General information about the material

It would be superfluous to describe the foam, since almost every one of us has come across this material. But in most cases, we saw it as a packing element that fills the space in a box and is designed to fix its contents and reduce damage in the event of a fall. Not everyone knew, but the use of foam is actually not limited to the packaging industry, as the material is extremely widely used for insulation. At the same time, the properties of the foam are such that it can also be used to insulate the outer walls.

Safety regulations

Unfortunately, it is not always possible to abandon the use of foams, but the harm can be minimized as follows:

- Do not use for internal insulation of living quarters and premises with constant presence of personnel.

- Do not use in insulation systems with a ventilation gap.

- With the external "wet" method of insulation, perform work in accordance with the technology of the manufacturer of the material.

- Insulate the floors from the side of non-residential premises, do not insulate the ceiling of the balcony or loggia with expanded polystyrene.

- Purchase quality material from a trusted manufacturer or in a large retail network, upon purchase, require a certificate of conformity.

The material demonstrates its best qualities when it is used for insulating underground structures, refrigeration plants, preventing soil heaving in roads, bridges, airfield runways, wherever there is no direct human contact.

Material advantages

- Styrofoam is very durable. The material is not of interest to pests (mice do not eat it, but they can arrange it inside the nest), fungi and mold do not appear on it, and also does not change its structure for a long period of time. Its active service life, if properly installed, can be several tens of years;

- Low cost. It is not in vain that polyfoam is used in the packaging industry, since, with its technical characteristics, it is incredibly cheap, and its use does not greatly increase the cost of the finished product. The same rule applies to insulation. Therefore, if you want to insulate your home effectively, but at the same time on a budget, then foam will give you that opportunity;

- Complete environmental safety. This finishing method does not emit toxic substances into the air;

- The material has a low dynamic stiffness, which enables it to be a good sound insulator;

- Low weight. Also the quality of this material is known to all. The use of foam allows you not to reinforce the foundation, and also not to mount a solid frame structure. In addition, low weight also has a positive effect on the complexity of the work;

- High resistance to moisture. Polyfoam does not reduce its insulating properties when it comes into contact with water. Therefore, it can be actively used not only in outdoor insulation, but also in "wet" rooms;

- Versatility. The material is perfect for indoor and outdoor use, and can also be used for both vertical and horizontal surfaces (floors, ceilings). At the same time, foam can also be used for roof insulation;

- Extremely low thermal conductivity. Since the overwhelming majority of its mass consists of air, enclosed in polymer granules, it conducts temperature extremely poorly. But for this, it is advisable to use sheets of 10 centimeters and thicker.

Important! In winter, it gets colder in the premises, not because cold air penetrates there from the outside, but because heat leaves the environment.After finishing the walls with foam, we will reduce their thermal conductivity and prevent heat from escaping into the surrounding space.

Styrofoam in a frame wall is better than mineral wool!

frame wall - better than mineral wool!

Take a match, light it, and bring it to the styrofoam, even if it is a facade one. Do the same with a piece of ROCKWOOL. Feel the difference. Please note that we are not talking about glass wool from an unknown Chinese manufacturer, but about high-quality mineral wool. [Of course, you also need to take a high-quality foam plastic]. THE FIRST EXPERIMENT IS OBLIGATORY ON THE STREET AND IN NO EVENT DO NOT BREATHE SMOKE.

You can take tougher conditions. Put it under the burner. Compare the amount of smoke from foam versus cotton wool. At the same time, I am not saying at all that foam is bad, that it cannot be used, etc. It just has flaws and there are quite a few of them. Cotton wool also has them and there are a lot of them too. It is necessary to work correctly with each type of insulation and not to idealize any of them. The cotton wool does not burn, but only the binder burns. The combustion process is usually understood as the processes of oxidation with oxygen with the formation of oxides. Everything in cotton wool is already oxidized. A bunch of foams. The one you mean is called polystyrene foam. It does not melt, but flows. The leak starts much higher than 90 degrees. And from 90 degrees it quickly sits down, this is due to the so-called. glass transition temperature (too lazy to write, otherwise I can tell you in detail what a segment is, its mobility and glass transition temperature). Expanded polystyrene burns with pleasure. Organics should burn. PPP is a self-extinguishing material. During the combustion of PPP, a lot of heat is generated - 40 MegaJ / kg. Polystyrene foam and Styrofoam, different things? Or different names?

