Today, the relevance of using such a material as siding in modern construction is quite understandable: siding wall cladding perfectly hides all existing defects, makes the appearance of the house more attractive, and at the same time differs in a relatively low price compared to its counterparts. The main advantage of such wall cladding is that it provides for the installation of heat-insulating materials.

In this article, we will talk about the benefits of insulation for walls outside the house for siding, about the installation technology, price, we will find out the opinions and opinions of people and much more, which will help determine the choice of the best insulation for the walls outside the house or cottage.

Types of heaters

- Insulation materials for walls based on mineral wool are sold in roll and slab form with different densities, which affects their characteristics and, of course, the price of the material.

Photo: slab and roll mineral wool insulation.

- Glass wool. Such insulation for walls outside the house for siding is made on the basis of fiberglass. They are realized in slab and roll form. This type of insulation for walls outside the house is widely in demand in private housing construction as it has a low price, which makes the material available to all consumers.

Photo: glass wool in rolls and slabs.

- Styrofoam. This type of insulation for the walls outside the house is also very popular, although less than mineral wool and glass wool, but this does not mean that such insulation for the walls of the house is worse, it just loses to them in some respects, but in some respects vice versa is superior.

Photo: Styrofoam.

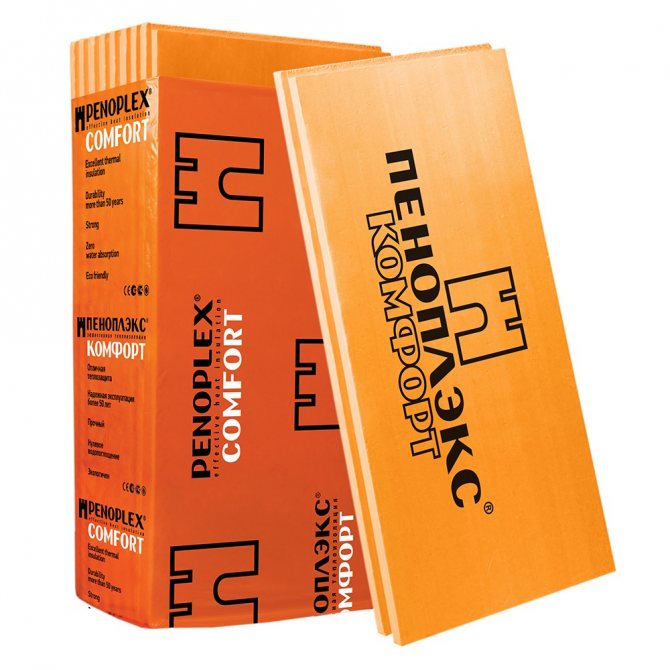

- Extruded expanded polystyrene. Such insulation for the walls of the house has good performance, which makes it widely in demand in modern construction. Insulation of a brick house from the outside with expanded polystyrene provides a high rate of heat saving.

Photo: expanded polystyrene.

It should be noted that insulation for walls outside the house, which would fully meet all the requirements, is not so easy to choose, because each of them is effective with its own set of characteristics, both good and bad.

And in order to choose the right insulation for walls for siding, which would be more suitable in your case, be sure to take into account the climatic conditions, the type of walls that will need to be insulated, and so on. Many make a big mistake when, when choosing insulation for walls for siding, they pay attention only to the price, while they do not even think about what degree of efficiency will be provided to a wooden house with such wall insulation.

That is why, in order to know exactly what kind of insulation is best for your home, carefully read the reviews of people who had to deal with the insulation of the facade of a wooden house.

Below is a video clip, after watching which you will have an idea of how the external insulation of a house under siding is carried out with your own hands:

Styrofoam. This is a very good, and most importantly, low-cost insulation for siding for a brick house, which has high thermal insulation characteristics. Among the advantages of such a heater for siding, one should especially highlight its excellent moisture resistance, low thermal conductivity, low price and ease of installation not only outside, but also inside, for example, a log house, its installation can be carried out on vertical and horizontal wall surfaces.

Now about the disadvantages. Polyfoam is a kind of insulation for siding that can disrupt natural air exchange inside a wooden house, since it has low vapor permeability.The walls of a wooden house when facing with foam plastic will not be able to "breathe", because of this, moisture begins to collect between the walls and the insulation under the siding, which then appears in the form of condensation.

Also, the disadvantages of such wall insulation outside a log house can be attributed to its fragility - the operating time of the foam is twelve to fifteen years. In addition, the foam burns, while releasing hazardous substances.

As for the sound insulation of such insulation of a log house outside under the siding, it cannot boast of this either, since it actually amplifies the sound even more, acting as a resonator. Therefore, before choosing such insulation for the facade of a wooden house, weigh the pros and cons well, read the discussions about the material and only then decide the issue with its choice.

In the photo above, you can see how the facade of a private house is insulated with foam.

Mineral wool. Such insulation for siding, as well as its varieties, which include basalt wool and glass wool, can be called the best heat insulator, which is successfully used for external insulation of a house under siding, and it does not matter at all whether it will be a wooden or brick house, and in that and in another case, it will provide high thermal insulation.

