What is mineral wool

With the onset of cold weather, the issue of keeping warm in the room becomes especially relevant. The main pathway for heat leakage from rooms is the roof. The zealous owners strive to reduce fuel consumption, insulate the roof from the inside with mineral wool.

Mineral wool is deservedly considered an effective and demanded raw material. The main properties of mineral wool are:

- affordability;

- fire resistance;

- breathability;

- no toxicity.

Release format: in slabs and rolls. In terms of strength, the slabs are ahead of the rolls, they are easier to distribute along the perimeter of the roof. Rolls are lighter in weight and cheaper than slabs.

Experts distinguish four types of mineral wool:

- Stone wool is of basalt origin. Due to its short fibers, it does not restore its original shape after compression, panels made of it are hard and not prickly, and do not absorb water well. The blocks are able to withstand high mechanical loads without changing their shape, therefore they are more often used as insulation for flat roofs.

- Glass wool - the manufacturing technology is similar to that of glass. Long fibers give the boards elasticity, softness and excessive looseness. In comparison with stone, it wins in terms of thermal insulation, weight, noise absorption, hygroscopicity and price. Sheets are installed without fasteners for insulating a pitched roof, fragile structures, for repairing heat-insulating coatings.

- Slag wool - obtained from blast furnace waste. It is inferior to stone and glass in terms of its ability to insulate heat, but its cost is much lower. It easily oxidizes metal surfaces, quickly absorbs moisture and pricks strongly, therefore, its scope is limited to auxiliary buildings.

- Basalt - does not contain dolomite, limestone, blast furnace waste. On contact with fire, it does not burn, the fibers are only slightly melted. It is well stored in rolls, has a very low hygroscopicity.

Features of roof insulation from the inside with mineral wool, and the cost of work

Mineral wool is the collective name for three types of insulation, which have one thing in common - their fibrous structure.

Basalt or stone wool is made from rock. It serves for a very long time, therefore it is used for capital construction. The most expensive type of mineral wool.

Glass wool made from the same components as regular glass. Cheaper than basalt, but its service life is much shorter. It is used in those places where it can be replaced quickly and cheaply.

Slag wool, for the manufacture of which wastes from blast furnaces are used. Price and properties are similar to glass wool.

These materials come in a variety of forms. It can be slabs, rolls, mats, and cylinders.

Insulating the roof with glass wool from the inside is the most effective and affordable way to keep warm in the attic.

In order to insulate the roof from the inside, especially when it comes to a structure made of wooden structures, materials that meet serious requirements should be used. They should be:

- Non-flammable (fire safety class from G3 and higher).

- Long lasting.

- Eco-friendly.

- Resistant to decay.

- Possessing not only insulating, but also soundproofing properties.

- Not suffering from temperature extremes.

- Resistant to damage from insects and rodents.

Mineral wool meets these requirements most of all. To insulate the roof from the inside, mineral wool is used in the form of a roll or mattress.The last option is the most convenient for installation.

Prices for mineral wool allow you to use it for the purpose of roof insulation for almost every owner of a cottage, bath or garden house.

The only drawback of this material is its ability to absorb water, while losing up to 40% of its thermal insulation properties. However, the insulation of the roof from the inside with mineral wool, carried out in strict accordance with the technology, helps to prevent liquid from entering the insulation.

Well, the quality of roof insulation can be seen with the help of a thermal imager, which can instantly show the places through which heat loss occurs.

What set of tools and consumables will be needed to insulate the roof from the inside?

When carrying out roof insulation on your own, you should prepare everything you need to carry out the work:

- Minvatu.

- Wooden bars with a cross section of 40 mm.

- A vapor barrier (for example, any waterproofing film).

- Drill.

- Glue.

- Antiseptic solution for wood.

- Nails or screws.

- A hammer.

- Mineral wool dust mask.

Pros and cons of mineral wool

Insulation of the roof from the inside with mineral wool is an important point in finishing, it is important not to be mistaken with the material for insulation. Among heaters, mineral wool is considered a favorite due to its many benefits. Pros:

- High fire resistance: the composition includes silicate melts that cannot ignite under the influence of high temperatures, and they also do not undergo deformation.

- Resistance to chemicals: the insulation does not come into contact with various chemical reagents, ensuring safety when cladding educational and research laboratories, factory workshops and school chemistry classes.

