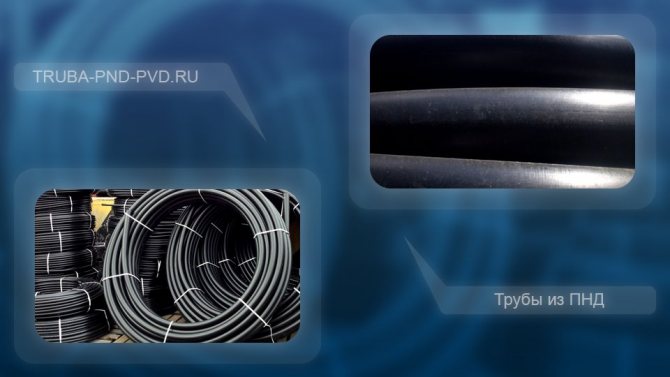

Plastic pipes made a real revolution in laying communications. If earlier metal pipes had to be replaced every 5-10 years, then with the advent of plastic pipes, utilities breathed freely. Plastic pipes do not burst if water freezes in them: they just expand, and then return to their previous shape. HDPE plastic pipe does not rust. Corrosion is the main cause of failure of metal pipes.

The production of plastic pipes from HDPE is environmentally friendly, since granules from recycled polyethylene (PE 100) are used. Technical plastic pipes do not harm the environment: low pressure polyethylene is resistant to aggressive chemical environments and does not emit harmful substances.

Direct sale of plastic pipes, wholesale or retail, has been carried out by our factory since the day of its foundation. Plastic pipes from the manufacturer mean several benefits to the buyer. The high quality of our products is due to constant monitoring of raw materials and equipment. The low price of a plastic pipe is ensured by minimal costs and well-established sales channels. The high production speed is made possible by the operation of several lines. And delivery to any point in Russia is carried out only by trusted companies or on our own. Call us at any time: our specialists will promptly fulfill the order and deliver the pipes on time. The catalog of plastic pipes is constantly updated with the introduction of new lines, and on an individual order we can make a pipe of any shape. The technical characteristics of plastic pipes along with prices are indicated in the catalog: it will not be difficult to choose the right product.

The use of plastic pipes.

Technical plastic pipes HDPE, due to its good wear resistance, neutral effect on them of high and low temperatures, are widely used:

- For drainage systems of private country houses;

- For ventilation equipment in household premises and industrial buildings;

- For the arrangement of plumbing wells;

- As protective covers when laying electrical and telecommunication networks;

- For equipping free-flow sewerage systems for country houses.

HDPE pipes have a long service life, are not subject to mechanical damage and chemical attack. The use of plastic pipes is growing every day. This is facilitated by the low cost of the plastic pipe and the incredible reliability.

Technical plastic sewer pipes.

Due to the low price, plumbing pipes made of plastic are in demand for arranging gravity sewerage systems in summer cottages and country houses. Replacement of traditional metal pipes for these purposes with plastic ones allows to significantly reduce the accident rate of underground utilities due to corrosion, to avoid expensive repair work with the involvement of special equipment. The price of plastic sewer pipes is a significant factor when choosing, but its exceptional reliability is much more important. Sewer plastic pipes will last much longer than steel ones, due to their high resistance to aggressive media and corrosion. They can withstand higher temperatures. Their inner surface does not need painting, it is smooth, thanks to which household waste and debris move through the pipes better, minimizing the possibility of clogging. Outdoor plastic sewer pipes from HDPE are easily assembled with each other using profile gaskets and socket joints.The outer and inner diameters of plastic pipes for sewage can vary, depending on the design flow.

Technical plastic tube for optical cable.

One of the important areas of application of technical plastic pipes is the equipment of telecommunication systems, telephone and television cables. Its inner walls have a smooth surface, so the cables laid in it do not encounter resistance. This method of laying telecommunication cables allows you to protect the communication line from mechanical damage, to protect them from the effects of an open flame (HDPE pipes are not flammable) or high temperatures.

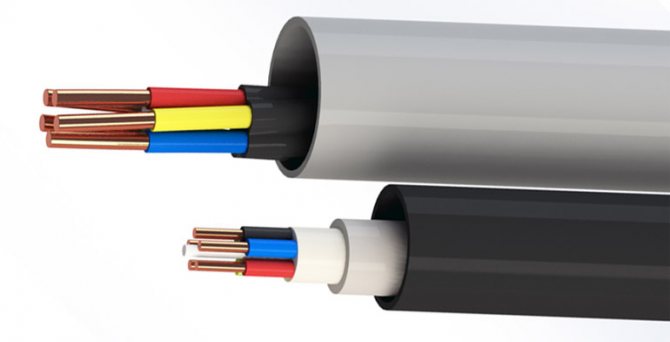

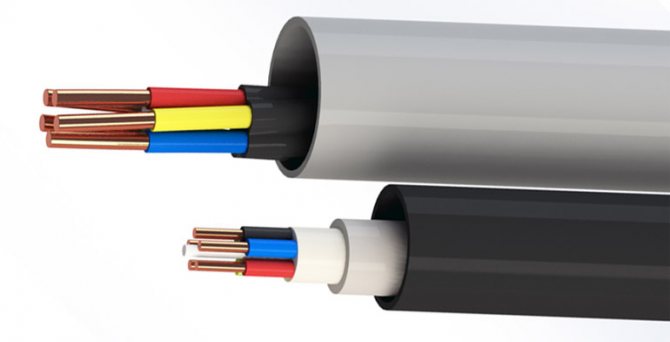

Plastic PE pipes for electrical wiring.

With the help of plastic PE pipes, channels and protective sheaths of power cables and electrical wires are created, laid in a hidden way, outside buildings or in the ground. This method of conducting electrical wiring is used in industrial premises, warehouse complexes, office and residential buildings. The use of PE plastic pipes for electrical wiring allows you to protect the cable from external damage, prevent the possibility of electric shock to a person in the event of a cable insulation failure. After a short circuit occurs, the PE plastic pipe will prevent combustion.

Plumbing pipes made of plastic for draining.

