Gas-firewood

The advantage of universal gas-firewood heating boilers lies in their autonomy: a smooth transition of the system to burning firewood in the absence of gas. Also, if you wish, you can connect the "warm floor" structure, because the boilers are supplied with the necessary connections and branch pipes.

Such universal boilers "gas-wood" can be single-circuit and double-circuit, so it will not be difficult to connect a boiler to heat water or heat water in a flowing way.

The disadvantages include the large dimensions of such units. Most often, they require a separate room for installation, and implies complicated service. Typically, such boilers are produced only of the floor type.

Combined gas-wood boilers for the home imply increased requirements. The norms and rules of operation are described in PPB, SNiP and SP.

The combined gas-firewood boiler for a private house includes the following elements:

- Firebox chamber. It is made of cast iron or steel. The boiler can be with one firebox or two (more convenient). In the double version, firewood is burned in the upper section, and a gas burner is installed in the lower one.

- Hot water and heating circuits. They are produced by companies specifically for heating, or for heating to obtain hot water (double-circuit). Heating of hot water supply by the flow method.

A universal gas-firewood heating boiler assumes savings. This can be seen by looking at the following table.

| Type of fuel | Approximate cost of 1 kW of energy, $ | Approximate cost of 1 m³, $ | The approximate cost of heating a house with a volume of 450 m³, $ |

| Gas | 0,01 | 0,00047 | 0,2115 |

| Firewood | 0,02 | 0,0094 | 0,423 |

| Coal | 0,055 | 0,002585 | 1,16325 |

| Electricity | 0,03 | 0,00141 | 0,6345 |

| Diesel fuel | 0,04 | 0,00188 | 0,846 |

High-quality equipment for wood and gas is produced in Russia: "Zota MIX", "Kupper PRO" ("Teplodar"), "Karakan" ("STEN"), "PARTNЁR" ("KOSTER"), "STS" ("Steel Solid Fuel Systems "). And also foreign companies: Austria and Germany ("Wirbel"), the Finnish concern "Jaspi" and others.

It should be noted that in foreign counterparts, it is less common to notice flaws in the assembly and automation of the unit. They boast reliability and quality. However, the domestic manufacturer is constantly improving in accordance with the wishes of buyers.

Prices for combined heating boilers "wood-gas" depend on the country of origin, on the brand's popularity. For example, a model ("KOSTER") will cost an average of 23 thousand rubles. Much will depend on the configuration, power and other indicators. But "Jaspi" will pull all 130 thousand rubles. The takeoff run is large, however, unlike the Finnish one, where everything is regulated by automatic equipment, in the Russian analogue, all boiler settings will have to be carried out independently.

Criteria for choosing gas-firewood boilers

The main parameter of any heating equipment is its power, the correct choice of which provides a comfortable room temperature at a minimum cost. If you do not make complicated calculations, then when choosing a boiler, you need to keep in mind that 1 kW of thermal power is needed for 30 m³ in a well-insulated room. The heat engineering calculation of professionals is more accurate and takes into account such factors as the thermal insulation of the room, the presence of other types of heating, the functional purpose of the room

Since one of the energy resources of this type of boiler is gas, its pressure in the network should be taken into account. Boiler performance decreases at low gas pressure. In this case, a possible shortage of capacity is taken into account.

Following important parameter, according to which the boiler is selected, is its appointment... If only heating will be included in the boiler's functions, then you can opt for single-circuit equipment. In the case when it is required to provide housing with hot water supply, a double-circuit boiler is purchased. This device is of two types: with a built-in boiler or with a built-in coil. The first always has 40-60 liters of hot water ready. The second type of device is inferior to the boiler in terms of water volume, but at the same time it has more compact dimensions, weight and saves more fuel. You can always use a single-circuit boiler connect additionally indirect heating boiler.

When purchasing a boiler, an official certificate must be required. Without this document, it will be difficult to register heating equipment and acquire a permit for its connection to gas supply systems.

