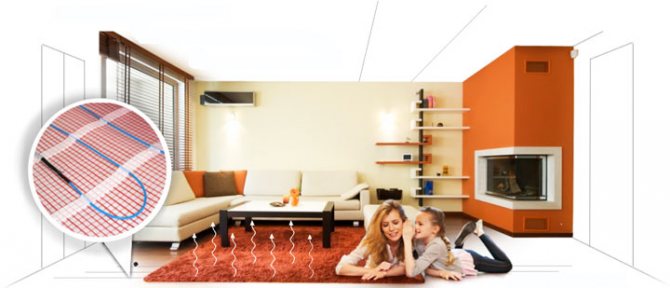

The rapid development of heating through floor heating in a room has led to the fact that over the past decade, several varieties of floor heating systems have appeared, each of which has its own characteristic features, advantages and specific operation.

To understand which warm floor is better and choose the most efficient (which will be warmer, better heated) and economical (which consumes less electricity or gas), you need to consider all the existing options and choose the optimal one, taking into account the basic requirements for the system.

Which warm floor is better - species comparison

To simplify the comparison, you need to consider each type of floor and their distinctive features, advantages and disadvantages, and then compare the key indicators in a tabular form.

1 group - water heated floor

In this group, there is only one representative - a warm water floor, the heating element is a system of pipes through which a heat carrier (water) circulates.

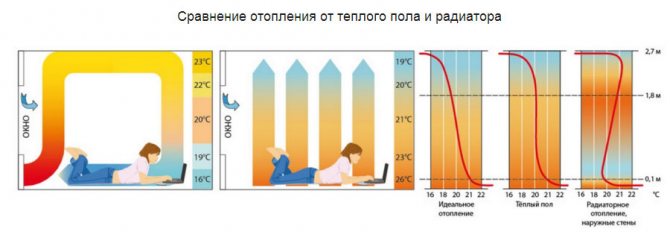

Pros: reduction of heating costs by 25% (in comparison with radiator), minimal installation costs, the ability to equip autonomous heating or connect to a central system;

Cons: complexity of design and temperature control, high screed, low maintainability, risk of flooding, the need to approve the project when connecting to the central heating main, the need to equip a boiler room and purchase additional equipment, high operating costs.

Group 2 - electric floor heating

This group is represented by several types of floors, so you need to evaluate which electric warm floor is better already in terms of subgroups.

Subgroup - electric cable underfloor heating

Cable heat-insulated floor in a coil (in a bay, per meter)

Floor heating cable systems are quite popular among manufacturers. And many of them offer to buy a ready-made kit. Among the leaders in the market are the companies Devi (Denmark), Caleo (South Korea), Teplolux (Russia). The price for a set varies from 10,000 to 37,000 rubles. depending on the heating power, length and type of cable.

The package bundle also affects the cost. There are options that include only cable, regulator and sensor, and some even contain a mounting tool. You can reduce the purchase cost if you complete the system separately. For example, the price of a DEVIflex cable (100 W) is 3,850 rubles / 10 lm, a thermostat with a sensor will cost 6,670 rubles.

Pros: relatively cheap, well suited for use under tiles;

Cons: the complexity of calculation and installation, the height of the room is reduced by 50-100 mm.

We recommend a detailed description - electric underfloor heating device

Cable heat-insulated floor in mats

It is advisable to choose this option for those who plan to carry out the installation on their own. The price on the example of Devimat ranges from 4,950 to 22,750 rubles. The cost is influenced by the area of the mat, its power, the type of heating cable used.

Pros: thinner cable, simplicity of calculation, it is convenient to lay out the mats (the mesh on which the cable is attached can be cut) and mounted, a constant distance between the cable turns is maintained, there is no need to fill the screed, due to the thickness of the warm floor, the ceiling height is reduced by 10-30 mm ;

Cons: higher cost of mats (25-30% higher compared to the cable system).