Same. It's all styrofoam!

I would like to draw attention to the vapor - air permeable properties of foam, its neutrality to water and durability. There are some misconceptions about this. I will make a reservation that we are talking about expanded polystyrene of the PSB-S brand. Other foams may have slightly different properties. The first misconception is that expanded polystyrene does not allow steam and air to pass through. It is true only for foams with a closed-cell structure - extrusion, for example. PSB-S has an open-cell structure. The foam balls are connected to each other only by part of the surface. There are pores between them, through which steam and air pass through the thickness of the slab. The vapor permeability coefficient of PSB-S is about 0.05. For comparison, pine has 0.06. Everyone talks about the individual properties of heaters, arguing at the level - better, worse. I'm trying to explain that cotton wool and polystyrene are completely different insulation materials. With completely different properties. And frame houses will have completely different properties, depending on what kind of insulation to use. Polyfoam is no worse and no better than any other insulation. He is different. Mineral wool has a drawback (in my opinion), which radically changes the entire structure of the house - wool must be closed with a vapor barrier. And the better this insulation is made (and you can't do badly - the cotton wool will get wet), the more airtight the plastic bag in which you have to live. In such a house (plastic bag), you become hostages of the ventilation system. In the summer, wherever it went - opened the windows and breathe fresh, warm air. And in winter? Slot ventilation and dampers on the windows are drafts and huge heating costs. And now we seem to strive to save energy? This means that special ventilation and heating systems are needed. And these are additional costs for the purchase and regular maintenance. Plus, they consume electricity. And if it is turned off for a while. The use of polystyrene in a frame wall makes this wall similar in properties to a wooden wall (frame, timber), but much warmer Walls really "breathe".And, if the air exchange in the log house is mainly through the mezhventsovy insulation, since there is the thinnest part of the wall and tow, flax, jute, etc. heaters are much less dense than a log, then a high-quality insulated frame wall filled with foam passes air into the house through its entire surface. By the way, with a strong wind and the presence of a ventilation gap (gap) between the foam and the outer skin, I observed a rather strong blow-through of PSBS-15. In winter, this can lead to a decrease in indoor temperature, in comparison with the same temperature parameters, but without wind. However, this is typical of other materials as well. But I would recommend that, when using PSBS-15, sheathe the frame from the outside with windproof vapor-permeable plates - OSB, fiberboard, etc., and then do extra on them. lathing and ventilation facade (siding, brick, etc.). Or, directly on the racks, beat the lining (simulator of a bar, blockhouse, etc.) without making any gaps between the frame and the boards. So, excuse me, I was distracted, a frame house, insulated with expanded polystyrene, does not need additional supply ventilation. Only a hood is needed to ensure normal air exchange and remove excess moisture and polluted air from the bathroom and kitchen. The second misconception is that polystyrene degrades over time. This will happen if, for example, PSBS-15 is buried in the ground to insulate the foundation. How to drink, let it collapse. It will be saturated with water through and through, freeze, be crushed by heaving and fall apart after a dozen or two such cycles. So don't do it! In the wall or in the ceiling of the frame, conditions are completely different. The PSBS has remained unchanged there for decades. I saw with my own eyes the foam, which has been working in the frame for more than 20 years. NO changes I am sure that he will live for another hundred years, since in 20 he has not changed a single millimeter. And bury the EPSS in the ground. It was created for such conditions, therefore it is much more expensive. The third misconception (for today the last one - already tired of clicking on the keys) is the release of styrene and other harmful substances. I can admit that this is the case, BUT ... .. Only in the initial period of the life of expanded polystyrene. It really smells right after making it. And it doesn't smell like roses. But, over time (several weeks or months), this smell disappears. I don't know if styrene smells at all. The smell, in itself, does not yet indicate the harmfulness of the material. Remember, any plastic item smells right after purchase. And not only plastic. And the fact that polystyrene is harmless is clear at least from the fact that it is used everywhere (not only in construction) and has all the necessary certificates. I have not seen a single conclusion that PSB-S expanded polystyrene (the official manufacturer), as a heater, has caused harm to human health. By the way, your refrigerator is insulated with it. good. But there are products!