Coal-gas

The universal gas-coal boiler is environmentally friendly and easy to maintain. However, when choosing this type of construction, you will have to constantly monitor the presence of solid fuel, because coal ends quickly. If you suddenly come to the conclusion that "two in one" does not suit you, then you can always replace the burner - and the boiler will already run on natural gas.

More details about the features of the pellet boiler can be found here.

Most often, the coal-gas combined boiler is allowed to heat with wood. For example, in the technical characteristics of the two-circuit model "Birch B" in the item "fuel" it is indicated "natural gas / coal" (see table). However, buyers use such a boiler for heating and firewood.

| Manufacturer and model | Characteristic |

| ATEM (Zhytomyr, Ukraine) Berezka V | The boiler is made of steel, is versatile and completely independent of electricity. It acts as a budget solution for heating summer cottages, utility rooms, outbuildings. Units of the "B" brand are created with the production of consumer hot water. Fuel - natural gas / anthracite (coal). The area of the heated room is 125 m². Rated thermal power - 12.5 kW. The maximum gas consumption is 1.5 m³ / h. Nominal gas pressure (min / max) - Pa 1274 + 100 (635/1794). Working pressure of water - 0.1 MPa. The efficiency when using solid fuel is 78%. The efficiency when using natural gas is 90%. Weight - 119 kg. DHW water consumption - 280 l / h. The combustion chamber is open (chimney). The number of contours is double-circuit. |

Gas-coal-firewood

The advantage of the gas-wood-coal boiler is that it does not depend on electricity. This allows you to create autonomous heating systems. Fuel for such a unit is available in any locality and, moreover, at a low price. The firewood-coal-gas boiler from the manufacturers listed in the table below is easy to service and has an attractive design.

| Manufacturer and model | Characteristic |

| Hearth KSTG-10 (Russia) | This company has been on the market since 2003. It is a dynamically developing and reliable manufacturer. Boiler type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 200 m². Power - 20 kW. The gas is natural. Solid fuel type - wood, coal. Working temperatures - 95 ºС. Heat exchanger material - steel. The efficiency is 77%. Weight - 70 kg. |

| Outbreak KSTGV-12.5 (Russia) | This model of the coal-firewood-gas boiler is non-volatile and stable when operating at reduced gas pressure. Due to the optimal design of the combustion chamber, the boiler has a high efficiency. Built-in water heater that provides hot water. Includes a gas pressure regulator. The boiler body is resistant to temperature fluctuations. Type - double-circuit. The combustion chamber is open. Installation - floor. Heating area - 125 m². Power - 12.5 kW. The gas is natural. Solid fuel type - wood, coal. The boiler is built-in. Working temperatures - 95 ºС. Heat exchanger material - steel. The efficiency is 83%. Automatic shutdown - no. Weight - 120 kg. |

| Raton KS-T-12.5 (Belarus) | The boilers are designed for heating individual houses, buildings and structures equipped with continuous hot water heating systems with natural circulation of the coolant and an open expansion vessel. Type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 130 m². Power - 12.5 kW. Solid fuel type - wood, coal, peat. The display is not. Heat exchanger material - steel. Ignition is mechanical. The efficiency is 77%. Weight - 138 kg. The service life of the boilers is at least 15 years. |

| Brestselmash KST 12.5 kW (Belarus) | By the type of fuel, the boilers manufactured by Brestselmash OJSC belong to multi-fuel boilers designed for burning solid and gaseous fuels by means of re-equipment that does not require dismantling the boiler. Installation - floor. Heating area - 125 m². Power - 12.5 kW. The gas is natural. Solid fuel type - wood, coal, peat. The display is not. Working temperatures - up to 95 ºС. Heat exchanger material - steel. The efficiency is 90%. Weight - 180 kg. Designed for heat supply and hot water supply of residential buildings and buildings for public utilities, equipped with water heating systems with natural circulation, with a working water pressure of up to 0.1 MPa (1.0 kgf / cm²) and a maximum temperature of water leaving the boiler up to 95 C °. |

| Boiler PARTNЁR 24 (Russia) | The advantages of the products of this company are in their own innovative unique design developments. The manufacturer carries out guaranteed quality components, raw materials and materials. This is a stable high-tech production. The combustion chamber is closed. Installation - floor. Power - 24 kW. Solid fuel type - wood, coal. The efficiency is 80%. Weight - 108 kg. Height - 79.5 cm. Width - 42 cm. |

