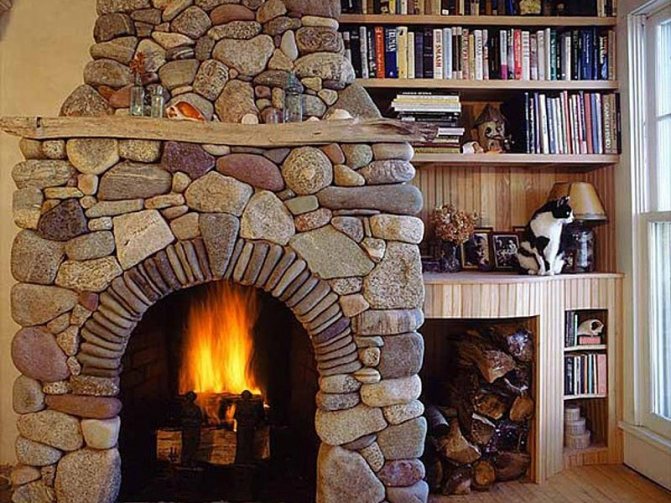

Since ancient times, man has been enjoying the contemplation of fire. Having learned how to build a dwelling, he happily brings a fire into his dwelling, in the form of a hearth. They rest and warm themselves near the fire, cook food on it, and also hold fascinating conversations with the family and with friends. Nowadays, the fireplace serves as a kind of natural fire.

In this article, we will consider the independent manufacture of a foundation for a fireplace, as well as many other interesting issues related to the preparation of a foundation for construction.

Safety engineering

First of all, it is necessary to choose a suitable place that meets the fire safety conditions.

The fireplace is a source of open flames and embers can ignite with a slight draft. Therefore, it is not recommended to place it opposite windows and doors.

There are a number of rules that should be followed:

It is prohibited:

- Place the fireplace on a floor covering, as it is usually heavy and can push through the floor slab.

- Install a large fireplace in a small room of a wooden house, with a total area of less than 11 m2. It burns oxygen and dries out the air, thereby harming the house and deforming the connection of logs and planks.

Fireplace that does not require a foundation

The preparatory work associated with pouring the foundation is a very long and laborious process, but is it possible to somehow make your life easier and do without a base for the fireplace? Yes, it’s quite possible. Only such a device is called completely differently.

In everyday life, a fireplace without a foundation is the most common stove-stove, which is familiar to every second Russian since childhood. It is a heating device made of metal that works properly on wood and coal, i.e. solid fuel. The device is installed directly on the floor plane.

In the process of using heating equipment, some models allow not only to maintain a comfortable temperature in the room, but also make it possible to cook food and just admire the flames.

The aesthetic design of a modern stove-stove can be made as a decorative portal made of plasterboard, concrete or natural stone, and the stove can also be decorated with wood. Such decorative elements make it look like a classic type fireplace.

Construction technology

When choosing a foundation project for a fireplace, it is worth considering the following data:

- the mass of the fireplace, its dimensions;

- soil characteristics (soil type);

- earthworks.

Considering that the fireplace is heavy and large, its foundation is poured regardless of the base of the house. The distance between the walls of the bases, that is, the gap, must be 50 mm. The gap is filled with a mixture of crushed stone and sand.

It is important to follow this technology, since each foundation has its own specific gravity and its own shrinkage time.

On clay soil, the foundation gradually subsides and deformation occurs, which leads to its destruction. Therefore, it is necessary to build a foundation on a sandy base, then the soil is compacted under the influence of the gravity of the structure.

It is advisable that the main foundation is 20 cm below the freezing of the soil, since movements and swelling are possible in the winter months.

Why do I need a separate foundation for a fireplace

In practice, you can find cases when the owners of the house consider it optional to equip a full-fledged foundation under the fireplace.Often people simply confine themselves to props in the basement, but then over the years they begin to notice that the masonry is gradually collapsing and the fireplace requires a separate foundation. The most reasonable solution is to lay the fireplace foundation in parallel with the implementation of the main foundation of the house. This will save money, time and labor. But it is a mistake to believe that it is possible to make these two foundations a single whole, because they are designed for different loads and, as a result, give a distinctive drawdown. That is why the bundle of the foundation for the house and the fireplace base is strictly not recommended. There must be a gap of at least 50 mm between the foundations, which is filled with compacted sand.

Foundation for light fireplaces

To evenly distribute the load, it is necessary to dig a pit with an ideal horizontal plane and the desired dimensions.