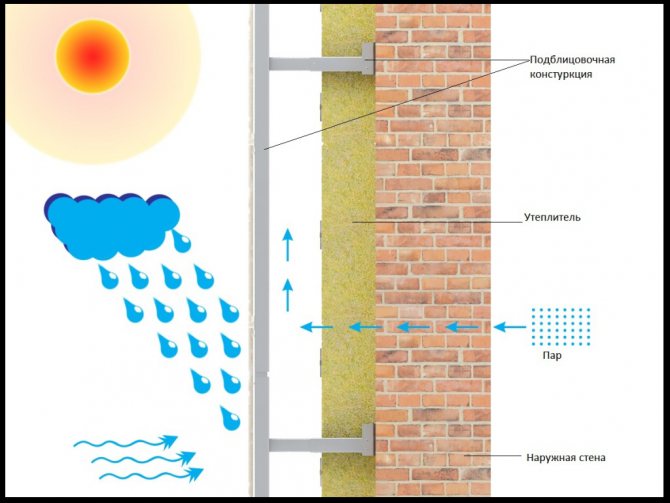

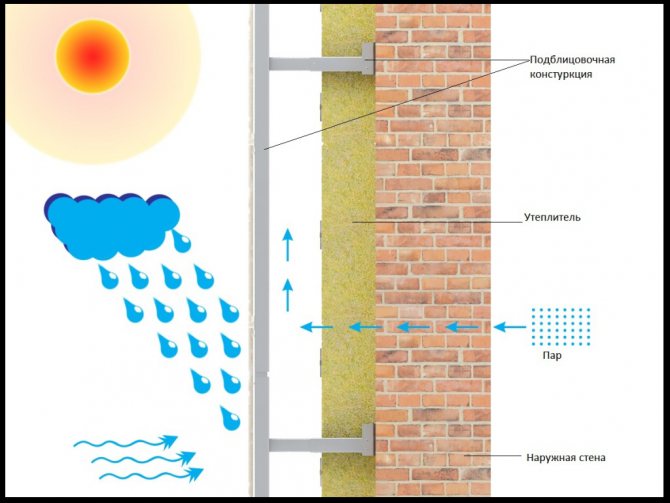

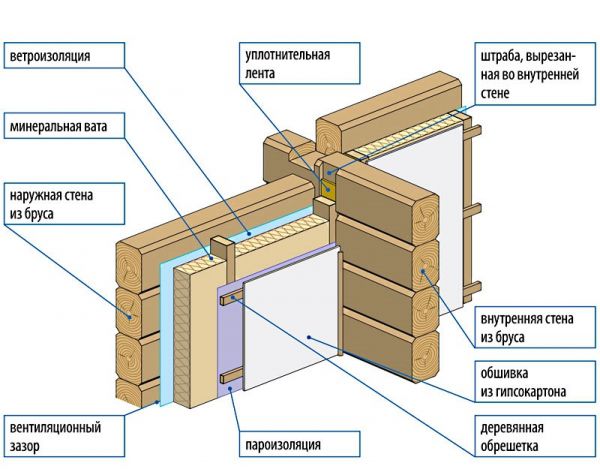

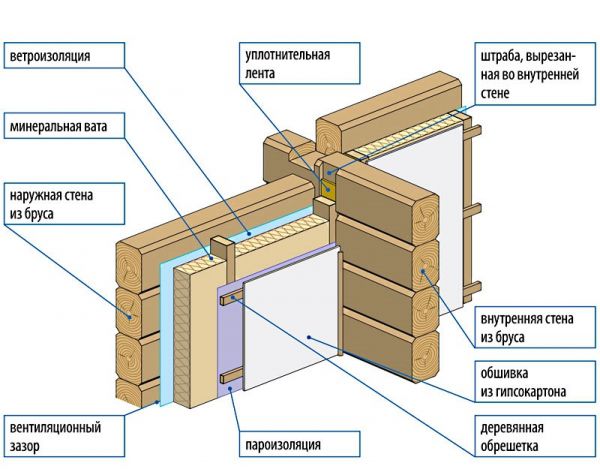

In terms of thermal insulation characteristics, mineral wool is not much inferior to foam plastic. The main advantage of mineral wool is that it does not burn, this makes the insulation of a wooden house outside with mineral wool for siding completely safe. In addition, all the modifications of mineral wool that exist today are vapor-permeable and, based on people's discussions, are considered the best sound insulator for the walls of a log house, and this speaks volumes. Below in the photo you can familiarize yourself with the scheme of wall insulation with mineral wool.

In the photo you can see the insulation of the walls of a wooden house with mineral wool.

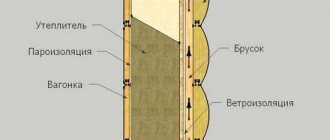

In the photo you can see a diagram of the device of the "insulation cake" on the walls of a wooden house.

Despite the huge number of advantages of insulating a wooden house outside with mineral wool, the material has a big drawback, which is its hygroscopicity, it is seventy percent. Therefore, when insulating a wooden house outside with mineral wool, you will need to apply a waterproofing material. However, there is also a big problem here, that is, if an ordinary film is used for waterproofing, then the vapor permeability of the mineral wool will come to naught.

To provide better protection of the insulation against moisture penetration into the interior, it is necessary to use diffusion membranes for the waterproofing device, in which the vapor permeability index will be from four hundred to one thousand g / m2 per day or more.

The use of such waterproofing by fifteen to twenty-five percent will increase the estimate for wall insulation outside for the siding of a wooden house or cottage. Also, of the minuses, it should be noted that mineral wool when insulating a house can cause allergies as it is very "dusty", so it is better to use it only for insulating walls outside a brick house, and not inside.

Extruded styrofoam. The material is successfully used to insulate a wooden house. The main advantage of expanded polystyrene is its ease of installation and durability, it can last thirty years, and even more. Unlike foam, such insulation outside the house for wall siding has higher strength characteristics.

Air cells in the structure of extruded polystyrene foam improve its thermal insulation properties. The one and only big minus that is inherent in this insulation is a high degree of fire hazard, and it is not so much the fire itself that is terrible, but thick suffocating smoke that causes poisoning.That is why it is better not to use it to insulate a house or cottage whose walls are built of wood.

Extruded polystyrene foam compresses very badly, this makes it resistant to breakage, and if it happens that, for example, a log house begins to shrink, then the expanded polystyrene installed on the walls will not crack and crumble. In addition, the insulation has good resistance to moisture and temperature extremes. From the numerous reviews of people, one can understand one thing that such insulation of walls outside with foam plastic for siding for a house is one of the best options.

In the photo you can see the insulation with extruded polystyrene foam.

Photo: installation of extruded polystyrene foam on a brick wall.

Each material for insulating walls has its pros and cons, therefore, before choosing one or another type for insulating a wooden house for siding, you will need to compare their characteristics, read people's reviews and find out their opinion about this or that insulation. Below is a table of characteristics, looking at which you can understand the main advantages and disadvantages that are inherent in materials for insulating a house for siding with your own hands.

| Thermal insulation characteristics | Styrofoam | Mineral wool | Basalt wool |

| THEIR THERMAL CONDUCTIVITY COEFFICIENT | 0.037 W / MK | 0.052 W / MK | 0.035 W / MK |

| STEAM PERMEABILITY PROPERTIES | Minus. | A plus. | A plus. |

| WATER RESISTANCE PROPERTIES | A plus. | Minus. | Minus. |

| FIRE SAFETY PROPERTIES | Minus. | A plus. | A plus. |

| EASY TO INSTALL. | A plus. | Pole. | A plus. |

| ENVIRONMENTAL COMPONENT. | Minus. | Minus. | A plus. |

Looking at the table, you can see that all these materials for insulating a house for siding have a very similar thermal conductivity. The highest characteristics are inherent in basalt wool, which makes this material the best option for insulating the outside of the house with mineral wool for siding, and it can be used to insulate brick, lumber and wooden houses for siding.

