of;

- low cost;

- ease of installation work.

Rolled insulation is frost-resistant. Such a self-adhesive insulation withstands temperature changes, moisture and chemical environment. Its installation leads to an improvement in the sound insulation of the surface.

Penolen NPE MK PET

Isover advantages

Insulation "Isover" in rolls is distinguished by excellent thermal conductivity: due to the peculiarity of the composition of fiberglass, the material retains and conserves heat for a long time. The thermal conductivity coefficient of Isover is only 0.041 W / m • K. The difference between insulation and analogs is the ability to maintain a percentage throughout the entire period of use.

Rolled insulation "Isover" is made of special fibers that do not lend themselves to combustion. Such products are designated by the abbreviation "NG". Due to its non-combustible materials, the heat insulator can be used at enterprises and factories with an increased fire hazard. There are also SG heaters - low flammability. They are covered with special foil, fiberglass or Tyvek film.

Due to the well-thought-out structure of the "Isover" insulation, extraneous sounds will not interfere with sleeping or doing business in the office. An air gap is located between the fibers of the material, due to which sounds do not pass through the insulation. In our assortment, we sell special models for insulation with increased sound insulation.

The difference between the insulation is also the absolute environmental friendliness and harmlessness of the materials that are included in the composition. This hypothesis has been repeatedly confirmed by Finnish scientists and specialists from the University of Cancer. Isover facade insulation contains water repellents - a special liquid based on organosilicon compounds. Such an impregnation is used for water repellency, thereby preventing moisture accumulation and the appearance of mold on the insulation.

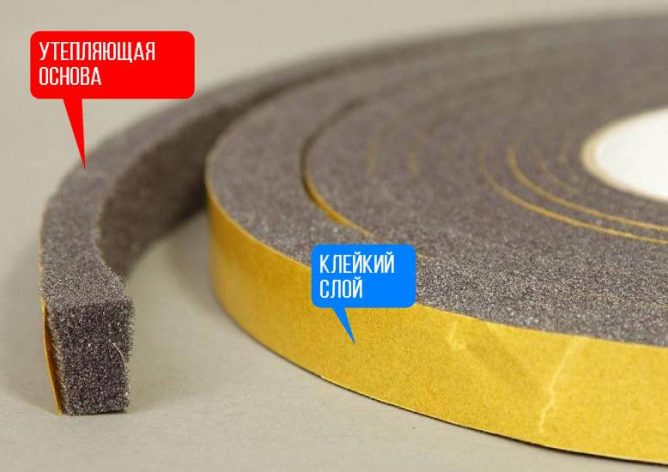

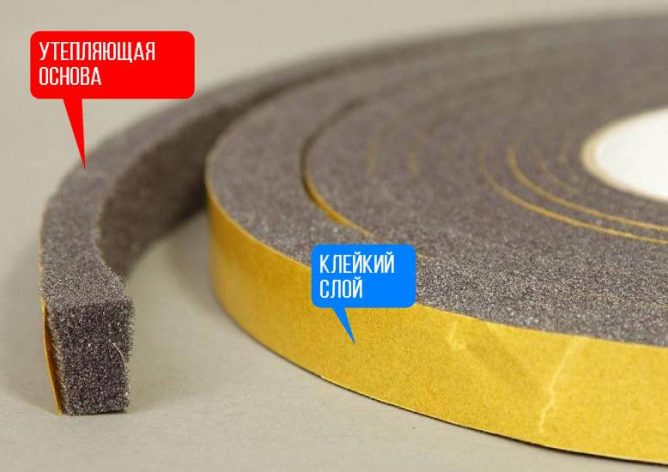

Self-adhesive tape

A common material is tape for insulating windows and doors, pipelines and tile floors. It is a strip 1-7 cm wide. For its manufacture, rubber or polypropylene is used. Thanks to this, the material has the maximum resistance to the transfer of thermal energy.

Insulation tape of rectangular shape is used for sealing even cracks up to 4 mm in size. If the gaps in the door or window openings are not too even, then it is better to use a material with a profile.

It is recommended to give preference to a soft insulation that fills all the cracks evenly. Rigid material will not compress well, as a result of which cold air currents will penetrate into the room.

