Energy saving principle

All electric heaters are energy saving, their efficiency is 98-99%. This means that when using 98-99 W of heat, 100 W of electrical energy is consumed.

If we take for comparison 1 kg of dry firewood released during the combustion of 4.8 kW of heat, 3.6 kW is consumed for heating the room, respectively, the efficiency of the unit is 75%. An electric heater with a consumption of 4.8 kW gives 4.75 kW.

Infrared heaters

Infrared heaters give off heat to surrounding objects and do not dry out the air.

Characteristics:

- Power. Household appliances are characterized by a performance of 300 - 2000 W, and for industrial purposes - 3-4 kW and above.

- Wavelength. There are 3 types of radiation: short-wavelength with a wavelength of 0.74 - 2.5 microns, medium-wavelength 2.5 - 50 microns and long-wavelength - 50 to 1000 microns. The shorter the wavelength, the higher the radiation temperature.

- Voltage. Household appliances up to 2 kW are connected to a single-phase network - 220 V. Production models are connected to a three-phase network (380 V).

- Moisture protection. If the IP24 marking is indicated in the technical passport of the device, you can safely install the device in rooms with high humidity.

- Technical parameters. For the manufacture of the case, steel or aluminum is used. The difference is the level of strength and weight (from 3 kg to 20 kg). The dimensions of the elongated models are 10-15 cm in width and height, and up to 1 m in length.

- Design features. There are devices on the market with and without a built-in thermostat.

Features of the use of steel for the manufacture of heating devices

Steel is produced by mixing iron and carbon. The material has an increased level of strength, which made it incredibly popular in the manufacturing and construction sectors. For the manufacture of heating radiators, steel has been used for more than half a century. The first technology failed. This material was forgotten for a while. More recently, experienced engineers, using modern equipment, have invented a new technique.

Steel radiators produced today are produced in several stages. This is metal sheet stamping, welding and painting. The first and second stages make it possible to obtain a structure that can evenly distribute heat and provide a high level of efficiency. Modern radiators heat up quickly. For their operation, a minimum amount of coolant is required. Metal painting helps to increase the resistance of products to corrosive processes. Thus, the quality of the paint application determines the reliability and durability of the radiator. Since the devices are manufactured by welding, the joints of the elements are sensitive to water hammer. To prevent ruptures, you will have to use an additional part in the heating system - a pressure reducer.

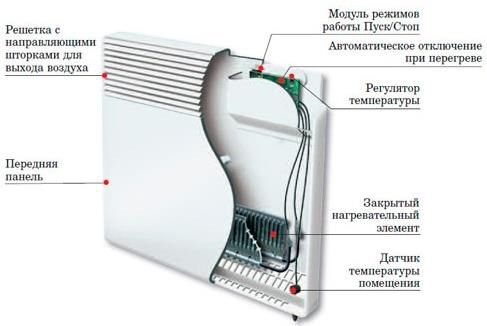

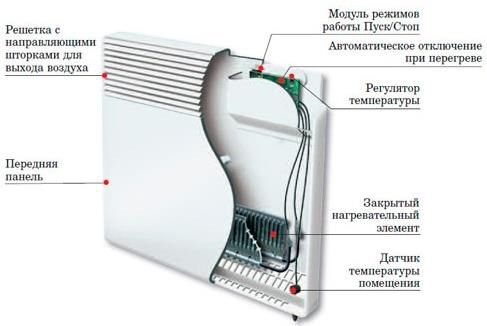

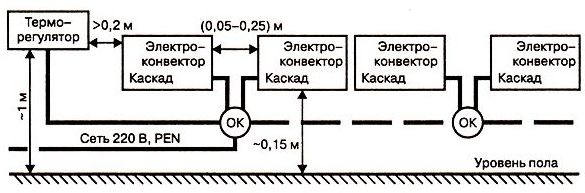

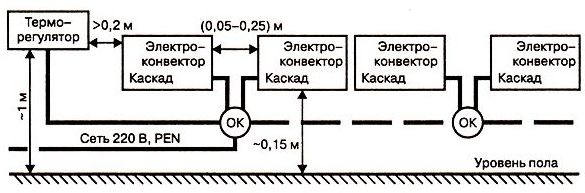

Heating convectors

Wall-mounted devices are mounted in areas where water batteries are located - under the windows, allowing to provide a barrier from the air flow coming from the windows. As a result, thermal insulation of the windows and the maximum level of energy savings are formed.