Plumbing plastic pipes are used for arranging rainwater gutters in private houses, in personal plots. The low weight and high elasticity of such pipes allow you to quickly, without much labor, mount a drainage system of any height, at any time of the year. The drain on the house, installed with the help of plastic pipes, will look beautiful and neat, and it will perform well its main function - water drainage.

Ventilation plastic pipes.

Plastic pipes are used to create supply and exhaust ventilation ducts for residential buildings, industrial and public buildings. Unlike metal pipes, on which there are roughness in the area of \ u200b \ u200bthe joints that slow down the movement of air flow in the system, plastic ventilation pipes are devoid of this disadvantage. Such ventilation systems are durable, mobile, not subject to corrosion, and fully comply with hygiene requirements. They avoid air mass leaks due to the absolute tightness at each connection.

Plastic pipes, like parts of other products.

A technical jacket pipe is also used as an accessory for pipelines with thermal insulation. Due to its resistance to most chemically active substances, such a plastic pipe is used to protect standard metal pipelines in many industries where there are corrosive environments. In addition, such plastic casings significantly reduce heat loss, increasing the economic benefit in the operation of pipelines.

How do you like a greenhouse made of plastic pipes? This non-standard application of HDPE pipes is just one example of where these products can be used. Tubes and table legs are also made of plastic pipes of various lengths. Rigid or flexible pipes are used depending on the requirements for the product. A bow and even a catamaran are made from plastic pipes!

Reinforced plastic flexible pipes

Flexible pipes made of metal-plastic are also found on the market of repair and construction materials, and have a number of positive characteristics, such as:

- high resistance to pressure inside the pipe;

- increased resistance to mechanical stress;

- ease and ease of installation;

- wide range of operating temperatures (from -15 to +60 ° C).

The assembly of structures from metal-plastic pipes does not present any particular difficulties and is most often carried out by means of threaded fittings.

The price of a plastic pipe.

Technical pipes made of plastic are cheaper than similar ones made of other materials.However, in many quality characteristics, they are not inferior to metal pipes. The use of PE granules from secondary raw materials in the production of plastic pipes significantly reduces the cost of the final product, making it possible to reduce the total cost of laying sewage systems, various telecommunications and electrical networks, drains. The low price of plastic pipes is also due to the presence of our own production with modern equipment that provides low energy costs and high productivity. You can find out how much a plastic pipe costs on our website in the section with prices (price-list) or by one of the phones. The price of a plastic pipe depends on the batch size. Wholesale plastic pipes are cheaper than with a small order.

The main varieties and their features

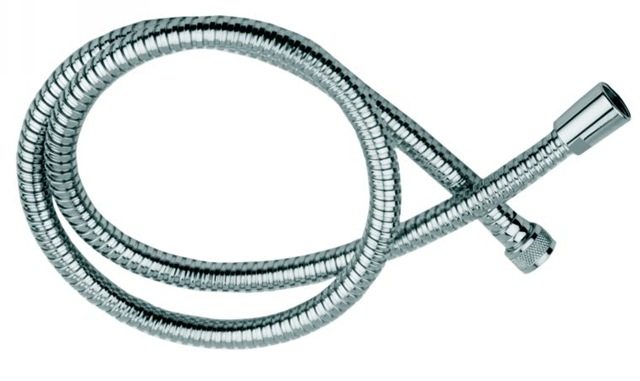

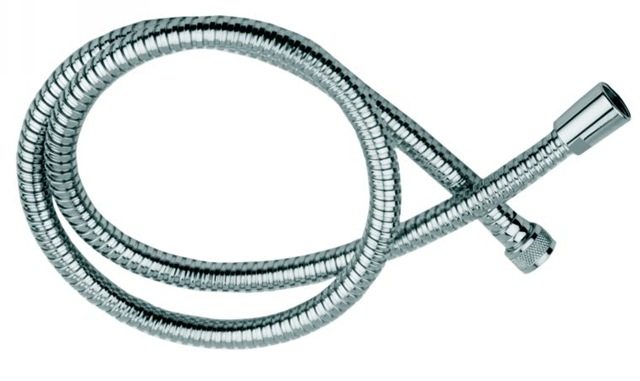

Flexible shower hose

Flexible water pipes are used to connect certain plumbing fixtures to water supply lines.

Among the obvious advantages of this type of connection, we note the following:

- affordable price of the finished result in comparison with the use of rigid communications;

- reliability and durability of the connection, provided that the installation work is done correctly;

- simplicity and ease of connection;

- the ability to perform installation work using a simple tool.

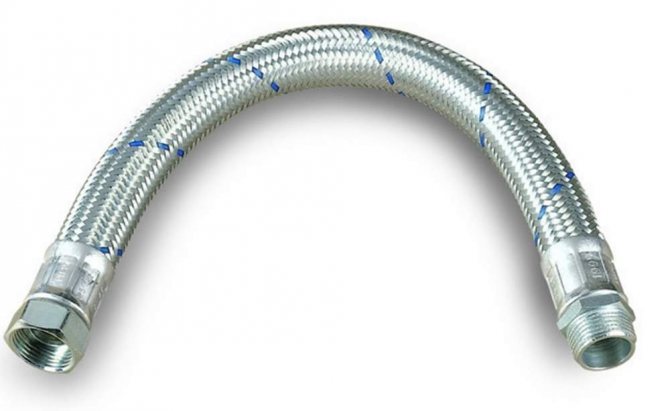

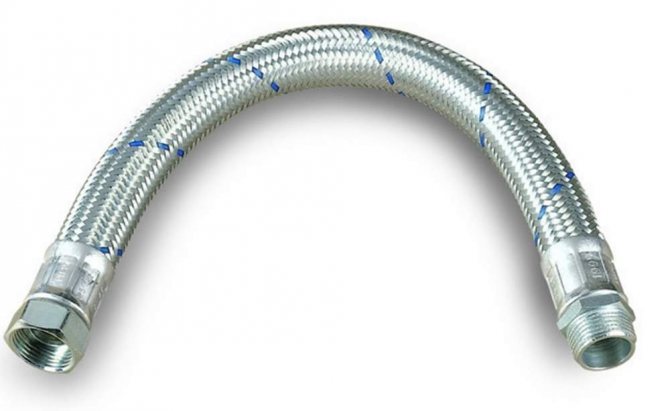

Rubber hoses in a metal braid when arranging a pumping station

One of the important conditions for guaranteeing high quality of the connection is the correct choice of flexible hose.