Resistive cable device

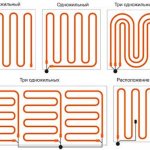

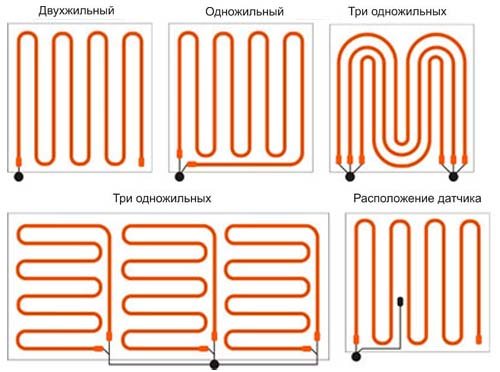

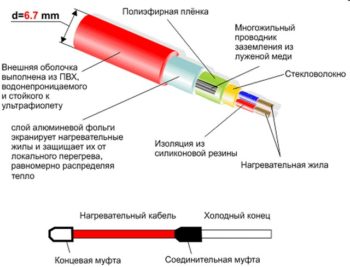

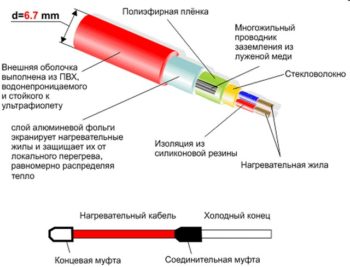

According to their device, two types of resistive cable are distinguished: single-core and two-core.Their design resembles a conventional electric heating element, consisting of a tube with a heating coil inside. Depending on the type, the cable consists of 1 or 2 insulated conductors covered with a protective metal shield on top. It protects the heating conductors from mechanical damage and makes the cable rigid. Another layer of insulation is applied over the screen.

For connection to the mains, special couplings are used. They are put on the ends of the cable. But the connection diagram itself is slightly different. A closed circuit is required for the electrical cable to work. A single-core cable will have to be laid according to a complex scheme so that both ends return to the connection point. A two-core cable can even be laid in one line without returning the other end to the connection point. The two cores located inside make it possible to connect only one end of the heater at the connection point. A cap is put on the second free end, which connects the two cores, forming a closed circuit.

The cable must be laid according to a certain pattern, for example, a snake, on a homogeneous floor material. The couplings remain under the floor covering in the screed. The "cold" wire coming out from them is lifted to the wall for connection to the thermostat and the junction box. Both types of electrical cable work in the same way. An electric current flows through the inner conductor and generates heat.

If we compare these two types, then a two-core cable for a warm floor is more expensive at a cost. However, its layout is much simpler, plus a lower intensity of the generated electromagnetic field. Both cables have one major drawback. When power is supplied, the veins are constantly heated, and the heat that is not discharged in time threatens to burn out the cable. That is, furniture and other objects that interfere with heat dissipation should not be placed on the floor area where the heater is laid. Even the voids formed inside the screed are dangerous for the cable, since air is a poor conductor of heat.

Subgroup - infrared floor heating

Despite the fact that the infrared floor is a kind of electric, it is advisable to place it in a separate group, since the infrared floor has a number of characteristics that are not characteristic of electric cable floors. The key feature of infrared floor heating is that it does not create electromagnetic waves, which is typical of the two previous options. It also has two varieties, which makes it necessary to find out which infrared heat-insulated floor is better to choose.

Infrared continuous (film) warm floor

The IR heating system is a flexible heating element placed between two layers of polymer - an infrared heating film for the floor.

Pros: the ability to mount on any surface (floor, walls, ceiling); ease of installation; low cost compared to cable, uniform heating of the room, the minimum film thickness makes it possible to dispense with the elimination of floor height differences during installation;

Cons: the need to plan the arrangement of furniture, the complexity of using under the tiles, low inertia.

Infrared rod carbon underfloor heating

It is the most advanced underfloor heating system on the market today. It is distinguished by the presence of a carbon heating element made in the form of a rod. The heating rod is made of a composite material, which gives the system the ability to self-regulate, which eliminates overheating and makes it possible not to be limited in choosing a place for installing floor heating. Carbon mats can be installed over the entire floor area, and rearranging furniture or installing household appliances will not cause any inconvenience, unlike a film floor.

Pros: self-regulation. The system monitors the temperature of the floor surface to reduce energy consumption.Moreover, there is no need to use additional devices. The adjustment is due to the fact that an increase in temperature leads to an increase in the distance between the graphite particles that make up the carbon rod, as a result, resistance increases and heating decreases.

Reliability; no side effects, such as electromagnetic waves, etc., health-improving effect, cost-effectiveness. In terms of heating costs, it is the carbon core floor that is more efficient in operation, due to the reduction in energy consumption. Also, the core heat-insulated floor is distinguished by long-term performance without repair.

Cons: high cost of the kit.

Energy saving

The next argument, which, in theory, should save the buyer from any doubts in favor of the IR floor, is energy savings. In fact, the trick goes deeper than the usual measurements of the amount of current consumed. In such tests, an electric IR floor will be 20% more efficient than a cable floor. In IR structures, a more complete transfer of heat to surrounding objects occurs, without the cost of heating intermediate conductor materials. But the trick is that in such a "clean" dimension, the energy intensity of the entire underfloor heating system is not taken into account. Although the IR film heats the floor quickly, it cools down just as quickly when the power is turned off. Thus, in order to maintain a constantly comfortable temperature in the room, the infrared floor must function continuously.

