- 1 of 1

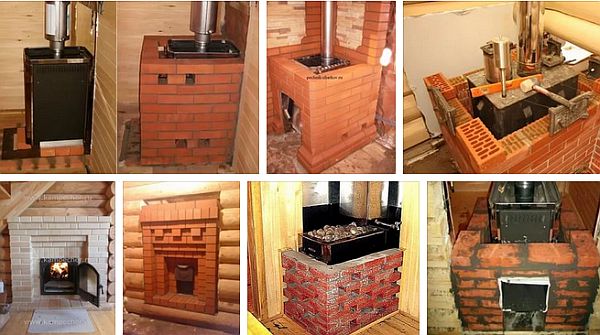

On the picture:

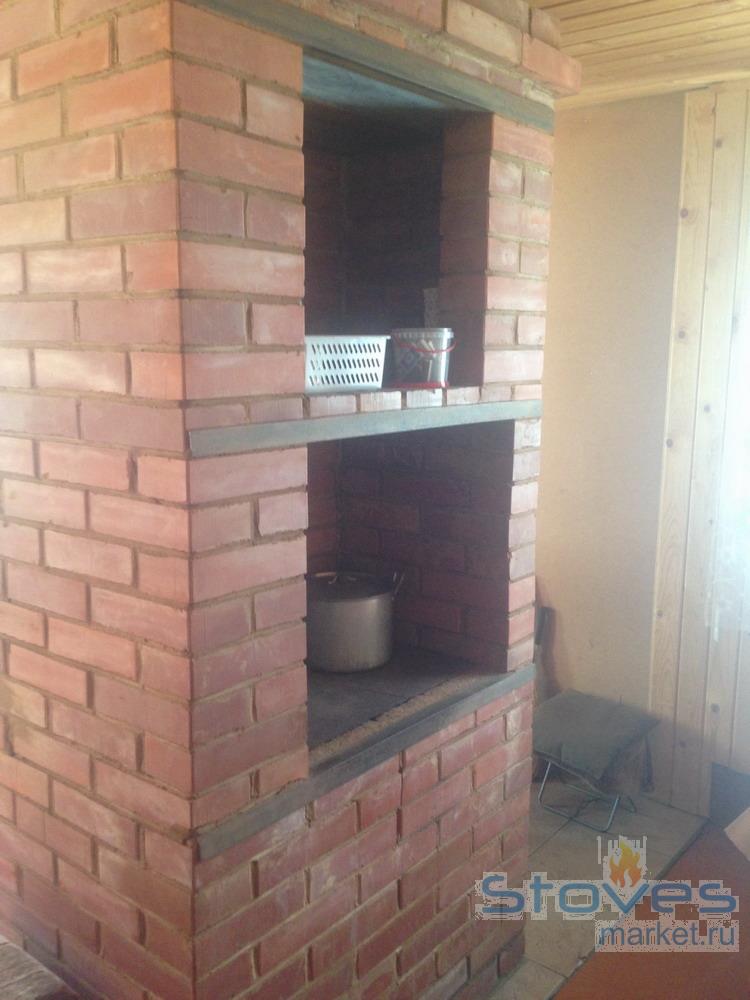

In terms of size, masonry ovens are almost always superior to factory-made metal ovens.

Gas heating is not possible in every country house. And often you have to choose between heating with electric heaters, boilers with imported fuel (liquid, solid) or stoves. But even if the choice is made in favor of stove heating, it is not clear which type of device should be preferred: a masonry (brick oven) or a ready-made (metal) stove?

There is no definite answer to this question. Each design has its own advantages and disadvantages. Therefore, you should proceed from what heating capabilities are required in your particular case.

On three sides.

The rule "only heats his room well" applies equally to both the finished and the brick oven. But the construction of a brick oven is usually built into interior partitions. Moreover, they try to do so that its facade and side walls go out into three rooms. And with the right design, the masonry stove gives off heat evenly to all three rooms.

Pictured: A stove built by the Masonry Heaters.

Heated area

It must be admitted that both a brick stove and a metal stove are not the most effective means of heating houses with an area of more than 60 m² (with a ceiling height of up to 3 m). Practice shows that the stove will "cope" with such a volume of air only during off-season periods. It is difficult to achieve a comfortable temperature throughout the house when the outside temperature is -10 ° C. Or it is necessary to install several stoves in different parts of the house.

