Primer gf-021 gray and red-brown for metal and primer for pipes

Primer GF-021 is widely used in outdoor works for preliminary protective coating of wood, metal or other products with which it has good adhesion, allowing for a long-lasting resistant pre-paint anticorrosive treatment. Before priming, especially if it is done with a spray gun, it is required to dilute GF-021 to reduce the viscosity level. In this case, xylene GOST 9949 or 9410, solvent GOST 10214 or 1928, or any of them together with white spirit (nefras C4 155/200) GOST 3134 in the recommended ratio of 1: 1, but the proportion of solvents should not exceed a quarter of the mass of the primer itself. It is possible to use turpentine; when painting in an electrostatic field, thinner RE-4V or its analogue RE-3V should be used. The surfaces to be treated are pre-completely cleaned of dirt, dust and old paintwork, traces of possible corrosion are removed, thoroughly degreased and dried. The applied coating retains its declared characteristics in the temperature range from forty-five degrees of frost to sixty degrees of Celsius, does not react with sea or fresh water, does not lend itself to the influence of mineral oils and detergents.

Application of GF-021 soil It is produced by roller, brush, spraying or vacuumization, immersion or other method at an ambient temperature of at least five degrees and not more than twenty degrees Celsius, preferably in two layers. The time required for the first layer to dry at a temperature of + 20 ° C is an astronomical day. The same conditions must be observed before working with the primer if it was at subzero temperatures during storage or transportation.

It is used as a base for paints and varnishes such as PF, GF, EF, FL and the like, but it can also be used as an independent coating. It is produced mainly according to GOST 25129-82 in red-brownish color, or according to TU in light gray tones.

Primed structures differ smooth matte finish, or have a dull gloss, excellent sanding without "greasing" abrasive materials. Excellent strength and quality characteristics are primarily due to the use of high-quality high-molecular copolymers in the manufacturing process, and the relatively low cost of GF-021 is due to their domestic origin.

The primer should not be in the area of direct sunlight, the container must be hermetically closed, limiting the ingress of air and atmospheric precipitation. When working with it, you should use personal protective equipment that prevents the composition from getting into the eyes and on open areas of the body. It is recommended that painting work be carried out either outdoors or in a well-ventilated area, away from possible sources of ignition. It must be remembered that the GF-021 soil is toxic and requires specialized disposal; draining of residues into the general sewer system is categorically excluded.

CONSUMABLES AND RELATED PRODUCTS:

Paint brushes

flat and flange

Overalls and

household inventory

Moscow and other regions of Russia can find out the cost of delivery by contacting any nearest terminal of a transport company working with St. Petersburg. We, for our part, will ensure prompt delivery of cargo to any carrier you choose.

There is a discount system for bulk orders.Regular customers are always a priority for us, but for new ones we are always open to dialogue and mutually beneficial cooperation. Our product catalog includes the most complete list of offered goods, and for the objectivity of your choice, only original photographs are posted on all pages of the site. The price list, reflecting prices in real time, will help you to choose and buy the products you are interested in at the most favorable prices. Any of your comments, complaints and suggestions will not be ignored, we are waiting for them on our email. the address

video instruction on how to paint a galvanized pipe with your own hands, photo

Many do not understand why paint zinc-coated steel, because it is already very reliable and durable. Nevertheless, in the process of use, there is often a need for additional protection, and the aesthetic appearance of such a coating is not very attractive. Consider how to paint the galvanized steel, and how to do it in accordance with the technology.

In the photo: staining not only protects the surface, but also significantly improves the appearance

Features of Galvanized Steel

Nowadays, surface coating with zinc is one of the most common options for protecting metal from adverse weather conditions, especially moisture. This type of materials is most in demand for roofing, but galvanized steel with a polymer coating is used there, which makes it even more stable and durable.

But what if you already have a structure made of galvanized steel or there is simply no money to purchase material with additional coating? After all, the price of sheets without a polymer layer is much lower, which is why they acquire them, despite their not very attractive appearance.

That is why we will consider the question of how to paint galvanized steel, and how to do it as efficiently as possible. In fact, this process can be divided into several main stages, which we will look at in more detail.

The main stages of work

So, when carrying out work with your own hands, you need to carry out all the activities in a certain sequence. This will simplify the whole process, because you will know exactly what and why to do.

Choice of paint

This is a very important stage, since not every train is suitable for work.