There are two types of hoses on the market today, including:

- Rubber modifications in a metal reinforcing braid - the most affordable and easy-to-manufacture type of connectors. Due to the simplicity of manufacture, the price of such products is the most affordable. Structurally, the connector is a flexible tube, on the ends of which sleeves are pressed - on the one side with a union nut, and on the other with a union or also with a union nut.

Important: Despite the presence of a reinforcing braid, the rubber core tends to become covered with microcracks after several years of operation, which negatively affects the degree of tightness.

- Bellows modifications are similar in functionality to the previous product category... But there is one significant difference, here, instead of a braid, a wear-resistant corrugated sleeve is used. Another distinctive feature is that the sleeves are not crimped, but are directly welded to the sleeve. Due to these design features, the connectors are more durable and reliable. In addition, bellows connectors are designed for a wide range of operating temperatures.

Characteristics of metal braided rubber hoses

Quality cold water connector

Modern plumbing flexible hose 1 2 ″, as well as similar products with other standard sizes, is a worthy replacement for plastic metal pipes. As already mentioned, the flexible connection allows you to work in cramped conditions, and if necessary, move the connected mixer or sink from place to place without the need for dismantling.

Do-it-yourself ease of installation is ensured not only by the flexibility of the hose, but also by the presence of rubber gaskets inserted into the inner cavity of the union nut and the presence of O-rings on the fittings. That is, by purchasing this type of connectors, you get not only the hose itself, but also fittings for connecting it.

When choosing a flexible hose with a metal braid, you need to pay attention to such points as:

- Temperature limits. Hoses can be designed to supply cold or hot water. Cold water versions have braid with woven blue stripes, while hot water products are marked with red stripes.

- The maximum working pressure is indicated in the marking applied to the sticker, less often the marking is applied directly to the braid.

- The material used to make the tube. Depending on the rubber content, the strength and durability of the rubber can be higher or lower. In addition, there are technical rubber products that smell throughout the entire service life. At the same time, there are products made of food grade rubber, which does not smell and, accordingly, does not have a negative impact on the quality of consumed water.

- The material used in the manufacture of the braid. As a rule, stainless steel or galvanized steel is used for the manufacture of protective braiding. Distinguishing one from the other is easy, since galvanized steel shines less and has a characteristic gray tint. In this case, it is preferable to choose products with a stainless steel braid, since they do not deteriorate longer.

- Length of the product. As a rule, modifications of hoses with a length of 40 cm to 1.5 meters are presented on the market. It is important to choose the right length from the very beginning, so as not to lengthen the short hose later.

- The service life of the product can last from 1 to 10 years. As a rule, the more expensive the eyeliner, the better it is.

Common operational disadvantages

Braid loosening due to twisted hose

What operational disadvantages are most often inherent in a flexible hose based on a rubber hose?

- Insufficient compression of the liner and, as a result, the possibility of leaks. According to statistics, more than half of braided water hoses are made by handicraft using manual equipment and metal sleeves of obviously low quality.

- Deformation of union nuts and fittings during installation work. Such a disadvantage is not common, but it is typical for connecting elements made of low quality metal. For example, to reduce the cost of production, manufacturers of no name connectors make union nuts and fittings from silumin. The use of low-quality alloys leads to the fact that the nuts not only deform, but also crumble.

- Reducing the tightness of the connection due to the appearance of microcracks on technical rubber of low quality. This rule is true both for the tube inside the braid and for gaskets that crack or crumble after a year of operation.

Damage to the sheath near the sleeve

- Braiding unraveling occurs due to corrosion of galvanized steel after a year of operation.

Water pipe breakage can be prevented by using a high-quality flexible hose with non-toxic rubber tubes - EPDM. The braid should be high-density stainless steel (AISI-304). Compression sleeves should be stainless steel and nuts and fittings should be brass.

Important: Truly high-quality branded connectors are supplied to the market with a quality certificate and a passport.

Bellows characteristics

Bellows connectors

High-quality bellows liner on the domestic market is supplied by two companies: PARIGI (TAM model range) and WITZENMANN (Hydraflex brand products).

This type of flexible hose is a stainless steel hose with brass end fittings. Due to the design features and the type of materials used, the liner has a number of characteristic advantages in comparison with rubber hoses in a metal sheath.

Connecting the washbasin to the water supply

Among the advantages of a bellows line, we note the following:

- Long service life, on average, up to 25 years, since the structure does not contain the most vulnerable part - a rubber tube.

- High resistance of the connector to the negative effects of aggressive chemical substances, which is more than relevant, given the composition of water in modern central water supply systems.

- Minimum risk of rupture due to overpressure in the network. It is more likely that the main pipe will be damaged than with a flexible hose, which consists of many peculiar stiffeners that provide high strength and resistance to high pressure and water hammer.

- Minimum chance of connector rupture at the sleeve and sleeve attachment point. If modifications with conventional braiding are equipped with a crimp sleeve, then the sleeve is welded here.

- The hygiene of the bellows liner due to the absence of technical rubber in the design, which is capable of releasing toxins into the transported medium, and simply negatively affect the taste of water.

Installation work rules

Ease of installation due to the elasticity of the connecting sleeves

- Before connecting the liner, we inspect the sleeve for damage to the thread, reinforcing coating, etc. If such damage is found, the hose cannot be used for its intended purpose.

- Half an hour after the end of the installation, we wipe the sleeve and the joints with a dry cloth and thus determine the presence of leaks.

- Try to keep the nuts and fittings from the same material. For example, a steel nut is screwed onto a steel pipe thread. In this case, it becomes possible to prevent the development of corrosive processes.

- The installation instructions for the flexible hose allow installation with a bend radius 5 times the outer diameter of the cross-section of the hose used.

- The sleeve should be loose and not taut or twisted.

- When tightening the union nut, do not apply excessive force (maximum permissible tightening torque - 0.4 Nm), as you can strip the thread, damage the union or push through the gaskets.

