Polyfoam in the national economy is used almost everywhere today. It's hard to find an industry that doesn't use it. It is used in shipbuilding to fill compartments, which ensures the unsinkability of ships. In medicine, it is used to seal containers. Decorative elements for interior decoration are made of this material. In trade, it is used as a packaging and protective material. As insulating gaskets for warming the facades of houses and interior walls of premises, the material is used most often and in large volumes.

Register for a free marathon

How to create passive income in 4 days

A marathon where you will create passive live income from scratch and learn specific strategies for investing in apartments, houses, garages, cars and even profitable websites

To begin

If you buy equipment for the production of polystyrene, then you can set up its production. It is a highly profitable business. Material and other manufacturing costs generate a low production cost. This allows you to sell the finished product at a large mark-up.

Foam production technology

Styrofoam is a plastic mass that results from foaming. Its density is very low, since most of the volume is taken up by gas. The material is very lightweight. Its high porosity provides the very sound and heat-conducting properties for which it is valued. Thin cell walls poorly conduct sound and air currents. There are several types:

| 1 | polyurethane |

| 2 | polyvinyl chloride |

| 3 | phenol formaldehyde |

| 4 | urea-formaldehyde |

| 5 | polystyrene foam |

For different applications, a different type of foam is chosen. They differ mainly in the composition of raw materials and processing technology. Consider the manufacturing technology of a polystyrene type. She will help you choose the equipment for the production of foam, which you need.

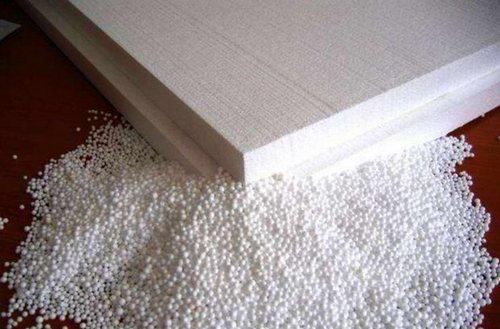

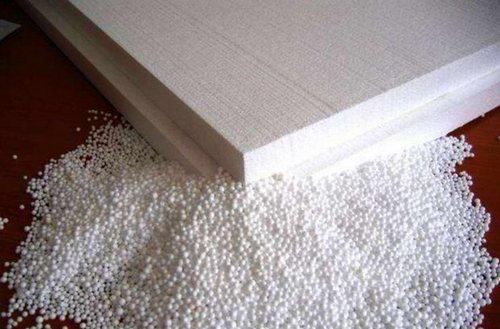

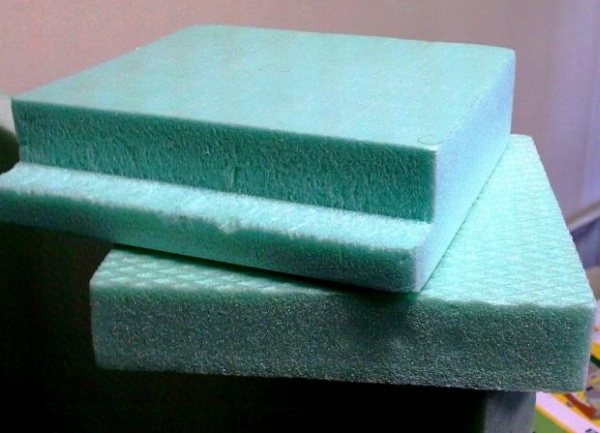

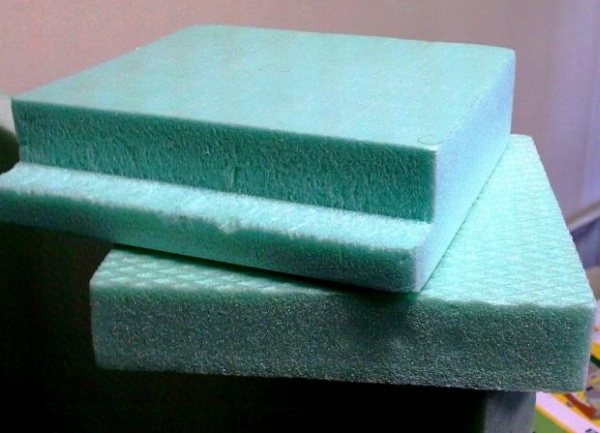

Expanded polystyrene is an accumulation of balls that are elastic to the touch. It is white and odorless. It is considered an environmentally friendly material, therefore it is used in the construction of almost any object.