- Biological resistance: not affected by molds, not attractive to rodents and insects.

- Low shrinkage, preservation of the original volume, due to which the tightness of the room is ensured, the design parameters are preserved.

- Most types of mineral wool do not absorb water well.

- High permeability of water vapor: cotton wool passes water vapor well without accumulating condensate, so unpleasant odors do not persist in the room, but quickly evaporate.

- High noise-insulating characteristics: not only heat loss will decrease, but also the penetration of loud sounds from the outside.

- Ecology: no allergic reactions, safety for human health.

- Ease of installation: it is not necessary to have professional construction training, roof insulation with mineral wool from the inside with your own hands is up to a novice builder.

- Durability: the service life is around 70 years, so there is no need to change the material several years after installation.

The cheap types of mineral wool, along with the pros, have also disadvantages:

- When working with glass wool, caution is required when insulating the roof from the inside with mineral wool, since when the fibers break and get on the open areas of human skin, pieces of insulation can provoke pain.

- If fragments of glass wool are inhaled, there is a risk of damage to the respiratory tract and lungs. This disadvantage is solved through the use of a respirator, gloves, goggles and a protective suit.

- In the composition of inexpensive types of mineral wool there is a formaldehyde resin capable of oxidation at high temperatures and the release of phenol, a poisonous gas. In the case of working with such materials, experienced craftsmen wear special clothing and a gas mask.

Internal roof insulation with mineral wool - Pros and cons of the material

Characteristics of mineral wool

Do-it-yourself roof insulation with mineral wool has the following positive characteristics:

- High thermal protection of the structure;

- sufficient strength and durability;

- good resistance to adverse effects: mold, fungus, rodents;

- low flammability - to ensure the fire safety of the building, a very important factor;

- easy to install - when insulated from the inside, does not require additional fastening (the lower crate is the retaining element of the structure);

- thermal insulation with mineral wool, contributes to the free movement of air, which has a beneficial effect on the microclimate of the entire building.

Also, it is required to understand that the protection of the pitched roof of the house with mineral wool has both positive features and disadvantages:

- Do-it-yourself installation of a mineral wool heat insulator presupposes the obligatory presence of overalls, gloves and a mask. This approach will help to completely avoid the ingress of fiber particles on the skin, which means unpleasant itching and irritation;

- High water absorption of mineral wool, requires mandatory vapor barrier and waterproofing;

- A mineral wool heat insulator is comparatively heavier than polystyrene and polystyrene foam. Therefore, insulating the roof of a house with mineral wool on its own assumes some safety margins when calculating the roofing structure and the building as a whole.

Calculation of the thickness of the insulation and the height of the rafters

The thickness of the insulation layer is directly related to the climatic factors of the region. Basalt insulation with a low density of 25 kg / m3 is best suited for the zones of Moscow and the Moscow region. The use of another insulation over time leads to its subsidence.

The higher the height of the rafters, the thicker the insulation should be. When choosing the optimal height of the boards for the manufacture of rafter legs, they rely on calculations of the thickness and strength of the insulation. In residential buildings located in central Russia, the thickness of the mineral wool layer is within 15 cm; for the northern regions, the thickness is increased.

You can calculate the approximate consumption of insulation and its thickness using our calculator: Calculator for calculating the thickness of insulation for walls or balcony overlap

Important nuances of installation

According to the technology, work on roof insulation (prices) from the inside begins with the installation of underlay waterproofing. First, the insulating film is mounted on the rafters, and then the insulation itself is attached. It is important to take into account that the film canvases should be located across the roof slope, and the edges overlap at a distance of 10-12 cm. The final stage of securing the waterproofing will be the installation of a counter-lattice. To prevent the film from tearing during operation, it should sag a little - within 1-2 cm.

Counter-lattice plays an important role in the process of roof insulation. In fact, this will be a ventilated layer that will protect the roof from the accumulation of condensation from the inside. The optimal cross-section of the bars for the counter-lattice is 2 cm.

If the roof is insulated from the inside with plates with mineral wool, then it is not recommended to compress it. The quality of thermal insulation will not suffer from this, but the material consumption will increase significantly. It is also not recommended to bend the material, as kinks will appear in which moisture will be retained. In addition, it is necessary to provide "ventilation" gaps between the insulation material and the roof covering.