- Every six months, you need to inspect the connection in order to timely notice leaks or damage.

Production of a plastic pipe at a plant in the Moscow region.

Plastic pipe production at our plant in the Moscow region it is made from high-quality recycled polyethylene granules, which are pre-checked for the declared characteristics. As additional components, various ingredients are added to them that increase the resistance of the finished product to external influences, giving the technical plastic pipes the necessary performance.

The creation of plastic pipes is carried out by the method of extrusion - extrusion of finished products using special nozzles. Thanks to this technology, pipes of various cross-sections and unlimited lengths can be produced. The finished product is formed under the influence of high pressure, pressing it against the calibrating mold. Our plastic pipe factory is capable of producing any number of custom-made reservoir pipes. The shape of the pipe can be not only round: square and triangular pipes are not all that our equipment is capable of. The answer to the question: "where to buy plastic pipes of our production?" - extremely simple. You can buy our products without leaving your home. Just give us a call and the pipes will be delivered to the specified address. You can save on delivery if you pick up the pipes by self-delivery in the suburbs directly from the plant. You can also order the delivery of a plastic pipe in Moscow: if the products of the required diameter and size are available, we will deliver the required quantity on the same day.

What raw materials are the products in question made from?

The elasticity of flexible sewer pipes depends on the material and design. The material in this pair plays a major role. Polyethylene and polypropylene water pipes are considered practical and reliable.

Polyethylene is a type of plastic that, like any polymer, has the following advantages:

- anti-corrosion properties - the polymer is suitable for “service” in conditions of constant contact with water;

- resistance to chemicals;

- resistance to high temperatures, which makes it possible to use for connecting a washing machine and a dishwasher;

- low likelihood of breaks and cracks in the event of ice plugs.

Polypropylene has the same properties, but also has its own characteristics. This pipe material is capable of operating at the highest possible temperatures, up to 100 ° C.

Thanks to the reinforcement (laying a layer of fiberglass between the layers of the base material), the resistance of the polypropylene water supply system to pressure surges increases.

We note polyvinyl chloride as a popular material for a number of sewer systems, but it is inflexible. Elasticity can only be achieved when making a corrugated pipe. Polyvinyl chloride functions without interruptions at temperatures from -15 ° to + 65 ° C and is not suitable for installation in areas subject to temperature changes, freezing.

Plastic pipes for summer cottages.

Most owners of summer cottages, country houses, cottages prefer to buy a plastic pipe for the following reasons: arrangement of an autonomous gravity drainage system, creating a drain and laying a cable. There are several advantages of using technical plastic pipes when installing a summer cottage sewage system:

- She has no restrictions on the ground, the depth of freezing;

- Installation of plastic pipes is carried out in a trench with a shallow depth;

- Low weight allows to reduce the load on the supporting structures;

- Installation of a plastic pipe in such a system is done manually (low weight), there is no need to use construction equipment;

- Plastic downpipes not subject to corrosion;

- Excellent tightness of all connections;

- To clean the system, it is enough to rinse it with water.

For outdoor drainage systems in the country, gutters and drains are pre-installed, and then a plastic pipe is mounted. For tightness, rubber gaskets are installed in all joints. Installation of such a drainage system can be carried out even in winter, and it itself can be operated for several decades. Plastic pipes for summer cottages are indispensable: only with their help can you make sewers so easily and protect external wiring. Thick-walled plastic pipes are used to create the sewage system. Both thick-walled and thin-walled plastic pipes can be used for cable laying.

Where rigid PVC pipes are used

Rigid smooth PVC pipes are used to insulate various types of wires during the installation of household and industrial communications.

Main areas of use:

- power cables;

- wiring;

- television cables;

- internet communications;

- telephone wires.

Rigid smooth-walled pipes made of polyvinyl chloride meet the goals of isolating wires from external influences as much as possible. They reliably protect communications from mechanical damage and moisture. A distinctive feature of PVC pipes is their ability to self-extinguish (up to a temperature of 650 degrees). They are self-extinguishing, which is critical in the event of a wire fire.

The use of rigid PVC pipes for gravity drainage and drainage systems is possible, but this is an additional area. By their intended purpose, these are electrical materials.

Electrical pipes allow you to lay wires:

- open method - the degree of flammability of load-bearing structures is not limited;

- in a closed way - only into non-combustible building structures or into a concrete massif (to a depth of no more than 1 m).

One or more insulated wires are laid in one pipe.

Note! Do not lay cables in an electrical PVC pipe, the total voltage of which is higher than 1500 V.

Plastic pipes in the apartment and office.

In an office or apartment, technical plastic pipes are used for arranging electrical wiring, computer networks, and for equipping internal drains.

Due to the fact that such pipes are easily mounted in concrete walls, do not collapse with prolonged use, they are indispensable for conducting electrical cables and computer lines in the office. They can be hidden behind plasterboard slabs, suspended or suspended ceilings, in raised floors.

The use of plastic pipes for internal drains in an apartment allows you to provide reliable protection of housing from moisture, condensation and bacteria, does not create problems when repairing with the replacement of components. To connect plastic pipes, special corners are used, which ensure the tightness of the connection. To clean the drain from HDPE pipes when large debris gets into it, special plugs are used.

Rigid metal electrical pipe

Rigid metal piping is usually installed in rooms where there is a high risk of fire or explosion. Such pipes provide maximum protection for the wiring, but are extremely inconvenient for laying. The thickness of the metal rigid pipe protects the electrical wiring from impacts and negative environmental influences. Electrical metal pipes can be made of aluminum or steel. Rigid metal pipe can also be considered to protect the wiring from corrosion. Rigid steel pipe has the maximum weight compared to other types of pipes and has the thickest walls. Aluminum electrical pipes are used to prevent corrosion and are preferred for installations where there is a lot of water. Aluminum pipes are not poured with concrete, as the metal reacts with alkalis in the solution and deteriorates. However, aluminum pipes can be coated with additional protective agents to prevent reaction with concrete when used in concrete slabs or walls.

Plastic shaped pipes.