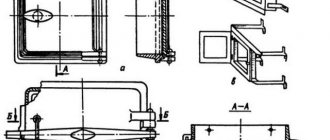

Do not be fooled by the advertising promises of some metal ovens. Statements that the stove is capable of heating 100 m² or more imply a single room not divided by partitions into rooms. A metal stove - a potbelly stove or a fireplace stove - successfully heats only the room in which it is installed. Special convection heating ovens are able to heat several interconnecting rooms, but the temperature between the room in which the oven is installed and the adjacent one will vary greatly.

- 1 of 1

On the picture:

Heating scheme for several rooms with one stove.

Cast iron stove

Many have heard about the advantages of cast iron as a material. And in fact, what they say about him is not in the least exaggerated. Due to its porous structure, cast iron perfectly tolerates heat, practically without deforming and without losing strength.

In addition, cast iron is famous for its amazing heat capacity, which is especially important for the production of furnaces. Even after stopping heating, this material continues to give off heat to the environment for a long time.

Among other things, it is worth paying tribute to the build quality of cast iron stoves. Unlike steel, cast iron is difficult to weld, so all elements of the furnace are cast, and then connected by dad / mom grooves. This is a big argument in favor of durability - products last much longer than welded steel.

One of the important factors is the presence of a heater where the stones are heated. For example, Vesuvius stoves, which do not have a stove that is heated by fire, and stones are poured onto the stove with a shaft and, as a result, poor heating of the stones and wet steam. Light steam is obtained from stones heated to over 300-350 degrees. But such simplified ovens are cheap.

Cast iron grade - most manufacturers cast furnaces from gray cast iron grades SCH15, SCH20, SCH25. The real resource of such stoves is 10-20 years, and with a careful attitude it is 30 years or more.You can, of course, make stoves from chrome cast iron, but they will be very expensive. Also, some manufacturers make cast-iron stoves from an alloy, the brand of which is hidden, here it is necessary to be careful with such products. It is not known what this will result in when using ovens.

Prefabricated cast iron stoves have the ability to replace any part during repair, this will greatly reduce your costs in the future, you do not have to change the entire stove.

Also a huge plus of prefabricated furnaces is their transportation. The heaviest part weighs no more than 40 kg, while bolted furnaces or welded steel furnaces weigh 200-300 kg or more. And also have large dimensions and do not pass through doorways.

However, when describing a cast iron stove, one cannot but mention its shortcomings. Of course, they are all rather relative.

A significant disadvantage of a cast iron stove, according to many, is fragility during sharp cooling. So, there will be no cast iron from splashing cold water. Cast iron stoves have thick walls (more than 10mm) and perfectly tolerate the ingested water. In addition, there are 100-200 kg of stones in the stove, which evaporate the water in the first place. So you have to try very, very hard to be able to make the cast iron burst. And for a complete guarantee, there is a protective stainless steel pallet. steel for cast iron stove.

And, finally, the decisive factor for many is the price. A cast iron stove will always cost more than a steel one. Because you can weld metal anywhere, but to cast iron you need high-quality molds, industrial furnaces and a metallurgist who will weld the right cast iron. But the resource of cast iron furnaces is much longer than that of steel ones.

Cast iron stoves in cladding are a modern version of brick stoves, less heating in time, and less troubles with capricious bricks, smaller dimensions, commensurate heat capacity and greater safety, because the entire combustion process takes place in a cast iron furnace.

Heating duration

In terms of the time that the stove is capable of giving off heat, models made of brick and stone are in the lead. A brick oven, for a long time (from 14 hours to a day), retains the accumulated heat, gradually giving it to the rooms. On average, from 1 m² of its surface area, 500 watts are released hourly. Thus, even in severe frosts, the brick oven is ignited a maximum of a couple of times a day.