Electrical devices are characterized by high efficiency up to 95%, service life up to 25 years and the presence of additional elements:

- thermal sensor (mechanical or electronic);

- power indicator;

- sleep timer;

- humidifier.

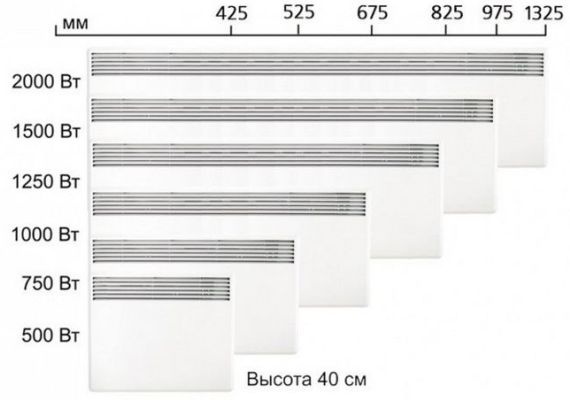

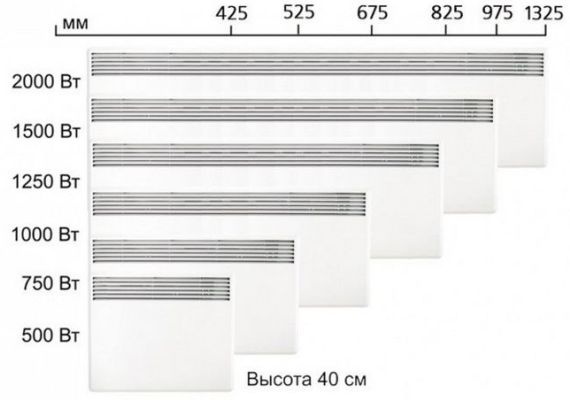

Features of the choice of an electric convector

The selection of convectors is made for the area of the room at the rate of 80-100 W per 1 m2.If the area is 10 sq. m., you will need a 1 kW device. With a ceiling height of 3 m, productivity should be increased up to 20-50%.

It is important to consider the type of thermal sensor - mechanical or automatic. Mechanical thermostats are manually set. They are 25-30% less expensive. But they provide less accurate work than electronic ones. Mechanical devices respond less accurately to changes in temperature below a predetermined mark.

Programmable devices more flexibly respond to changes in temperature conditions, provide hourly level of its maintenance. For example, during the absence of tenants, the temperature is set at + 12C, and upon return - + 22C.

The optimum level of moisture resistance is 21 IP. If the product is to be installed in a room with high humidity, the IP 24 device is recommended for purchase.