We offer all residents of the Tula region and the city itself favorable conditions for the installation of the roof. The price of our services is more than reasonable, and the quality of work and the whole range of services are at the highest level. Contact now and your life will become much more comfortable. Our prices are very affordable!

Mineral wool brands

Cotton wool brands for insulation differ in density:

- Mineral wool with a density of up to 75 kg / m3, areas of use are limited.

- P-75.75 kg / cubic meter, is applicable for the insulation of heating plants, oil and gas pipelines, and also for insulating attics.

- P-125, 125 kg / cubic meter, has excellent sound insulation, excellent for insulating floors, interior walls, partitions and ceilings.

- PZh-175, 175 kg / m3, due to its rigidity, serves as an excellent insulating material for metal and reinforced concrete floors.

- PPZh-200, 200 kg / cubic meter, material of increased rigidity, contains special additives that allow to withstand high temperatures without the risk of ignition, is used for thermal insulation of metal walls.

How to cut mineral wool

A construction knife is used to cut the material. If it is absent, a kitchen knife with a grooved edge, a small saw, will do. Minvata in rolls are cut without unpacking. Measure the desired length with a tape measure, fix the cut with tape and cut the desired fragment with a saw in the longitudinal direction. For a transverse cut, the roll is unsealed, unwound a little and an incision is made with a knife or hacksaw.

How to insulate a ventilated flat roof

Knowledge of how to properly insulate the roof of a house from the inside with mineral wool will help preserve warm air and reduce heating costs. For this purpose, layers of mineral wool are laid between the rafters, and then secured with ropes and metal brackets using a pistol to avoid shedding. Glass wool is elastic and able to hold between the rafters on its own. Basalt wool is more rigid, and for its fastening it is necessary to build a crate.

The thickness of the material is chosen depending on the climate of the geographical area in which the house is located. If winters are harsh, the layer should be thicker, the panels can be laid in several rows. Mineral wool fibers repel water well, but moisture can accumulate in the voids between them. In the case when water in the insulation accumulates more than 2% of its own weight, its efficiency is reduced by half. To avoid this phenomenon, the insulation strip is protected by a vapor barrier film, which is pulled over the top layer of mineral wool.

Laying mineral wool: step by step instructions

Suppose you have at your disposal an attic room with already installed battens, rafters, and a cold roof. In this situation, the desire to improve energy efficiency will be on the list of natural needs. You will want to fill the space with warmth so that you can not only stay inside, but also sleep on long winter nights, when the frost is 40-45 degrees outside the window.

Step one

Laying the diffusion membrane. Its function is to reduce the level of moisture on the side of the roof if it suddenly flows. Using a cutting tool, we make even stripes, then lay them with an overlap of ten to fifteen centimeters. The formed joints are covered with thermal tape. It is sold in any hardware store. Five or six skeins will be enough.

Step two

Installation of an insulating sheet of sufficient strength. To make an engineering calculation, keep in mind that the thickness of the fabric must match the width along the rafters. Don't be alarmed if the product you have purchased does not comply with engineering regulations. Cloth of lower operational density is applied in two or three layers. Experts advise placing slabs overlapping in a checkerboard pattern.

Step three

Reinforcement of structural elements with a waterproofing agent. It is usually replaced with a diffuse membrane, which is reinforced to the rafters with aluminum brackets. The method does not differ from those considered in the first and second stages. The improvement is made with an overlap, provides for the use of black or blue adhesive tape, depending on the type: industrial or domestic class.

Step four

Completion of the main work with the transition to finishing. Finishing measures for the arrangement of the interior space include the application of a paper base, vinyl wallpaper, decorative panels.Nine out of ten consumers choose plywood, chipboard, less often plastic, washable non-woven wallpaper. Insulation of the attic is completed if the rules for safe operation are followed and no mistakes are made.

Roof insulation technology with mineral wool

In order to increase the heat-insulating ability of the roof from the inside with the help of mineral wool, it is necessary to select the technology of economically justified insulation by preparing the necessary materials:

- wind protection;

- waterproofing;

- insulation;

- vapor barrier.