A technical plastic pipe does not have to be round in cross section. The so-called profile technical pipes can have various shapes. It can be a square, a triangle, a rectangle, or a rhombus. Manufacturers even sometimes have to make custom-made plastic HDPE shaped pipes in the shape of a star.

Manufactured plastic profile pipes made of low-density polyethylene (HDPE) with the use of a special original nozzle for the extruder, and technology and modern equipment make it possible to produce such products for whole kilometers.

XLPE piping

One of the types of plastic water pipes is produced from low pressure polyethylene. These products are intended for various water supply systems. HDPE is an environmentally friendly material, the characteristics of which make it possible to withstand a wide range of temperatures without changing mechanical or other qualities.

This type of pipe is not afraid of exposure to ultraviolet rays, has sufficient flexibility and is resistant to frost. In general, flexible pipes for water supply are quite in demand. Due to its elasticity, the number of fittings can be reduced, which contributes to faster installation.

Joining polypropylene products is inexpensive and uncomplicated. Installation is carried out using diffusion welding or special fittings, both methods ensure tightness.

Required for work:

- fitting;

- rotameter;

- insulating material;

- shut-off valves.

Measurement and further control of the water flow occurs on the inner surface of the pipeline. Thanks to the fittings, it is possible to achieve a reliable bond.Shut-off valves allow you to control the flow of hot or cold liquid, and the insulation serves to protect the water supply from external influences.

When welding polypropylene pipes for hot water, a seam is formed that has a strength exceeding the products themselves - this will require a special device. Depending on the characteristics of the material, they can be used in lines with a pressure of 10, 16, 20 atmospheres.

The price of pipes made of XLPE is much higher than that of other materials. As the manufacturers assure, such products will last up to a hundred years. They offer increased flexibility to accommodate long pipelines with a minimum of joints, thus reducing the likelihood of leaks.

Pipes are sold with a diameter of 1.6 to 6.3 centimeters. They are suitable for arranging hot water supply.

But at the same time, one must not forget that, like any other material, products made of cross-linked polyethylene also have some disadvantages:

- They must not be operated in strong sunlight.

- During installation, it is unacceptable to use glue for insulation - this will lead to premature wear of the product.

When installing XLPE products, it is necessary to use compression and press fittings. Flexible plastic water pipe does not require a lot of time and money for installation, since there is no need to create many joints. And this is essential if the pipeline will be of considerable length.

When installing them in an apartment building, it is recommended to find out the features of the water supply. So, if the water pressure is close to the maximum value that the pipeline will be able to withstand, this can lead to the fact that in the event of a water hammer, the system will not withstand, and this is fraught with serious consequences (read: “What is a water hammer in a pipeline - causes and consequences ").

Flexible materials: Calculation of the pipe reamer when bending.

Therefore, you should not rush, it is better to carefully weigh all the advantages and disadvantages of the products on the market. However, it is undesirable to save on the pipeline, since high performance is a guarantee of a long service life.

Some heating schemes provide for complex sections of the main line. In fact, making them using steel or plastic pipes is problematic, and most often impossible. An alternative is stainless steel for heating: corrugation, corrugated pipe, corrugated pipe. What are its advantages, and what performance properties should be considered before installation?

LLC "Heating Water" offers all its own customers to purchase flexible pipelines of the highest quality and inexpensively. Here you can also order their styling. Additionally, services are provided for laying the heating main.

Flexible pipes, regardless of the material of their execution, are endowed with a number of features. Of course, they are a real lifesaver when laying or replacing pipes in difficult areas. The main advantage of such a pipeline over the others is the ability to bend it at any angle. The pipeline assembled from such elements is completely protected from corrosion. Of course, plastic products are generally not subject to rust formation, while steel products are coated with anti-corrosion compounds.

Among other things, as noted above, flexible pipes are universal, since they are able to withstand not only the pressure of cold water, but also perfectly cope with the supply of hot water. Another advantage of such products is their resistance to water hammer. Speaking about practical application, it should be said that flexible water supply elements easily allow you to include a washing machine or dishwasher in the system, the approach to which is often rather complicated. With the help of flexible pipes, it is easy to insulate the floor, providing the house with a "warm floor" system.

Polypropylene flexible pipes

Among the total number of flexible pipelines, polypropylene options are especially popular. Why is their popularity already so great? There is nothing surprising in this, polypropylene with a heat-insulating coating is able to cope with high pressures up to 10 atmospheres, while short-term pressure can reach 13 atmospheres.

A water supply system consisting of such elements does not pose any danger to people, since when high temperature water flows through it, plastic does not emit any harmful substances. Thanks to this, a person has nothing to worry about. It should be said that the minimum bending radius of a polypropylene pipe does not allow it to be rolled into a bay, therefore pipe sections are sold in 4 meter lengths.

Among all materials, steel is the strongest and most durable. In addition, on the question of which pipes bend well, she is the clear winner. Stainless steel, from which such pipes are made, perfectly resists the formation of corrosion and rust, copes with aggressive substances, and, of course, is an environmentally friendly material. It should be noted that such a water supply system is the most expensive, but at the same time the most reliable.

Steel flexible pipes have the longest service life, which can exceed 100 years. Steel pipes withstand temperature extremes, retain their shape and do not lose their properties and qualities. Installation of a plumbing system from such elements is carried out through the use of steel fittings and sealing materials. Of the tools, the master only needs two adjustable wrenches and a sealant, which are available in every plumbing store.

Flexible materials: Flexible stone technology

The main advantage of flexible pipelines is the ability to bend them at any angle without damaging the wall structure. Thanks to this, they can be used without problems when laying communications in twisted and complex areas.

In addition, flexible lines are not corrosive. If for plastic pipes corrosion is not characteristic of itself, then in the case of steel products, their surfaces are covered with anti-corrosion protective compounds.

Flexible pipes are perfect for laying not only cold water systems, but also hot water supply systems. In addition, they are resistant to water pressure and water hammer, and also have good thermal insulation properties.

Polypropylene flexible pipes for water, heating and other communications are also very popular, which is not surprising: firstly, they have a special heat-insulating coating; secondly, they are able to function at a coolant temperature inside up to 95 ° C; and thirdly, they are resistant to very high internal pressures of the order of 10-13 atmospheres.