Installation of lathing and laying of insulation

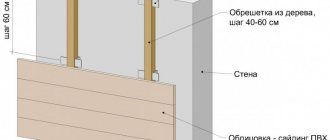

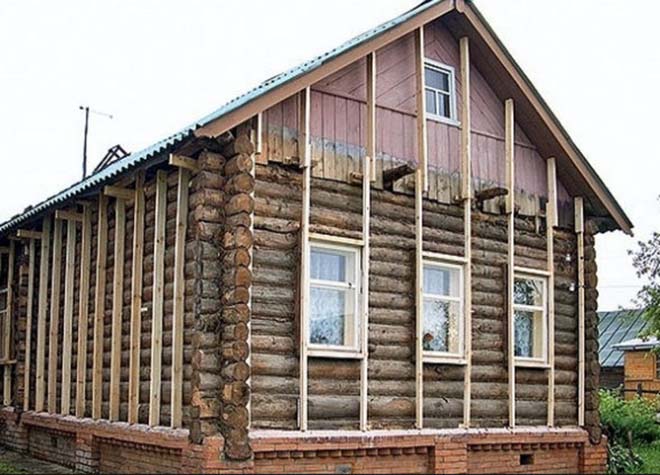

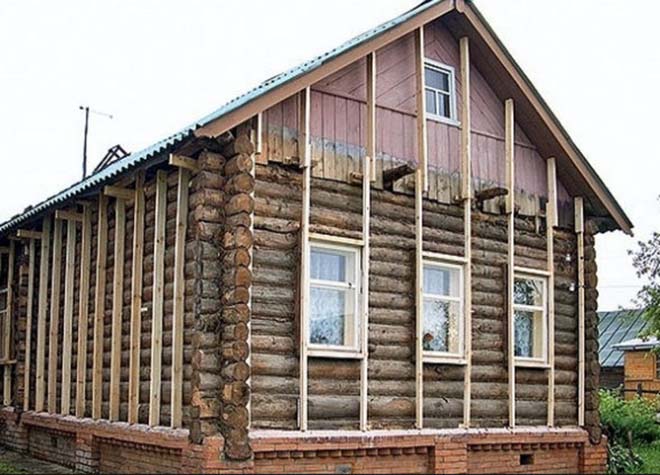

For reliable fixation of both insulation and siding, a crate in the form of a frame is mounted on the wall of the house.

When choosing a crate for insulation, pay attention not only to its price, but also to its durability.

This frame can be mounted both from a metal profile and from a wooden bar. The cost of steel elements is higher than wooden ones, but, on the other hand, the durability of metal is much higher than that of wood. So you have to make the choice yourself - either the price or the durability.

The thickness of the lathing elements directly depends on the choice of insulation, or rather, its thickness. It is necessary that the frame and the thermal insulation material are at the same level.

If you have chosen a wooden crate, then you need to attend to the processing of all wooden parts with compounds that protect them from the effects of microorganisms and fire. It is also better to cover the walls with a waterproofing compound or film under the beams. The wood of the frame must be properly dried, and it is better to choose conifers for it, they will last you longer.

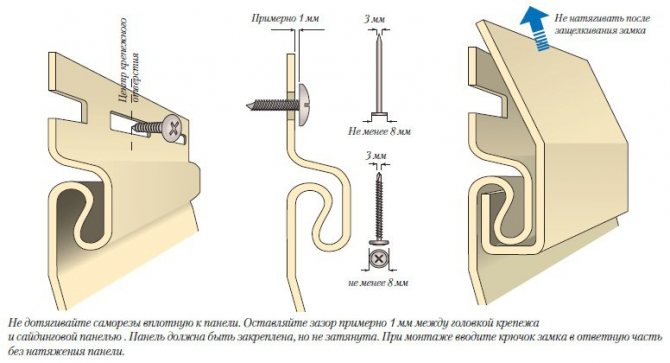

The elements of the lathing are mounted perpendicular to the position of the siding, that is, for horizontal siding panels, a vertical lathing is installed and vice versa. The distance between the battens of the sheathing depends on the siding, more precisely, on the distance between the places for fixing the panels, since it is to the sheathing that the siding will be attached.

If you take accurate measurements when lathing the window and door openings of the house, then the installation of siding will not cause additional difficulties.

Additional elements of the lathing require the corners of the building, places around the openings of windows and doors.It is imperative to achieve precise flatness of the entire structure, for which water or other levels are used. The ability to install siding panels depends on the accuracy of this work.

The lathing is fixed to the wooden walls of the house using galvanized nails 100 mm long.

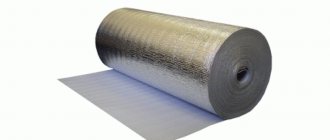

Some experts advise placing a layer of vapor barrier film between the wall and the insulation to protect it from moisture. But most experienced builders do not recommend doing this, and their opinion is supported by various studies. This detail is superfluous for our climate.

The pre-cut insulation fits tightly between the elements of the sheathing. Try to do everything as accurately as possible, there should be no voids between the pieces of insulation, no overlapping of material on top of each other, even too tight contact between the elements of the insulation is undesirable.

Choose only certified films for insulation, low-quality films become clogged with dust over time and the insulation will no longer fulfill its function.

The material is fastened either with glue or with special disc screws with a huge head. After that, the entire surface of the insulation is covered with a special one-sided protective film, it will keep your walls from moisture getting into the insulation, but at the same time the water vapor contained in the insulation itself and the walls, it will freely pass into the street. The same film will protect against the all-penetrating wind. It is attached directly to the crate.

Such a membrane will work effectively only if there is an air gap with a width of 20 to 50 mm between it and the siding, for which wooden beams or a profile of galvanized steel are attached to the crate.

Some builders question the need to use such a film, since in low-rise construction it is not particularly effective, but at the same time it is characterized by high flammability and a rather high price. Here, too, you need to think and choose your own path.

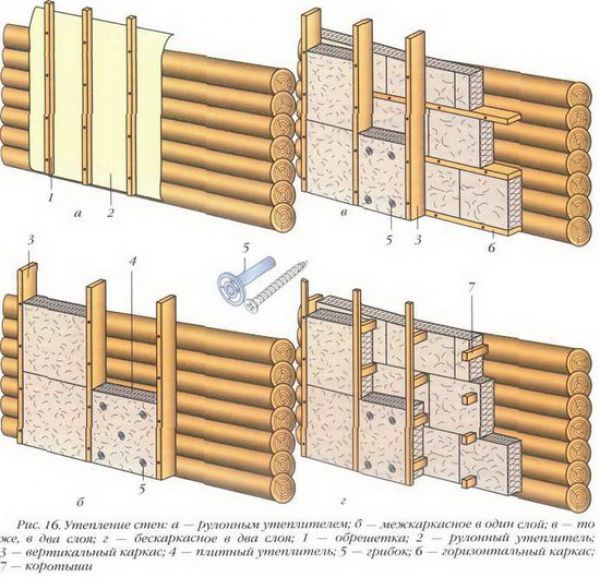

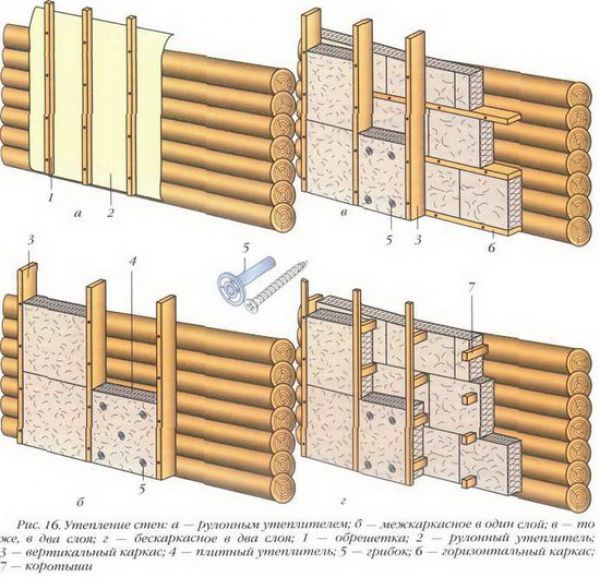

Cross insulation

The most effective, but at the same time costly and time-consuming installation, is cross-insulation. Its essence lies in the fact that on top of the laid frame with insulation, as described above, another level of both the frame and the insulation is superimposed. Just remember that in this case, the first level of the frame must be horizontal for horizontal siding, since the second level of the frame will be installed across, that is, vertically, and vice versa.