Checking the quality of the product is carried out as follows: it must be bent and released. If the self-adhesive tape quickly returns to its original shape, then this material can be purchased.

A slow-drying adhesive is applied to the reverse side of the tape to provide greater effect when sealing gaps.It will also help in case of material changes.

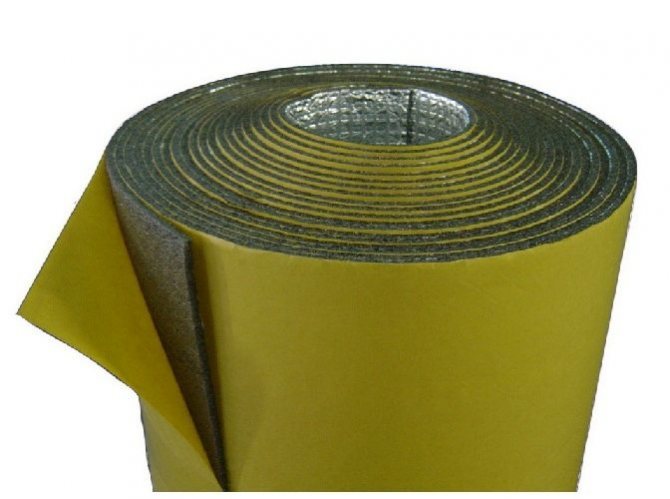

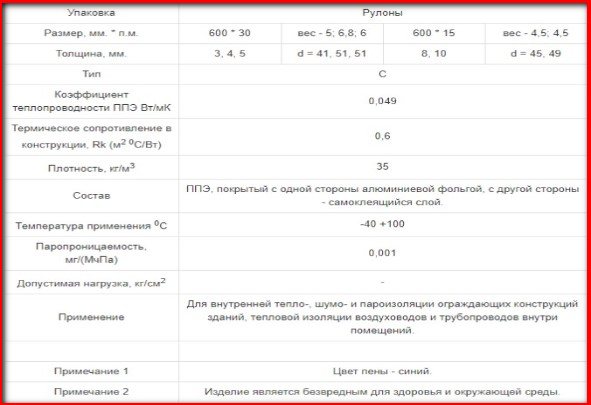

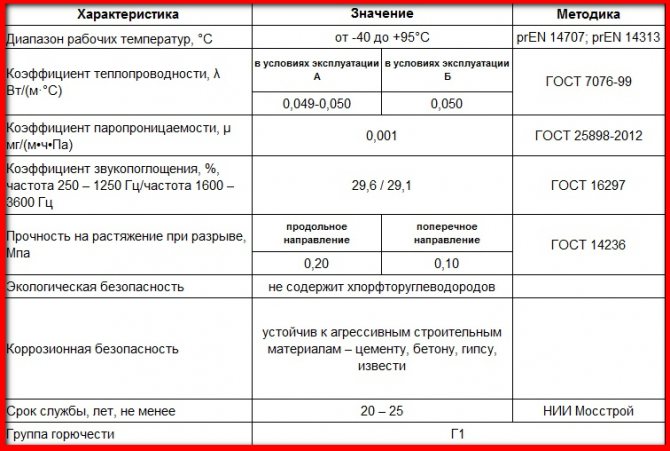

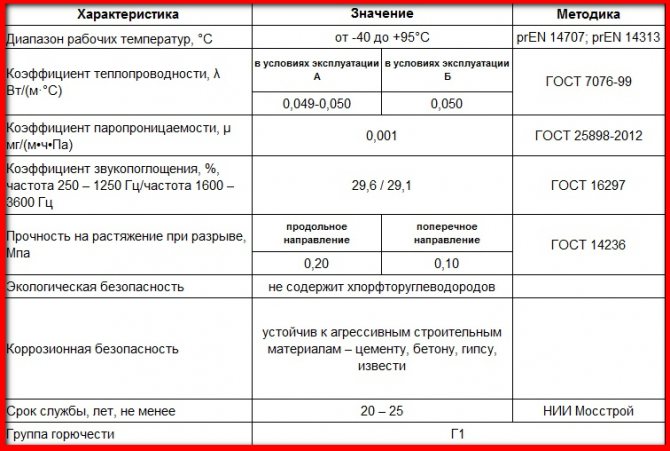

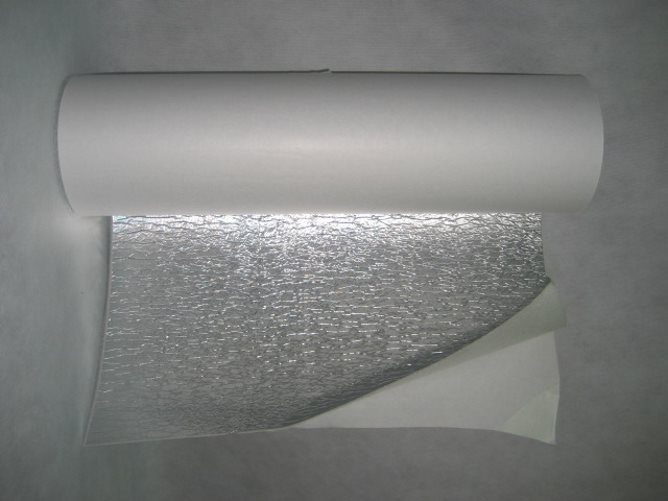

Penofol type c: self-adhesive reflective insulation

Penofol type C is polyethylene foam that has closed pores, a layer of aluminum foil and glue with a protective film. This self-adhesive insulation is lightweight, thin, flexible and environmentally friendly.

In most cases, self-adhesive penofol is used for thermal insulation of a metal surface: car vans and interiors, pipelines and air ducts, industrial drying cabinets. Thanks to the closed system of air bubbles, it can be used as a vapor barrier.

Reflective insulation Teplokent

Reflective insulation Teplokent - is an environmentally friendly and highly efficient insulating material made on the basis of extruded polyethylene foam. Its structure allows not only to provide good thermal insulation, but also excellent soundproofing the premises, while reducing the noise coming from the street... That is why Teplokent reflective insulation is a versatile insulating material that has a wide range of applications. In addition, Teplokent has a number of important advantages, including durability, light weight, economical price, easy installation and high fire safety.

Stizol

Stizol adhesive insulation is a product of the Russian construction industry. The basis of the material is high density polyethylene (up to 40 kg / m³). Styzol is characterized by resistance to aggressive environments.