Liquid mini-boilers

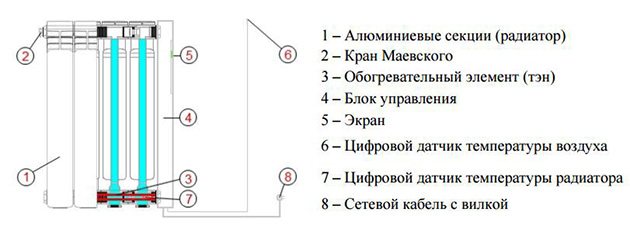

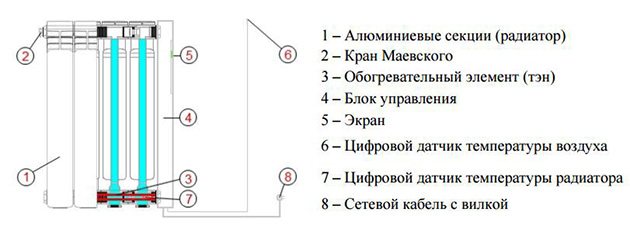

The next economical electric batteries are similar in design to traditional oil radiators. Only here several aluminum sections, combined into one heating device, are filled with antifreeze liquid. A heating element is placed in the lower horizontal collector, which heats this liquid. As a result, the hotter medium rises to the upper zone of the battery, gives off heat and returns back to the heating element. That is, there is a constant circulation of the coolant inside.

The device is equipped with an electronic thermostat functioning in tandem with a temperature sensor. The scheme of work is classic: after reaching the set temperature in the room, the thermostat turns off the electric battery, and after a while, when the air cools down, it starts heating again.

Additional functions:

- 7 modes, from the most economical to the maximum;

- overheating safety shutdown system;

- LCD display with calendar and clock;

- indication of the presence of grounding.

Note. These electric batteries for a country house or apartment are offered in wall or floor versions. The most famous Russian heaters are sold under the EffectEnergo brand.

Oil radiators

Structurally, oil radiators are presented in the form of metal batteries with hermetically connected sections and built-in electric heating elements. The increase in performance is provided under the influence of an anti-corrosion coating. To transfer heat, a technical oil with the 4th - the safest class of action on the human body is used.

Oil wall mounted batteries are supplied with a ground wire and plug. There are LED blockers and power adjustment elements on the side of the case. The power cord is located at the bottom of the device. And the thermal sensor is located inside it. A number of models are equipped with two types of clamps (floor and wall). This allows the wall unit to be placed on a stand or wheels.

Brass radiator production

Brass is an alloy of several metals. The species and quantitative content of the latter can be different. Most often these are copper, zinc, nickel, tin, lead, iron, manganese and other components. Brass radiators are durable and have a high level of thermal conductivity. This alloy perfectly tolerates the negative effects of chlorine present in central water supply systems. The performance of brass is comparable to that of copper. At the same time, the first is distinguished by a more affordable cost.

The main disadvantage of brass is its susceptibility to abrasion. In places where there are strong eddies and bends, solid particles circulating with the coolant damage the radiator walls. They become thinner over time. Leaks form in places of bends.

Having studied the features of steel, aluminum, cast iron, copper, brass, we can conclude that each material has its own characteristics and advantages. The latter, as a rule, determine the operational characteristics of finished structures. Modern manufacturers have learned to improve the quality of metals through the use of additives and coloring. When choosing a radiator, it is necessary to take into account the financial capabilities, the features of the heated object and the communication system. The modern market offers a wide range of domestic and foreign heating devices. These are both classic systems and unique design solutions. Thanks to this, each consumer has the opportunity to choose a battery that meets the needs of both quality and cost.

Proceed

Technical specifications

Battery performance varies between 0.5-3 kW. This indicates the possibility of full heating of a room of 5-30 m2.

Functional features:

- power level control (2 or 3 steps);

- a ventilating device to accelerate the heating of the room;

- a thermal sensor for maintaining a given temperature regime (from +5 to +35 degrees);

- timer for programming the device at a convenient time;

- decorative panel to increase traction (vertical channels create a convection effect without the use of fans, this improves traction and ensures quiet operation).

- removable frame support for linen.

- humidifier;

- ionizing device;

- heated towel rail.

Moisture protection level:

- unprotected version - IP20;

- drop protection - IP21;

- splash-proof - IP24.

Premises and staff

The choice of a building for a plant for the production of radiators should be in an industrial zone, where the rent will be much lower than in other parts of the city. In addition, in such areas, a wider selection of premises already equipped for production purposes is offered. At the same time, it is necessary that the territory has a convenient access for large-sized freight transport.