As a rule, the following options can be found in trading:

- Most often, special galvanized roofing paints are used. They are highly resistant to weathering and give the surface a water-repellent effect, most often acrylic resins are the basis of the composition. The packaging should specifically indicate that the composition is suitable for zinc coatings, you should not take the seller's word for it, since it is unlikely that he himself painted such materials.

Roof paints are sold in large containers

- If materials are exposed to aggressive influences, then it is better to process them with more durable compounds. These include alkyd-urethane coatings, which are very reliable, but their cost is also higher. Do not forget that the instructions on the packaging are required to be studied before use, this will avoid problems during the work.

Alkyd-urethane composition has high performance properties

- If you have galvanized finished structures that need to be additionally protected from fire in case of a fire, then you need fire retardant paints for metal Polistil, there are other manufacturers, but this product has a reasonable cost and has proven itself well among specialists. The difference between these compositions is their property to bubble under the influence of fire and create a protective coating that increases the strength of the structure.

Polistil paint will multiply the fire resistance of structures

- Another option is Zinga conductive paint.It is a one-component composition, which consists of 96% zinc, which gives it the highest anti-corrosion properties. This is a kind of analogue of factory hot-dip galvanizing, the work is carried out quite simply, so you will not have any difficulties, the paint is expensive, so it should be used only where the highest degree of protection is required.

This composition is one of the most reliable, but its cost is corresponding

A very common question - how to paint a galvanized pipe? We note right away that if it is heated to high temperatures, it is unlikely that any composition will be durable. But if the temperature is low or the pipes enter the ventilation system, then they are painted with the same paints as sheet metal.

Remember! All galvanizing paints are intended for outdoor use. Therefore, if you carry out work inside, do not forget about the need for high-quality ventilation of the room before the paint dries, the evaporation of the compositions for steel is far from always harmless.

Surface preparation

A very important stage, since without high-quality preparation, the paint simply will not lie down and will peel off after a short time.

Everything is quite simple here:

- The best preparation is natural aging of the surface. It's very simple: galvanized steel is left in place for 1 year, it is exposed to temperature changes, humidity and other factors, due to which the surface becomes rougher, which improves adhesion. In addition, inhibitors that deteriorate the adhesion of the paint are washed off from the material.

- If a powdery coating (the so-called white rust) has formed on the surface, it must be removed, and you should not be too zealous so as not to damage.

- It is best to treat with any alkaline solution (even washing powder is suitable), it will remove dirt and stains from lubricants and other materials.

- The last stage is rinsing the solution with water, it is best to do this with a high-pressure apparatus - it will wash away both dirt and the cleaning solution.

For work on the roof, it is better to choose a light and compact sink option.

Painting works

Everything is quite simple here:

- If there is no primer in the paint, the surface is treated with a special primer. You can continue to work only after it dries.

- Painting is carried out from the ridge along the slope. Work can be carried out in different ways: with a brush, roller or spray gun (this method is the most economical).

Advice! To avoid slipping, you should walk on the roof in felt boots or shoes with felt heels, this will significantly increase safety during work.

Work is quick and easy with the spray gun

Output

Painting galvanized surfaces is an important and responsible process that must be done strictly according to the technology, any violations are unacceptable (see also the article "Galvanized painted sheet: technical characteristics of the material").

The video in this article will help you understand some of the details of the workflow even better.

Add to favorites Print version

nashaotdelka.ru

Avoc specialists dialogue> priming and painting of pipes hvs and gws

It turns out that you can paint, you can not - a question of aesthetics?

(What welds should be primed / painted is in the normative)

SNIP 3.05.01-85

"Welding of galvanized steel pipes should be carried out with self-shielded wire of the Sv-15GSTYUTSA grade with Ce in accordance with GOST 2246-70 with a diameter of 0.8-1.2 mm or electrodes with a diameter of no more than 3 mm with a rutile or calcium fluoride coating, if the use of other welding materials is not agreed in accordance with the established procedure.

The connection of galvanized steel pipes, parts and assemblies by welding during installation and at the procurement enterprise should be carried out provided that local suction of toxic emissions or cleaning of the zinc coating for a length of 20-30 mm from the abutting ends of the pipes is ensured, followed by coating the outer surface of the weld and the heat-affected zone with paint,containing 94% zinc dust (by weight) and 6% synthetic binders (polystyrene, chlorinated rubber, epoxy resin).