Cable underfloor heating

In the cable system, which is laid in the screed layer, the concrete acts as a heat accumulator, and there is no need for continuous operation of the heating elements to maintain a constant temperature. An electric thermostat with temperature sensors in cable systems makes them less expensive for continuous heating of premises, despite the higher rated power.

Important! Cable underfloor heating is more efficient if you need to heat a large room.

Today, non-committed experts recommend a reasonable combination of cable and infrared flooring in the room. The film floor provides quick heating to a comfortable temperature, and the cable floor performs subsequent continuous heating and maintains the set temperature.

Which warm floor is better - a comparative characteristic

The table summarizes the main parameters for comparative analysis.

| Index | Water floor | Electric floor | |||

| Cable | Cable in mats | Film | Rod | ||

| Heating type | Convection | Heat radiation | |||

| Warm-up time, min. | 30-60 | 20-30 | 20-30 | 5-10 | 10-15 |

| Overheating resistance | – | + | + | + | – |

| Add. equipment | boiler | – | – | – | – |

| Installation restrictions | |||||

| - on the balcony / loggia | – | + | + | – | – |

| - in a private house / in the country | + | + | + | + | + |

| - in the apartment | - (permission required) | + | + | + | + |

| Power for 1 sq. M. | Depends on the power of the boiler | 180-220 watts | 180-220 watts | 25-45 watts | 25-50 watts |

| Food / fuel | Gas, solid fuel, electricity | Electricity | |||

| Mounting method | Wet works | Wet works | Wet works | Dry works | Wet works |

| Removable and reusable | – | – | – | + | – |

| Installation restrictions | Cannot be installed under furniture and other low items | ||||

| Installation in a large room | + | (due to the cost of electricity) | |||

| – | – | – | – | ||

| System inertia | high | average | average | high | low |

| Temperature adjustable | – | + | + | + | + |

| Repair-suitability | – | – | – | + | – |

| Demolition of the entire floor is required | Easier due to lack of screed | Dismantling | |||

| Effect on the height of the walls | up to 150 mm | 50-80 mm | 30-50 mm | 5-10 mm | 20-30 mm |

| System weight underfloor heating for 1 sq. squares | 200 Kg | 30 Kg | 30 Kg | 2 Kg | 30 Kg |

| Installation speed | 4-7 days | 1-2 days | 1 day | 1 day | 1 day |

| Time before the start of operation | 7 days | 7 days | 7 days | 1 day | 28 days |

| Initial investment | low | low | average | high | very high |

| Operating costs | high | very high | very high | high | average |

| Economical compared to radiator heating | up to 25% | up to 50% | up to 50% | up to 70% | up to 80% |

| Installation in a room with high humidity (bathroom, sauna) | + | Possibly with reservations | Not recommended | + | |

| Floor Compatibility | |||||

| - natural wood (flooring, parquet) | – | – | – | – | + |

| - laminate | + | + | + | + | + |

| - linoleum | + | + | + | + | + |

| - tiles / porcelain stoneware | + | + | + | + | + |

| - carpet | + | – | – | + | + |

| Radiation | no | electromagnetic | infrared | ||

| Popular / famous brands | – | – | Devi, Teplolux | CalorIQue, Devi, K-Techno -logies (ТМ Caleo) | K-Techno -logies (TM Unimat), Felix (TM Excel) |

| Price, rub / sq.m (average range) | 200-500 | 400-900 | 700-2000 | 1350-1700 | 1500-2685 |

| Estimated service life, years | 10 | 15-20 | 15-20 | up to 50 | up to 50 |

Material prepared for the site www.moydomik.net

Heating mats

This is a cable heating system, which is designed to simplify the process of installing a warm floor. Such a mat is a heating resistive cable laid out with a certain pitch on a plastic heat-resistant mesh and attached to it with a fixing tape. Average mesh width - 50 cm.

This type of underfloor heating is suitable when the screed is ready and it remains to lay the floor covering. Installation of the mat can be done on tile adhesive with a layer from 3 to 5 mm.

The mats laid in this way reduce the height of the room only by the thickness of the adhesive layer and the tiles.

Dignity

- It is sold as a finished product with a certain calculated step, that is, there is no need to calculate the power per 1 m2 of area, the laying step, etc.