To organize a small production with one technological line, it will take about 600 sq.m. A large-scale enterprise with specialized equipment for the production of different types of radiators will occupy at least 5000 sq. m. In addition, separate premises should be allocated for the arrangement of other zones, including:

- office rooms;

- 2 warehouses (one for raw materials, the other for radiators);

- utility and service rooms for employees.

In total, a mini-plant for the production of one type of radiator will need about 800 sq. m.

The staff of such an enterprise will be small, since modern technological lines are almost completely automated. The state should include:

- master technologist;

- supply and sales manager;

- specialists in the shop;

- auxiliary workers;

- cleaner.

The manager may be the entrepreneur himself. It is recommended to hire an accountant at 0.5 rate or hire through an outsourcing company.

Device parameters

- Size - 500-700 mm high, 600 mm wide (narrow structures are 300 mm wide). The depth of the devices is 150 - 260 mm, but the ultra-thin devices are 100 mm thick.

- Number of sections - their number (5-12) directly affects the power of the device.

- Weight - from 4 to 30 kg.

- Configuration - oil radiators are produced in flat (compact) form and sectional.

The cost of the devices varies in the range of 500 - 6000 rubles.

Heating radiators: characteristics, types, types

The type characterizes the basic design principle of the radiator. - Panel. As the name suggests, a key element in the design of such radiators is the panel that connects the upper and lower manifolds; There can be several such panels, for more details see "Panel type".In any case, models of this type are characterized by good efficiency (due to the large area of heat transfer) at a low cost and do not require additional decorative elements, because the panel itself looks quite aesthetically pleasing. In addition, panel radiators do not accumulate dirt and are easy to clean: although the panel has characteristic protrusions-ribs to increase the heat transfer area, there are a minimum of slots and secluded places into which dust can clog in models of this type. Thanks to all this, this type has become very widespread today.

- Sectional. Radiators consisting of separate vertical sections. The sections are able to connect and disconnect, which allows you to choose their number at your own discretion (for example, disassemble a ten-section product into two separate radiators of 5 sections each, or even purchase additional sections if initially they are not enough). The most common design of such radiators provides for the presence of a set of thin plates in each section, which plays the role of a convector and increases the heating efficiency. Such devices are very effective, but more complicated and expensive than panel ones; in addition, the plates tend to accumulate dust, and it is rather difficult to clean it out from there. Therefore, sectional radiators are found somewhat less often than panel radiators (although they are also very popular). Another type of model of this type is outwardly similar to tubular (see below) and differs only in a collapsible design.

- Tubular. Radiators of a traditional design, familiar to many from the cast-iron batteries of the Soviet era: the upper and lower collectors in them are connected by characteristic pipes. By themselves, tubular structures are quite simple and inexpensive, but less effective than panel structures, and even more so sectional ones. In addition, the appearance of such a radiator often does not fit into the design of the room and requires the use of additional decorative panels, and the abundance of secluded places in the design leads to the accumulation of dust and makes cleaning difficult. As a result, this variety is very rare among consumer-class models and is gradually losing popularity; and the majority of modern tubular radiators are designer items with original design.

- Convector. A specific type of radiators, which, in accordance with the name, provides heat transfer mainly due to convection (unlike other varieties, where a substantial proportion of heating is due to thermal radiation). Convectors have a hollow body, inside of which heating elements are placed, and slots are made from above and below (or from the sides), due to which constant movement and heating of air is ensured. For a number of reasons, this type has not received special distribution; nevertheless, convectors are very useful where it is not possible to use classic radiators - for example, in shop windows.