When mixing the concrete mixture, it is necessary to maintain the following proportions: 1: 2: 3, where 1 part of cement (m-500), 2 parts of sand, 3 parts of crushed stone. The amount of water for filling the mixture is poured at the discretion of the master.

The ready-mixed concrete is poured onto the bottom of the pit 15 cm thick.

A stone (river, hard sandstone or even old broken concrete) is laid in this mixture. It is undesirable to use broken brick, since it consists of clay, and this is a fragile material for filling the foundation for a fireplace, it can crack.

A concrete mixture is poured over the stone.

For the above-ground part of the foundation, a formwork of the required size is installed, its sides must be strictly vertical. Then the filling continues in layers to the desired height, the base horizon is checked with the building level.

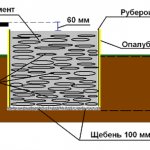

Explanation: floor level (1), brickwork (2), shut-off waterproofing (3), mortar screed (4), fraction (5), foundation pit (6).

Lightweight foundation

The lightweight foundation is laid on the basis of a sand cushion. This option is suitable for non-porous soil. First of all, a pit is pulled out with a depth of about one meter. The first layer is sand, which is filled with water and compacted. Then we repeat this procedure until a distance of about 300-500 millimeters remains to the floor level.

To give the foundation strength, crushed stone, broken stone or brick is used as the top and final layer.

Also, the foundation will be needed not only for buildings located inside a closed space, but also for street buildings. Such outdoor stoves and fireplaces may have a slightly simplified design, and the chimney may be shorter or simply absent.

Since street structures are in the most unfavorable conditions all year round, you will need to acquire foundation blocks to create the most solid, stable and durable foundation. With the help of such a material, the surface is perfectly flat, without much effort.

The sequence of assembling a fireplace from ready-made gas blocks

- We are building the foundation.

- We moisten the finished blocks.

- We fix the chimney at the height indicated in the instructions, leaving the outlet open. On the DSP we attach sheets of mineral wool along the entire length of the chimney.

- We install the blocks on top of each other without adding DSP and mark with a construction pencil the size and location of the smoke hole. We cut it out using a grinder with a diamond disc.

- We install the blocks on the fireplace table made of iron sheet, fastening them with a mixture of clay and sand.

- We insert the finished podzolnik.

- We lay out the fireplace chamber.

- We fix the plate.

- We make the cladding with bricks.

Even a girl can easily handle the laying of such a fireplace, as shown in the next video.

Types of fireplaces

Stoves and fireplaces are used not only for space heating. They create a comfortable, warm atmosphere in the house and are used for cooking.If you look at the flickering flame for 15 minutes, fatigue disappears and your mood rises.

The construction of such a structure must be approached with all responsibility. An obligatory step is the installation of a chimney and the construction of a reliable foundation. The room in which the fireplace is installed must be of sufficient space.

It is easiest to foresee the presence of a fireplace during the construction phase. You can, of course, build the structure into a previously built house, but this will require additional financial and labor costs.

Types of brick fireplaces and their characteristics are presented in the table:

| № | Fireplace type | Specifications |

| 1 | Angular | They are mounted in one of the corners of the room. The firebox is located diagonally. The smoke chamber is arranged with inclined walls, the chimney is mounted inside the fire-resistant wall. Heats two rooms at once: in which it is located and located behind the wall, by the fireplace. |

| 2 | Built in | Erected only at the stage of building a house. It can be built into a wall, a column, a non-combustible thick partition. The advantage is that it does not take up much space. Not suitable for use in wooden houses. |

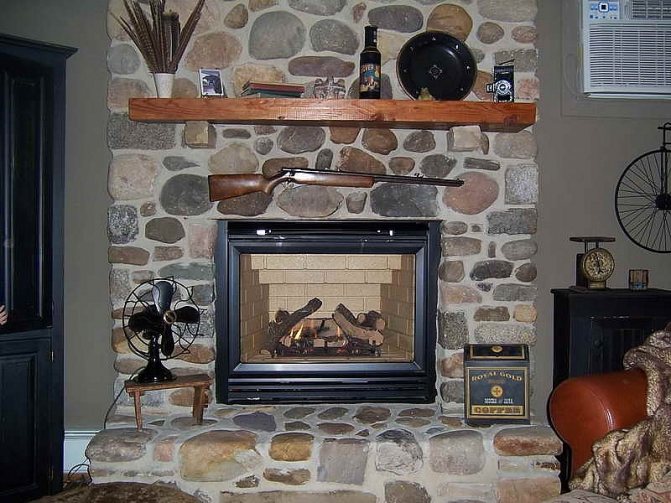

| 3 | Wall-mounted | It is used for large rooms, as it has significant dimensions. Typically, the structure occupies the entire wall area. A chimney is arranged on the outside of the wall. |

| 4 | Ostrovnoy | Installed in the center of the room or in any part of it, has open approaches from all sides. This design takes up a lot of space. Do not mount the fireplace near walls built of combustible materials. If the proper distance is observed, it can even be installed in a wooden house. |

When entering a fireplace construction project, all fire safety requirements must be observed.