Features of operation of gas-firewood boilers

Since one of the energy resources of the boiler is solid fuel, it is required to constantly monitor the cleaning of the chimney.

The operation of the gas-firewood boiler assumes work on the delivery and loading of firewood, and the loading is done manually. Operation of equipment on wood does not exceed four hours.

When buying firewood, their moisture content is taken into account, which should not exceed 20%. Better to buy firewood in a specialized store.

Uninterrupted work heating and hot water is possible thanks to automation. If one type of fuel (solid) is missing, the combi boiler automatically starts the other (gas).

Firewood-coal-pellets-gas

Currently, these units are offered by: the manufacturer of the universal boiler "Cooper" "gas-wood-coal-pellets", and others.

A large selection (pellets, firewood, coal, gas) gives such a boiler a great advantage. In the absence of one type of fuel, you can always switch to another type and stay warm.

| Manufacturer and model | Characteristic |

| Teplodar Kupper OK15 (Russia) | Boiler type - single-circuit. The combustion chamber is closed. Installation - floor. Heating area - 150 m². Power - 15 kW. The gas is natural. Solid fuel type - wood, pellets, coal. The display is not. The efficiency is 78%. The chimney diameter is 150 mm. Weight - 98 kg. Double-turn heating, formed by a removable visor, which provides complete flame suppression in the tube sheet. In addition to the standard water jacket, there is a heat exchanger in the firebox. Power regulation from 30 to 100% (boilers can be equipped with a combustion regulator). A spacious firebox that allows you to load firewood with a length of 400 mm horizontally and 500 mm vertically, or two buckets of coal. The presence of a tubular electric heater allows maintaining the heating system after the end of the fuel combustion process. |

| Raton KS-TG-35U (Belarus) | Boiler type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 340 m². Power - 35 kW. The gas is natural. Solid fuel type - wood, pellets, coal, peat.The display is not. Ignition is electric. Working temperatures - 95 ºС. Heat exchanger material - steel. The efficiency is 77%. The boiler is designed for heating residential buildings that are equipped with continuous heating systems with natural or forced circulation of the coolant. |

| Teplodar Uyut-10 (Russia) | "Uyut" is a budget heating boilers for rooms up to 100 sq. m. The firebox is in a horizontal position, which allows the boiler to be heated with wood up to 0.5 m long. The high efficiency of the boiler is ensured by the original design of the water circuit: stagnant zones are excluded, and the area of the heat-removing surface is increased to 1.1 sq.m. Possibility of installing a gas or pellet burner. Boiler type - single-circuit. The combustion chamber is closed. Installation - floor. Heating area - 100 m². Power - 10 kW. The gas is natural. Solid fuel type - wood, pellets, coal. The display is not. Ignition is mechanical. The efficiency is 72%. The chimney diameter is 115 mm. Weight - 67 kg. |

How to ensure long-term burning of a solid fuel boiler.

Heating set.The kit includes: controller, fan, coolant temperature sensor, emergency thermostat 85 ° C. | |

| Maintaining the preset boiler temperature | |

| Heating hysteresis selection. | |

| Fan deceleration as the set temperature approaches. | |

| Fan speed setting. | |

| Protection against condensation and corrosion. | |

| Maximum temperature alarm protection (fan stop and forced start of pumps). | |

| Power loss protection. | |

| Room thermostat application. | |

| Maintaining the temperature of the water in the boiler. | |

| DHW hysteresis selection. | |

| Boiler or heating priority. | |

| Summer mode. | |

| When ordering through our website You will additionally receive from us a diagram of connecting the controller to the fan and to the boiler pump. Price: 10 400 ₽ | |

Heating + Boiler set.