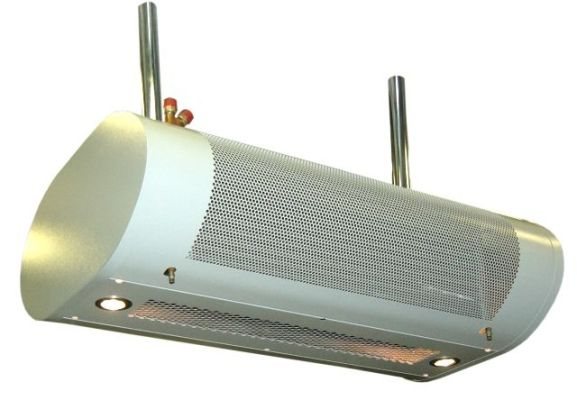

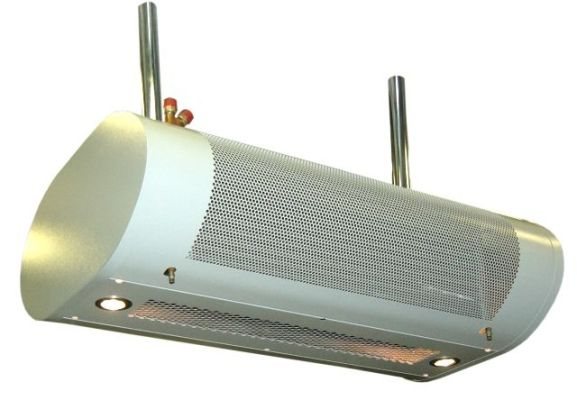

Fan heaters (thermal curtains)

Thermal curtains are used to protect the premises from the ingress of cold air from the street, penetrating through the cracks in the windows or doors. In the summer, they are used with the heating option turned off. Then the curtain prevents the penetration of insects and maintains the temperature set by the air conditioner. They are used in everyday life, production and storage facilities.

Structurally, the device is represented by 3 elements:

- body part;

- heater;

- ventilation device.

Below are the comparative characteristics.

Dimensions (edit)

The length of the fan heaters ranges from 600 to 2000 mm. When placing the device above a standard entrance door, the optimal size is 800 - 1000 mm, that is, the parameters of the curtain exaggerate the dimensions of the problem area.

Power

For heating 10 sq.m.with a wall height of up to 3 m, 1 kW is consumed. It will not be possible to heat a room with thin walls with a heat curtain - warm air may leak through the cracks.

Mounting type

Horizontal placement is important for protecting windows and doors. Vertical products are mounted where horizontal installation is not available. The height of the heating device is 3/4 of the height of the opening where the device is mounted.

Heat source

The heating curtain is heated from the electrical network and a hot water source. The attractiveness of the second option lies in the ability to operate at high power and cost savings. Such models are commonly used for industrial purposes.

Heating element

The spiral heating device is made of nichrome. It is represented by a thin wire wound on a glass-ceramic base. When opened, the product takes the form of unprotected wire coils, and closed products are presented in the form of coils protected by a glass reservoir. When the wire is heated, its temperature reaches up to 1000 degrees, which can lead to a fire if it is incorrectly positioned.

The ceramic heater is distinguished by increased safety, its heating reaches up to 150 g. Manufacturing technology is based on pressing the powder with further firing in a furnace. Finished products have a large number of openings that allow air to pass through. Their area is larger, relative to spirals or tubular heating elements, which makes it possible to speed up the process of heating the premises.

Heating elements are tubes made of metal or quartz, inside which there is a rod made of graphite or wire. Quartz sand with manganese oxide is filled between them. Element heating reaches up to 500 g, which allows to increase the service life, relative to spiral products.

Since the heating element provides a manifold increase in the performance of the heat gun, such devices are well used in the industrial field. They are called "heat guns", the power varies from 2.5 watts.

Industrial gas heating boilers

Gas burner for industrial heating boiler

One of the differences between industrial models of gas boilers is the type of burner. Structurally, it is a matrix consisting of several sources of thermal energy.

Thus, heating radiators for industrial premises receive a hot heat carrier with the highest possible temperature. In this regard, the combustion chamber in industrial gas heating boilers is much larger than that of household ones. This makes it possible to increase the rated power of the equipment.