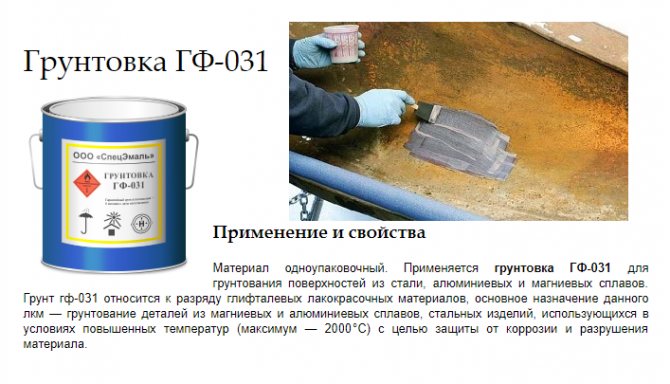

Why use a heat resistant primer?

Is it really necessary to prime the surface, which will subsequently heat up? To answer the question posed, it is necessary to understand the peculiarities of the operation of such items. Here are a few of them, which are the most obvious:

- The need to increase the adhesion of the dye to the surface. It's no secret that many primers have a fairly high degree of adhesion. In addition, they increase the adhesion characteristics of the painted surface itself. It is thanks to the primer composition that the metal elements, which are amenable to heating, acquire a certain film that is resistant to dissolution when a dye is applied to it over the metal.

- Protection against the appearance of corrosive disturbances. Heat-resistant primers are not only necessary in terms of surface preparation for paint application, but also act as a protective material themselves.

- Reduced paint consumption. After applying a heat-resistant primer, a kind of film appears on the product. When painting a surface with coloring compositions, the absorption process is almost completely absent, which ensures an economical paint consumption. This property is relevant when decorating stoves or fireplaces. The fact is that compositions for painting of this type are quite expensive. Therefore, it is better to carry out a high-quality priming than to spend money on paint.

Related article: Varieties of acrylic primer and its application

Corrosion resistant steel pipe insulation

1. Primer Primer Primer Primer Primer 2. Bituminous enamel Bituminous enamel Bituminous enamel Bituminous enamel Bituminous enamel 3. The same The same The same The same 4. - Kraft paper Hydroizol Hydroizol Hydroisol 5. - - Bituminous enamel Bituminous enamel Bituminous enamel 6. - - The same The same The same 7. - - - Kraft paper Hydroizol 8. - - - - Bituminous enamel 9. - - - - The same Total insulation thickness, mm 3.5 4 8 8.5 10.5

Insulation works are an important part of the overall complex of laying a steel pipeline, since the service life of pipes depends on the quality of the insulating coating and its resistance to destruction. The quality of the insulation depends on the quality of the insulating materials and the implementation of technological discipline during their installation.

Damage to the insulation and exposure of metal leads to the development of concentrated foci of corrosion and to premature through rusting, which can occur after 5-6 years of pipeline operation and even earlier. Damage to the finished insulation can occur during the transportation of the pipe and when lowering it into the trench.

Insulation work consists of the following main processes: pipe surface cleaning, surface priming and insulation patching.

Rust removal is best done with steel wire brushes (by hand or machine), sandblasting, or chemical cleaning. In the process, rust is swept away with a brush or broom, and the pipe surface is wiped with a dry cloth. The pipe is cleaned to a metallic sheen. Manual cleaning is a tough and time-consuming job. It can be facilitated by using an electrified tool in the chuck of which the shaft of a metal brush is inserted. The cleaned pipe should be primed on the same day. If the pipe is left overnight without a primer, then the cleaning before priming must be repeated. Cleaning of pipes in wet rainy weather is not allowed. If moisture gets on the cleaned surface, then after drying, cleaning must be repeated.

The primer can be prepared by dissolving one part of heated bitumen in three parts of gasoline. For the preparation of the primer, the same bitumen should be used as for the bitumen coating.Usually, dewatered grade IV bitumen (without filler) is used for this purpose.

To prepare the primer, the required amount of bitumen is chopped into pieces weighing 1-2 kg and loaded into a boiler, where it is heated to a liquid state (usually at a temperature of 160-180 ″ C). Then the bitumen is poured into the tank and allowed to cool to a temperature of 80-70 ° C. Gasoline is prepared at a distance of at least 50 m from the boiler in a special tank. Bitumen is poured into gasoline in a thin stream through a watering can, continuously stirring with a wooden stirrer until the bitumen is completely dissolved.