The kit includes: controller, fan, coolant temperature sensor, boiler temperature sensor, emergency thermostat 85 ° C.

| Maintaining the preset boiler temperature | |

| Heating hysteresis selection. | |

| Fan deceleration as the set temperature approaches. | |

| Fan speed setting. | |

| Protection against condensation and corrosion. | |

| Maximum temperature alarm protection (fan stop and forced start of pumps). | |

| Power loss protection. | |

| Room thermostat application. | |

| Maintaining the temperature of the water in the boiler. | |

| DHW hysteresis selection. | |

| Boiler or heating priority. | |

| Summer mode. | |

| When ordering through our website You will additionally receive from us a diagram of connecting the controller to the fan and to the boiler and boiler pumps. Price: 11 700 ₽ | |

Important notes:

1. On the door of the ash pan (blower) you need to make a hole for the fan. 2. The boiler must be sufficiently tight with the doors closed so that the fan does not blow out the combustion products into the room. 3. The tightness of the boiler is also required so that the combustion does not continue when the fan is turned off and the damper has fallen.

But there is a ready-made solution.

About him at the end of the article.

Application of the "Heating" kit.

We light up the boiler and turn on the controller. The fan starts, which blows air into the combustion zone. As soon as the boiler warms up a little, for example, to the 40 ° C set by us, the circulation pump turns on. This function protects the boiler from condensation and the resulting corrosion during cold start-up. Further, the pump no longer stops. The boiler must heat up to the operating temperature set by us, for example to 70 ° C. Closer to it, the fan starts to slow down and when the set 70 ° C is reached, the fan turns off. In this case, the damper is lowered and the flow of air into the boiler stops. Combustion stops, pumps remove heat from the boiler and it cools down. We can also set the value by which the boiler temperature must decrease in order for the fan to start working again. For example 5 degrees.If there is no air supply to the boiler, the temperature will start to drop. When the temperature drops by hysteresis, the fan will start working and the temperature will rise again to 70 ° C. And so that during this time the boiler does not go out at all, the controller turns on the fan for a short time and keeps the fuel smoldering.

Application of the "Heating plus DHW" set.

The controller already controls the heating circulation pump, the boiler pump and the fan. Connection of a room thermostat is provided. We light up the boiler and turn on the controller. The fan starts, which blows air into the combustion zone. As soon as the boiler warms up a little, for example, to the 40 ° C set by us, the heating circulation pump or the boiler pump is turned on, or both pumps, depending on the priority we have chosen. This function protects the boiler from condensation and the resulting corrosion during cold start-up. Further, the pump is already controlled by a room thermostat and a boiler temperature sensor. The boiler must heat up to the operating temperature set by us, for example to 70 ° C. Closer to it, the fan starts to slow down, and when the set 70 ° C is reached, the fan turns off. In this case, the damper is lowered and the flow of air into the boiler stops. Combustion stops, pumps remove heat from the boiler and it cools down.

The same will happen when the set temperature in the room is reached and when the boiler is fully heated, regardless of whether the boiler has warmed up to the set temperature or not yet. The same will happen when the boiler is heated in summer mode.

We have already mentioned the emergency thermostat. It is in both kits. It will forcibly stop the fan if, for some reason, the temperature of the boiler coolant exceeds 85 ° C.