The principal difference in the choice of equipment is the type of gas used:

- Natural gas... To do this, you need to connect to the central highway. The equipment is selected taking into account its characteristics - the amount of incoming gas, its pressure;

- Liquefied gas... Relevant for the creation of fully autonomous heating systems for industrial facilities. As a storage place, special containers are used - gasholders. Despite the increased initial costs, heating with liquefied gas has clear financial advantages over similar electric or solid fuels.

Industrial gas boiler

For all types of gas equipment, industrial heating batteries can be used. It is important that they correspond to the selected temperature regime.

In most cases, single-circuit boiler models are used to organize industrial gas heating. If it is necessary to make additional hot water supply, they install indirect heating tanks (heat accumulators) connected to the mains.

An important point when choosing a gas boiler is the possibility of replacing the burner.So you can increase its rated power without buying the rest of the components - a housing, a heat exchanger.

| Model name | power, kWt | Price, rub |

| Euroterm KTN 1.100 CE | 96 | 111000 |

| Protherm Grizzly 100 KLO | 70/99 | 152000 |

| Ross Lux AOGV-96 | 96 | 68725 |

| Fondital Bali RTN E 90 | 90 | 81800 |

Condensing gas boilers have the highest efficiency factor. But their cost is 45-50% higher than the classic ones.

Fans - plastic or metal

Axial ventilation systems are equipped with conventional blades and are designed for small appliances.

Tangential ventilation devices have an oblong conical shape. The cone accommodates 20-30 parallel blades. The device is characterized by high performance and quiet operation. The large length of the cone determines the possibility of its placement only in stationary heater-columns. The power of the devices is 1.8 - 2.5 kW. They are available with a built-in rotary device.

Fan heater control

There are models with a built-in remote control or a wired one. The first type includes small-sized devices placed above doors or windows. The wired remote control is completed with industrial or semi-industrial products. Together with the remote control, it is possible to install a temperature sensor that blocks the operation of the curtain when the set temperature is reached.

Fan heater prices

Copper is the basis for the manufacture of radiators

Stranded - is not a leader in the production of radiators. This is due to the high cost of the metal. In fact, the material has a huge number of positive qualities. It is not afraid of corrosion, does not enter into chemical reactions, and is able to prevent the development and reproduction of pathological microorganisms. During the operation of copper batteries, an oxide layer appears on their inner surface. The latter increases the strength of the metal. Due to this, particles present in the water of the central heating system do not damage the walls of the appliance. An additional protective layer does not reduce the level of thermal conductivity of the metal and does not disturb its smoothness.

Copper has excellent heat absorption and heat dissipation properties. Batteries made from this material allow you to regulate the temperature in a particular room. A significant advantage of copper is its high level of water hammer resistance. The metal has a soft and fairly plastic structure. This contributes to an even distribution of power loads. Also, plasticity allows the metal to easily withstand large temperature differences. Externally, copper is very attractive, which makes it possible to refuse staining during the production of heating devices. The advantages of such radiators include light weight. Installing copper batteries is straightforward. Plus, you don't have to use durable fastening systems.

Para-droplet heating batteries

Conversion of electricity into heat is provided by heating a small volume of water (in a sealed device case), which turns into steam when boiling. The steam forms condensation water which flows down the heating elements.

Products are produced in several versions:

- Aluminum devices with automatic control, with a capacity of 500, 900, 1500 W.

- Steel PCNs have a power of 1000 - 1500 W.

- Industrial heating appliances with explosion-proof housing and wall-mounting options.

Carbon Heaters

Carbon (graphite) is used as a heating element using nanotechnology. Structurally, it is represented by a glass tube containing graphite fibers in a vacuum environment.

Due to the complete isolation of the heater from humid environments, the service life of the product is increased.The design of the device is designed for automatic unfolding with a radius of 120 - 180 gr., Which ensures uniform heating.