P.S. The article is taken from the Internet.

Home page »Styrofoam in a frame wall is better than mineral wool!

Disadvantages of Styrofoam

- The material is flammable, and this is one of its most important disadvantages. Unlike mineral wool, this polymer insulation does not tolerate high temperatures. At the same time, it is very difficult to extinguish the foam, but when it burns, it emits black and very acrid smoke, which we all remember well from childhood;

- Low strength and high fragility. The material cannot be strongly bent as it will break. As a result, only straight surfaces can be insulated with foam. Low strength translates into susceptibility to deformation even with minor external influences. So on top, the foam needs a reliable finish;

- The foam does not allow air to pass through. In this regard, the walls cease to "breathe", which violates the microclimate in the room. So, it can provoke high humidity;

- The material is afraid of many chemical compounds (turpentine, acetone, solvent, alcohol, gasoline, many resins, kerosene and others).All of these chemicals can erode the foam structure very quickly.

Important! In general, all the disadvantages of polystyrene can be leveled by its competent use. At the same time, it must be remembered that an equally large list of disadvantages in general can be found in very many heaters.

Styrofoam as insulation

The use of foam as a wall insulation Foam as a heater is used almost everywhere. It is one of the most popular thermal insulation materials used in both individual and mass construction. Let's find out whether such a high popularity of foam as a heater is justified, let's figure out what its pros and cons are.

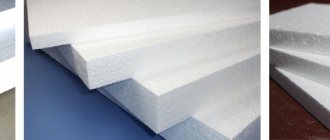

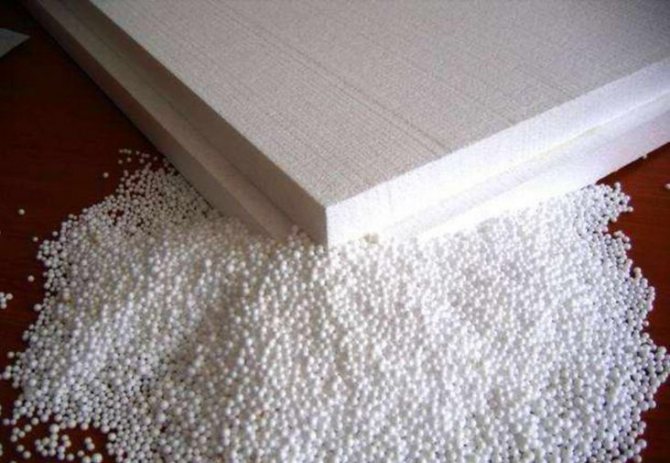

Polyfoam is a type of materials whose structure is made of foamed masses. The main volume of the foam structure is occupied by gas (air). Because of this, the density of the foam is several times lower than the density of the raw material from which the foam itself is produced. This significantly affects the low weight of the foam panels (boards). Due to the large amount of air in the foam structure, the material has high thermal and sound insulation qualities.

Foam plastic of different density, with different mechanical strength is obtained from various raw materials. The higher the density, the smaller the volume of gas is inside the structure and, accordingly, the lower the thermal insulation qualities. But at the same time, the values of resistance to mechanical stress increase.

As a heater, foam plates of different density are used, having, respectively, different levels of strength. Foam boards with a low density index require maximum protection from mechanical damage when installing insulation. Plates with a low density are most often used as a heater with a frame installation method. That is, where all the loads fall primarily on the outer protective layer of the insulation and on the frame.

All stages of wall insulation by gluing foam plastic

- Preparatory work on the walls. First of all, it is necessary to thoroughly clean the walls from dirt and other unnecessary elements. In this case, the surface is primed in order to improve adhesion with the adhesive composition;

- Starting profiles are attached to the wall, which are installed on special dowels with a step of about 30 centimeters;

- Applying glue to walls and foam boards. Prepare a special glue for mounting this type of insulation. The adhesive must be free from chemicals that can destroy the foam structure. At the same time, apply the composition to the walls and at least half of the area of the foam plates themselves, distributing it in an even layer. That is why it is important to align the walls at the preparatory stage, since otherwise the composition will have to be applied along the lighthouses;

- Bonding material. The foam boards are installed on the starting profiles and fixed horizontally. In this case, it is necessary to try to remove excess glue and not leave large gaps, which are then sealed with sealant or polyurethane foam. Fasten the foam sheets in a checkerboard pattern.