Such pipes are completely environmentally friendly, since polypropylene does not emit any toxic products. Their only relative disadvantage is that the permissible bending radius does not allow polypropylene products to be rolled into coils, and therefore they are produced in sections up to 4 meters long.

For the installation of polypropylene pipe products, special scissors are required for their even cutting and a soldering (welding) machine. If the required scissors are not available, then you can use a hacksaw, however, after sawing the products, you will need to clean the cut surfaces from burrs.

Flexible polypropylene pipes are connected by welding (brazing). It is mandatory for the welding process to have fittings that play a connecting role between pipe products. The pipe and fitting are put on the nozzles of the welding machine and heated to the required temperature.

Steel is the strongest and most durable of all materials used for construction and repair work. This also applies to flexible steel pipes, which, along with strength, also have the property of excellent bending. Such pipes are made of stainless steel grades, and therefore another additional advantage is their anti-corrosion resistance.

Manufacturers of plastic pipes in Russia.

The largest volumes of plastic pipes in Russia, which are in great demand in industry, construction and for private needs of the consumer, are produced today in the Central region, as well as in the Volga and North-Western regions. The number of enterprises producing such demanded products is also increasing. This is due not only to the constantly stable growth in demand for plastic pipes, but also to the well-functioning organization of their production, which makes it possible to obtain good products without huge investments. Our factory is one of the leading plastic pipe manufacturing enterprises.

Plastic pipe manufacturers in Russia, they appear and close quite often, which is why constant cooperation is so important. Over the years of our activity, we have gained many partners and a reputation as a reliable manufacturer of technical pipes. Own production of plastic pipes means low prices for plastic pipes and quality assurance. Why buy plastic pipes from Turkey or China? Order Russian pipes: they are not only cheaper, but also surpass their foreign counterparts!

Sale and installation of flexible pipelines for water supply

LLC “Heating Water is a supplier of flexible pipelines for water supply ... That is why we have the most democratic prices. We are ready to offer you high-quality, but at the same time at attractive prices, Flexalen tubes of various markings from direct manufacturers. Close cooperation with factories producing piping systems, including modern flaxalen , allows us not to overstate the cost of the products sold.

Our company offers not only buy flexible piping for water supply, but also to carry out their high-quality installation... If a boiler room requires the dismantling of pipes that have already been used, then our specialists will first dismantle them, and only then will they install new pipes.

If you have any questions regarding products or installation conditions, please call the contact number. We work for you seven days a week. Our managers will comprehensively answer your questions and, if necessary, take an order. Call, order, and our employees will fulfill your order in the very near future. Trust the professionals, buy flexible heating pipes from direct suppliers!

- Flexible heat-insulated pipes Flexalen

Features of products from Flexalen Our country has a very harsh climate, which puts in the first place the solution of issues of heat supply and thermal insulation ... - Correct pipes

Replacing piping systems in the field of heating in an apartment is a rather serious business, labor-intensive and has a lot of subtleties. After all, if you do not spend with ... - Types of heated pipes Flexalen

In order to organize an efficient heating system, cold and hot water supply, without worrying about the integrity and functionality of those ... - The use of Flexalen pipes in the practice of our country

Flexalen flexible pipes are innovative technologies that guarantee you the highest level of reliability. The company has taken care of the comfort of its ... - Insulated pipes Flexalen in production

Today FLEXALEN is one of the most promising fields of activity. The manufacturer Thermaflex is associated with the manufacture and conversion of flexible p ... - Delivery of the heating main to Iksha

The possibility of an involuntary fire or fire are among the greatest disasters that can result in loss of life and significant ... - Insulating material in pipes in Flexalen insulation

Due to climatic conditions, the issue of heat supply and heat regulation is always the main one. For the laying of most of the networks were used ... - Why are Flexalen products suitable for heating mains?

Energy efficiency and energy saving developments bring new technologies and systems to the market. An innovative material that allows you to minimize ... - Heat-insulated pipelines for heating

Heat-insulated network channels are used for the external network of heating activities, when laying water canals, as well as for the air conditioning function. - Flexalen insulated pipes in remote monitoring systems

The operational remote control system is designed to continuously monitor the layer of polyurethane foam insulation throughout the entire time ...

Black plastic pipes HDPE.

The basic color of technical plastic pipes is black. It is in this form that black plastic pipes for sewerage for private houses, for the protection of electrical networks and telecommunications, for ventilation and air ducts, for gutters. However, the use of PE granules of various colors allows us to obtain HDPE plastic pipes of various shades. Such a color difference will be appropriate, for example, for laying electrical cables in the same wall, but going to different consumers.

How to choose the diameter of a flexible hose, taking into account its type

Flexible hose for water consists of rubber hoses in a metal or nylon braid and bellows hose. The flexible water connection has two tips (one for each end of the hose), which provide the ability to connect according to the principle of union-union, nut-nut and union-nut to pipes with a diameter of 1, 1/2, 3/4 and 3/8 inch. The inner diameter of the flexible hose affects the throughput of the hose.

Flexible hose in metal or nylon braid Is a hose made of ethylene-propylene rubber (non-toxic rubber), braided on the outside with stainless steel or nylon thread. This braid protects the hose from water hammer and increases its mechanical resistance.

The material used in the production of flexible liners is safe for health (non-toxic), therefore it is often used in drinking water supply systems. This eyeliner is resistant to high temperatures up to +95 degrees Celsius. These characteristics make it possible to use it in heating systems and in hot water supply.

The high mechanical resistance of the flexible hose allows it to withstand hydraulic shocks (working water pressure up to 20 atm). Depending on the required water flow, the diameter of the flexible hose (flow area) can be different. In water supply systems, a liner with an inner diameter of 8 mm is most often used. A blue braided thread indicates the possibility of its use in cold water systems, and a red one - hot.

The stainless steel sleeve provides a secure connection between the braided metal hose and the nickel-plated brass sleeve. For a more convenient installation of this type of connection, there are two types of fittings equipped with gaskets for a tight connection: a threaded union (for a reliable connection with an internal thread on the connected equipment) or union nuts (for connecting to a pipe with an external thread). When installing a flexible hose in a metal winding, it is recommended to use hoses no more than 2.5 m long. The service life is no more than 5 years.