The material does not emit harmful substances, does not rot or crumble. Excellent eco-friendly properties make self-adhesive styzol a popular material for insulating living rooms. A thin layer of insulation does not increase the thickness and complexity of the structure.

Self-adhesive thermal insulation Adgilin is the best option for thermal insulation of ventilation system elements. It is a roll of insulation made of polyethylene foam. It is characterized by low vapor permeability and excellent moisture resistance.

The presence of glue in Adgilin makes installation work quick and convenient. Moreover, any surface is processed. Excellent adhesion properties and resistance to moisture prolong the operational period of the insulation, and the presence of a foil layer ensures a decrease in heat loss.

Teplokent advantages

- High efficiency

Reflective insulation Teplokent has a very high efficiency as heat and sound insulation when properly installed.

- Reliability and durability

The service life of Teplokent insulating material is more than 50 years and throughout its entire length the insulating material retains all its properties. In addition, it does not rot or deform.

- Simple and convenient installation

When installing Teplokent reflective insulation, no special devices and devices are required, so its installation is quick and easy.

- Reliable protection against moisture and steam

Due to its structure and structure, Teplokent insulation is resistant to the negative effects of moisture and steam.

- Excellent sound insulation

As a sound insulation material, Teplokent prevents sound propagation in all types of buildings.

- Elastic and durable

Extruded polyethylene foam, which is the basis of Teplokent reflective insulation, gives it high elasticity and physical strength both in tension and compression.