Pre-frother P - 04. Price - 79 800 rubles.

The raw material for production will be polystyrene, which has the ability to foam. The technology is as follows. The polystyrene granules are placed in a pre-frother. This is a special chamber in which they inflate and become like small balls. This operation can be repeated several times if the already foam material needs to be increased in size.

The main technical characteristic of a material is its actual weight. The number indicates how many kilograms one cubic meter of material will weigh. This indicator can be used to judge the density of the material. The described one-time foaming principle allows a low density product to be produced. If it is necessary to obtain a material of higher density, the raw material is foamed several times. A set of equipment for the production of foam is selected based on what parameters the final product will have.

At the second stage, the granules are kept in a special hopper. They are loaded pneumatically from the foamer. At rest, in the granules, chemical processes are normalized. The pressure in them becomes constant. If it is necessary to carry out the foaming procedure several times, then the curing is duplicated.

The third stage is the formation of granules into a homogeneous product. When they are completely dry and cured, they are exposed to steam in special forms. This takes place in an enclosed space.The expanded polystyrene balls expand and join together. Further, it is possible to cut the product to those forms that are necessary. It can be carried out only after the block is completely dry. Before this process, the material is again kept for some time. Now that you have completely decided on the assortment that you will produce, you can pick up a set of equipment for the production of foam.

What is Styrofoam?

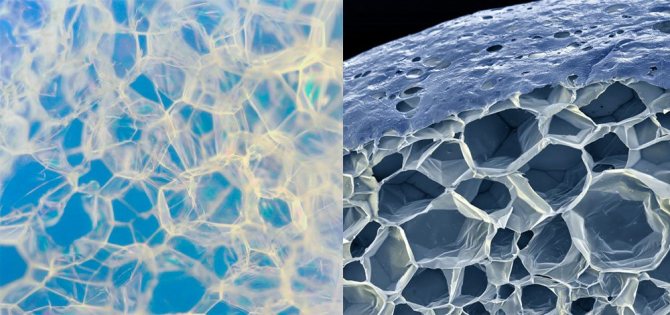

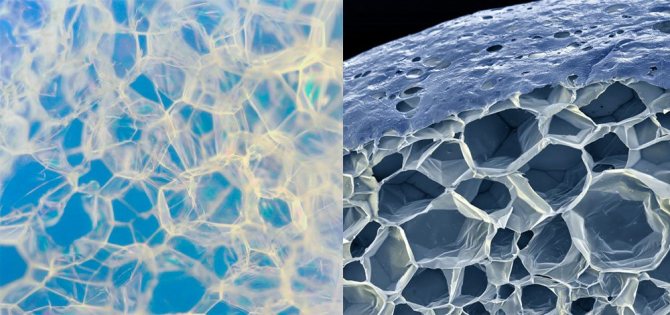

The macro photo shows that the foam consists of closed cells filled with air.

Foams include all types of gas-filled plastics.

Distinctive features of the material:

- porous structure, which consists of closed cells;

- low level of density;

- high sound and heat insulation properties.

The group of foamed plastics includes:

- polyvinyl chloride material;

- polyurethane analogue;

- urea-formaldehyde foam;

- phenol-formaldehyde material;

- polystyrene analog.

Most often, foam is produced from granular polystyrene.

Expanded polystyrene is the most common material. I will describe its production. Expanded polystyrene was created in 1951 by the German company BASF. Then he received the brand name "styrofoam".