Important! When insulating external walls in this way, a reinforcing composition is usually applied on top in two layers, between which a reinforcing mesh is laid. After that, the finishing is carried out with a special facade plaster that can withstand the effects of the external environment.

The harm of foam

No one denies that the poisonous component of styrene is used in the production of foam. One can argue how much it did not react, how much it is released and how harmful it is. Some say that everything is fine, others insist that we will all die. I am not an expert from SES, so I don’t know the correct numbers. But the right foam has all the hygiene certifications, firefighters. So it says something.

But even taking a bad option is harmful. Polyfoam, and other heat-insulating material, is not placed inside the house because of the high chance of dew point and moisture formation in the wall between the main wall and the foam. It must be installed externally. Well, in the soil it will be harmless, because it is also covered with tiles or concrete. And outside on the walls (“wet facade” technology) it is blown by the wind and so that it does not stand out, the MPC simply will not have time to form.

Penetrating a house through a 40 cm wall from a block is fantastic! In the house, the temperature is higher and they are trying to make vapor permeability from the house, which means that the steam will press out of the house. And in order to transmit this pressure, you need energy from somewhere else, but there is none.

The other side of the coin is ventilation. Even in a house without ventilation, rooms must be ventilated, there is exhaust ventilation and there is an exchange of air in the house and outside. According to the norm, the air exchange should be at least 20 m3 / h for 1 person in the room. So even in a hall of 40 m2 and a ceiling height of 3 meters for a family of 4, a complete air change will take place in 30 hours.

So if styrene can get inside from the walls, it will be removed. It's another matter if the foam is inside the room in the walls and so on. Not everything will be so rosy here.

Insulation of a frame house with this material

- The frame surface must be pre-prepared and free of irregularities. Protruding nails and other elements also need to be removed, as well as cracks;

- Plates are laid in the gaps between the frame posts with a certain gap, which is then filled with a sealing compound in order to exclude "cold bridges". This allows the slabs not to change their position during thermal expansion. In this case, the plates are fastened either to plastic dowels or to an adhesive composition;

- Although the foam does not absorb water, moisture can still penetrate under the material and cause the wall to collapse. Therefore, the surface must be covered with glassine, various membrane coatings or plastic wrap. Try to achieve complete tightness by overlapping the coating sheets;

- In this case, the inner surface of the wall is covered with a vapor barrier coating;

- Finishing is carried out according to the existing project.

Below you can watch a detailed video on how to do the exterior wall decoration with foam plates with your own hands.

Types of foams

Foam plastics are now of two types: ordinary polystyrene foam and extruded polystyrene foam.

Common polystyrene foam, which was produced 10 years ago, you will not find on sale anymore - the technologies do not stand still and, having slightly changed the technology, the manufacturers achieved that the expanded polystyrene was self-extinguishing. All that was needed was to make foam plastic in carbon dioxide. So this foam is referred to as PSB-S. In the absence of a heat / fire source, it emits carbon dioxide from the pellets and the fire immediately goes out.

And the polymerization technology has improved significantly, so if earlier about 2% of the polymer components had not reacted, now it is less than 0.5%.

The strength of such a foam is not very high, but it is a heat-insulating material, not a structural one. The granules (balls) are closed and therefore the foam practically does not absorb water and does not rot, and this is the main advantage over the mineral wool board.

EPPS from TechnoNIKOL

Extruded foam (EPS) is made using a slightly different technology and much denser. It has a homogeneous structure, denser and has practically the same thermal conductivity. But it also costs much more. Usually the store is full of it under the brand name "Technonicol" in the form of pink sheets with quarters.

EPPS is also made by other companies that add other dyes (blue, green). It is more stable and withstands compression very well. It is just it that is used to insulate the blind area and foundations outside.And it is he who is laid under the screeds, concrete on the floors on the ground.