The second layer is attached in the same way as the first, that is, using glue or special screws with large heads. It is necessary that the second layer of the frame with insulation overlaps all the joints and seams of the first layer, then there will be no bottlenecks in your insulation.

Of course, the cost of cross-insulation is much higher both in terms of material costs and work performed, but the insulating quality of such walls will be much better.

This ends the house insulation with your own hands.

House insulation technology under siding

Currently, there are several technologies that allow you to install insulation outside the house with mineral wool under siding with your own hands with little time. The first option for insulating a brick house with mineral wool can be considered really budgetary, this is when simple insulation materials in rolls are used for insulation, their installation is as follows: the insulation is glued to the surface of the wall and then fixed on it with the help of the crate made. Judging by the reviews of many people, this technology is currently simple and affordable.

The next installation option is do-it-yourself interframe insulation of a log house under siding.Here, insulating plates of increased rigidity are used as insulation, the installation of which is carried out in the cells of the previously made lathing for siding and are fixed to the wall surface with screws or glue. The mineral wool installed in the cells of the crate will lie flat and adhere well to the brick wall.

The photo shows a diagram of the device for interframe two-layer wall insulation.

There is another technology for insulating a log house - installation on a cross frame. It must be said that it is precisely this technology of insulating a log house, according to experts, is the best, only the price of work and materials in this case will be rather big.

The fact is that with this technology, the installation of insulation takes place in several stages: first, a crate for siding is fixed to the surface, it is filled with insulation, then another crate is installed on it and also filled with insulation. Installation of the first lathing for siding with insulation is carried out vertically, and the second horizontally, so you can completely get rid of cold bridges.

Although such wall insulation outside for siding is expensive, it will always be warm in your wooden house. This technology is also well suited for the insulation of brick and concrete walls. Below you can watch a detailed video on how the installation of insulation under siding is carried out using a simple technology:

What kind of insulation to choose?

A house made of wood has the ability to let vapors outside, so that it is always comfortable to be in the premises. If you choose the wrong material for insulation, you can completely close the waste of moisture, which will lead to its accumulation in the walls of the building. This will lead to premature destruction of the entire structure.

Mineral wool

Experts say that there is no better insulation for an old wooden house. And indeed it is. Minvata has the following properties:

- Keeps warm well.

- Isolates indoor spaces from extraneous sounds from the environment.

- Light weight helps to do everything quickly and efficiently.

- The structure of the material allows you to hide all the irregularities.

- Fire and environmental safety.

- Rodents are not used to create nests.

But there are also a number of negative points:

- protection from moisture is necessary, because mineral wool is torn with a vapor barrier membrane, on the one hand, and a windproof film, on the other;

- requires mechanical fixation.

But such shortcomings are easy to cope with, therefore this option is suitable for an old house and or a new building.

Styrofoam

Insulation from the class available. Therefore, it is in demand among all construction companies and private developers. In addition to this positive point, there are a number of others:

- Good thermal insulation properties.

- Soundproofed.

- Does not absorb moisture.

- Withstands light mechanical stress.

But a small set of disadvantages makes polystyrene unsuitable for insulating a country house from a log house:

- lack of steam permeability;

- rapid destruction under the influence of ultraviolet radiation;

- rodents and insects love to create their homes in this material;

- the foam is highly flammable, and then smolders with the release of corrosive substances.

The tree burns well anyway, and if the finish is such that it will be life-threatening to be in such a house.

This material is closely related to foam. But the manufacturers slightly improved the properties of the insulation, due to which the cost also increased. What are the characteristics of penoplex?

- Improved thermal insulation properties. If you need 10 cm thick foam to insulate a house, you can replace 5 cm with foam.

- Withstands heavy mechanical stress.

- Does not absorb moisture at all.

- There are also soundproofing properties.

- Penoplex is produced with the addition of fire retardants, substances that prevent the material from igniting when exposed to fire. Therefore, compared to polystyrene, penoplex is safer.

It is sometimes used as thermal insulation for wooden buildings. But it is only suitable for a plinth or foundation. This is due to the lack of steam capacity. As a result, condensation will form on the walls, which means it will contribute to the development of mold and mildew.

The tree must be specially treated before proceeding with any outdoor work. Especially if the structure is closed from the eyes of the owner. Therefore, carefully and carefully adhere to the insulation technology, if you do everything yourself.

And if you have trusted the masters, then do not forget to control the brigade. It often happens that employees want to get the job done earlier and do a little hack. This can lead to premature failure of the structure.

First, let's prepare the base:

- Remove all dirt and stains, insects or fungus.

- Remove old decorative coating.

- Remove hinged structures that will interfere with all work.

- Close all cracks.

- Cover the wooden structure with protective compounds. These are antiseptic impregnations or mastics and moisture-repellent compounds. Which will significantly extend the life of the base.

If the packaging says that it is desirable to make several layers, then it is better to do as the manufacturer recommends. If you save at this stage, then you can regret it later.

After the impregnation is completely dry, they begin to lay the membranes. This layer will protect the walls from moisture and allow vapors to pass through the insulation and go outside without hindrance.

- start laying from the bottom of the wall in vertical stripes;

- each subsequent strip finds, on the previous one, by 10-15 cm;

- the joints are fixed with tape;

- the membrane itself is fixed with a construction stick.

Installation of the lathing

For the frame, wooden bars or metal profiles are used. If a wooden frame is chosen, then its parts also require special processing in order to last as long as the decorative layer. In addition, the bars will not be able to hide the unevenness of the walls, which means that you will have to put pegs or chuck them in some places.

With metal, everything is much simpler - we take it and install it. Special retractable brackets will easily hide all the flaws. But such a construction will cost a little more than a wooden one.

The method of installing the frame depends on whether you will use insulation or not, as well as on what kind of decorative material it was decided to install on the facade.

The rough plan is as follows:

- first we do the markup. The step between the elements is equal to the width of the insulation;

- screw on the elements;

- we check how evenly the parts are installed using the building level.

A material that acts as a heat insulator is placed between the elements of the sheathing. The mats are laid tightly. At the same time, make sure that no gaps are formed. Mineral wool should not bristle.