Foam plastic for its main purpose is a heat-insulating material. It is 98% air. The gas is contained in many small, thin-walled polystyrene foam cells.

What kind of raw materials are used?

Polystyrene granules are used as raw materials for the manufacture of foam boards.

Expandable polystyrene is used as a raw material for polystyrene:

- It is obtained by means of suspension type styrene polymerization.

- The process takes place with the addition of a pore-forming agent, which is a mixture of isopentane and pentane. The volume of the mixture in the material is 5-6%.

- If the foam is intended for construction, then 1% of a fire retardant is added to the raw material. These are usually bromine compounds.

Polystyrene is produced in the form of granules. These spherical particles are treated with antistatic agents. They prevent the accumulation of electric charges by the material during its transportation. Also, processing improves the manufacturability of raw materials. Polystyrene granules in Russian denote PSV (expandable polystyrene).

Manufacturers differ in brands, types of foam and raw materials. Therefore, before purchasing the material, read its symbol in the technical documentation.

Imported polystyrene is most often labeled as EPS.

- EPS (expandable polystyrene), expandable polystyrene. This is the international designation for granules. FS (self-extinguishing polystyrene) Is another possible marking.

- PSB (suspended non-pressed polystyrene foam) Is the Russian designation for polystyrene.

Standard packaging of PSB-S grade 25 foam, containing 1 cubic meter of material.

PSB-S (suspended self-extinguishing foam polystyrene) - another version of the Russian marking.

After such a designation, there is a digital indication of the grade of material by density.

Where is Styrofoam Used?

The use of foam was determined by its technical characteristics. Both molded products from expanded polystyrene and its crushed waste are used.

Sheathing the walls with expanded polystyrene plates will make the house warmer.

Foam boards are used in construction:

- For do-it-yourself insulation of facades and interiors of buildings.

- For the production of non-removable formwork.

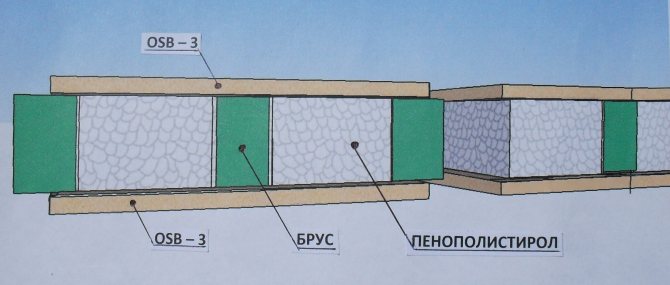

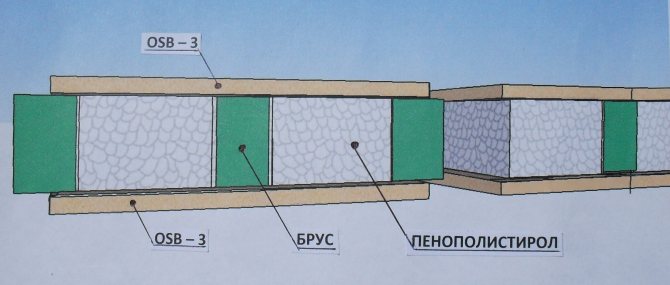

Sandwich panels with an insulating foam layer serve as the walls of light frame buildings.

- In sandwich panels.

- As an insulating layer inside load-bearing structures (three-layer reinforced concrete panels or blocks, layered masonry).

- As an insulating base under the screed for mastic or rolled roofs.

- For thermal insulation of floors and basements.

- As protection against freezing of the road base.

Also, foam is used:

- in shipbuilding;

- in refrigeration devices;

- when arranging pontoons and floating piers;

- as packaging for food and household appliances.

A polystyrene foam baguette is much cheaper than gypsum, wood and polyurethane counterparts.

Due to the low price and easy processing, decorative foam molded products are now widely used:

- skirting boards;

- ceiling tiles;

- moldings, etc.

How much money is needed for production?