The key advantage is the absence of magnetic radiation, when connected to the network, the device quickly turns on in operating mode. Infrared radiation is similar to the spectrum of far radiation (the length of the rays is 5-20 microns). The cost of the device varies in the range of 2,500 - 4,100 rubles.

Lithium Bromide Heater

The device consists of vacuum sections filled with a lithium bromide compound. When heated, the liquid is converted into steam, which heats up the entire appliance. For heating, 0.5 l of the liquid composition is enough, which affects the reduction in the level of energy consumption.

Wall-mounted appliances are used for permanent installation or integrated into a common heating system. The absence of pressure in the system ensures the safety of heating. The independent arrangement of the upper vacuum from liquid and air media ensures long-term operation. Lithium bromine prevents the formation of oxides on the metal.

Products are equipped with a protective system against "airing" and a thermal sensor. The temperature range includes a range of 20 - 75 g. Remote control is possible. Heating of the coolant (water or antifreeze) is carried out in an electric boiler. The batteries are used in the beam and gravity system. The cost of products varies from 800 rubles. for 1 section.

Requirements for the organization of industrial heating

General and zone heating

When creating a system for maintaining the required temperature regime in production facilities, the current standards are compulsorily observed. Most of them are described in SP 2.2.1.1312-03... According to this document, industrial heating batteries, boilers and other elements of the system are selected.

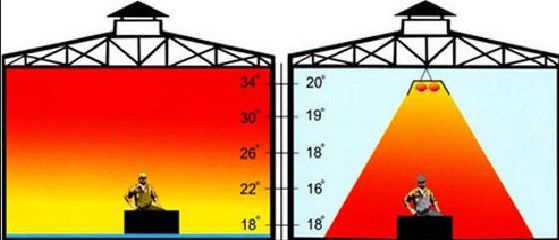

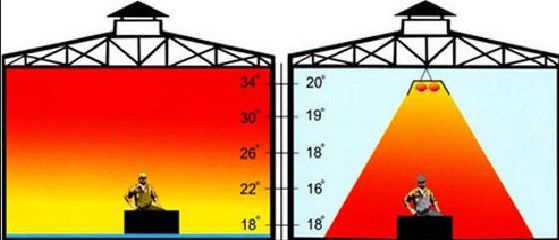

The first step is to determine the type of heating system. Currently, there are 2 types - zonal and general. The first is intended for the point maintenance of the temperature regime. Most often these are infrared industrial heating systems. They are characterized by economical operation and the ability to quickly regulate the degree of heating.

Infrared heating unit

If it is necessary to maintain the temperature level throughout the volume of the room, then the best option would be to install a pipe circuit. It can be industrial gas heating, electric or solid fuel boilers. In addition, when choosing a specific scheme, the following factors are taken into account:

- Features of the production process... In particular, the optimal temperature level and the possibility of its rapid regulation;

- Heat loss of the building... It is not always possible to make effective insulation. In this case, it is best to install a zone industrial air heating;

- Energy cost... To a greater extent, this refers to the planned production costs, which will ultimately affect the cost of production;

- The cost of equipment, components and labor costs for their installation... According to this parameter, the most effective are infrared and air heating of industrial premises.

To determine the best option, you need to perform a lot of calculations. But there are already well-known "pluses" and "minuses" characteristic of certain systems.

SP 2.2.1.1312-03 does not provide recommendations on the choice of a specific heating system. This regulatory document describes the mandatory requirements for the temperature regime of heating and ventilation.

Selection Tips

Oil batteries are recommended for installation in apartments, one device is enough to heat the room.

Convectors, due to their low heating temperature (60 ° C), do not burn air, they are mobile, noiseless and fireproof. The efficiency reaches up to 99%. Warm up the room quickly and are protected from overheating.Programmable products are successfully used to integrate into an electric heating system.

Fan heaters are characterized by an increased heating rate, but are noisier. Open coil devices burn oxygen. IR emitters are used to heat individual areas of the room.