If such flaws appear, then they will later become cold bridges, which partially or completely neutralizes the work on insulation. Therefore, the material should lie tightly, but evenly.

It is customary to lay a windproof membrane on top of the insulation. This material will protect the mineral wool from the penetration of atmospheric moisture under the finish. The installation principle is the same as for vapor barrier foil:

- We start work from the bottom.

- Making vertical stripes.

- We put in an overlap of 105-15 cm.

- We glue the joints with tape.

- The membrane is fixed with a stapler to the crate.

Here it is appropriate to use more dowels-fungi. This mechanical fastener will additionally fix the insulation and the membrane.

Further, according to the plan, the installation of a counter-lattice or frame for the finishing material. The lathing can be horizontal or vertical, it all depends on how the trim is installed.

The additional lathing also creates a ventilation gap that allows for the removal of steam escaping from the interior. The size of the gap can vary from 3 to 8 mm. It all depends on the thickness of the insulation material and the region in which the house is located.

As a finishing material for a wooden house, you can choose any known option. It is important to take into account the state of the structure, that is, the strength of the structure. If the houses are too old, do not choose heavy material, as the structure may not withstand the load and collapse.

But there are basic recommendations:

- fully follow the installation instructions provided by the manufacturer;

- fix the details to the elements of the lathing;

- choose dry weather;

- insulate a wooden house only in the warm season.

The advantages of insulating wooden walls from the outside:

- External walls are additionally protected from moisture and solar activity, which increases their service life;

- Removing the dew point outside without the possibility of condensation;

- Providing highly efficient thermal insulation;

- Preservation of the volume of the room;

- Possibility of sealing external holes and cracks;

Disadvantages:

- Changing the appearance of the building facade;

- high cost of work;

- dependence of work on the season and on weather conditions;

External insulation for siding

The advantages of internal insulation:

- low cost;

- the emergence of the possibility of aligning the walls;

- independence of work from the season and weather conditions;

Disadvantages:

- Dew point displacement inside the room and the likelihood of condensation and mold;

- Reducing the volume of the room;

- Possible change in the interior for the worse;

Internal insulation

Types of outdoor insulation:

- Strengthening heat insulators on the wall surface using adhesive solutions and plastering;

- Non-ventilated walls in three layers. The insulating material is fixed with a solution and a single-brick outer wall is installed in compliance with the air gap;

- Ventilated facade. The walls are protected with a waterproofing material, on top of which an insulating material is mounted. Then a windscreen is installed, and the frame is sheathed with clapboard or any other siding. This method allows installation even in winter due to the lack of the need to use adhesive solutions.

We suggest that you familiarize yourself with How to fasten a tree

IMPORTANT!

The main secret of a proper house is the construction of its walls. The so-called “wall cake” determines a healthy microclimate and longevity of the structure.

Thermal insulation of walls from a bar can be carried out using facing bricks, concrete or ceramic stones, small blocks. The only thing is that a projected air gap should remain between the cladding and the surface of the wooden wall, which is provided in order to remove excess moisture from the tree.

The following can also be used as heat-insulating materials:

- Stone wool is a heat-insulating and sound-insulating material that is made mainly from molten igneous rock. It is a type of mineral wool. Gabbro-basalt rock is a raw material for the manufacture of material fibers;

- Expanded polystyrene is inexpensive, hygienic and sanitary safe, lightweight, but tough material. Its insulating properties fully satisfy common requirements, but the possibility of cracking from thermal expansion to which the walls are exposed does not allow us to call it the best solution for insulation;

- Ecowool is an absolutely natural, environmentally friendly, ideally soundproofing material, which is made up of cellulose and antiseptics based on borax and boric acid. The material is moisture resistant, hypoallergenic, it is laid without forming seams and voids. Does not require the use of a vapor barrier layer when insulating timber walls;

- Basalt wool is characterized by excellent vapor permeability. Basalt is a non-combustible material that provides fire protection for a wooden log house. The material has good soundproofing characteristics;

- Foam glass is foamed glass made up of thousands of glass cells. The material is elastic, moisture resistant, environmentally friendly, fireproof, very durable and can withstand any temperature fluctuations. It does not attract insects and prevents mold and mildew from forming. Among the shortcomings, one can note the lack of steam conductivity, high fragility and high cost of the material;

- In the case of wooden walls, mineral wool is ideal as a thermal insulator. It meets almost all the requirements for insulation, namely, it has a high coefficient of thermal insulation, a minimum coefficient of thermal conductivity and low hygroscopicity. She is not afraid of high temperatures, fungus, mold, insects and rodents. It perfectly copes with the removal of vapors to the outside, is non-toxic, non-flammable, breathable and, importantly, is durable and can last from 30 to 60 years, based on the declared characteristics of the material.

| Photo | Name | Rating | Price | |

| #1 |

| Mineral wool | ⭐ 99/1001 - voice | More details |

| #2 |

| Extruded polystyrene foam | ⭐ 97 / 100 | More details |

| #3 |

| Styrofoam | ⭐ 88 / 100 | More details |

Which insulation is better for siding: expert advice

Many who decided to insulate their wooden house very often ask themselves the question: what kind of insulation for the facade is better to choose for siding and why? It is impossible to unequivocally answer this question, since all heaters for siding differ in their pros and cons.

For example, polystyrene and all its varieties are distinguished by good resistance to the effects of moisture on them, because they have a small degree of vapor permeability, but because of this, the effect of stuffiness will always be present in a wooden house. But as for the mineral wool, when it gets wet, it loses about fifty percent of its inherent thermal insulation properties, therefore, during insulation with mineral wool outside the house, it will be necessary to equip additional protection for the insulation with the help of waterproofing materials.

Despite the weaknesses, mineral wool today, based on numerous reviews, is considered the best material for insulating walls outside for the siding of a wooden house, cottage. It must be said that such a facade insulation for siding in combination with a waterproof barrier will be able to provide a log house with excellent thermal insulation and sound insulation performance.

In addition, mineral wool is one hundred percent environmentally friendly, can last for many years, while the cost of mineral wool is low, which makes such insulation for the facade available to all buyers. As for the opinion of experts about mineral wool, they all unanimously assert that mineral wool insulation outside the house for siding is the most reasonable solution that can solve the issue of arranging the best facade insulation at home with your own hands.

General information

What is siding

Initially, siding consisted of herringbone planks nailed to the wall, i.e. the top edge of the board covered the bottom. Thanks to this arrangement, they do not penetrate into the gaps between the boards, which affects the durability of the finish.

It should be noted that nowadays wooden siding is rarely used, since there are many materials that authentically imitate wood, and at the same time are more durable. These include:

| Siding type | Features of the |

| Pvc | It is currently the most common type of siding due to the following qualities:

|

| Cement | Externally, it can simulate various materials due to the variety of textures. A feature of these panels is fire resistance. In addition, they have many other positive performance characteristics. |

| Metal | A durable material that can be painted in a wide variety of colors. It should be noted that the cost of metal panels is quite high. Therefore, they are most often used for finishing industrial premises. |

PVC siding

I must say that the installation process of all of the above types of siding is carried out according to the same principle, which we will get acquainted with below.