Necessary equipment for the production of foam, which will need to be purchased:

| Name of equipment for the production of foam | Cost, thousand rubles |

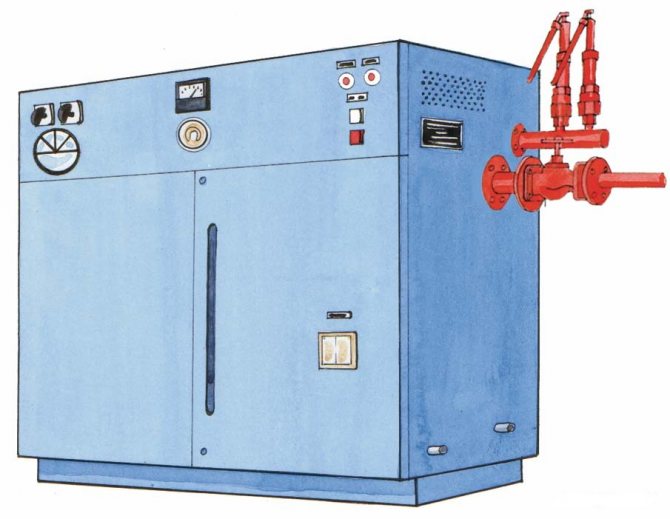

| Steam generator | 50,0 |

| Pre-frother | 145,0 |

| Secondary foaming machine | 25,0 |

| Drying hopper | 13,5 |

| The form | 89,0 |

| Steam generator | 55,0 |

| Crusher | 35,0 |

| A device for blowing air into the drying chamber | 11,0 |

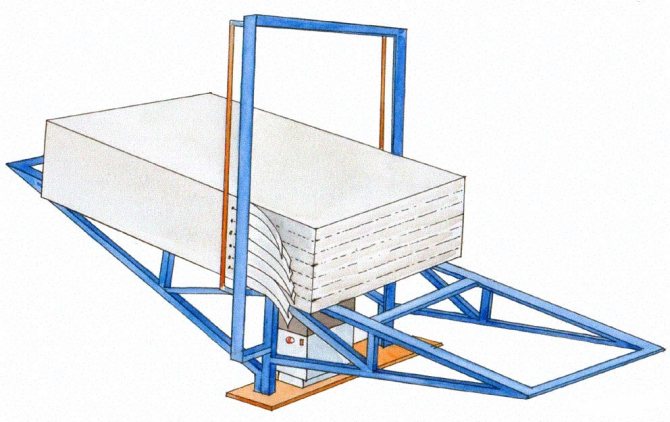

| Slicing stand | 25,0 |

| Trimmer | 25,0 |

In total, the purchase of equipment for the production of polystyrene will require approximately 500 thousand rubles.

Properties of expanded polystyrene

Let's talk about each property more specifically.

Strength

Thanks to the production technology, extruded polystyrene foam takes precedence in strength. Ordinary polystyrene cannot boast of such strength, therefore, at present it is less in demand.

By extrusion, you can obtain a material that is better for insulating, strong and resistant to moisture.

Thermal conductivity

One of the main properties of expanded polystyrene is its low thermal conductivity. Polyfoam consists directly of polystyrene and air bubbles in it. Since the air is securely contained inside, it serves as an excellent heat insulator. This property allows the use of foam in construction and insulation work. Due to the availability and relative cheapness of the material, this is a fairly profitable choice when heating your home.

Moisture resistance

Extruded polystyrene foam has a fairly strong resistance to moisture. Unlike conventional foam, extruded polystyrene foam always stays dry. This property allows you to lay the foam in places of the greatest accumulation of moisture or the flow of liquids.