Art-concrete in the interior with a biofireplace

We found 18 photos with current designs.

Art concrete and brick

In a spacious fireplace room, there is no need to choose between concrete, brick and stone. They go well with each other.

A fashionable concrete fireplace is not a reason to abandon the classic brickwork

Tiles or plaster for microcement will easily make friends with stone finishes.

Especially impressively, concrete will complement the hearths of an unusual complex shape. The interior by Alexandra Afanasyeva is decorated with an L-shaped corner burner.

Art concrete and wood

A more comfortable, but no less modern duet - concrete and wood. The combination is successful both for finishing a niche for a biofireplace, and for the room itself.

The concrete hearth visually warms up if there are wooden surfaces nearby

The array can be replaced by MDF plates or porcelain stoneware with a wood pattern.

Wood-like porcelain stoneware is useful for low shelves above an open firebox. Unlike MDF and wood, it is not afraid of overheating.

Bright colors

«A warm palette will help to cheer up the strict finish. For the fireplace area, fire shades are suitable: orange and yellow, red and pink.

A gray concrete wall is a great backdrop for both living flames and bright colors.

Paintings and graffiti, bright pillows and green plants will add coziness and colors.

You can inexpensively replace graffiti from a design project with vinyl decoretto stickers, and vertical landscaping with flowers in pots.

Shades of gray

An expensive look of a dull mantel will provide a difference in textures. Smooth and rough tiles of the same color will become the backdrop for art objects.

A single-colored recreation area with a biofireplace will be decorated with a combination of materials and decor

Paintings will replace open shelves and shelves for your favorite books and souvenirs.

A spectacular interior without figurines will be supported by an unusual round biofireplace. The flame in it will seem brighter if you add stemalite to the hearth or paint the backdrop black.

Concrete and machinery

A calm background will stylishly complement a built-in fireplace, a TV, and a computer, even if you place all of the above on one wall.

A biofireplace and modern technology can be easily combined with a concrete finish.

The "brick" ledge and "chimney" of the portal in the photo mask communications.

Any metal fragments will support the combination: from track lamps on the ceiling to thin furniture legs.

Concrete and leather

Leather will help make budget cladding luxurious. Today it is found not only on sofas and armchairs, but also on the walls of the mantel.

A concrete niche for a biofireplace will become solid if the interior is complemented by leather details

The photo on the left is decorated with smooth husky furniture, and on the right - velor wall tiles.

If desired, you can also trim the box under the hearth with leather. But the ideas in the photo are more practical: inexpensive leatherette is suitable for them.

Sofa by the fireplace

Leather or textiles for the sofa are selected in the same shades as art concrete. Large bright furniture is rare in design projects.

Universal option for a concrete fireplace - gray rectangular sofa

The texture of the upholstery is the opposite of the finish of the hearth: smooth material is combined with relief.

But small poufs and armchairs are distinguished by a pattern or color. In the interior in the photo a separate resting place is supported by wooden details.

Furniture "under the concrete"

You can get a concrete fireplace in 4 ways: clean and varnish a real wall; decorate a niche with decorative plaster or tiles; use MDF painted "like concrete".

Not only tiles and plaster, but also MDF panels can make a fireplace "concrete"

The framing for the hearth and the facade of the low pedestal in the photo are made of the same material.

The latter option is dust-free and suitable for compact apartments.

Niche or portal?

The "concrete" biofireplace in the portal will reduce the time for finishing and cleaning. It is enough to place it on a smooth wall and play with accessories.

On sale there are both finishing materials and ready-made fireplace portals "for concrete"

The manufacturer's version does not change the appearance of the walls and is simply assembled according to the instructions.

The combination of concrete with a smooth surface is also suitable for a built-in hearth in a small area. Ceramic firewood for the furnace will add comfort.

Biofireplace table

If time is not a pity, an exclusive biofireplace table can be made of concrete and a burner-furnace. The massive suburban version is assembled from building blocks, and the elegant office one is cast in a special mold.