The finished ovens are mostly made of metal. This material heats up easily, but also cools down just as quickly. The stove stops heating the room immediately after the last coals burn out in it. Manufacturers are struggling with this drawback: they either use internal inserts made of heat-consuming materials - the so-called heat accumulators, or provide a special slow combustion mode, when the wood barely smolders for several hours, keeping the furnace body warm. But, nevertheless, metal furnaces are not yet able to compare with a brick oven in terms of heating duration.

- 1 of 4

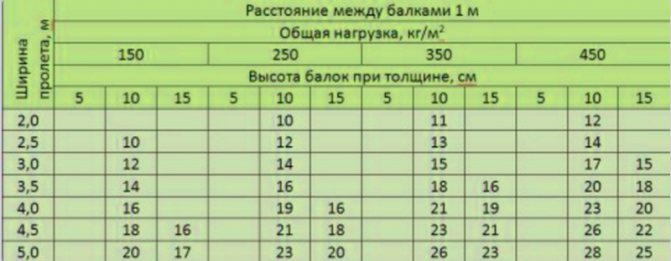

On the picture:

In modern metal stoves, fireplaces, in addition to open and closed fire modes, a slow combustion mode is often provided.

Imitation of a masonry oven.

Speaking of masonry stoves, we mean stoves made entirely of stone or brick. What you see in the photo is a finished stove lined with ceramic tiles. It does not require as complex construction as a masonry oven requires.

In the photo: Ceramic oven 06 from the Gutbrod Keramik factory.

Choice of stove and fireplace. To make of bricks or to take a ready-made metal one?

The answer to this question, in many respects, depends on the operating conditions, the mode of use and the circumstances of the installation of the Heat Generating Apparatus (hereinafter referred to as TGA), which you are going to install.

It is almost impossible to give, in the slightest degree, intelligible advice without the consumer's answers to the following questions:

one.In which house (building characteristics and materials, best complete project) will the TGA be installed?

2. Will the house be permanent residence or temporary residence, during the cold season?

3. Will the selected stove or fireplace be used as the main or additional heat source?

4. How much volume of the room needs to be heated, or what power of TGA is needed?

5. Has the building's heat loss been calculated?

6. How many rooms do you need to heat?

7. In what mode will the TGA be operated? (fuel loading frequency and combustion mode)

8. What kind of fuel were you going to use?

9. What is the TGA function? Heating? Or for beauty? Or for beauty and cooking? Or something else?

10. Is there a foundation? How much weight can it handle?

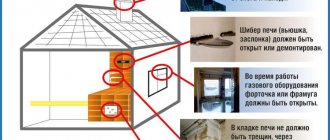

11. Is there a chimney? His high? Location relative to the skate? Diameter?

12. Are there any preferences for materials, its location in the living space, etc.?

13. What is the estimated budget for the construction of the furnace?

For instance: ·

- for full heating;

- as the only source of heat;

- in the presence of a reliable foundation;

- in a well-insulated house of permanent residence, with an area of up to 50 m2, with two rooms;

- preferable use as fuel - firewood and briquettes with tabs, no more than twice a day.

- There is a chimney, brick, section, "five", 140 * 270 mm;

The most suitable would be a thick-walled, brick, heat-consuming furnace with a capacity of 4 to 5.5 kW * h.

To reflect the full range of opinions and possible options, below are the pros and cons of locally manufactured and purchased stoves and fireboxes. I hope it will be useful to you in order to form your own opinion, and will help in further making the final decision on the choice of materials for your own fireplace and (or) stove.

Arguments BEHIND finished stove (firebox):

- Withstands prolonged heating without destruction and deformation;

- Withstands sharp warming up;

- Much faster begins to give off heat;

- A large number of possible variants of shapes and sizes;

- More technological product;

- Modified and completed product;

- Less weight in comparison with the brick version of the same thermal power;

- Smaller size a purchased firebox in comparison with the same capacity of a firebox made of bricks;

- Installation possible without foundation;

- Possible artistic delights... Original back wall, fence-fence (bulls);

- Options available ready heat storage furnaces made of ceramics, chamotte, heat-resistant and composite concrete There are many different options heat storage inserts and facings;

- There is a possibility of heating remote premises by means of connection heat exchanger or hot air distribution;

- The customer receives complete presentation final appearance;

- Huge number of options finishes;

- Less list and scope various materials;

- Save time and money for the purchase and delivery of materials;