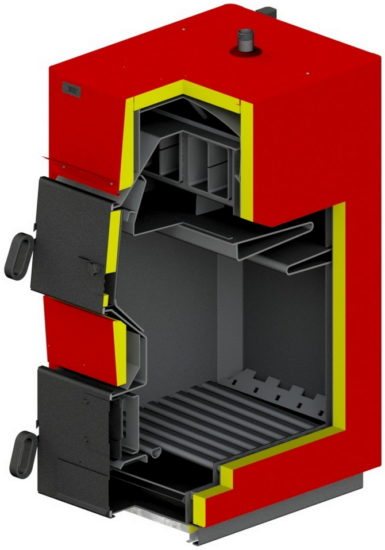

Ready-made solution.

The Lavoro ECO L series boiler is already equipped with automation and a fan. it is a modern steel hot water boiler operating in semi-automatic mode. Designed for heating residential and industrial premises, as well as for preparing hot water (DHW). Wood, coal, various types of fuel briquettes are used as fuel. Due to the fact that modern automation is installed in the boiler kit, which controls the air supply by means of a blower fan, the duration of fuel burning on one tab is significantly increased and its consumption is also reduced. The principle of operation is based on the fact that the boiler heats water to a predetermined temperature by controlled supply of air to the furnace, upon reaching which it smoothly goes into smoldering (economy) mode. The boiler operates in both closed and open heating systems, it is made of 09G2S steel with a thickness of 5 mm. All walls and partitions of the boiler are filled with water. The boiler is equipped with large and convenient doors with a tightening mechanism for a tight fit. This makes it easy to clean and maintain. Also, all boilers are equipped with a place for installing an electric heating element. In the basic configuration, the boiler is supplied with a "Heating" controller, it controls the fan and the central heating pump; upon request, the boiler can be equipped with a "Heating + DHW" controller, which can additionally control the boiler pump.

Contents of delivery

Boiler Automation Fan Boiler cleaning scraper Grate Thermomanometer

Power from 12

before

102

KW Factory price from

49 900

₽ to

209 900

₽ accordingly.

When ordering through our website, you will pay immediately to the plant, receive a boiler at the factory price, as well as additionally and free of charge you will receive from us

- the most detailed detailed diagram of the turnkey boiler piping. You just have to assemble according to the scheme; - detailed equipment table; - wiring diagram of the controller to the fan and to the boiler and boiler pumps. Except for us, no one does this.

Gas pellets

A pellet-gas boiler is equipment that easily changes its operation from heating with one type of fuel to heating with another. This usually takes about 15 minutes.

Here it is also possible to replace the burner in the event of a conversion. A tubular electric heater is available in many models.

Connection of a LPG cylinder is allowed.

The efficiency of a pellet-gas boiler reaches 90%.

The unit has several combustion chambers. The kit includes two burners and many regulating and shut-off devices. Has a high degree of security and automation. But despite this, a gas-pellet boiler, like any combined gas boiler, requires compliance with the rules of PPB, SNiP (some excerpts are described at the beginning of the article).

Do not forget to clean the boiler from time to time. During maintenance, it is necessary to remove accumulated wood dust, soot from the electric drive and moving parts.