When purchasing a flexible eyeliner, you must carefully examine the products. The presence of dents, bulges and other flaws on the nut and winding is not allowed. The braid threads must be straight, without protrusions, etc. The fittings must be aligned with the hose. The gasket must not wrinkle or come loose.Deficiencies in the decorative coating are also unacceptable. When choosing a product, ask for a product passport and specify the warranty period. If possible, purchase eyeliner only from authorized dealers.

Bellows liner - sleeve (hose) made of stainless steel in the form of a corrugation. To produce this type of liner, a stainless steel strip is twisted into a tube and welded with a laser beam along its entire length, and then compressed into a corrugation. Rolled sleeves are welded to the sleeve. The service life of such a liner is higher than that of a hose in a metal winding, and can be up to 25 years. Due to the corrugated structure, the bellows liner is capable of withstanding large pressure drops, water shocks and absorbing thermal expansion (it is capable of retaining its properties in the temperature range from -50 ° C to + 250 ° C).

During operation, microcracks are formed on the metal from alternating pressure, which contributes to destruction. Under extreme conditions, a protected version is used - a bellows liner in a metal braid. It is easy to install, it has excellent flexibility and, at the same time, the flow area is not disturbed (at least 11 bends per point).

In addition to the advantages, the bellows liner also has disadvantages. With the simultaneous use of the water supply in the bathroom and in the kitchen, vibration and hum of the corrugated hose are heard, which intensifies with an increase in the water pressure. For this reason, it is recommended to select a flexible hose with a larger diameter. For high water consumption, it is recommended to use a 3/4 ”flexible hose diameter. Another way to combat vibration and hum is to use a plastic-coated bellows that also protects the bellows from damage.

Read the material on the topic: How to choose a flexible eyeliner

Flexible plastic pipe.

The diameter of the plastic pipe determines whether the pipe is flexible or rigid. Flexible technical plastic HDPE pipes (usually of small diameter) are easy to install. With their help, you can quickly and conveniently assemble any system, be it a watercourse, protection for electrical cables or a gravity drain. Flexible plastic pipes, for example, can be bent 90 degrees (radially) without difficulty, without heating and without fractures, laying a cable route in concrete for monolithic housing construction. To cut such a plastic pipe, you can use an ordinary metal hacksaw, a simple knife or a special device. Rolled into coils, these pipes are easily transported and stored without taking up much space. Flexible plastic HDPE pipes are usually connected to fittings and accessories with clamps.

What to look for when starting installation

In order to avoid breakdowns, leaks and blockages in the future, pay attention to the nuances of installation and features of use:

- Avoid mechanical damage during transportation, storage and assembly. Do not expose parts to open flames.

- For a high-quality connection, lay the gasket at a temperature above + 5 ° C.

- The sewer must be located at a slope. Taking into account the high rates of internal permeability of flexible pipes, a slope of 2-3 cm is sufficient.

- When installing, avoid turns of 90 ° C or less, which lead to blockages. If such turns are necessary, use high quality polyethylene corrugated pipe.

- Avoid bending during long runs along the walls; additionally install brackets and holders.

- Do not use soldering during assembly in the case of free-flow water flow, this will only increase the complexity and cost of installation work.

- When installing plumbing underground, in walls and floors, consider the possibility of expansion of certain areas due to temperature.

- When installing outdoor areas, carefully study the instructions, which describe the possible depth of installation.

- Required materials and tools: angles, fittings and couplings. Auxiliary tools: shovel, drill, hammer, screwdriver, screws and dowels.

Rigid plastic pipes.

Rigid plastic HDPE pipes, unlike flexible ones, can only be used in straight sections. Large plastic pipes are generally rigid and cannot be coiled. In them, you can effortlessly, it is convenient to lay an electric cable or telephone line. At the same time, accidental damage to the insulation is completely excluded, thanks to the absolutely smooth inner surface. Very often, rigid HDPE pipes of small diameter are used to lay electrical cables along the outer (front) part of the building to power lighting systems or burglar alarms. Large-diameter plastic pipes are used in the laying of sewers. When installed in the open air, it does not disintegrate under the influence of sunlight and precipitation, does not lose its strength characteristics even in winter. Rigid plastic pipes are connected, as a rule, by gluing, soldering or welding. Also, the connection of a plastic pipe can be made using a fitting.

Metal-plastic and PVC products

This is the most popular type of flexible pipe. They are especially often used in the arrangement of water supply lines. In particular, flexible plastic water pipes are suitable for installing not only cold water lines, but also hot water supply lines.

To connect the plastic pipes together, you need special scissors or a hacksaw, sandpaper, cleaner, glue and a brush. If the cutting is done with plastic scissors, then, as a rule, additional processing of the cut places is not required. However, in the case of using a hacksaw, the end sections have to be cleaned with emery paper from irregularities and burrs.

After that, processing of the ends of the products to be joined with a cleaner is required. This facilitates softening of the surface layers and greater penetration of the adhesive.

Next, the outer surface of the pipe and the inner surface of the fitting are processed with glue. The pipe is then inserted into the fitting and rotated internally by about a quarter of a circular arc. This contributes to a more even distribution of the glue over the surfaces of the products and greater bond strength.

The adhesive used for joining PVC pipes has some features. In particular, it somewhat dissolves the surface layers of plastic products, after which the dissolved substance, mixing with it, forms a homogeneous mass with high strength.

Flexible pipes made of metal-plastic are also found on the market of repair and construction materials, and have a number of positive characteristics, such as:

- high resistance to pressure inside the pipe;

- increased resistance to mechanical stress;

- ease and ease of installation;

- wide range of operating temperatures (from -15 to 60 ° C).

The assembly of structures from metal-plastic pipes does not present any particular difficulties and is most often carried out by means of threaded fittings.

When arranging pipelines, the following materials are used:

- metal-plastic;

- polyethylene;

- polypropylene;

- polyvinyl chloride.