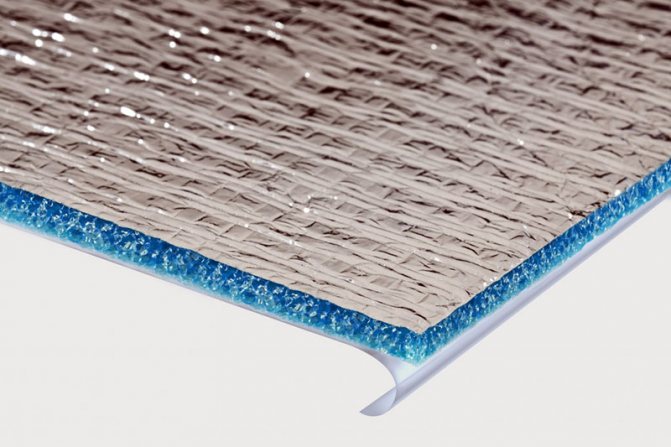

Armofol

In the production of self-adhesive armofol, aluminum foil and glass mesh (or fabric) are combined. Fiberglass mesh acts as a carrier layer. Due to this, the insulation has high strength and can be used at various temperature conditions (-50 ... + 150 ° C).

The latter characteristic made it possible to use the material in refrigeration plants and saunas, outdoor pipelines and industrial premises with high temperatures.

Self-adhesive insulation Armofol is a reliable barrier against penetration of radiation and electromagnetic radiation.

Megaflex

Megaflex belongs to the universal heaters. For its manufacture, foamed polyethylene is used, which is able to take the form of a finished coating. For this reason, Megaflex is an effective tool for sealing rough and uneven surfaces.

Partitions between walls, interfloor floors, window frames, heating and ventilation systems are insulated with self-adhesive material. When covering ventilation ducts, the sound-insulating properties of the structure are improved, the level of noise and vibration is reduced.

DUCT INSULATION

The use of Adgilin M for thermal insulation of the air duct and ventilation system allows us to solve the following critical tasks:

- Heat, steam and waterproofing of air ducts;

- Noise and vibration isolation of air duct systems;

- Low vapor permeability, as well as moisture absorption of the material;

- Reducing your labor costs and installation time.

Now let's talk in more detail

Thermal insulation characteristics of ventilation systems insulation

The choice of a wide range of heat-insulating material for energy saving is chosen for elementary economic reasons. Insulation of the Adgilin M brand is a clear leader among its agalogues. At the same time, the difference in price / quality between Adgilin and other similar thermal insulation materials can reach 300% (!), Not to mention the fact that the quality of analogues, unfortunately, often leaves us much to be desired ... In choosing the main tasks for the thermal insulation material duct is a sharp limitation of the physical properties of heat exchange by air flows passing inside the duct and its external environment. The reduced coefficient of thermal conductivity (due to a specially developed composition formula) of the insulating property of Adgilin-m 0 = 0.038 W / m2 during long-term operation of the ventilation system will allow you to get a clear and tangible saving of your energy resources. It should be borne in mind that any heat-insulating material has its own cost, which is subject to depreciation in the future. In this, economic efficiency can be determined by calculating the difference between the cost of energy saved by you for the year and the annual costs of depreciation of insulating materials and the cost of installing a thermal insulation effect. It's easy to check! Most often, it is customary to use Adgilin M with a thickness of 5 or 10 mm. Let us take into account that it is not always possible to use the desired thickness in order to achieve the greatest economic efficiency. For example, in the case of a channel laying device (in suspended ceilings) - where, as you understand, the space is clearly limited. In this case, the thermal insulation of air ducts based on polyethylene foam has a clear (in any respect) advantage over another type of thermal insulation material, for example, from basalt fiber, just as much as Adgilin-M has a higher thermal conductivity coefficient with an equal thickness.

Sound insulation and vibration and thermal insulation of the air duct system

Air duct device - air preparation system and air distribution system, as a rule, create noise and vibration, which also propagates through the air duct system itself.Noise in the duct system occurs not only due to the resulting turbulence of the moving air flow in the ventilation system, but also due to the operation of the fan, during which not only vibrational, but also other acoustic effects are created. Through the air duct system, noise penetrates from room to room. Duct noise can be muted and attenuated. It is possible to use special "silencers" and soundproofing cover. Insulation of air ducts brand "Adgilin M" has good vibration, sound and noise insulation properties and can be used as heat, steam and sound insulation of ventilation systems. Based on the above, when choosing "Adgilin M" insulation to create technical insulation for an air duct, we have, in fact, a double effect.