- Since the mat is located directly under the tiles, the floor heats up quickly enough.

- Changes the floor level a little.

disadvantages

- Produced for a specific heating area: 0.5 m2, 1.0 m2, etc.;

- The area is limited by the width of the mat and a certain skill level is required when laying on an area of complex shape

- Do not lay on insulation, this can lead to overheating of the cable.

- The mat is easier to damage than the cable, which should be taken into account during installation, including when laying tiles.

- The shallow installation depth can also be attributed to disadvantages, since the floor cools down quickly after a power outage.

Both systems are reliable and their service life is approximately the same. from 15 to 20 years old... Electricity consumption for small heating areas is also approximately the same. That is, the main selection criterion is the installation conditions.

Which floor heating to choose for a private house and apartment?

The selection of a floor heating system is carried out taking into account such factors as:

- the size of the room, in particular floor area and height;

- type of heating. Whether the underfloor heating system will be the main source of heating or an additional one will have a significant impact on its power.

What to look for when choosing a warm floor

- indoor setting... All underfloor heating systems, except for the infrared rod, are very sensitive to overheating, which means that they cannot be mounted under furniture and heavy household appliances. The minimum height is 350 mm. This often leads to the fact that one part of the floor is significantly warmer than the other. Uneven heating (temperature changes) negatively affects the wooden flooring (floor board, solid board, parquet);

- wall height... It should be borne in mind that some underfloor heating systems are mounted exclusively in a screed. This statement is true for a water heated floor, rod and electric with a heating cable or mats. The higher the height of the heating element (pipe diameter or cable section), the thicker the screed will be. If the height of the walls does not allow raising the floor by 70-100 mm, then film warm floors should be considered;

- system maintainability... The screed completely blocks access to the system elements, which creates additional problems in the event of a malfunction, i.e. cannot be repaired quickly. Even identifying the place of failure without dismantling the floor is problematic;

- work speed... The speed of work is understood as the implementation of all types of work: from design to final surface finishing. Despite the fact that the core floor is installed within a few hours, it is not recommended to turn it on until the screed is completely dry, and some manufacturers (for example, Kaleo) set a limit of 28 days. The water floor is also mounted for a long time, which is associated with the specifics of the piping and also requires the complete solidification of the screed. The best option from the point of view of "operation immediately after installation" would be a film infrared heat-insulated floor.

- type of finish flooring... In many respects, the final choice is determined by the answer to the question, which warm floor is better for tiles, or which warm floor is better for laminate. Indeed, in one case, the use of glue is required, and not all systems are suitable for this, and in the other, it is necessary to take into account the tendency of wood to deform and the presence of harmful substances in the composition of materials (it is possible to release, for example, formaldehyde, when heated).

- profitability... Regarding which warm floor is more economical, users are unanimous and give the palm to rod floors for the economy of operation, and to water floors for the initial investment. But, is it always worth focusing on what is given cheaper? No, it is advisable to compare not by price, but to calculate the average costs for the operational period, and here infrared floors are in the lead.

As you can see, there are many factors that affect the final choice of a warm floor system, the fullest possible consideration of which will help to make the right choice.

Tags:

Floor Warm floor Heating

Safety, reliability and service

The difference between the cable and infrared floor heating system for these indicators is also significant.

In terms of reliability and the risk of failure of the entire structure, the IR system surpasses the cable. The film itself with soldered elements has high strength. The parallel connection scheme prevents the failure of the entire system in the event of a breakdown of an individual element. In a cable floor, if the wire is damaged, the entire system stops working.

IR films are mounted without a screed, the topcoat (laminate, linoleum) is laid directly on top of the heating mats. This determines such features of IR systems as:

- ease of installation;

- the speed of heating the floor surface to the desired temperature;

- if a separate heating module fails, the system continues to work, and replacing the damaged element will not be a big problem. Removing the topcoat locally is easier than removing the cable from the tie.

But the modular system of parallel connection leads to the complication of the electrical part of the design. The use of additional power supplies makes the system vulnerable to power surges.

In terms of security, some cable floors are preferred over infrared. Electric two-core screened cable for underfloor heating, located in the thickness of the screed, is practically invulnerable and excludes electric shock.

Two-core shielded wire

Foil floors are laid directly under the topcoat, so they are demanding both in terms of strength of the base and limitation of mechanical loads from above.

But the cable floor also has a weak point: despite the fact that it does not have many connection points for individual modules, the only connector hidden under the floor surface often fails. Therefore, its location is always marked on the room plan for quick search and replacement.