Equipment for the production of foam

| 1 | The pre-frother can be operated by one person. The capacity of the foam plastic production equipment allows processing 6-7 cubic meters for the first time. meters of raw materials. Secondary and subsequent foaming will be faster. 12 cubic meters are processed per hour. meters of expanded polystyrene. |

| 2 | Steam generators can run on gas, diesel or wood. Natural gas will be the most expensive to use. It is cheaper to use the last two fuels for generating steam. There are types of boilers that operate on wood waste and oil production residues. The use of this type of fuel will further reduce the production cost. Such a device costs 155 thousand rubles, but due to its performance and economy it pays off very quickly. The disadvantages include the ability to work it only in a separate room. In addition, to maintain the equipment for the production of foam, one more person will be needed to add waste to the furnace. There is another option for boilers - electric. Their price is low - from 56 thousand rubles to 80 thousand rubles. However, it is unprofitable to use electricity itself as a source for power supply. The cost of the final product will only increase from this. |

| 3 | Block molds, which are included in the set of equipment for the production of foamed plastic, are usually designed for 6-7 cubic meters of material. If you need to make a denser material, above 12, then a second block mold is ordered for this. It will cost more than 100 thousand rubles.The use of such a non-standard form will entail the purchase of a steam accumulator of greater power. The mechanization of this equipment for the production of polystyrene makes it possible to exclude human participation completely. Thanks to automation, the sheet geometry is almost perfect. |

| 4 | A table with an electric motor is used to cut the material into blocks. This category of foam equipment is purchased when production volumes are large. They also buy liner bags for the aging bunker. One unit of such an auxiliary container is not enough. Its quantity depends on the range of products and production volumes. Experts recommend buying at least two units. If it is planned to produce a standard quantity of 6-7 cubic meters, then one liner bag will be filled in 3 hours. For expanded polystyrene with a higher density, the need for packaging is greater. |

| 5 | Since any technology for the manufacture of polystyrene is waste-free, its trimming must be further processed. For this, a crusher is used. It is fashionable to add recycled raw materials in the amount of 10% of the total amount of foamed material. |

The payback of the equipment for the production of foam is approximately 10 months... To do this, you need to organize uninterrupted work in one shift and regular sales of finished products. Given the high profitability, this is not difficult to achieve.

What is needed for production and where to buy raw materials

The basis of production is polystyrene granules - PSV-S. They are obtained by polymerization of styrene, the surface is treated with substances that prevent the accumulation of electrostatic charges, which greatly facilitates storage and transportation. In Russia, polymer raw materials are produced by the following companies:

- Gazprom neftekhim Salavat;

- Nizhnekamskkhim;

- The ABC of Polymers;

- Plastprom.

The cost of domestic raw materials is from 56 rubles per 25 kg.