Reduced vapor permeability and moisture absorption of the insulating material

By insulating air ducts carrying cold air, we perform the main task - to prevent once and for all the formation of condensation on the outside of the walls of the air ducts. The formation of condensation can lead to corrosive damage to the surface of air ducts, as well as the formation of all types of mold and mildew. But that's not all, moisture can penetrate the interior of the room, causing damage to the decoration and furnishings. To prevent such a phenomenon, it is necessary that the temperature of the outer surface of the duct is not lower than the temperature of the "dew point" of the air in the room in which the duct is laid. This phenomenon can be avoided by using Adgilin M as insulation of the air duct, which, together with low thermal conductivity, has low vapor permeability and moisture absorption. Low vapor permeability and moisture absorption is provided due to the closed-cell structure of the material. It should be borne in mind that over time, a certain, albeit insignificant, moisture absorption occurs in any thermal insulation materials. This increases their thermal conductivity.

Reducing your labor costs for the installation of technical insulation Adgilin M

The width of the roll of Adgilin M can be from 500 to 1000 mm. The use of self-adhesive material eliminates the need for wire ties and self-adhesive pins. The high degree of adhesion of the adhesive layer to the metal surface ensures reliable fastening of the thermal insulation of the air ducts to both rectangular and circular air ducts. The special adhesive is resistant to moisture, which guarantees durability of the duct insulation coating.

Tilith Black Star Duck

Foamed polyethylene is used for the production of this roll insulation. The main field of application is the thermal insulation protection of the ventilation system. TILIT Black Star Duct is safe for human health.

The insulation has a long service life (up to 25 years) and is resistant to a humid environment. Condensation will not appear on the surface finished with self-adhesive TILIT Black Star Duct.

The lineup is represented by two products. Self-adhesive material with AL marking indicates that it contains polished aluminum foil.

Where and how to use it correctly?

Another name for self-adhesive material is teplofol.

It is actively used for thermal insulation:

- walls;

- roofs;

- floor;

- pipes;

- wall surfaces in baths and saunas, etc.

The insulation is suitable for both interior and exterior decoration, primarily due to its resistance to atmospheric precipitation. Visually, it is a roll with a width of 1 meter and a thickness of up to 20 mm.

The structure of the self-adhesive heat insulator ensures reliable protection of the surface from moisture, steam and condensation.The material belongs to the category of environmentally friendly thermal insulation, simplifies the installation process due to its special structure with an adhesive layer.

On the market, you can buy different brands of reflective insulation that does not require special installation.

Foam insulation NPE MK PET with an adhesive layer

NPE MK PET foam has the same characteristics as Penofol C. Insulation is a reflective insulation consisting of two parts: a duplicated metallized film and an adhesive layer.

In addition to thermal insulation, NPE MK PET foam acts as a vapor barrier and sound-absorbing product, is resistant to negative environmental influences and is easily attached to the surface.

The scope of application is extensive. It can be used both for underfloor heating and for bath insulation.

Installation of self-adhesive insulation

At the initial stage of thermal insulation work, the surface to be treated is checked. The old insulation is removed. If necessary, alignment of the walls is carried out. Windows, pipes, air ducts are washed, degreased and dried.

When insulating windows and doors, measurements of structures are made. Self-adhesive material must be glued in a single piece without cutting in the corners. When gluing, the protective film is peeled off gradually.

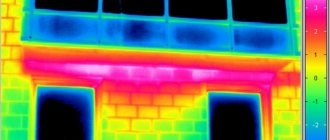

The quality of the work is checked with a candle. The flame from a lighted candle near a window or door should not fluctuate.

If the walls are covered with foil insulation, it is recommended to fix it to the crate. This will create an air gap for ventilation. The material is laid with the foil side inside the room. The joints are glued with tape or tape.

Positive traits

Self-adhesive foil thermal insulation is quite widely used in various fields, due to its special properties:

- Low thermal conductivity with low thickness. This factor is not possessed by many heaters, so this is a huge plus in the piggy bank of self-adhesive material.

- High reflectivity due to foil coating. Another advantage that allows you to save on additional thermal insulation materials.

Savings are relevant for secondary structures - garages, warehouses, utility blocks

For your information! Only foil insulation will reflect outward scorching heat rays in summer, and in winter, truly precious warmth, inside the house. Not a single massive insulation can "boast" or even come close to its 97% reflection of thermal radiation.