Insulation

To perform high-quality thermal insulation, you need to choose the right insulation for siding for a wooden house. As you know, the main advantage of a wooden house is its ability to let steam through. When choosing a heater, it is necessary to be guided by this property, which should not suffer as a result of insulation.

Therefore, the use of expanded polystyrene and other similar materials is not recommended. But a great option is mineral wool, which is most often sold in the form of mats.

Advice! Polyurethane foam is often used as insulation for wooden houses. However, special equipment is used to apply it. In addition, the vapor permeability of this material is very low.

It can also let steam through itself, and besides, it is a non-combustible material, which is no less important when insulating a wooden house. In addition, the cost of this heat insulator is quite affordable. The only thing to consider is that the thickness of the mat must be at least 100 mm.

Mineral mats

Therefore, below we will consider how the insulation of a wooden house is carried out using mineral mats.

Note! Any finishing work can be done only one and a half to two years after the construction of a wooden house. It is necessary to withstand such a period so that it has time to shrink.

Protective impregnation for wood

Do-it-yourself insulation of a house outside with mineral wool for siding: step-by-step instructions

To make it clear to you how the insulation is installed, below we will present instructions for installing insulation for siding. So, if the insulation outside the house for siding will be carried out with the help of mineral wool, then in this case it is better to purchase hard slabs and attach them to the surface of the walls with a wet method. The step-by-step instructions below will help you make facade insulation with mineral wool yourself.

- First of all, we need to fix a metal cornice at the bottom of the wall surface. This is necessary so that the insulation, in our case it is mineral wool, lays down evenly, in addition to this, in this way you will provide the insulation outside the house under siding with the best protection against rodents, which, judging by the discussion of people, for some reason prefer mineral wool more than other materials.

- The wall on which the mineral wool insulation will be carried out must be well primed.

- To make a reliable attachment to the wall of the mineral wool, we need polymer-cement glue, it is not difficult to make it, you just need to pour water into the dry mixture and mix well until you get a homogeneous mass. The finished glue must be applied to the back of the facade insulation.

- It will be necessary to fix the mineral wool starting from the bottom and moving to the top in such a way that a dressing of the seams is formed (as with brickwork). During the installation of mineral wool, you need to ensure that the plates fit well to each other. The mineral wool slabs glued to the wall surface should be additionally fixed with plastic dowels, which have large caps, although this should not be done immediately, but wait one day. When fixing the facade insulation under the siding, you need to ensure that the plates do not disperse to the sides.

That's all, mineral wool insulation of a wooden house is ready. And in order for you to better understand how such work is done, read people's reviews and watch the video instruction:

Safety engineering

Even if you are not allergic, when working with mineral wool, be sure to protect your nose and mouth with a respirator, and your eyes with goggles. You will also need tight clothes with long sleeves and pants below the ankle and gloves. Otherwise, the smallest particles of mineral wool on the skin will provoke irritation.

We put a barrier to the cold

Hired workers often insulate the facade from the outside with mineral wool, installing a 100 mm thick insulation plate in one layer. However, cold air will still penetrate into the cracks between the mineral wool. It is safer to fix 50 mm slabs in two layers, with a slight offset. If there are gaps and gaps somewhere, they can be insulated with pieces of the same material. It is best to insulate the top layer with mineral wool of a higher density.

The next stage is facade waterproofing. For this purpose, a perforated diffusion membrane is used. It is mounted outside, between the mineral wool and the cladding, installing the rough side to the insulation. This technique will ensure the movement of water only from the inside out. This means that your do-it-yourself insulation will be reliably protected from dampness.

What to attach the cladding to?

The main highlight of the ventilated facade is the presence of a gap between the mineral wool and the facing material. And the constant movement of air quickly dries up the water droplets.

For this purpose, slats with a thickness of 50 mm are mounted on the frame on top of the waterproofing. They will be used for external finishing - siding or facade panels, block house or wooden lining, etc. Lay them from the bottom up. If wood cladding is used, the locks are oriented up with a tenon and down with a lock. Then water will not get into the joints of the boards.

HELPFUL TIP: When decorating with panels, start work from large areas. The remaining cuttings - pieces of panels - can be used in corners and when finishing structural protrusions of a wooden structure.

Above and above, they must leave air vents. But outside they are covered with a fine metal mesh - from rodents. And the last thing: the insulation will increase the thickness of the timber walls by almost 20 cm. Do not leave the insulation open either from the bottom or in the places of window and door openings. Install slopes, sills, and ebbs that are wide enough.

Insulation of the walls of a brick house with expanded polystyrene

If you decide to insulate the walls with expanded polystyrene, then such work is best done in the summer, when the weather is hot outside the window. By the way, mineral wool insulation is also best done in dry weather. The surface of the wall, which we will insulate with expanded polystyrene, must be dry, that is, moisture should not get on it for three to four days before the installation of the insulation begins.

- First, you need to well clean the surface of the wall from the dirt on it, if there are irregularities there, you also need to get rid of them.

- As soon as the walls are prepared, they will need to be leveled; a primer is used for this.

- We glue the insulation sheets to the wall surface.

- Next, you need to cover the insulated area with a primer, and only then you can proceed to installing siding on the walls of a wooden house.

The photo shows how to insulate brick walls with mineral wool.

Such wall insulation for siding will be very effective and will provide you with a comfortable existence even in the most severe frosts. The main thing is to competently carry out work on the walls insulation with expanded polystyrene from all sides of the wooden house, otherwise the wall insulation for siding will not be of high quality, therefore, there will be drafts and cold in the wooden house.

To prevent this from happening and you would not have to throw money down the drain, you need to approach the work of insulating walls with expanded polystyrene responsibly and strictly adhere to the video instructions:

and then the result will not disappoint you.

Siding

After the installation of the insulation is finished, you can proceed to siding fastening on mounting strips. Moreover, it is desirable that there is free space between the siding and the windscreen, and there are gaps from the bottom and top that allow air to circulate through this free space. Due to this circulation, excess moisture is removed, which is released from the premises even through brick. This mounting system is called ventilated facade; it is very effective and durable. My dream - fiber cement Japanese slabs Nichiha... They have an amazing texture that absolutely imitates various building materials - from plaster, brick and stone to wooden beams or even shingles.

On siding not worth saving... There are cheap options - they can let you down. I've seen substandard siding that just melted in the sun.

When choosing the option of cladding a house outside, you also need to be guided by what load your walls can withstand. In my case facing material weight extremely important, since the brickwork of the house is made only in half a brick, and too much weight, and even with a large offset relative to the outer surface of the walls, can become a problem. Therefore, most likely, I will still have to dwell on plastic siding - it has much less weight than fiber cement slabs, and the houses sheathed with it look very nice.