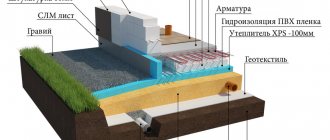

To ensure the comfort of the building, as well as to increase the service life, the layers of the roofing cake are arranged in a certain order in the direction from bottom to top:

- ceiling sheathing from the inside of the room;

- lower lathing;

- steam isolation;

- rafter legs;

- insulation between the rafters;

- waterproofing;

- lathing;

- roof covering.

Insulation of the roof from the inside with mineral wool - the choice of mineral wool for roof insulation

Following towards technologies that provide roof insulation from the inside with their own hands with mineral wool, manufacturers are constantly updating insulation models, endowing them with unique properties and quality characteristics

Prices for mineral wool

- Foil plates - look decent, but create additional problems, disrupting the natural magnetic background.

- Slabs covered with a film, insulation from steam - the presence of a film does not negate the insulation of the entire surface of the roof from water vapor by a single membrane.

- Slabs with layers of different densities - the upper layer of increased density, a ventilated facade that is not blown through for normal conditions in the system, but the main one is lighter and more heat-insulating.

- Mineral wool, covered with a superdiffusion film - provides vapor-permeable protection of mineral wool against blowing, however, in comparison with others, it is more expensive.

Mineral wool slabs are more durable. When insulating the roof with your own hands, fixing them will not be difficult and will not require special devices.

Insulation of a sloped roof with mineral wool.

During the insulation of the pitched roof, the mineral wool is placed between the rafters. In this case, the size of the strata becomes important. The master chooses the width of the blocks of mineral wool by a couple of centimeters more than the distance between the beams. The sloped roof is insulated with sheets with a density of up to 160 kg / m3. without fixing. After compression, the panels do not regain their shape and do not hold on their own. To strengthen their position, you will need a crate. The attic roof is most often insulated by laying the material inside the frame, which reduces the operating time. Experts advise to insulate the pitched roof during the construction of the building, along with the thermal insulation of the walls of the house from the inside. It is only necessary to carry out work in dry weather. In the autumn, the roof cladding is mounted, and then the insulator is laid from the attic side to the prepared place. It is also possible to insulate the roof with mineral wool from the inside in old buildings.

Insulation of the roof from the inside with mineral wool - thermal insulation of a flat roof

Rigid slabs are used to insulate a flat roof from the inside. Stone wool works best, but high-density glass wool can also do the job. Do not use soft mineral wool samples. When walking on the roof, under the weight of the snow cover, they sag and this can lead to a violation of the integrity of the vapor barrier membrane. To preserve the waterproofing, the sheets are covered with a cement-sand screed and increase the load on the floor, as a result of which the use of the screed depends on the degree of strength of the structure.

Pitched roof insulation materials

First of all, it is worth briefly dwelling on the materials that are simultaneously used for roof insulation. In addition to mineral wool, you will need to buy:

- wood preservative;

- waterproofing;

- vapor barrier;

- wooden slats;

- fasteners - staples, screws, knitting wire;

- front finishing material.

The last point is needed only in cases where the attic space is planned to be operated as a residential one. In other options, it will be possible to stop at a vapor barrier. In the choice of all these materials, it is better to trust the professionals, since today there are a lot of mineral wool, hydro and vapor barriers on the market, which, contrary to the assurances of the sellers, do not correspond to the declared characteristics.

Insulation of the roof from the inside with mineral wool - safety technology

When working on roof insulation from the inside with your own hands, you need to follow safety rules.

- Carry out insulation work exclusively with goggles and a respiratory mask. Mineral wool fibers trapped in the air can enter the respiratory tract and cause serious discomfort.

- Particles of glass wool can get on the exposed skin and damage it and cause irritation, so long sleeves are required for work.

- Keep material out of reach of children.

- The correct approach after work is to collect all the remnants of the insulation, not to allow it to scatter throughout the yard. Of all types of insulators, glass wool is the most dangerous.

Roof insulation with mineral wool

The largest heat loss occurs on the roof of a residential building. People on the ground floor do not suffer from discomfort, while their guests or friends sleeping in the attic feel a slight chill. This is especially felt in winter, when the ambient temperature goes beyond 35 degrees with a minus sign. The owners of chalets and cottage houses in the northern part of Russia know that this issue cannot be solved with an oil or electric heater.