The prepared primer should be stored in a closed container. The primer is applied to the pipe surface in an even layer 0.1-0.2 mm thick with a bristle brush or roller without drips, clots and gaps. If rusty spots show through the primer, these spots are cleaned and primed again. Drying of the primer is checked by lightly pressing on its surface with the palm of your hand. The dried primer should not leave any marks on your hand.

Bituminous insulating coating (bitumen enamel) is made from grade IV bitumen (75-80% of the mixture weight) and a filler - kaolin (20-25% of the mixture weight). Instead of bitumen IV, bitumen of grades III and V can be used in a 1: 1 ratio with the addition of kaolin. Instead of kaolin, asbestos No. 7 can be used as a filler in an amount of 5% by weight of the mixture. To prepare the enamel, bitumen is loaded into the boiler in an amount of 75% of the required mass, and after heating to a temperature of 160-180 ° and dehydration, the rest of the bitumen is added.

After warming up the entire mass, a filler is poured into the molten bitumen in small portions with continuous stirring of the mixture. In the industrial line construction method, an insulating coating is applied to the pipeline using an insulating machine. The application of the insulating layer by hand can be done using a tarpaulin cloth and a watering can with a spout in the form of a narrow slot (Fig. 1).

Fig. 1. Manual application of an insulating coating:

1 - tarpaulin cloth;

2 - watering can:

3 - pipe

Wrapping the pipeline with waterproofing is performed immediately after the application of the insulating coating until it hardens. This will ensure good adhesion of the winding to the coating.

Hydroisol in the form of a tape 50 cm wide is wound around the pipe in a spiral with overlapping seams by 1-2 cm. The wrapper should fit tightly onto the pipe without wrinkles, folds and bags.

Waterproofing sheets should not have holes, tears, folds, bumps, etc. The ends of the rolls must be flat. Hydroisol should be stored in a dry room, protected from rain and sun, on a plank floor or deck.

The gaps of the insulating coating in the places of the seams that are welded in the trenches must be pre-cleaned, covered with a primer and an insulating layer with overlapping of the insulated part of the pipe.

Control over the quality of work

Control over the quality of work is carried out after each stage (welding, insulation, installation, etc.). If this is not done, then after each operation on the installation of the pipeline, the result of the previous work will become unavailable for verification.

For example, the imposition of the first layer of the seam no longer makes it possible to establish whether the joint was assembled correctly, whether the required gap was set, etc. And the application of bituminous insulation makes it impossible to check the quality of cleaning the pipe surface and the quality of the primer.

Therefore, in the construction of steel pipelines, quality control must be carried out continuously and in stages during operation. All materials used in welding and installation work must have certificates confirming their compliance with the requirements of GOST.

Checking the qualifications of welders is carried out by test welding of joints in conditions that are identical with the work ahead. During welding, welding modes are checked, the order of seam placement and slag cleaning between layers when welding multilayer seams.

When examining the joint, you should pay attention to the fact that the surface of the seam is even, slightly convex, without sagging, undercuts, pores and other surface defects. The joint presented for acceptance must be free of slag, splashes and dirt. Insulation quality control consists in checking the materials that are used in the process. Before the insulation is applied, the quality of the pipe surface cleaning is checked by external inspection (absence of rust, dust deposits, moisture, etc.).

The application of the primer can be started only after the quality of surface cleaning has been certified. Acceptance of completed works on insulation is carried out by external examination of the insulation coating, checking the thickness of the insulation layer, the degree of adhesion to the pipe. The cover should not be squeezed out from under the edges of the wrapper.

After lowering the pipeline into the trench, it is necessary to check the correct laying of the whip and the safety of the insulation coating. Defective spots found during inspection should be immediately cleaned up and restored.

In internal water supply networks, steel pipelines of small diameter, until recently, had practically no competitors. The high cost of copper and stainless steel pipes made it possible to use them only in exceptional cases, where increased costs were justified.

The picture changed somewhat with the introduction of asbestos-cement and polymer pipes, which began to actively displace steel and cast-iron pipelines.