This is how chip siding looks like

Installation of insulation under siding: step-by-step instructions

In order for the insulation with mineral wool or any other heat insulator to be done correctly, you need to follow the instructions and make the calculations correctly.

- To install wall insulation for siding, it is required to take insulation, the thickness of which must be at least four to five centimeters.

- With the help of glue, the siding insulation is fixed to the crate, which is installed on the surface of the outer wall of a wooden house.

- Installation of insulation for siding starts from bottom to top.

- As soon as the walls of the wooden house are fully lined with material, you can proceed with the installation of siding.

Photo: laying insulation on brick walls under siding.

Thermal insulation of a wooden structure from the inside

The walls of a wooden house, as a rule, are not thick enough to provide reliable thermal insulation in domestic climatic conditions. Therefore, such a house requires additional insulation, which is best done with mineral wool.

To obtain sufficient frost protection for wooden walls, the thickness of the insulation must be at least 10 cm.

Preparatory stage

All walls are thoroughly cleaned of dust and possible dirt. If necessary, remove old plaster. After that, the surface is treated with an antiseptic, preferably in two layers. This will avoid rotting of the structure and increase the service life of the structure as a whole.

Sometimes engine oil is used as an antiseptic. It costs much less than special formulations, but it gives a specific smell, and its vapors are harmful to health.

The electrical wiring must be detached from the walls so that it does not remain under the insulation.

After the preparation has been made, you can begin to work. In order to ensure their high quality with a minimum investment of time and money, they are made in stages:

- cracks are caulked;

- vapor barrier is done;

- the crate is mounted;

- mineral wool is laid taking into account the ventilation system;

- external finishing is in progress.

Cauliflower

Since a wooden house is prone to shrinkage, cracks often appear in its walls, which impede normal thermal insulation. Therefore, they need to be caulked.

It is best to do this with jute, it is an inexpensive, environmentally friendly material that is resistant to decay. You need to dig all the walls, otherwise the house will warp.

Vapor barrier

One of the disadvantages of mineral wool is that it loses its properties when wet. Therefore, after caulking, you need to take care of the vapor barrier.

The special film is laid with a rough surface to the wall and attached to it using a conventional construction stapler. The joints must be glued with tape.

Lathing

For the frame, a 50x50 mm bar is best suited, which, however, can be replaced with an ordinary metal profile. When installing the battens, distortions must not be allowed.

For this, special racks are made in the corners of the room, between which the frame is mounted using self-tapping screws. The lathing is installed vertically if the mineral wool is in rolls and horizontally if in mats. The distance between them should correspond to the width of the insulation.

Laying material

The rolls of mineral wool are laid vertically, and the mats are simply placed between the battens. The material is fixed with anchor nails. The surface should be firm, without gaps.

After that, another layer of vapor barrier is laid, with the rough side to the mineral wool. This will become a reliable barrier against the ingress of dust and harmful substances into the room.

Finishing

After that, another crate is made perpendicular to the first. For example, if the first was vertical, now it is horizontal. GKL, GVL or other finishing material is attached to it.

Lathing for siding with insulation

The cladding of the facade of a wooden house should be started with the installation of the battens. At the moment, the best and most inexpensive way is the use of bars or slats, such a crate will not only allow you to conveniently install the siding, but also install the insulation under the siding. The step of the wooden lathing should be between thirty-five and forty-five centimeters. All wooden elements of the lathing for the facade must be treated with a special antiseptic.

In the photo you can see the device of the wooden lathing of the facade of a log house, as you can see here everything is very simple.

The need for lathing is due not only to the fact that it is necessary to align the walls, but also to arrange a place for laying insulation.

There is another type of lathing for facade insulation, it is made of metal. Such a crate for the facade will last for more than a dozen years. In order to be able to set the offset you need from the wall surface, you will need to use special suspensions.

In the photo you can see the lathing device for the facade of a brick house.

The photo shows a diagram of the installation of lathing and siding.

To better understand what a crate for a house for siding is, watch the video presented for you:

You can also read the discussions of people who made the crate for siding with their own hands.

The price of work on the insulation of the facade for siding

It is not difficult to do any of the existing methods of insulating walls outside a wooden house for siding yourself, but if for some reason you cannot do this, then entrust such work to specialists.The cost of insulating a wooden house for siding will directly depend on how much work needs to be done. In the table below you can see the approximate price of insulation for siding the facade of a wooden house.

| Type of materials used | the cost of the material in rubles per square meter. | The cost of insulation without material in rubles per square meter. |

| Mineral wool (glass / min.) | From one hundred to one hundred and fifty rubles. | From two hundred fifty to three hundred rubles |

| Styrofoam | From seventy rubles. | From one hundred and twenty rubles. |

| Vapor barrier | From twenty five rubles | From fifty rubles. |

| Vinyl siding | From one hundred rubles. | From four hundred and fifty rubles. |

Technology of insulation of the basement and the blind area of the EPSS, stages of work

• Possible unevenness of the walls made of round logs. • The need for simultaneous preservation of the "breathing" properties of wood, protection of structures from external moisture and the removal of internal steam and condensate. • Requirements for fire and sanitary safety. Closing wooden walls with flammable and vapor-proof, but capable of accumulating moisture under unfavorable conditions, heaters such as ordinary foam plastic is not encouraged, even if openings and other areas are cut off with non-combustible materials.

Modern foamed insulation with a closed cell structure (sprayed polyurethane foam, compacted polystyrene foam) meets these requirements only partially. Due to their low vapor permeability, they can be used to insulate the facade only if there is sufficient ventilation of the wooden house, ensuring the protection of structures from internal vapors and free drainage of condensate.

Ecowool, soft glass-window mats, penoizol for self-insulation of facades of wooden houses (as opposed to internal structures) are not suitable due to high hygroscopicity and the need for additional equipment.

As a result, only rigid or semi-rigid mineral wool slabs, used in combination with steam and waterproof films in wet and ventilated façade systems, have suitable characteristics. The first method is rarely used when insulating log cabins due to the mobility and unevenness of the wooden base, an exception is made only for walls made of profiled timber or well-polished structures that have passed the stages of the main shrinkage. Ventilated facade technology, on the contrary, is considered optimal for walls from one row of sawn timber and is implemented more often than others.

The essence of this method is to close the facade with breathable plate heaters, which are protected from wind, precipitation, moisture and condensation with special films and finishing materials.

• Preliminary protection of all closed wooden elements (both walls and lathing frame) with compounds with additives of fire retardants and antiseptics. impermeable materials • Consideration of the risks of shrinkage of a wooden house when choosing the timing of work.

Stages of work

• Sprayed polyurethane foam with a density of 50 kg / m3, characterized by increased adhesion, resistance to moisture, freezing and decay. The use of polyurethane foam makes it possible to simplify the stage of preparation and waterproofing of the surface, the sprayed thermal insulation has no seams and is successfully held on any vertical and inclined bases. The disadvantages of PPU include only the high cost and the need for special equipment for preparing and supplying foam to the walls of the base.