The type you need can be selected by its appearance - by the color of the pipe or the colored stripe on it. For example, if the product is blue, or such a strip passes through it, then it is intended for cold water supply. Red tubular products are used to create underfloor heating, white - heating system and hot piping. The yellow pipe is for gas supply.

The plastic water pipe has many advantages:

Flexible materials: Flexible hose for faucets and toilets

- Strength.

- Durability.

- Elasticity.

- Low weight.

- Does not change the chemical composition of the flowing liquid.

- Low degree of thermal conductivity.

- Ease of installation.

Technical parameters are specified in the product regulations.

As for the shortcomings, there are very few of them:

- restrictions on the temperature of the environment;

- possible difficulties with the installation of fittings;

- differences in the laying of different types of pipes.

Plastic pipes for water are also widely used, for the manufacture of which aluminum is used. Multilayer metal-plastic products are ideal for both water supply. The outer and inner layers are made of plastic, and there is an aluminum layer between them. The weight of such pipes is small, and the strength is significant.

The disadvantage of metal-plastic products is the difference in the compression rates of aluminum and plastic in the event of a sharp jump in temperature. The aluminum layer has a higher speed and for this reason, the strength of the pipe joints in combination with high pressure decreases.

Rectangular plastic pipe.

Rectangular plastic pipe is one of the varieties of shaped polyethylene pipes. It is made using a special original nozzle for the extruder. The main purpose of this pipe is air ducts, although it can also be used to equip external watercourses in private houses. Due to their rectangular shape, such air ducts are easy to install, they are easily attached and rest on any surface: walls or ceiling. Rectangular plastic pipes are compactly placed in residential and industrial premises.

Round plastic tube.

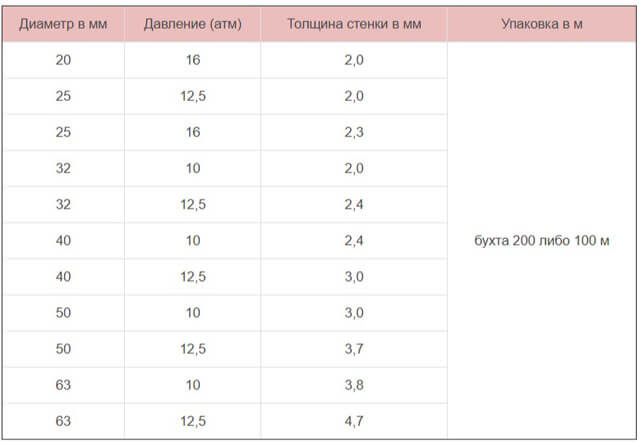

Round plastic pipe is the most common type of product of specialized enterprises. Small diameter pipes (from 20 to 63 mm) made of this material are perfect for laying electrical cables, telephone and computer lines, they can be used to equip an internal drain in an apartment or house.

Round plastic pipes with a diameter of more than 75 mm can be used for external gutters of summer cottages and country houses. They are used to make air ducts in residential and industrial premises. Compared to metal, ventilation systems made of plastic pipes are much lighter and more durable, cheaper in price, and look more modern. They can be used in humid rooms, in places with aggressive environmental conditions.

Classification

Manufacturers offer standard smooth-walled electrical PVC pipes with a diameter of 16 to 75 mm. The minimum size is used for laying household communications, in conditions of low external loads. A diameter of 20 mm is popular for laying telephone, television, Internet cables in an open way. Materials of maximum diameter are intended for laying electrical wires in conditions of increased fire hazard, in rooms with explosive materials.

Note! Tubes from 8 mm to 250 mm in diameter can be made to order.

Standard products are dark gray. Materials of any color are made to order.

Depending on the wall thickness and resistance to loads, according to GOST 18599-83, rigid PVC pipes are divided into 4 categories, each of which has its own marking. Namely:

- T - heavy;

- C - medium;

- SL - medium-light;

- H - non-standard.

We recommend that you familiarize yourself with: PVC-U casing pipes for well arrangement

Standard lengths are 2, 3 or 6 meters, with a tolerance of 50 mm. New pipes are laid in bundles, packed in polypropylene film.

Technical non-pressure plastic pipes.

Non-pressure plastic pipes are used for external sewerage - transportation of domestic wastewater from buildings and private houses to drain wells. They have a smooth inner surface that prevents the formation of deposits, are highly inert to microorganisms, and perfectly resist wear under the influence of aggressive media (alkali, acid, etc.).A distinctive feature of such plastic pipes is their increased elasticity, which allows them to be used even at negative temperatures, after which they take on their original shape. Another advantage is their low thermal conductivity, which does not contribute to the formation of condensation on the outer surface of the pipes. Sewerage made of non-pressure light plastic pipes is easy to install: they are connected to each other through a socket and a rubber sealing ring.

Product characteristics

Rigid PVC pipes share all the advantages of modern plastic materials, plus specific characteristics (for example, they do not spread combustion) that explain their electrical use.

They have:

- light weight;

- high chemical inertness, which makes them invulnerable to moisture;

- service life over 50 years;

- low cost;

- aging resistance.

We recommend that you familiarize yourself with: Types of plastic taps and their application

PVC pipes are manufactured according to certain technical conditions (TU) and state standards (GOST). Electrical PVC rigid pipe materials come in several varieties, each of which has its own requirements developed and documented. For example, the requirements for the flammability of electrical materials are regulated by GOST 30244, the requirements for the flammability of GOST 30402.

Specifications:

- resistance to mechanical shock is from 10 to 20 N / m, depending on the type of pipe (light, heavy);

- protection against penetration of water or dust into communications according to GOST 14254 from ip 65 (with high-quality installation, the degree of protection rises to ip 67, which means safe short-term immersion under water up to 1 m depth);

- resistance 100 mOhm when exposed to voltage of 500 V;

- material elongation at break up to 30%;

- retain dielectric properties at a current frequency of 50 Hz and a maximum voltage of 2000 V;

- operating temperature from - 25 to +60 degrees.

All characteristics for each type of PVC pipes are indicated in the accompanying documentation - a quality certificate. The absence of such a purchase may indicate an unscrupulous manufacturer and low quality pipe material.