Recommendations for preparing for painting

The first stage of painting is preparatory work. Using sandpaper and solvents, the pipe is cleaned from rust, scale, oils, and old paint residues. Dirt and dust are washed off with detergents (you can use washing powder). This is to prevent the new enamel coating from peeling off. It is also important to get rid of the fat that builds up on the pipes in the kitchen.

We recommend that you familiarize yourself with: Characteristics and features of the use of corrugated PVC pipes

To remove fatty and oil deposits, use alkaline, acidic, alcoholic or water-based fat solvents, special emulsions (Chistomet-Ts, FAS-104, acetone half with toluene, etc.). Dry the surface after washing.

Note! After cleaning the surface with chemicals, it is washed with clean water, because the remnants of salts and other active compounds reduce the protective properties of the enamel coating, and corrosion centers are formed under it.

The second stage of preparation is priming. The primer itself already has a protective function. In addition, it provides reliable adhesion of the paint to the metal surface. It is not recommended to use alkyd compounds for priming, because they have a negative effect on zinc. Noteworthy are the following materials: Rostex Super, Grit Metal, Special Metal Primer.

Painting and protection of pipes and pipelines against corrosion, condensation and moisture

Name Standard AS-5305 enamel for marking on steel welded pipes during their manufacture TU 2313-028-21743165-2004 PF-5117 enamel for protection of lead-tin and aluminum pipes TU 6-10-1372-78 FL-613 enamel for surface protection of oilfield equipment, tanks and pipelines at chemical industry enterprises TU 6-27-163-2000 Enamel KhV-533 for coating the inner and outer surfaces of tanks and pipelines operating in the temperature range from -50 to +50 ° C TU 6- 10-1375-78 EP-5116 enamel for anticorrosion protection of pipelines, as well as for painting field oil pipelines and oil reservoirs of waterflooding systems GOST 25366-92 Enamel AK-1379 for painting various metal structures, oil pipelines, tanks, mechanical engineering and machine-tool products TU 6-27- 231-2001 Enamel KO-8104 for painting pipelines, heating devices, chimneys, railway tanks, tank equipment TU 6-00-04691277-42-96 Primer EP-0282 for protection anti-corrosion of metal structures, equipment,various products made of steel, galvanized steel, aluminum and its alloys TU 6-27-18-295-2000 EP-0287 primer for anticorrosion protection of metal structures, painting mineral carriers, and other surfaces made of carbon steel, stainless steel and aluminum TU 6-27- 211-2001 EP-0280 GL primer for anticorrosion protection of carbon steels, stainless steel, aluminum and its alloys, copper alloys and other non-ferrous metals TU 6-27-169-2000 Aqua-Tube primer for interoperative corrosion protection of the outer surface of steel pipes and other metal surfaces TU 2316-038-27524984-2004 Primer "Gamma-Okhtek" for protecting the surface of steel pipes of field pipelines for transporting oil and saline waste water TU 2312-041-27524984-2004 Inhibited composition XC-500 for corrosion protection metal and reinforced concrete structures, pipelines in an industrial atmosphere of chemical plants TU 6-10-2002-85 Universal enamel XC-1169 for creating chemical ski-resistant paint coatings that protect various surfaces from aggressive environmental influences GOST 9355-81 Paint 85-1-93 to protect metal surfaces of equipment for hot water supply TU 2312-430-0-05034239-94 EP-5226 enamel for the protection of pipelines, field oil pipelines and oil reservoirs of waterflooding systems TU 6-27-164-2000 Organosilicate composition KOS-12-03N (enamel KOS-1203 N) for protection against atmospheric corrosion of metal structures, outer surfaces of chimneys, pipelines of water heating networks TU 2312-003-24358611 -2006 Enamel EF-1242 for painting pre-primed or unprimed rolled metal, thin sheet steel TU 6-21-5011902-5-90 Enamel FL-61 for corrosion protection of surfaces of turbine mechanisms, pumps, tanks and cisterns washed with oil, as well as for metal pipes of ship pipelines TU 2312-131-05034239-99 FL-412 enamel for corrosion protection of pipes of various ship pipelines, tanks, systems, etc. microcapes exposed to hot water and steam TU 2312-131-05034239-99 Metal primer paint "Ukhra 1503" for surfaces of pipes and tanks for drinking, technical, reclamation water supply, as well as for corrosion protection of metal structures for various purposes TU 2316- 001-29346883-2001 Anti-corrosion primer paint VD-AK-1503 ("Morning-1503") for anti-corrosion protection of various metal structures, tanks and water supply pipelines TU 2316-003-56869885-2005 OS-5103 enamel for corrosion protection of water heat pipelines networks (with a coolant temperature of up to 180 ° C) and other purposes for underground laying in non-passable channels TU 6-138-49235.074-89 KO-8111 enamel for anti-corrosion painting of steam pipelines with superheated steam, product pipelines, oil pipelines, gas pipelines, chimneys and any other metal structures exposed during operation to high temperatures up to 600 ° С TU 2312-001-59545798-2003 Enamel for diators "Profi" for finishing painting of radiators, pipes for water heating and water supply in domestic and building conditions TU 2313-012-32998388-2003 Composition "Kornika" (anticorrosive primer-enamel EP-1-100) for priming and self-protection of metal surfaces, operated in an open atmosphere and high humidity, in gasoline, oil and oil products, salt and other solutions TU 2312-100-00209711-2000 "Gramirust" primer for priming metal structures, pipelines, cooling towers, enclosing structures, tank equipment and other objects to the impact atmosphere containing corrosive gases and vapors, oils and various petroleum products TU 2312-088-00209711-2007 Basalt fiber heat-insulating material BVTM for thermal insulation of building structures, pipelines, industrial and household equipment, heating devices, ventilation systems TU 95.2691-98 Basalt fiber heat-insulating material STBF material for mouth thermal insulation of equipment for industrial and household use, industrial pipelines TU 5761-001-08621635-98 Heat-insulating incombustible cylinders "EURO-SHELL" (Euro-Shell / F) for thermal insulation of pipelines of hot and cold water supply systems, heating networks,oil and gas pipelines, industrial pipelines for any purpose TU 5762-012-08621635-2010 KO-868 enamel for protective (anti-corrosion) painting of metal equipment operating in conditions of high humidity and high temperatures TU 2312-001-49248846-2000 Primer VG-33 for corrosion protection of oil and gas tanks, bridges, pipes and other metal structures TU 2312-004-29727639-97 EP-0259 primer for protection of hydraulic and port facilities, power plants, ships of the sea and river fleet, steel tanks and oil pipelines and petroleum products TU 2312-174-00209711-2005 EP-5285 "Epofeniplen" enamel for decontaminated finishing of structures of premises and external surfaces of equipment and pipelines at nuclear power facilities TU 95-2184-90