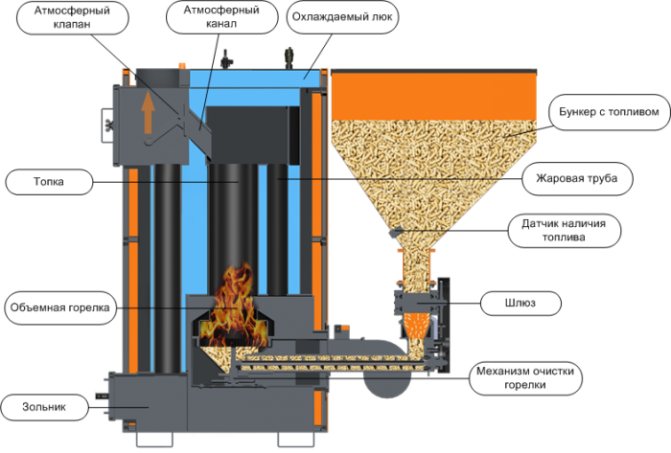

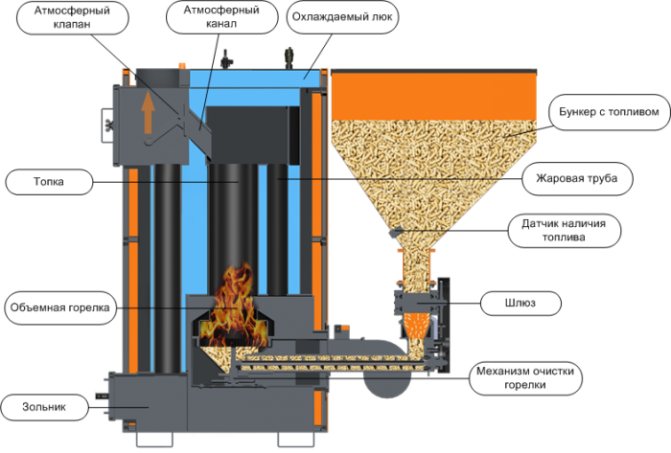

What do you need to work with pellets?

To convert the boiler to fuel pellets, you need to install a pellet burner, which is connected to the fuel hopper. After all operations, the functioning of the boiler is as follows:

- along the conveyor from the fuel hopper, the granules are fed to the burner;

- electric ignition occurs immediately by means of a piezoelectric element;

- a built-in fan is triggered in the burner, which increases the pressure, and the pellets are burned at a high temperature, artificially raised.

Usually, gas-pellet boilers are made of cast iron, and due to their large dimensions and weight, the structure is placed on a concrete base.

What do you need to work on gas?

Pellet boilers with a gas burner are primarily connected to cylinders and gas tanks. Such units are gaining popularity in the construction of houses and plots where natural gas is planned to be installed soon.

To connect a gas burner, first, close the unused firebox with an airtight hatch. Then, a burner device must be installed in a place specially designated for gas equipment. After all, set the switch for gas consumption. Everything. The rework took no more than 15 minutes.

Combined boiler Wirbel ECO-CK 20

Do it yourself

For residents of the private sector, connecting to the gas main is not a cheap pleasure. Based on this, many are trying to save money on the purchase of a gas boiler and leave their solid fuel boilers by inserting a burner into the lower compartment. However, the owners of such a heating system do not quite understand that they will spend much more by consuming gas, since solid fuel boilers are not designed to work with gas, and, accordingly, such alterations have a very low efficiency, since all the heat goes into the chimney, i.e. it turns out that we are simply heating the street. On the other hand, the efficiency of a solid fuel boiler can be significantly improved if significant changes are made to the design. But first of all, I want to warn that later this boiler can no longer be used for heating with solid fuel.

The essence of the alteration of the KST solid fuel boiler is reduced to welding steel pipes (1 inch in diameter) above the burner inside the boiler. In this case, the burner flame will not directly go into the chimney, but will heat the pipes in which the water circulates.

First of all, you need to dismantle the boiler and remove the cladding. Then we proceed to the markup.

When marking up, it is necessary to take into account some important nuances: - Place the pipes at a distance of 30mm. from the burner. - Pipes should be sloped to avoid stagnation and boiling of water in the pipes. - Pipes must be staggered in 3 rows at a distance of 15-20mm from each other

From the outer side of the boiler, using a grinder, we cut out a window in a water jacket. It is necessary to cut with a margin, so that later it is convenient to cook the pipes.For drilling large holes in metal, under pipes, it is necessary to use a crown with victorious solders. The bit diameter must be a couple of millimeters larger than the pipe diameter (in this case, the bit diameter is 35mm for 1 ″ pipe) in order to be able to position the pipe at an angle.

So that the crown does not overheat and the victorious soldering does not fly off, the drilling site must be continuously watered with soapy water. For these purposes, you can use a mineral water eggplant with a punched cork.

