Wood covering

Using planks is the best answer to the question of how to make a floor in a private house. The wooden covering looks very impressive, is practical, highly maintainable and lasts a long time. For the installation of such a floor, first of all, you will need to prepare the following materials:

- Edged board at least 2.5 cm thick.

- Waterproofing agent. You can take a very thick plastic wrap or roofing felt.

- Heat insulator. Rigid mineral wool slabs are considered the most suitable option for floor insulation. However, you can take more expensive polystyrene foam. Also, the floors in country houses are often insulated with sawdust or expanded clay.

- Beams for lags are bought only if these elements have not been installed during the construction of the house. In any case, their thickness should be at least 15 cm.

- Steam insulator. This material will prevent the insulation from getting wet due to condensation from the side of the room.

You will also need to prepare a hammer or screwdriver, nails and screws, steel corners.

Wooden floor on logs in the interior of a private house

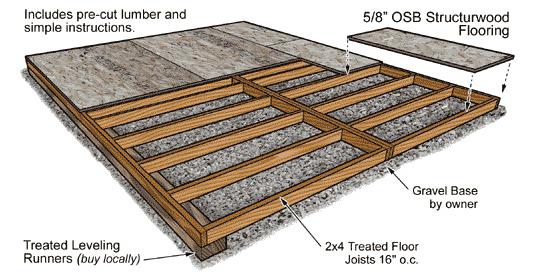

This type of construction was used in the last century, in old Russian houses and today it is used in modern private houses. It is advisable to build them on the ground, where the subsoil waters are at a depth of up to 2 m, in order to avoid contact between the floors and the ground. The floor level is up to 15 cm above the ground. The distance must not be increased, because this will lead to heat loss in the heated room. How to install wood floors? The preliminary preparation of the soil surface is the same as for monolithic structures.

Step number 1. Marking the height of each layer of the structure. Soil preparation. We made the markings, now, first of all, you need to remove the upper soil layer of the soil, clear the surface of the future floor from debris. Then we align and tamp thoroughly. Moisten with water for a better seal. Using the level, we check the horizontal position.

Step number 2. Laying of gravel. Thermal insulation. We sprinkle crushed stone with a fraction of 4 × 5 mm, evenly distribute it over the surface of the sand. We are ramming. If the soil is high moisture, we lay a double layer of film or smear bituminous mastic and glue the roofing material.

Assembling wood flooring

So, let's see how to properly make a floor in a private house from planks. In order to arrange a wooden covering, the first step is to carefully level the ground. Next, a thin layer of sand is poured. You can skip this step if you wish. Then the roofing material is laid. The overlaps between the stripes must be at least 15 cm.

Next, the lags are mounted. To do this, first, a bar is laid along the perimeter of the room. Then the actual lags themselves are installed. You can attach them to the strapping beam by means of corners.

The distance between the lags should be equal to the width of the insulation. Mineral wool slabs set up a spur. A vapor barrier is pulled over it. In this case, too, the overlaps should be at least 15 cm. The vapor barrier can be fastened with rails (two per lag on the sides on both sides).

At the final stage, the boards are mounted. They should be well dried and trimmed on top. In addition, they must be treated with an anti-fungal composition. When assembling, the boards should be fitted as tightly as possible to each other. Otherwise, during operation, gaps may form between them, the floor will begin to creak, etc.

Finished wood floors can be varnished or painted.Sometimes linoleum is also laid on top.

Instructions for insulating a wooden floor

- Before starting work, it is necessary to lay a sub-floor. It is made from untreated boards, and they are attached to beams. When it comes to renovation, first you need to dismantle the old floors.

- Lay the logs on the subfloor. Secure them with self-tapping screws. The distance between the bars is 0.6-1 m.

- Lay the waterproofing material.

Thermal insulation of a wooden floor

- Position the insulation so that it fits snugly against the joists. Lay waterproofing on both sides. If expanded clay is used, it just needs to be poured into the space between the bars.

- The next layer is vapor barrier. This is a special film or membrane that extends the life of the insulating material. It should be laid with a smooth surface to the insulation.

- Installation of a fine floor covering.