- Good sound insulation.

- Insulation with foil has the highest vapor barrier (almost 100%)... The foil insulation installed inside the premises will also serve as a vapor barrier. This is true for bath rooms, where it is necessary to keep not only heat, but also steam.

Important! When insulating with foil insulation on the outside, use perforated material. This will help prevent condensation from humidifying the building envelope from inevitable vaporization in the home.

- Lightness, flexibility and ease of installation. An important characteristic both for special teams with large volumes of work, and for a private trader who has conceived do-it-yourself insulation. You just need to remove the protective layer and press firmly with the adhesive side to the insulated surface. Previously - the work surface must be prepared.

- A variety of forms of execution of these products. Along with the roll material of different widths, which is customary for heaters, a heat-insulating self-adhesive tape is produced. It is convenient to use in hard-to-reach places.

Narrow tape is used to seal window and door openings

At the same time, a fairly reasonable price is in favor of self-adhesive foil insulation, which completely ensures a pleasant balance for the consumer with the quality of this product.

Where to apply

All of the above has led to the most diverse use of self-adhesive insulation in:

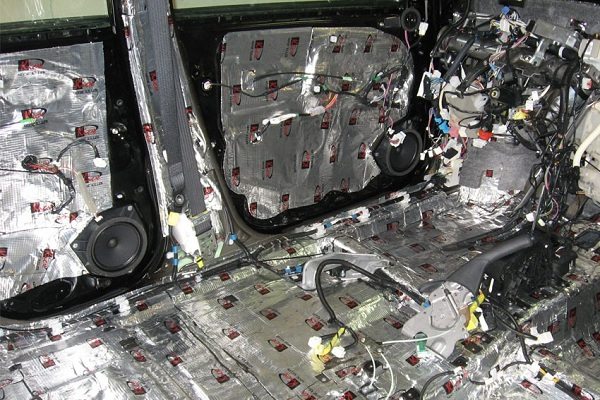

- Construction. Thermal insulation of building structures and engineering systems of pipelines (ventilation, sewerage, water supply).

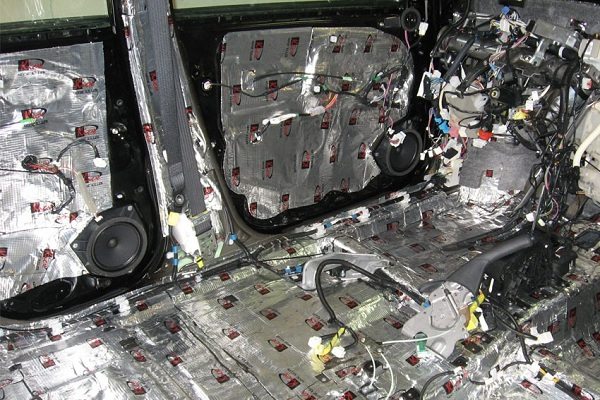

- Mechanical engineering. Noise insulation and insulation of car and bus interiors.

Such materials are used for the modern direction - car acoustics

- Food, gas, oil refining, chemical and other industries. Insulation and sound insulation of process pipelines (steam supply, transportation of aggressive process liquids and gases, air conditioning systems), etc.

The foil surface does not allow heat and steam to leave the boundaries of the insulation

Self-adhesive heat-insulating tape is successfully used both as a heater and as a seal for windows and doors. And as well as damper pads for packing and transporting equipment, fragile appliances, furniture, glass, glassware and household appliances.

In the technical support center of any manufacturer of self-adhesive thermal insulation and in the places of its implementation, you will be provided with any advice and detailed instructions on the use of the products of this line.

Insulation features

- It is not necessary to use a material with a foil surface on both sides; in fact, foil is needed only in the part where there is noticeable heat loss.

- The adhesive base of the insulation does not interact with greasy and dusty surfaces, therefore, the wall or floor should be carefully processed and prepared.

- The joints of the rolls must be sealed with tape to avoid heat loss. You can use special adhesive tape with a shiny surface, or purchase standard masking tape.

In the photo there is an ordinary transparent tape, which reliably grasps the sides of the insulation together