Roof insulation is a radical solution to the problem of insufficient thermal energy and comfort on the upper floors of buildings. There are 5 materials for roof insulation. Expanded clay porous stone, sawdust, recycled shavings, glass, basalt, mineral wool. From the article you will find out what advantages the mineral wool has, get acquainted with the history of the insulator and the frequently made installation mistakes.

Tips for insulating a roof with mineral wool

Here are a few points that need to be taken into account in connection with the insulation of the roof from the inside with mineral wool.

Roofing material is more often than others exposed to moisture. Water is a known enemy of thermal insulation.

Roof insulation is installed according to the principle of ventilated facades. This means that it is not fenced off from fire by either concrete or plaster elements. You need to choose the type of mineral wool that is least prone to fire.

Regardless of whether it is a flat or pitched roof, the area of roof insulation with mineral wool in both cases is high, so the cost of the material should be affordable and fit organically into the construction estimate.

It is impossible to check the quality of the material upon purchase, but it is possible to determine the condition of the insulator if you adhere to simple rules:

- Buy dry products. Moisture reduces the basic characteristics of the slabs, promotes decay of wooden beams and battens.

- Store insulation in a dry and ventilated place. In the case of outdoor storage, the products must be carefully packed in a sealed plastic wrap.

- Purchase mineral wool exclusively in branded hardware stores in order to avoid buying counterfeit goods.

- High-quality products are provided with a label with all the necessary information about the characteristics, release date, and areas of application.

- The cost of the goods depends on the degree of the manufacturer's popularity, the type of mineral wool, the stiffness of the sheets and the uniformity of the density of the blocks.

- German manufacturers, who are anxious about the certification of insulators, are rightfully considered the leader in the production of quality products.

However, it is not enough to simply insulate the roof and put a thick layer of mineral insulation. When installing mineral wool, many mistakes can be made that affect the decrease in the effectiveness of insulation and the increase in heat loss of the building.

Insulation advantages:

Thermal conductivity

The ability of mineral wool to accumulate useful thermal energy is 0.034 watts per cubic meter. A similar technical indicator of red brick with a ceramic base is 0.56 watts in relation to a cubic meter.

Specific strength

The average density of a mineral slab is from 30 to 200 kilograms per cubic meter. The weight of the insulator is added from this characteristic. The higher the level of strength from the factory, the more dry weight, price, energy efficiency. For roof insulation, slabs with a density of 50-60 kg / m3 are used.

Vapor permeability

A property that promotes air circulation through the main insulation layer. Due to the index of 0.49-0.58 mg / m-h-PA, the insulation cushion absorbs and releases oxygen. A high-quality air exchange takes place in the living room, a comfortable microclimate is created.

Incombustibility

Insulation of the roof from the inside with mineral wool automatically increases the fire safety of the interior, which, of course, is important for every owner of a wooden house. Wanting to increase fire resistance, the vast majority of homeowners are leaning towards this insulation.

Low shrinkage

Unlike competitive products, mineral-based slabs practically do not sludge. Engineers predict 0.5 to 3 percent shrinkage after thirty years of use.

Insulation of the roof from the inside with mineral wool - installation errors

Most often, heat leakage can occur at the joints between thermal insulation and timber beams. This usually happens because the mineral wool does not fit tightly to the beam, leaving gaps.

The beam is also a heat bridge, as it comes into direct contact with the concrete slab and heats up. It is best to insulate the beam itself by blocking its top, for example, with an additional layer of thermal insulation. Another weak point, although it is rare, is the knot between the floor and the wall. Most often, the entire roof should be insulated. Then the main problem becomes the choice of high-quality insulation and sealing of the joint. If the joint is poorly sealed and the wind blows under the roof, then cold air quickly spreads along the walls. It increases heat loss in rooms, causing a draft. When insulating a roof with mineral wool, inaccuracies are most often made due to incorrect installation, the appearance of thick seams, if the insulation is damaged or crumpled, moisture gets on it, the wrong device or lack of steam and water protection. The use of insulation from scraps of cotton wool is initially doomed to failure, leading to uneven heat losses and a decrease in the effectiveness of insulation in general. Also, a weak spot in the insulation is the joint between the roof and the load-bearing wall.