Attention! Ventilation is required between the two floor levels. For this, special holes are made in the upper floor covering - vents.

This version of the double floor, consisting of a "draft" and "clean copy", is also suitable for a concrete base. However, it should be borne in mind that this design reduces the ceiling height by about 6 cm.

What varnish to choose for wood

Plank floors can be trimmed with almost any means. Polyurethane varnishes are very popular, for example. Their advantages include, first of all, environmental friendliness and the fact that they are not afraid of even very serious loads. Also, quite often the floors are covered with acrylic-based products. They are not too resistant to all kinds of mechanical stress, but they are easy to apply and are very inexpensive. Can be used for wood flooring and alkyd, quick-drying varnish or very durable epoxy.

How to make a concrete floor in a private house

This option can also be used in a country building. Most often, concrete floors are made in the utility rooms of the house. They are filled in as follows:

- A shallow pit (10 cm) is dug in the room.

- Its bottom is leveled and compacted with a hand roller.

- Sand is poured in a layer of 5 cm. It also needs to be tamped.

- Reinforcing mesh is laid on wooden blocks.

- Lighthouses are exhibited.

- Concrete is being poured.

It is better to start laying the mortar from the corner farthest from the door. It is advisable to fill in one step.

The strength of the poured concrete floors will gain strength not earlier than in two weeks. After this period, you can start walking on them. However, it is worth bringing heavy furniture or household appliances into the room no earlier than in a month.

Concrete floors

The concrete floor has its merits. This is a strong, durable, fundamental floor, with a perfectly flat surface, which is achieved with the help of modern self-leveling mixtures. Making concrete floors is easy enough. The main snag is the correct, reinforced cement screed.

The base of the concrete floor is a waterproofing layer, then the prepared base is poured with mortar. Faster maturation of concrete is achieved by covering it with a film and "keeping" alone for a month. Then the screed and finishing coat are mounted.

Fine finishing

Of course, just a concrete surface is not only ugly, but also not very comfortable. Therefore, such floors are usually finished with tiles or thick linoleum on top. The second option is used, including in living rooms, if, for some reason, concrete floors are still poured into them. Tiles, as in a city apartment, are used to decorate the toilet, shower room, hallway and kitchen. Attach it with special glue.

It is better to lay linoleum on a concrete floor with a special one - with a warm substrate. It will, of course, be quite difficult to fix it on the cement coating. Sticky tape will definitely not work in this case.Therefore, the canvases can simply be laid loosely, fixing them with baseboards around the perimeter. Sometimes linoleum is also glued to concrete using a special mastic.

Warm floor

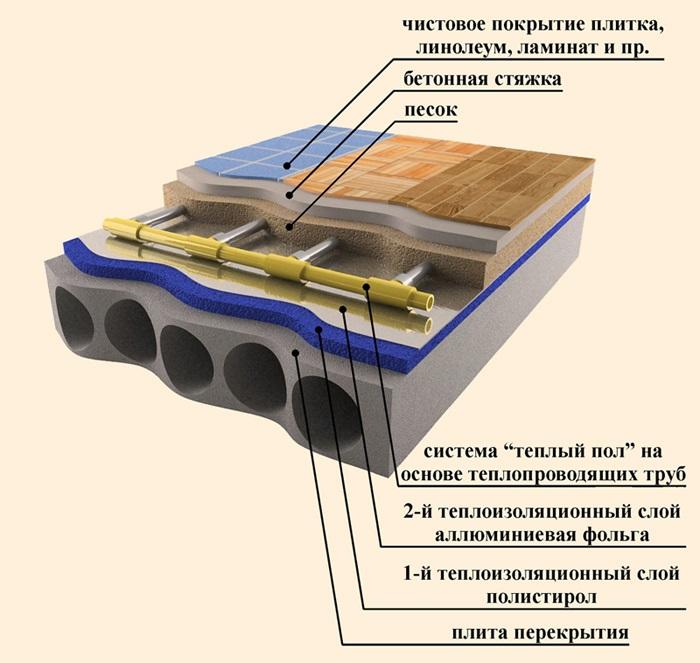

"What is the best way to make a floor in a private house?" - the answer to this question is, of course, ambiguous. Using planks or concrete mix is a great solution. However, the so-called "warm floors" are still considered the most comfortable and practical. The concrete screed in the living quarters of a suburban building is often made precisely during their arrangement. In this case, dense slabs of insulation specially designed for such systems are installed on the sand. Then pipes are laid on them according to the scheme. Then everything is poured with concrete mixture.