- Carried out precise engineering calculation gas dynamics and thermal physics of the furnace, even before manufacturing;

- Less possible design errors;

- Intelligible and understandable instruction for installation and operation;

- Less dependence on the professionalism of the master;

- Clear device diagramthat makes cleaning easier;

- Available self-assembly consumer;

- Installation of a finished stove (fireplace) less dirty and dusty in relation to masonry;

- Warranty obligations manufacturer;

- Manufacturer's responsibility for the materials used;

- No matching problems, explanations and argumentation in the relationship between the customer and the contractor;

- Bake immediately ready to work after installation and does not require a lengthy drying process - commissioning;

- There are many suggestions from the most inexpensive to very expensive.

Arguments AGAINST finished stove (fireplace):

- Fast cools down;

- If ice and snow with wood gets on hot surfaces, it may cracks;

- Overheats and dries up the air;

- Dust burns out forming harmful substances and burning oxygen; Can create danger due to heating to high temperatures;

- Less maintainable;

- Dont Have widespread materials and components;

- Enough high price most parts and accessories;

- Loose fit of parts, are observed most often on the furnaces of the cheap segment.

- Complexity changes to the design and custom design;

- Less durable materials.

Arguments BEHIND Brick stove:

- Keeps warm for a long time;

- Long time gives off warmth,

- Supports favorable temperature in room;

- Does not overheat or dry out room air;

- On surfaces dust does not burn;

- Surface less dangerous;

- Many different options forms and doors;

- Material availability;

- Application possible not expensive materials, including used parts;

- Available DIY repair;

- There is a possibility of the device heating plate (rude)

- Stove fully repairable... Each of the bricks can be replaced at any time;

- Any are possible even non-standard sizes;

- Various carved and artistic details;

- Lots of technological capabilities: secondary air, long-term combustion, convection pipes, boiler-heat exchanger, bread chamber, air flow, etc.

- A large number of finishing options (materials, colors and textures);

- Snug fit parts and joints;

- there is cheap and simple models;

- Durability of materials, and the whole structure

Arguments AGAINST brick stove (fireplace):

- Heavy weight during loading and unloading operations and the device of the furnace, leads to increased physical stress;

- Expensive work professionals;

- Much depends on professionalism and the decency of the performer;

- Lack of a project, and the completeness of the design;

- No guarantees from the contractor, if it is not a licensed firm;

- Elevated fare due to heavy weight;

- Big list (spectrum) and volume purchased components;

- Low quality of produced modern bricks;

- You need a powerful and solid foundation;

- The size a brick oven is much larger than the size of a purchased metal furnace of the same power;

- It is impossible heat up sharply;

- Need to dry for a long time after the end of construction;

- After starting the kindling does not give warmth for a long time;

- Expensive finishing;

- Design errors;

- Is absent clear instruction operation, repair and maintenance;

- Limited appearance (in the low-cost segment);

- Increase expenses for the production of work due to the duration, complexity, responsibility and weight.

Based on the above, we can conclude that both options are acceptable and the advantage of one material is more often attributed to the disadvantages of another.

Least of all I would like to push the stove-makers and the sellers of finished products!

Much here depends on the opinion of the person who chooses and, to a greater extent, on how much the manufacturer values his name, that he uses only high-quality materials.

Please note, within the framework of this article, factory-made heat storage furnaces were not considered.

Erection speed and cost

In these matters, the advantage remains on the side of the furnaces made in production. They are relatively lightweight and, in rare cases, require the construction of their own foundations. Factory furnaces are delivered ready-made: you only need to carry out fire-fighting work at the place of their installation, connect and isolate the chimney.

Brick stoves, taking into account the cost of the material and the work of the stove-maker, will cost more.The process of their construction is much more complicated, lengthy and messy. And often you need to think about building a brick oven at the time of building a house (after all, the structure is installed in partitions). Whereas a metal stove can be brought and installed in a finished structure.

Heating principle

The cast iron stove burns like a bonfire and warms up nicely when you are near it. This principle of heat transfer is called radiating, i.e. heat is transferred by radiation. Advantages of the method: the air does not dry out, it quickly warms up if you are near. It is important to note here that they must be placed away from the wall in order to exclude a fire.