• Rigid slabs of hydrophobic mineral wool used in combination with hydro and vapor barrier membranes or vapor-permeable plasters.For the insulation of the blind area and the areas of mineral wool covered with soil, for obvious reasons, it is not suitable, this type of insulation is chosen only if it is necessary to protect high basements of wooden houses from heat loss.

• Expanded clay with closed granules of medium fraction, filled up on the sides of the belt, around the supports or under the entire area of a wooden house. With all the advantages (simplicity of filling, compliance with fire safety requirements, resistance to decay, relatively low thermal conductivity), this type of insulation makes no sense to use in frequently flooded areas without drainage.

• Plates of regular or compacted polystyrene foam. The latter have the best characteristics of strength, moisture resistance and durability and are recognized as the optimal material for self-insulation of the basement and the perimeter of the blind area of residential buildings made of wood. Conventional types of polystyrene with all the advantages (cheapness, ease of installation, lightness) are inferior to extruded grades in all respects, except for price.

The given heaters are combined with roll or coated waterproofing and bulk materials for arranging the blind area. The thickness of the insulating layer is justified by calculation taking into account the climatic and geological features of the site.

The procedure depends on the type of foundation (strip or columnar) and the time of the work (during the construction phase or after putting the wooden house into operation).

1. The surfaces of the foundation are cleaned of debris and soil, small cracks and irregularities (if any) are filled with mortar or removed using angle grinders.

2. A clean and dry base is covered with coating or roll waterproofing materials, ideally combined ones. Materials are laid without gaps, with a 10 cm overlap and joint compound.

We suggest that you familiarize yourself with the design of the cellar outside

3. EPS sheets are attached to the outer dry layer of waterproofing using liquid nails or special glue. When working with special grades for foundations with grooved or L-shaped edges, it is allowed to install expanded polystyrene in one layer. In other cases, the insulation must be laid in 2 layers. Random gaps at the joints of the plates are filled with foam with a minimum expansion coefficient.

4. Work is underway to equip the blind area. At this stage, the part of the tape hidden by the soil is pasted over with geotextile, after which the trench is filled with rammed soil to the desired level. On top of the compacted soil, a 15-20 cm layer of sand and crushed stone of fine fractions is laid, and only then - sheets of EPSP with a thickness of 50 cm or more are laid.

A comparatively thick (from 7 cm and more) layer of concrete screed is poured over the laid insulation, if possible - reinforced with a mesh. The correct blind area has a width of at least 40 cm, the slope in the front is 1-10% (from 3% when building a house on subsiding soils), rising above the ground level by at least 5 cm.

5. The upper part of the insulated plinth is closed with finishing materials - plaster, panels, porcelain stoneware or decorative stone. When using heavy types of cladding, the base is reinforced with nets.

If it is necessary to insulate the EPSP of the columnar foundation, an additional frame is attached to the supports of the wooden house, which holds the pick-up from boards, shields or special panels. In the first case, the insulation is mounted outside, in the second - from the inside, with placement in special grooves. The work is completed with the installation of a drainage system; in especially difficult cases, drainage pipes or an insulated blind area are laid along the perimeter of the building.

Wood is a unique material that, among other things, is vapor permeable. And under the influence of moisture, it becomes vulnerable to the reproduction of microorganisms and fungi.

The porous structure allows moisture to penetrate from the inside and outside.This suggests that the insulation should have the same vapor permeability index so as not to impede the movement of vapors and air. Otherwise, the wood will begin to damp, rot and lose its quality as a building material.

- stone wool in slabs is a lightweight and convenient material that can be transported without problems and can be cut even with an ordinary knife. These slabs are laid between the elements of the frame, and then covered with a vapor barrier and waterproofing material from different sides. The main thing is not to squeeze or tamp them during the transportation of the mats, as they are easily deformed;

Various materials such as mineral wool, foam plastic, ecowool and the like can serve as a material for insulation.

- ecowool - a material created on the basis of cellulose, which is pressed and packed. For insulation with its help, you can use two options. In the first case, I take out the cotton wool from the open package, and slightly knead it, tamp it into the walls. It is difficult to say unequivocally how good this method is. Some manufacturers claim that with such insulation you will not know problems for 10 to 20 years. Although it is impossible to completely deny the possibility of shrinkage and deterioration of the thermal insulation properties of the material. The second method is called wet, since ecowool is sprayed onto the walls, due to which the material seizes with the frame and the risk of settling is excluded;

- Styrofoam is a very common and cheap way to insulate a building. Its low cost is due to its fragility, fragility, as well as the need to additionally cover it with a moisture-proof membrane in order to avoid the accumulation of condensate in the future. It is important that for insulation you need to buy only non-pressed foam sheets;

- polyurethane foam - a material consisting of two separate components mixed together under the influence of high pressure. On contact with air, it behaves in the same way as ordinary polyurethane foam - it expands. Thermal insulation of a wooden house with polyurethane foam is quite effective and minimizes heat loss. In addition, PU foam has the ability to repel water;

- heaters of natural origin are a variety of mixtures and slabs made on the basis of sawdust, straw, clay, etc. The cost of this method is low, but choosing this option, you need to be ready to tinker. The natural insulation materials that are easy to use include, perhaps, linen fibers.

All materials used for wall insulation are made as environmentally friendly and harmless to human health.

Extruded polystyrene foam - lightweight and durable material for wall insulation

Wall insulation scheme with siding trim

- the financial capabilities and personal preferences of the homeowner;

- season for finishing work;

- climatic features of the area.

- laying a vapor barrier layer;

- assembly of a wooden or metal frame;

- installation of heat-insulating material;

- surface waterproofing;

- external decorative facing of walls and pediment.

CAUTION!

Before installing the insulation on the crate, it is necessary to attach a vapor barrier membrane. It will let the water vapor of the premises outside, and the moisture that tends to enter the room from the outside, will hold back, not allowing it to be absorbed into the insulating layer and protecting its thermal insulation characteristics.

- Having secured the vapor barrier, they begin to lay the slabs of insulating material using a construction stapler. In addition, the space between the slats is fixed to the wall using umbrella dowels.

- A waterproofing membrane is mounted on top of the laid insulation, which will not allow moisture from the outside, but will take away a small amount of condensate that has penetrated the insulation layer;

- Further, the slats are installed under the facing materials, which perform not only the role of the frame and decoration of the facade, but also form the ventilation gaps necessary for ventilating the heat-insulating layer;

- Siding, clapboard, blockhouse are often used as facing materials for wooden houses.

Installation of the lathing on the timber

Methods for insulating timber

Mineral wool insulation scheme

- protect walls from the effects of climate change;

- decorate the facade;

- exclude heat leakage from the house;

- increase resistance to temperature extremes;

- close bridges of cold, cracks.

- wooden plaster;

- decorative rock;

- brick;

- wood;

- panels.