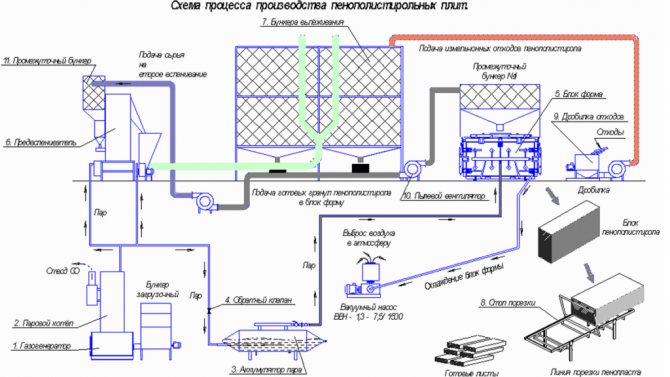

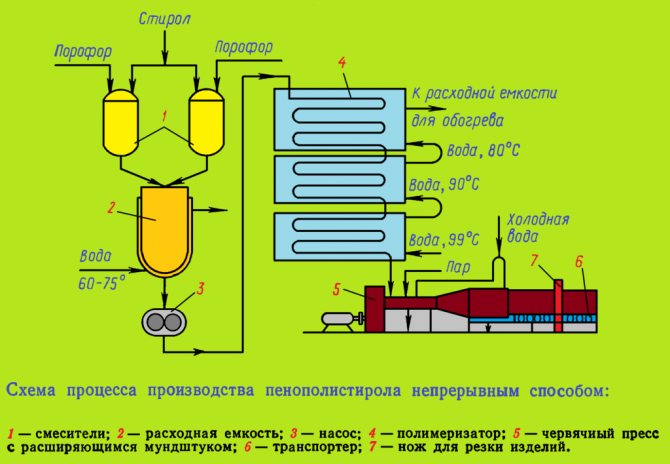

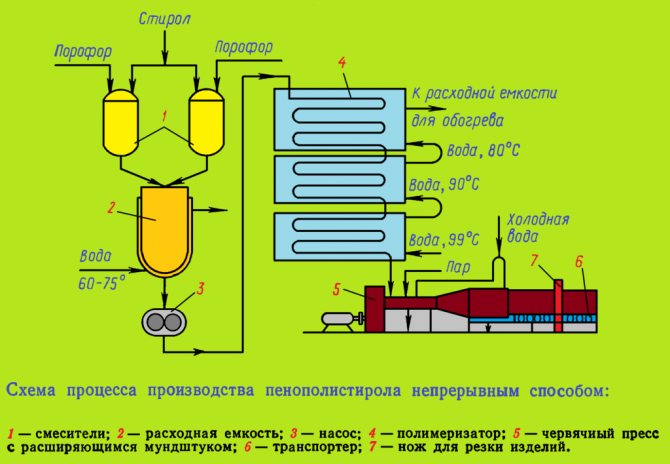

Diagram of the process for the production of expanded polystyrene in a continuous way

Imported raw materials from Chinese and European manufacturers will cost twice as much, but are of higher quality. When organizing production, it is necessary to take into account that expanded polystyrene granules should be stored at a temperature not lower than +18 o С and humidity not exceeding 70%. Violation of storage conditions will directly affect the process of making foam.

What documents are needed to open

For the manufacture of the above-mentioned building material, registration in the form of an individual entrepreneur is required. As an alternative - opening a legal entity. In the latter case, it is best to open a limited liability company. Individual entrepreneurship will require the collection of a minimum number of documents (an application of the established form, a photocopy of a passport, a document confirming the payment of a state fee). In addition, you need to open an account in any bank, register with government agencies. For legal entities, you will additionally need to provide a decision of shareholders on the creation of an LLC and the Charter of the company, information about the director and chief accountant, and obtain a legal address.

Where is used

The scope of application of polystyrene is extremely wide - it is a practical and lightweight material that has proven itself in business. Let's list the main directions where it is used:

- Building. It is used as insulation from the outside outside of the room, as sound insulation, as well as for creating decorative elements (plinths, columns, tiles, panels).

- Shipbuilding. It is used as a filler for compartments or floats to improve the buoyancy of the vessel.

- Business and trade. It is used as packaging for electronic equipment, food products, household appliances, etc.

- Medical field. Used to create thermal stabilizing chambers.

- Food industry. It is used as a heat insulator in refrigerators, freezers and other climatic equipment.

- Light industry. Used to create various goods: life jackets, floats, etc.

Of course, foam is most often used in the construction industry. However, if you decide to do production of foam, capture markets and promote their products, then you should pay attention to other industries - often selling products is much more profitable than ordinary sheets.

Financial plan

| Fixed costs (rub.) | |

| Premises for rent (130 sq.m.) | 105 000 |

| The salary | 100 000 |

| Overheads | 15 000 |

| Fare | 27 500 |

| Total fixed costs | 247 500 |

| Fixed costs per 1 m3 | 98,6 |

| Variable costs (RUB) | |

| Cost of raw materials RUB / kg | 53 |

| Total consumption of raw materials by brands | 760 000 |

| Electricity consumption rate, kW * h | 24,03 |

| Electricity tariff (excluding VAT) RUB / kW * h | 2,78 |

| Total electricity consumption by brand kW * h | 7280 |

| Profit calculation | |

| Market price of polystyrene (excluding VAT) RUB / m3 | 850 |

| Cost of 1 m3 (excluding VAT) RUB / m3 | 638,2 |

| Profitability (RUB) | |

| Net profit per month | 213451,9 |

| Initial investment | 1 500 000 |