How to pour a concrete floor on a basement floor

So, with how to make a floor in a private house, we figured it out. Now let's see how you can arrange the coverage in the basement. In this case, it is very important to pay maximum attention to waterproofing. Instead of sand, it is better to lay out the bottom of the pit with crushed stone.

Otherwise, the answer to the question of how to make a floor in the basement of a private house is extremely simple. Filling is done in the same way as in rooms. In the event that it is supposed to drive into the basement, for example, a car, the fittings must be tied as strong as possible. The rods for it are taken with a thickness of at least 12 mm.

Floor layer names defined by standards

1. Underlayment of the floor. This is the bottom layer of the floor, designed to evenly distribute the load on the ground. This layer is present in floors installed on the ground. The underlying layer is made of sand (60 mm), gravel (80 mm), concrete (80 mm).

Note: According to the regulations (SNiP 2-03-13-88), the underlying layer of sand and / or gravel is made only in industrial buildings.

It should be noted that in apartment buildings, the floor slab serves as the underlying concrete layer and does not a priori participate in our calculation of the floor thickness. However, when installing thermal and sound insulation of the floor, the screed becomes the underlying layer, which is made over the heat and sound insulation layers.

2. Floor screed. The second layer in the floor structure involved in the calculation is the screed. The screed layer serves to level the floor in the apartment and house, to hide utilities (pipelines and electrical wiring). Another purpose of the screed is to evenly distribute the load over the underlying layers of sand and / or gravel.

According to the standards, only clearly defined the smallest screed thickness. On the layer of sound - and heat - insulation, the smallest thickness of the screed is 40 mm. If the screed is made to cover engineering communications, its thickness should be 15 mm higher than the utility pipes.

3.Waterproofing layer or layers. In calculating the thickness of the floor, the waterproofing layer can be ignored due to the insignificance of the thickness. Stands on the floor, there may be several layers of waterproofing: under the screed and / or on top of the screed.

4. Layer interlayer. The name interlayer refers to the bonding materials that bond the coating to the undercoat. The layer can be:

- Parquet mastic (2 mm);

- Glue or mastic for vinyl coverings (linoleum, PVC tiles) - 1mm;

- Tile adhesive when laying tiles (3-5-7-9 mm, depending on the size of the tiles).

- Also, we refer to interlayers as technological layers for individual materials: for parquet it is plywood (12 mm in 2 layers), for laminate it is 2-3 mm underlay.

5. The last layer of the floor is called flooring.... Any finishing of the floor in the apartment and at home is its covering: parquet, laminate, linoleum, tiles, etc. The thickness of the coating layer depends on the type of coating: parquet 15 mm, floor tiles 10 mm, porcelain stoneware 12-14 mm, linoleum 2-3 mm, laminate 8 mm.

Self-leveling coating in a private house

Next, let's see how to make a floor in a private house using a special self-leveling mixture.This method of installing coatings in suburban buildings has recently become very popular. It is easier to make such a floor than even concrete. In addition, self-leveling coatings, unlike cement screeds, can be very beautiful.

So, how to make a jellied floor in a private house correctly. This operation is performed as follows:

- A concrete base is made. The method of filling it is no different from the above.

- The surface of the finished screed is dust-free. If the concrete floor has been poured long ago, it will most likely need to be touched up.

- The surface is primed.

- Using a perforator, the bulk mixture is diluted with water.

- The solution is applied to the primed base in small portions and carefully leveled.

- Immediately after pouring each portion, the solution must be passed with a needle roller to remove bubbles.

The finished floor should be covered with plastic wrap. In this case, it will gain strength better.