Choice of paint

When choosing a painting material for galvanized products, it is necessary to take into account the peculiarities and conditions of their operation. If the pipe product is intended for a chimney or a hot water supply (heating) system, then the emphasis should be on the heat resistance of the paint. For street gutters, it is much more important to consider the ability of the paint coating to resist corrosion.

Imported paints

For painting galvanized parts, the most popular are colorful compositions of the following brands:

- Hammerite;

- Tikkurila.

Hammerite paint can be applied even to a corroded metal product. The resulting coating is UV resistant, has high adhesion, excellent corrosion protection, wear resistance and durability. The enamel dries quickly and looks aesthetically pleasing, has a large number of color shades.

But high-quality application is not possible in all ways; when using a roller, small air bubbles can form. The paint layer cracks quickly if degreasing was not carried out thoroughly. Rust appears on the painted metal surface after 3-4 years, and salt deposits even earlier.

Tikkurila epoxy paint is free from these disadvantages. It is at the same time a primer, easy to apply. But it is better to do this in the warm season, since the composition adheres to the heated galvanized metal much more strongly. The coating is resistant to aggressive effects of atmospheric phenomena and chemical environments, withstands heating up to + 80 ° C, while allowing storage and transportation at subzero temperatures.

Domestic products

The most popular is Cycrol acrylic enamel on an organic solvent, it does not require preliminary priming of the treated surface and is applied only in 1 layer. The color palette is limited to only 5 colors.

The advantages of this material include:

- hiding power;

- resistance to ultraviolet rays;

- high adhesive qualities;

- moisture resistance;

- fast drying;

- high class of anti-corrosion protection.

High-adhesion acrylic one-component enamel Nerzhalux is produced in basic white color, but other shades can also be ordered individually. In terms of operational characteristics, this composition is in no way inferior to Cycroli.

Serebrol paint, made on the basis of aluminum powder, is used to protect galvanized steel in water and aggressive environments.