A modern biofireplace table made of concrete can decorate an apartment, office or a summer terrace

Built-in burners or tabletop bio fireplaces made of glass will add fire to it.

To inexpensively and quickly repeat the effect on the photo, just put the glass bio fireplace on the finished concrete countertop.

Spectacular view

Fireplaces made of glass and concrete work both indoors and outdoors: they are not afraid of the vagaries of the weather. Pass-through models look especially stylish next to large display windows.

Concrete bio fireplaces with simple geometry will harmoniously complement the urban landscape

They will emphasize a spectacular view from panoramic windows or a well-groomed landscape.

Traditional curtains in trendy mantels are replacing weightless curtains-threads or blinds with vertical rise.

Creativity

A living flame in concrete will also decorate a small room. The basic principle is this: the smaller the area, the lighter and neater the finish. One wall is enough for a hinged hearth or a desktop biofireplace.

A mini-bio fireplace made of concrete is suitable for a compact seating area - ready-made or personally created

For a model without protective glasses, we select a burner and a container of the required size.

Place the mini-burner in a concrete planter, fill it with sand and add decorative stones. The hearth for a terrace, balcony or low table is ready!

Other articles will tell:

- about "transparent" concrete and leather in the interior of the fireplace;

- how to make a country biofireplace, concrete decor and art concrete;

- how to choose a biofireplace for embedding and beat an open firebox.

Successful solutions and stylish interiors!

Dignity

Fireplaces made of concrete blocks or rings have a number of advantages. First of all, it is the simplicity and speed of the construction of the structure, because even a beginner can handle these works. The manufacturer describes in detail the sequence of actions in the attached instructions.

Concrete is a durable material that is resistant to temperature extremes and moisture. Various additives are used to enhance these parameters. The listed qualities make it possible to build street models of fireplaces from concrete, which are so necessary for relaxing in a country house.

A concrete fireplace copes with heating the room, as it removes heat well into the room. Due to its high thermal conductivity, energy penetrates through the walls of the fireplace into the surrounding air, heating it. But it should be borne in mind that for the same reason, such a fireplace will cool down quickly.

Fireplaces made of concrete rings

Currently, a wide selection of building materials allows you to select any components according to certain criteria. Concrete rings made from refractory mixes are ready for use in the harshest high temperature conditions, which means that such rings can be used to make a fireplace.

Manufacturers produce tiles and rings, which are assembled according to the instructions into a single product. Since the concrete fireplace is quite massive, it is unrealistic to transport it in one piece. The modular design allows you to quickly assemble a device that will have the same properties as a classic wood-burning fireplace.

Construction of a fireplace made of concrete in a finished room

- Preparation consists in dismantling a part of the floor and digging a pit to a depth of at least 500 mm. In a two-storey house - from 700 to 1000 mm. To mark the boundaries of the foundation, take the dimensions of the fireplace table and retreat 220 mm on each side.

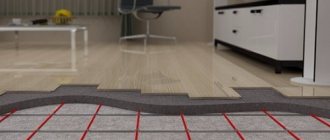

- When arranging a fireplace on the second floor, I-beams are used, which are mounted in the main walls to a width of 1.5 bricks. For light models, it is enough to strengthen the logs.

- Construction of the foundation. As a material for masonry, rubble or red brick is used. Its height should not be higher than the floor and it is imperative to have waterproofing to prevent moisture from entering the subfloor. When constructing a foundation made of rubble, the upper two rows are laid out with bricks. For the construction of a concrete foundation, a special solution is prepared with the addition of a sand and gravel mixture, which should be four times more than Portland cement. This solution should be reinforced with a reinforcing mesh. It can be bought ready-made or welded from metal bars with a cross section of 8 mm, soldering them together at a distance of 100 or 150 mm.

- After hardening, we begin to build a fireplace table made of concrete or special refractory bricks, to which the pre-furnace site is adjacent.

- We lay out the side walls of the fireplace.

- We are building a fireplace chamber. To connect the finished blocks, a mixture of one part of sand and cement and six parts of sand is used.

- We install a stove with a hole for a smoke collector. The latter is attached with a 1.5 cm thick mortar.

- Mantel. As a finish, it is worth abandoning ceramic tiles, as they may not withstand high temperatures. Usually brick or stone is used in such cases. Place it in the same way as when building a house - with an offset of half a brick.

Concrete fireplace rings

Prefabricated concrete fireplaces

Modern building materials provide a wide selection of individual pieces for the manufacture of prefabricated fireplace structures. For example, in the form of concrete rings and slabs, which are made on the basis of a refractory mixture. One of the advantages of a prefabricated fireplace is the fast delivery and installation process.