As you can see, using a self-leveling mixture is a very good answer to the question of how to make a floor in a private house. A photo of such a coating with a 3D pattern, presented a little below, clearly demonstrates its attractiveness and reliability. You can make such a coating, including with your own hands.

Manufacturing process

It should be noted that there are two fundamentally different ways to create such products. Both are fairly practical, but take a completely different approach. Moreover, in both cases, the surface of the coating can be wooden.

Rough floor

- First, you need to create a rough surface. It will serve as a support for future construction.

- In both installation methods, I use a regular board for these purposes. It is stuffed over the floor beams, tied to the walls with metal corners.

- It is worth noting that before starting the installation, the wood is treated with a special compound that will protect it from moisture.

- Then a layer of waterproofing is laid on the surface of the subfloor. It is better to make it from several layers of film.

Advice! Impregnation for wood should be chosen with antibacterial additives. This will prevent mold or mildew from appearing.

Concrete

One of the installation methods involves the use of concrete or cement floor screed. This is done in order to give the structure additional strength and protect it from the cold.

- To begin with, beacons are installed on the surface, which are made using a level or laser level. After that, the floor is tightened with cement mortar in a ratio of 1 to 4.

- To give such a screed additional strength, it is necessary to install a metal mesh on the floor before installing the beacons, although some craftsmen neglect this.

Advice! It is best to use concrete for this type of work. It is more practical and less susceptible to moisture.

Lags

- To create a wooden floor in a private house with your own hands, you should install special beacons. They are called lags and are used in both mounting methods.

- When using concrete, they are installed directly on the surface, fixing with impact dowels. It is worth noting that the height of the timber should be such that the insulation can be placed.

- If concrete flooring was not used, then the logs are attached to the walls of a wooden house with metal corners.

Installation of logs on a concrete surface

- When installing them, it is necessary to use a water level to create an even horizontal across the entire area.

- The distance between the lags is usually chosen by the masters at their discretion. However, it should not be too large so that the floorboard does not sag under the influence of the weight.

Insulation

When making floors in a wooden house with your own hands, it is necessary to pay special attention to the insulation. It is selected in accordance with the climatic conditions of the area, while creating a certain thickness.

When using a concrete coating, you can completely do with polystyrene foam of small thickness. For a wooden base, several layers of mineral wool or blocks of the same material are often used.

Advice! It is worth installing a waterproofing layer on top of the insulation. It will serve to protect against moisture formation due to temperature drops. In this case, additional coating over the insulation will not be superfluous.

Batten

- This stage can be considered final, although some craftsmen recommend resorting to a different method of creating wooden floors.

- For this type of work, it is best to use a tongue-and-groove floorboard. It has special grooves at its ends to create a lock when laying. This creates a surface that will not allow moisture or cold to pass through.

- The board is mounted on logs using a special fastener or using self-tapping screws.

- After installation, the surface can be sanded to remove minor imperfections or irregularities.

Advice! If a regular board is used, then after installing it, it is worth repairing all cracks or joints with a putty. This seals the surface and compensates for the lack of locks.

Plywood

- Quite often, building a floor in a wooden house with your own hands involves installing another topcoat instead of a floorboard. Therefore, you first need to prepare a solid foundation.

- It is made of special moisture-resistant plywood, which is fixed on the logs with self-tapping screws. Given that the surface of such a material is already protected, it does not need additional coating in the form of impregnations or primers.

- On such a floor, you can install almost any coating, from bulk mixes to wooden parquet. It will have excellent sound insulation parameters and will perfectly retain heat in the room. However, it should be noted that the cost of such a manufacturing method may be too high.

Advice! For this type of work, it is worth using plywood based on bakelite glue. It has the qualities most suitable for this application.

- When using concrete or cement screed, it must be borne in mind that the load on the load-bearing beams will be increased. Therefore, it is worth considering before choosing this manufacturing method.

- When creating a wooden floor in the house with your own hands, special attention is paid to the primer. The service life of the structure depends on its quality, so you should not save on this material.

- The wood must be dry to create all the elements of the floor. Otherwise, over time, various kinds of defects may appear in the form of distortions and drops.