Heating system installation steps

In the new private home general view of the system heating, its scheme and all the nuances are better thought out at the stage of design and construction of the building. So you will immediately imagine whether you need a separate room for the boiler room, where to lay technological niches for wiring system elements and installing equipment. This will greatly simplify further work and reduce installation time. In addition, if you are going to hide the pipes, then you should take care of this before starting the finishing work. The most convenient way to install pipes heating before the floor screed is poured.

Installation work can be started only after closing the thermal circuit of the building, that is, after installing windows and roofing. The season plays an important role. It is better to leave these works for the warm period of the year, since low temperatures deteriorate the quality of welding and increase the brittleness of metal-plastic elements. And, of course, it is necessary to calculate the installation time so that by the beginning of the heating season the system is checked and launched. This will allow you to meet the harsh Russian winter in a warm and cozy home.

The entire installation of home heating can be divided into several stages:

- system selection, design and calculation work;

- selection and purchase of materials and equipment;

- installation of a boiler room and installation of its components or installation of a boiler in another room (if the selected model allows it);

- installation of radiators;

- commissioning works.

An important issue to be resolved is the choice of the heating system. There are several of them: air, electric, open and traditional with a liquid heat carrier.

Heating system installation steps

AT air systemthe coolant is, as the name suggests, the air that is taken in from the outside, heats up and is distributed throughout the rooms through the duct system. This is the most secure system. But it is complex and costly in terms of installation and maintenance, and also has low heat transfer.

The most, perhaps, unpretentious in operation and environmentally friendly is electric heating system... Here, the heat carrier can be electric convectors, autonomous oil and infrared batteries, fan heaters, electric fireplaces. The disadvantage of such a system is obvious - large electricity bills and complete dependence on a stable supply of the latter.

AT open systems for heating, stoves and fireplaces are used, in the furnace of which a fire is made. The efficiency of such systems is rather low, and they are suitable only for small country houses.

A heating system with liquid heat carrier , which includes a heat source (boiler), heat pipelines and heating devices (radiators). At the center of the classic system is the heating boiler. Its choice should be approached especially carefully, thoroughly weighing all the pros and cons of each model.

We also offer, after the work, to conclude a service agreement, not only for the heating boiler, but also for the entire system as a whole.

You can read how to hide heating pipes in the baseboard.

Calculating the cost of heating

Heating system repair cost

Water supply installation cost

Calculating the cost of heating

Heating system repair cost

Water supply installation cost

Engineering systems: heating water supply:

- Painting copper pipes: the intricacies of work Copper has been used for many years as vessels for water and the manufacture of water storage tanks. It is a rather expensive material. Therefore, pipes made of copper have a high price and are considered elite. Copper pipe painting is a reliable protection against corrosion. Copper pipes and ...

- Optimal conditions for private heating. Private boiler house Heating of a house is a rather complex project, which must be carried out by a team of workers with certain knowledge and experience …….

- Welding of galvanized pipes The special welding technology of galvanized pipes allows them to be joined without damaging the zinc coating. A flux is applied to the joining site, which provides protection against coating burnout. Under the flux layer, zinc first becomes viscous-liquid due to heat, then it melts, but does not burn out and ...

- Sand and gravel mixtures for construction work. Specifications 1.1.Sand-gravel mixtures are characterized by: content of gravel and sand in the mixture; the largest grain size; indicators adopted for gravel assessment in accordance with GOST 8267-93 (grain size composition, strength, content of grains of weak rocks, frost resistance, content of dusty, clay and silty particles, clay in lumps and mineralogical and petrographic composition); indicators adopted for assessing sand by ...

- Welding of galvanized pipes: technologies Table of contents: [hide] Methods of galvanizing steel Galvanic method Spraying Hot-dip galvanizing Peculiarities of joining galvanized pipes Welding technologies of galvanized pipes Electrodes required for galvanized welding Rules for welding galvanized pipes Work carried out after welding galvanized pipes Nowadays, many industries and ...

- Painting of heating pipes Services for the installation of heating water supply DESIGN PRESTIGE LLC In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our page on heating> resant.ru/otoplenie-doma.html

- Painting pipes: why to do it, what and how Table of contents: [hide] What material to choose Sequence of work Calculation of the required amount of paint Metal pipes need protection against corrosion. The simplest and most affordable way of protection is pipe painting. It is only important to use coatings that correspond as much as possible to the material from which they are made ...