The steel stove is decorated and there is an air duct between the decor and the combustion chamber. As it heats up, warm air creeps up, and cold air takes its place. This is how heat is transferred by convection. As the air warms up, the air velocity increases, and the longer the channel, the faster and more intensively the air moves through it. The advantage of the method is instant heating of the premises and a uniform temperature over the entire area of the room. The disadvantage is that the air is dried, since it is he who heats up.

It is also necessary to briefly mention other characteristics of furnaces made of these materials:

- Life time.

Durability depends on the qualities and characteristics of the materials. Both metals are of high quality, they serve for tens of years even with intensive use. - Power.

Having the same dimensions, cast iron products are distinguished by increased power. The reason is the size of the furnace, where a lot of firewood can fit: more logs - higher heat output. - Fire overview.

With a variety of stove models, it is important to note that in general, there is no difference in the view of the fire. It all depends on the size of the glass. Panoramic horizontal and vertical glasses allow you to view the fire, enjoying it throughout the entire combustion process. - Maintainability.

You can repair a lined steel furnace using a welding machine. By the way, cast iron products can also be welded. But most of the models are assembled on a sealant, and bolted together. Therefore, you can easily and easily disassemble them and replace the desired part. If we talk about steel ones, then only the firebox can be repaired in them, replacing the damaged fireclay bricks with new ones, or the chamber itself completely. - Price.

Steel furnaces stand out for their high price: the cost of some models reaches 20,000 rubles. But there are options from 500 rubles. Cast iron products cannot be more expensive than 10 thousand rubles.

CONS OF METAL OVENS

The main disadvantage of metal furnaces is their low heat capacity. That is, the heat stays in the room after plowing for only a few hours, which means that by the morning it will be very cool in the house. The exception is long-burning ovens - only real ones, not fakes. These from one bookmark are capable of heating the room for 6-8 hours.

The service life of a metal furnace is a maximum of 20 years, but in practice they fail much earlier: the metal burns out, as a rule, at the bottom or ceiling of the structure. True, it is relatively easy to replace a failed "soldier".

There is one more thing that sellers do not warn about. The fact is that the heat radiation from most metal furnaces is very harsh and powerful. In addition, they dry the air greatly, causing the feeling of "nothing to breathe". Together, these two features can lead to the fact that not everyone will be comfortable near the stove for a long time, it happens that people complain of headaches, general weakness.

To protect against hard radiation, people often cover their stoves with solid bricks, thus turning them into a kind of small brick ones. What does this lead to? Firstly, the rate of warming up the room decreases (however, the heat capacity of the furnace increases). Secondly, the service life of the oven itself is reduced. And thirdly, with a high degree of probability, you will lose the manufacturer's warranty for the product.However, if you nevertheless decide to take this measure, first of all, evaluate the bearing capacity of the floor. The weight of the future brick screen is calculated using the formula: M = (K * P) * Mk, where M is the mass of the screen, K is the number of bricks in a row, P is the number of rows (when using a standard oven brick, the height of one row is 7 cm), Mk - the mass of one brick.

Remember that this weight will be added to the weight of the oven itself.

If the structure weighs less than 700 kg, it is enough to strengthen the logs: lay additional ones and fasten them to the main frame. If the weight is more or the floor structures do not inspire confidence, it is better to make a separate foundation for the oven. This work is dreary and hard: you will have to disassemble the floor and dig a pit of the same depth as the foundation of the house, but its width should be 15-20 cm wider than the future stove screen.

The foundation can be solid ("curbstone") or columnar.

In the latter case, a concrete slab or channel is installed on top so that there are no gaps between the posts without support. And be sure to lay waterproofing between the foundation and the building! The stove "coat" is erected after the concrete has hardened.

The optimal distance from the metal surface to the brick is 4-6 cm. You can, of course, lay a brick and almost close, retreating only 0.5 cm, but this reduces the durability of the lining: sharp heating is critical for a brick. A larger gap keeps the brick, but significantly lengthens its heating time. For furnaces equipped with slotted air heaters, from which streams of heated air come out, a gap of 10-12 cm is left on these sides.