- When working with laminated plywood, it is worth using assembly glue to fix it on the logs, so you can not spoil the appearance with nails or self-tapping screws.

- Before starting work, it is worth creating a small project of the entire structure. This will help ease installation and avoid errors.

For additional protection and to give the surface a good appearance, the wooden floor should be varnished or wax-based.

We perceive floors as the surface on which we walk, that is, it is wood floor, tiles, laminate, parquet or carpet. In fact, the floor has a complex structure consisting of several layers. Moreover, unlike an apartment, the arrangement of the floor in a private house has technological features, consisting of the following stages:

- Rough finish, concrete.

- Floor waterproofing.

- Warming.

- Another waterproofing.

- Screed, plank laying or covering.

If you follow the technologies of all the above steps, then making the floors in your home from scratch is quite easy. The device of floors in private residential buildings can be divided into two types: on the ground and on concrete slabs.

Immediately, we note that the second type does not suit us, because it is used for non-residential premises, since its technology does not provide for any insulation and is suitable mainly for summer cottages. For our case, namely for our climatic conditions, the first option is suitable, that is, the construction of the floor on the ground. These floors are of two types: with and without wooden logs (monolithic floor).

Advantages of floors on the ground:

- they are used in private residential buildings, in damp and cold climates;

- the soil on which the floor is settled usually has a temperature below zero;

- cost-effectiveness of materials (less concrete consumption);

- no need to additionally ventilate the space under the floor;

- these floors are warm and the temperature in the room is evenly distributed;

- high stability of the floor, applicable in a country private house, implies the installation of heavy structures, such as, for example, a stove or fireplace;

- in the end, you can use any finishing floor covering;

- has high sound insulation;

- provides a healthy indoor climate.

3D self-leveling floor

The pouring technology in this case will be the same as for the arrangement of a simple polymer coating. But in this case, you will need to make two layers. The base is preliminarily applied to the prepared screed. Next, a mosaic of pebbles or some kind of artificial materials is laid out. You can also use a picture on self-adhesive film. In this case, the base base is pre-primed.

At the final stage, the final layer of the polymer floor is applied. After it has gained sufficient strength, it should be varnished.

Well, we hope we have answered the question of how to make floors in a private house quite extensively. The methods of their assembly, depending on the selected materials, may be different. But whatever method the owners of the house choose, everything must be done carefully, adhering to the prescribed technology. In this case, the floors will last as long as possible and will look neat.

Floor preparation

Before covering the floors in a wooden house, you need to prepare the flooring. This will make it possible to carry out repairs at a high quality level. Floor treatment is carried out before painting and includes cleaning, preventive measures to combat moisture, fire, insects.

The amount of work directly depends on the age of the plank floor, the presence of previous layers of coatings.

Old flooring

How to cover wooden floors in the country, not the main question. But you need to know where to start.

An old plank floor, which has been in use for several years, has a protective layer of paint or varnish on it. Therefore, the first stage of preparation will be to remove the old coating with a spatula. If the paint cannot be removed quickly, heating with a construction hairdryer is used. The base will begin to bubble and can be easily removed.

Also, the covering material can be heated with an iron, through a cloth or paper. A small area of the floor is covered with a cloth and ironed. After that, the paint is removed with a spatula, and its remnants are sanded or dissolved (special washes are used).

You can also use an electric plane or grinder to clean the old plank floor. The wood dust formed during their use is not thrown away, but used to make homemade putty. This mixture of PVA glue and wood dust can be used to seal the gaps between the boards.

Work with a high level of dust is carried out in goggles and a respirator.

New flooring

Preparing a new flooring includes:

- checking the quality of the boards and their fasteners (the hats of the hardware must be completely recessed);

- puttying of seams;

- application of the selected coating.

First, it is recommended to cover the new flooring with a layer of antiseptic agents, fire retardants.Many types of paints and varnishes already contain antimicrobial, fire-resistant components. The degree of fire resistance is indicated on the packaging. This indicator is expressed as a percentage.

It is also advisable to use a primer to improve the adhesion of the paint or varnish to the floor.

Regardless of the age of the flooring, the quality depends on the chosen coating and the correct organization of the workflow.