On average, it takes 20-30 seconds to drill one hole in steel 3mm thick, and do not forget to take breaks after 3-4 holes to cool the drill.

Since the work is complex and demanding, it is best to weld pipes with gas welding or a semiautomatic device.

When all the pipes are welded, you can start sealing the water jacket, for this we weld a pin from the fittings in the center, which, in the future, will prevent the boiler from swelling at the rework site.

At the final stage, we scald the window that was cut out earlier around the perimeter.

Before putting on the casing and installing the boiler in its old place, fill it with water and make sure that there is no leakage. If a leak has appeared somewhere, then you will have to cut out the window again and boil the areas where the defect has come to light.

Firewood-pellets-gas

If you are interested in the design of this type of heating, the table below describes the manufacturer of boilers for gas, solid fuel and pellets, its most popular model and a brief description.

| Manufacturer and model | Characteristic |

| Atmos DC 18 SP (Czech Republic) | The new series of combi boilers "ATMOS" DC 15EP (L), DC 18SP (L), DC 25SP (L), DC 32SP (L) allows ecological combustion of wood on the principle of generator gasification in combination with a burner for pellets, natural gas or extra light fuel oils (depending on which burner is built into the boiler). Boiler type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 300 m². Power - 20.5 kW. Solid fuel type - firewood, pellets. The display is not. Boiler - external (optional). Boiler volume: 78 l. Heat exchanger material - steel. Overheating protection - yes. Frost protection - yes. There is a thermostat. Ignition is mechanical. The efficiency is 92%. Weight - 429 kg. The advantages of this model are also that the boiler takes up less space than a large number of boilers. As for ecological operation, the boiler, according to CSN EN 303-5, belongs to the 3rd class. |

Thus, combined boilers for heating a house are an excellent option for obtaining not only heat, but also saving money. Since there is always a choice of fuel and its autonomous switching, in the absence of one specific type of fuel, your home will be heated at any time of the year. Combined solid fuel and gas boilers are reliability, high performance and versatility.

Pyrolysis

Solid fuel boilers that work by pyrolysis combustion can be found under the name gas-fired boilers. Such boilers are not only reliable and durable, but also have the highest efficiency among all existing boilers. In addition, in such boilers, it is possible to regulate the power, which many analogues of this element of the heating system are deprived of.

Such boilers differ from conventional ones in that not only the fuel itself (wood) burns in them, but also wood gas, which is released from wood, due to the effect on wood fuel of an elevated temperature. Due to the fact that the wood gas is combusted, the formation of soot is completely excluded.

In addition, when using such a boiler, a rather small amount of ash is formed, which is quite an important feature for any type of boiler. The main disadvantage of boilers of this type is that they need to be connected to the electrical network for their operation, and they also have a rather high price. Such boilers can work on absolutely all types of wood or wood waste. In addition, homemade wood-fired boilers are fairly easy to make.

Pyrolysis boiler device

One of the positive features of gas-generating boilers is the fact that the boiler can successfully operate on one full load of solid fuel for 30 hours. This operating time is not standard. Like many other things, the operating time of the boiler on one solid fuel tab depends on many factors. These factors include:

- Outside air temperature;

- The air temperature in the room itself (its required limits);

- The quality of building insulation and the conductivity of thermal energy by the building material from which the walls of the building are made;

- Type of wood for fuel and its total moisture;

- The correctness of the implementation of the entire heating system and its condition.

But even with the most negative factors, such a boiler will work better and more economically than its counterparts. This became possible thanks to the combustion of wood gas. Burning any kind of wood that has some moisture does not give the same temperature as burning gas.

In addition, much less air is required to burn gas than burning wood or coal. Not only the combustion temperature of the fuel depends on this, but also the combustion time of the fuel material. An important factor is the ability to regulate the boiler power in a fairly simple way or automate such control using auxiliary thermostats. Thus, a gas-generating solid fuel boiler acquires all the functions of electric or gas boilers.