Concrete fireplaces assembled from blocks are harmoniously combined with natural wood in the interior

An open hearth can be quickly built from concrete rings in the house area.

Photo of a hearth made of concrete rings

There are several options for manufacturing the structure - you can choose the required depth and type of rings so that the hearth is high or low. He can just stand on the ground or be partially rooted to the ground.

You can decorate concrete rings with artificial or natural stone.

The process of assembling such a fireplace consists in placing the rings on top of each other, connecting them with cement for strength. The hearth is decorated with a stone. It will acquire a neat and finished look if the stone is laid out not only from the outside, but also from the inside.

Important! When the rings are decorated with stone internally, the diameter of the firebox will decrease.

Making a concrete hearth with natural stone

Particular attention should be paid to the area around the hearth. The floor is leveled and tiled, garden furniture is installed - wicker or wooden chairs, benches, tables, sometimes they arrange a canopy that reliably protects from the rain.

Foundation preparation and assembly

Concrete bench with hearth

Concrete fireplaces begin to be installed with the preparation of the foundation. It is better to do this work at the stage of building the house, but sometimes the decision about the need for a fireplace in the house comes later, when the house has already been built. In this case, you must first dismantle the floor.

Important! The foundation of the fireplace should not have common bonds with the base of the house - this will ensure the integrity and safety of the structure with natural shrinkage of the walls of the building.

Concrete fireplace in a modern living room

The work is performed in the following sequence:

- It is necessary to dig a pit, more than ½ meter deep and with an area slightly larger than the dimensions of the fireplace body;

- A sand-crushed stone pillow is laid out on the bottom;

- The cement-sand mixture is prepared in a ratio of 1 to 4, and poured into the pit;

- The upper rows (2-3) are made of bricks, laying roofing material between the masonry and the solution to drain moisture;

- The foundation should not be above or below the level of the floor covering;

- After erection, the base plate is left for a couple of days to freeze the mortar.

Concrete fireplaces in classic design

The chimney can be a separate structure with a smoke hole at the bottom, or be built into the wall structure when it is erected at the stage of building a house.

- In order for the hole in the fireplace to coincide with the chimney, the concrete ring must be attached to the wall of the chimney without using mortar, and the edges of the hole must be marked.

- You can cut a concrete product using a grinder and a special circle. The work on the construction of the fireplace is performed after the chimney is ready.

Modern concrete portal

- For the first two rows, which are not exposed to high temperatures and perform the function of an ash pan, when laying, a cement mortar is used, to which lime is added.

- For further installation, a solution of clay is used, which is crushed, after keeping it for a couple of days in water.

- The resulting mixture is passed through a mesh and mixed with sand. An elastic mortar is applied to the rings during operation, checking the position of each fragment with the help of a building level.

Advantages of the material and features of construction in the house

A natural stone fireplace is, of course, very beautiful. However, it is not easy to execute and costs quite serious money. Concrete in this case will save money and time.

For the manufacture of the fireplace portal, a special durable concrete mixture is used, for example, fiberglass concrete - a material reinforced with fiberglass. This material is capable of withstanding heavy loads, but at the same time it is lightweight and economical.

From concrete, you can create not only a portal, but also internal walls, as well as a mantel.In the right hands, concrete gives a huge field for experimentation: modern finishing technologies allow you to "turn" it into any material. The texture of natural stone - limestone, sandstone, granite - will be visually indistinguishable from the real one. This is a real find for an interior designer.

The construction of any fireplace begins with the foundation. After you have decided on the place and size of the fireplace (or rather, its base - the fireplace table), you need to dig a hole that will exceed the parameters of the table by 15-20 cm. The bottom of the hole must be covered with sand or a mixture of sand and gravel (this depends on the properties of the soil). The height of the sand cushion is from 10 to 70 cm, depending on the soil. The sand layer should be perfectly flat and well compacted.

After that, concrete is poured into the pit. The best option for a home fireplace is to mix Portland cement and a sand and gravel mixture in the proportion ¼. One layer is poured with this mixture, then a metal grating is placed, and on top - a second layer of concrete. It will take a couple of days for the foundation to solidify. After that, you can build a fireplace chamber, firebox, shelf and portal.

Concrete will allow you to make a portal of absolutely any shape and type. Today, ascetic monolithic portals, claddings of a classic look with columns and ornate patterns, rough "brick" (concrete imitation) or with a texture of natural stone are popular.

By the way, the concrete portal can be purchased ready-made.