Most often, the shield is raised to the top of the oven. The lining is led either into a half-brick or into a brick (in this case, it is sometimes done even without a clay binder). In the lower and one of the upper rows, be sure to leave convective slots a quarter or half brick wide - two on each side.

- The glass door of the oven is often covered with soot. If you do not start the situation, then you can clean it off with a damp cloth or newspaper, dipping it in ash. Glass that is still warm is especially easy to clean. When it cools down, or if tar deposits have already appeared on it, you will either have to use a fireplace glass cleaner, or ... a felt pad for a drill. Moistened with water, it easily removes even old deposits. But you should not use various metal brushes and scrapers - you can scratch the glass.

- If you decide to install a metal stove in your house, take a model with grates: they can be replaced when they burn out.

- To improve adhesion, the brick must be soaked in water before laying, the adhesion to the mortar will be much stronger. This is especially important for structures that will be regularly heated. The size of the seams is 3-5 mm, but do not forget about bandaging the brick.

Metal oven - expert opinion

When designing a house, the possibilities for choosing the type and model of heating equipment are the widest. Restrictions apply when installing in a residential building. So, a classic masonry fireplace or stove requires a foundation, and if it is not provided in the house, then the masonry option, including the brick chimney, is excluded. The "light" option remains - a cast iron or steel stove or a fireplace with a steel or ceramic chimney.

Additionally: how to impose a stone on an iron stove in a bath

Metal stoves for a bath, lined with brick

The decision should be taken in a balanced manner, therefore we will name the reasons why the lining of an iron stove with a brick in a bath is done.

Unfortunately, the metal stove itself is a source of not only rapid heat, but also hard infrared radiation, which burns the skin at a distance, without contact with an object.In addition, a rapid increase in the temperature in the bath leads to overdrying of the air, and this is a big obstacle to creating the correct bath microclimate.

Brick, on the other hand, is an artificial stone, and therefore, it heats up longer than metal and gives off heat much longer. The construction of a protective screen from this material allows relatively cheap (compared to natural stone) to eliminate the main disadvantages of a metal stove: to make the radiation softer, warming up longer, but without drying the air, to increase the efficiency of the stove, keeping the heat from the wood burnt in the stove longer.

The problem is that the story begins long before the stove in the bathhouse is overlaid. And it begins with a calculation, without which you will not be able to correctly estimate the weight of the stove together with the screen, and therefore, either in vain invest in the foundation, or, conversely, underestimate the weight and spoil at least the floor.

You need to collect the following information:

- dimensions (length, width, height) and weight of the future or existing furnace (manufacturers usually post such information on their websites);

- the mass of stones, in stoves with a closed and / or open stove (also indicated by the manufacturer);

- hot water tank (! about stoves with a tank here) - if it is supposed, then its mass and the volume of water that can be held (1 l = 1 kg).

Next, you have to figure out which brick you will use - red refractory or chamotte. Since the consideration of the types of bricks is waiting for you below, here we will indicate the size of only ordinary red refractory bricks, which, by the way, is the leader when choosing to cut an iron stove in a bath with facing bricks.

So, the dimensions and weight of one standard brick are 250 mm in length, 120 m in width, 65 mm in height, weight 4 kg.

Now, estimate how many bricks will go for 1 row if you put them along the walls of the oven with a minimum gap of 5 cm between the oven and the screen?

Screens are different - on four sides, on three, on two - choose your option, focusing on the height of the stove, and count how many rows will fit.

By the way! Do not forget that the brick in the masonry can also be laid in different ways (1/2, quarter, and other options), and this will affect the area of the base.

By multiplying the number of rows by the number of bricks in a row, you get the total amount of the required material, as well as its mass, by multiplying the result by 4.

Add the mass of the screen to the mass of the stove, stones, tank, water in the tank. Add 20% as a safety factor.

If the mass is less than 700 kg, you can safely make the base directly on the floorboards. Otherwise, you will have to build a separate stove foundation from the bathhouse.

Let's start with the more difficult one. You counted everything and it turned out that there is nothing without a foundation. The task is easier if you are at the construction stage, otherwise you may have to dismantle the furnace, the old base, part of the floor.