- Painting chimneys prolongs their service life Table of contents: [hide] Reasons for a decrease in the working capacity of chimneys Metal chimneys Reinforced concrete chimneys Brick chimneys Materials for painting chimneys Do-it-yourself painting chimneys Chimneys need preventive maintenance and periodic repairs, otherwise it happens decline ...

- Painting pipes and radiators - simple and quick Heating system of a private house is a guarantee of comfortable living and independent heating of premises, and hot water supply at any time of the year. But there are situations when the heating system needs to be repaired. Most often, this problem happens with pipes, especially if there were plastic ones, ...

- Technological regulations for the production of construction and installation works during the construction of buildings and structures. 11 Production of facade painting 1.1. This technological regulation applies to the production of facade painting works using ready-to-use paints based on aqueous dispersions of polymers (acrylic, silicone, polyvinyl acetate, styrene-butadiene, etc.), based on liquid potassium glass (silicate), soluble on the basis of acrylic resins, as well as filled decorative compositions. 1.2. Technological…

- The technology for the production of work on the installation of a winter water supply will be as follows. Development of a water supply scheme. The choice of pipe materials and the depth of their laying. Digging trenches for pipes. Installation of pumping equipment, accumulator. Connection of pipes with pumping equipment and a hydraulic accumulator. Cutting the intake pipe into the well. Installation of insulated pipes from the well to the house. Water supply system layout ...

- Replacing water pipes with your own hands: installation without work experience (video) Table of contents: [hide] From metal to polypropylene Methods for replacing old pipes What should you look for before replacing steel pipes? The cost of work: an example of calculation Often in our apartments it is necessary to replace the water pipes, since most of them have old ones from the moment ...

- On approval of the Rules for holding architectural and urban planning competitions in Moscow (as amended on December 28, 2005) 1. General provisions 1.1. These Rules have been developed to implement the order of the Mayor of Moscow dated April 5, 1996 No.N 176-RM "On the organization of a competition for the best architectural (urban planning) project in Moscow". 1.2 The rules are developed in accordance with chapter 57 ...

- Heating works Choosing an autonomous heating system for a country house In order for your house, office, warehouse, garage to always be warm and comfortable, regardless of the weather and the work of utilities, it is necessary to equip it with an autonomous heating system. Before starting the production of heating works….

- The cost of installation work HEATING WATER SUPPLY Heating repair ► calculation calculator ◄ Installation of heating in the country. Installation of winter water supply for a private house. Installation of a winter water supply system in the country, installation of heating in a private house. Repair of water supply pipes in a private house, replacement of water pipes of the heating system in the country, installation of pipes ...

- Rubber rings for coupling joints of asbestos-cement pipes. Specifications 1.1. Basic parameters and dimensions 1.1.1. Depending on the purpose of the ring, three types are made, indicated in table. 1. Table 1 Ring type Purpose Pressure no more than MPa (kgf / cm2) Ring section Coupling type CAM Water supply 1.8 (18.3) Shaped Asbestos-cement CAM according to GOST 539 ...

- The right choice of pipes Skilled employees from Design Prestige will help you to quickly and efficiently select pipes for carrying out communications of a one-story or two-story private or country house. The selection of reliable and durable pipes that meet quality standards and production needs is the key to success in ...

- Welding works during the repair and reconstruction of vessels and apparatus. Standard technical conditions 1.1 This organization standard is intended to guide the reconstruction and repair of vessels, apparatus, pipelines and their elements (hereinafter equipment) made of carbon, low-alloy, corrosion-resistant and two-layer steels, as well as titanium, nickel, aluminum, copper and their alloys, operating under pressure no more than 16 MPa (160 kgf / cm2) ...

- Elite doors. Painting at home. This article will be useful to those who are going to paint their luxury wooden doors at home so as to give them the perfect finish without ugly or unprofessional marks ...

- Painting the facade of a house with your own hands Table of Contents: Making a paint calculation Preliminary preparation of the facade for painting Features of painting the facade Additional recommendations Video Photo Painting the facade is the simplest, fastest and most affordable method of refining it. This is important because the facade is the face of the house and, in fact, ...

Previous Post Where to buy reverse osmosis in Ukraine?

The next post Do-it-yourself soldering of polypropylene pipes: instructions, temperature (video)