IMPORTANT! The dimensions of the foundation in terms of area are known to you from the above calculation. This is a platform formed by bricks on the sides of the stove. Add 10-15 cm to it on all sides.

Start digging a hole. If the soil can withstand (say, if, when calculating the bath foundation, it was shallow, then it is not necessary to deepen the stove too much), make it half a meter deep and fill it 3/5 with a mixture of sand and gravel, or just gravel.

Keep in mind! The stove and bath foundations should not just not touch, it is recommended to make the distance between them at least 5 cm.

On top of the pillow, a screed is usually made from a 1: 4 cement-sand solution.

On top of the screed, waterproofing is placed, formwork and a concrete foundation is poured, it can be reinforced, 20 cm high. It will be below the floor level.

Note! When drying concrete, it must be often sprayed with water so that it does not crack.

The concrete is waterproofed again, after which base bricks are laid on it - refractory red or chamotte, which are placed on a clay mortar. Height - 1-4 rows.Do not forget to check the horizontal level at each stage.

After that, put your device on and start erecting a brick screen for a metal stove in a bathhouse.

Base on the floor

It is easier to overlay a metal stove in a bath with a brick if the base is made directly on the floor. However, you need to take into account the structure of the floor and first calculate whether the concrete lumber will withstand the upcoming load.

SIGNIFICANT! In the old bathhouse, an obligatory procedure will be to open the floors and check the beams and logs for rot and other damage. Replacing the damaged one is inevitable due to the increasing load.

To begin with, the stove presses on the floor not pointwise, but approximately evenly, because it stands on a brick base. This means that we must add the weight of the base bricks to the previously calculated total for the stove and the screen, and then divide by the area occupied by the latter, measured in square meters. As a result, we get the load per square meter of the floor surface under the oven.

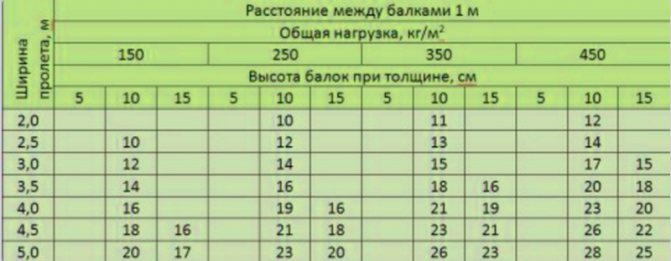

In the table below you will find the parameters of the beams (width, height, thickness) that will withstand the specified maximum load - 150, 250, 350, 450 kg per square.

If yours do not fit, do not worry - the beams can be reinforced with a channel, steel strip or rods, as well as wooden overlays.

If the beams are located at a distance of a meter or more, the craftsmen are advised to put an additional beam between them. For example, pine with a section of 100x150 mm.

The next thing to worry about is lag. For them, there are also extreme loads. Look for the values in the table below.

If there are no color marks, then the values are not even close to the ultimate strength. Green is an acceptable, but already limit value. Red is invalid!

Lags are easier to replace than beams.

So, with the preparatory work on the floor, you are ready to start creating the base. To do this, markings are made on the floor with an allowance from the screen of 10-15 cm. If some side or sides of the oven are not covered with a screen, then the allowance is made from the oven itself.

Do not forget that fire safety rules require you to protect the space in front of the firebox, excluding the ingress of sparks on combustible material. You can either extend the refractory by half a meter in front of the furnace, or put a pre-furnace metal sheet there.

After marking, a sheet of refractory is placed on the floor - the material of your choice: asbestos, ceramic fiber or another option. The edges are fixed in the floor with self-tapping screws.

asbestos cardboard (asbestos cardboard)

The next layer is already laid with base bricks, the height of which can be, for example, 20 cm. Use only solid refractory bricks - red or chamotte. Mortar - clay or with a small addition of cement. Alternatively, you can buy masonry mix at the store.

Most often they are limited to two rows of masonry. Excess solution is removed without waiting for drying. Evenness is also checked immediately using the level - this should not be neglected.

After such a long preparation, we are already close to the story of how to overlay an iron stove in a bath.

The variety of options is easy to demonstrate by breaking down into points.

Types of covers

Photo of the finishing of the stove in the bath (below the vent for convection control)

If you surround the stove with brick walls on all four sides, it will be a complete lining. Otherwise, it is partial. Regardless of how many walls are missing to full, there is a significant difference between the one and the other. It lies in convection controllability.

To put it simply: it matters only for lovers of the Russian bath, for which a separate article is devoted to stoves. If the convection is controlled, you shut it off at the right time, the hot air from the heated metal heats not the steam room, but the walls of the brick sarcophagus. Those transfer softer warmth.Heating slows down. You get the opportunity to maintain the conditions of a Russian bath - 55-60 degrees and somewhere the same - humidity.

To control convection at the bottom and top of the screen, air vents are made with doors or plugs from pieces of brick - in the open state, they do not interfere with the movement of air.

Even with one open wall near the stove, you can only count on the sauna. And the functions of the screen will be reduced to protection from burns, heat accumulation and fire safety. Which, in general, is also not bad).

Bricks for lining a metal stove in a bath can be laid in different ways. Let's list them all.

By the presence or absence of empty space between bricks:

- Solid masonry - rarely used, because it creates an obstacle to convection and significantly reduces the efficiency of the furnace.

- Laying in a row - gaps in each row, which is also an infrequent solution, because it also reduces the efficiency, this time of the screen itself. Heat is actively escaping through the vents, convection is uncontrolled, analogous to the absence of one or more walls.

Air vents below and above with doors are the most common option. Controlled convection.

By the position of the bricks in the masonry:

- In brick - rare masonry, which at the same time wastes a lot of material and reduces the efficiency of the furnace, since it takes too much time to heat a steam room with such a screen.

- Half a brick is the best option that most people do. The thickness of the walls and the stability of the structure are not satisfactory. But if you wish, you can reinforce it by putting wire or mesh in the seams between the rows.

- A quarter brick is a rare option, because the wall is both thin and unstable. The latter circumstance can be compensated for by wire / mesh reinforcement, but it is still recommended to install such a screen only if there is appropriate experience.

We must say right away that sand-lime brick is not suitable for these purposes at all. But what kind of brick you can impose on a steel stove in a bath is: red refractory or chamotte. The one and the other are better full-bodied. However, it must be taken into account that today you can find bricks on sale not only of different sizes, but also of varying degrees of decorativeness. In particular, there are options specifically for laying stoves and fireplaces.

ADVANTAGES AND ADVANTAGES OF METAL OVENS.

They are not afraid of temperature changes and long breaks in the firebox, they do not need booster heating after downtime. That is, for those who, in the cold season, come to a country house only for the weekend, this is the best option. Moreover, such ovens heat up the air very quickly.

TOOL FOR HOME AND GARDEN, NEEDLEWORK, ETC. PRICES VERY LOW

Another advantage is the relatively low cost (when compared with a brick oven). Again, to install such a "hot heart at home" you do not need to make a foundation or hire a stove-maker.

The compact size allows you to place the metal oven almost anywhere. But observe the fire-prevention indents, this is very important (the exact distances are indicated in the installation instructions). However, if the room is extremely compact, the indents are sometimes reduced. And fire safety is provided with the help of protective screens. The walls are fenced off with steel sheets, but not closely, but with a 2-3 cm air gap. There is also a gap of 3-4 cm between the edge of the sheet and the floor. Thus, the metal, when heated, enhances the convective movement of air near the wall. This protects the wall from overheating.

Last but not least, a factory made metal stove can have a fire safety certificate. This means that it is much easier to obtain permission from firefighters to use it (provided that the installation was carried out exactly according to the instructions).

Installation

The work is carried out taking into account the following rules:

- It is better to soak the brick in water in advance, this will increase the adhesion of its surfaces with the substance of the solution.

- The masonry is made with a thickness of half a brick, starting from the corner of the structure.We start the first and every odd row with an integer, every even one -.

- Fill the seams completely with mortar, and remove the excess immediately.

- We check the parallelism of the rows with a level, and the verticality of the walls and corners - with a plumb line.

- It is worthwhile to leave holes here and there for ventilation of warm air and faster warming up of the room.

- Remember to leave a hole in front of the firebox door for maintenance.

- The masonry stops at the level of the heater.

Metal oven lining