Why is there noise in the boiler?

Extraneous noise in the boiler is most often not as dangerous as it might seem to an ordinary person. The threat consists only in the appearance of malfunctions when the boiler needs major repairs or replacement. Do not postpone checking the heating system indefinitely when extraneous sounds appear in the gas burner. You need to immediately contact a specialist who can determine the cause of the noise and eliminate it. It is not recommended to disassemble the boiler yourself if there is no firm confidence in how it functions and what parts it consists of.

The most common causes of humming, tapping, hissing and other noise accompanying the operation of a gas boiler are:

- operation of anti-freeze media

- decrease in gas pressure

- limescale on boiler parts

- malfunction of circulation pumps

- incorrect installation of the burner

- fan failure

The main causes of noise and hum

Let's name the most common causes of boiler noise and humming:

- oxygen oversaturation of water in the heating system;

- sludge on parts from water circulation (including in the heat exchanger);

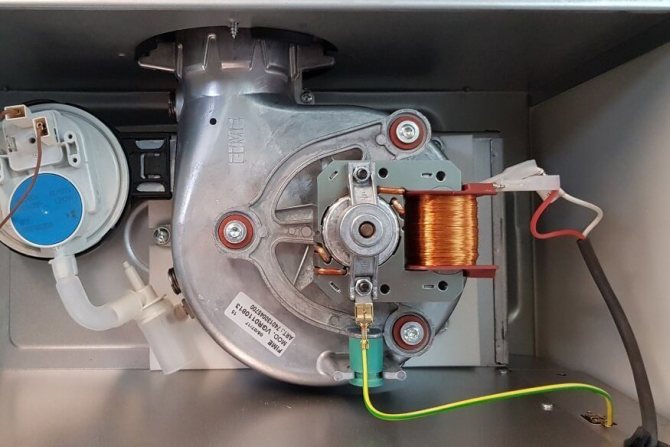

- fan failure;

- decrease in gas pressure.

Oxygen saturation of water in the heating system

The noise or hum of the device may be monotonous or spontaneous with crackling sound. With the first option, this happens even with new boilers. In this case, such sounds are usually produced by installations that are connected to a heating system with natural circulation. The reason may be the oversaturation of oxygen in the water in the pipes. Then, when the water is heated, small bubbles form, making noise. The noise is not dangerous for the boiler operation. But a small nuisance is still present, as it creates discomfort with noise in the pipes of the rooms. In this case, the system can be recycled to a closed one. The process of changing the type of system consists in installing valves on the boiler and changing the expansion tank to a diaphragm one. A weather-sensitive automatic system can be selected. These measures will help to extend the life of the boiler.

Sediment on parts from water circulation

But there are other reasons why the boiler hums. Wines can be in sediment, which forms as a result of water circulation. It is not pre-filtered; when heated, after some time, it forms scale on the parts. Their functions weaken, there is extraneous noise from the work process. The first to lose capacity is the heat exchanger. It heats up as a result of the combustion of the gas, transferring heat. Scale forms not only on the walls of pipes and radiators, but also on the entire system. The passage for water is narrowed, which provokes the appearance of steam. Such processes reduce equipment wear resistance and efficiency. Tapping appears. This means that the system must be descaled. Do the cleaning with special chemicals. After that, the boiler stops humming.

Fan failure

Another common reason a boiler makes noise can be a fan malfunction. He is responsible for cooling the system, removing combustion products outside the room, flue gas. The boiler specialist will determine the cause of the fan failure. This could be located over the main heating pad or lack of lubrication. Often the part is just clogged with dust. They inspect, clean this part, lubricate the bearings. If necessary, it is worth changing the fan so as not to buy a new boiler.

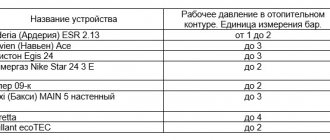

Decrease in gas pressure

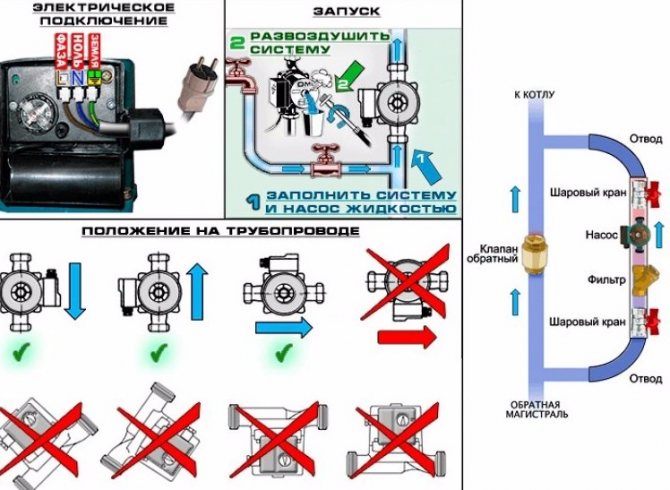

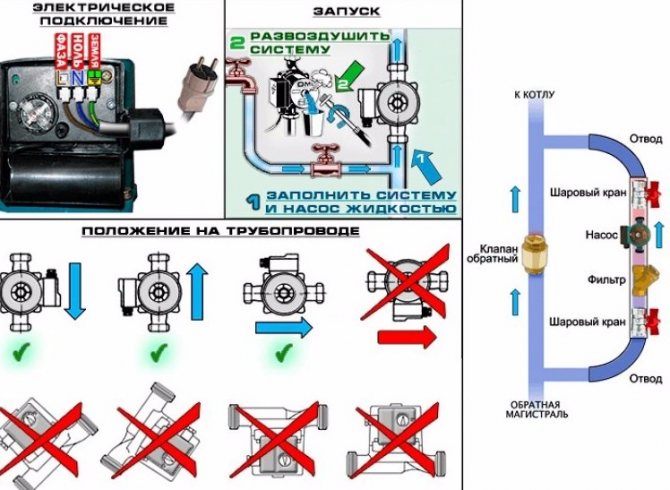

The boiler sometimes makes noise and hums due to a decrease in pressure. As a result, less water begins to circulate in the system, air locks appear, the boiler overheats and makes noise. The level of heat output of the device and its sections decreases. It is enough to adjust the pressure. Most boilers have a lever for such cases. You should know the optimal values and regularly check the condition of the boiler. Normal pressure is 1.5-2 atmospheres. Often a knock is heard from the pipeline and radiators, which means that air has entered the system and must be removed. If the pump itself makes noise, then a factory defect is not excluded.

If you carry out preventive cleaning of the heat exchanger from scale in time, regulate the gas supply to the system, and the pressure, then you can extend the life of your boiler. But remember, the exact cause of the noise in the boiler and the elimination of this problem can only be eliminated by a qualified specialist in heating systems.

Limescale on boiler parts

Due to the fact that water is not filtered before it enters the heating elements (read about the choice of a filter for heating in a separate material), therefore, sediment often remains on the inner surfaces of the gas boiler. Parts are gradually losing their functionality. The problems start with the heat transfer elements. Further, sediment forms on the walls of radiators, pipes, this reduces the space through which water must flow. It is quite simple to get rid of scale, just open the gas boiler and clean it using special means. In this case, only the wear resistance of the equipment itself suffers. To avoid similar problems in the future, it is enough to carry out periodic preventive cleaning.

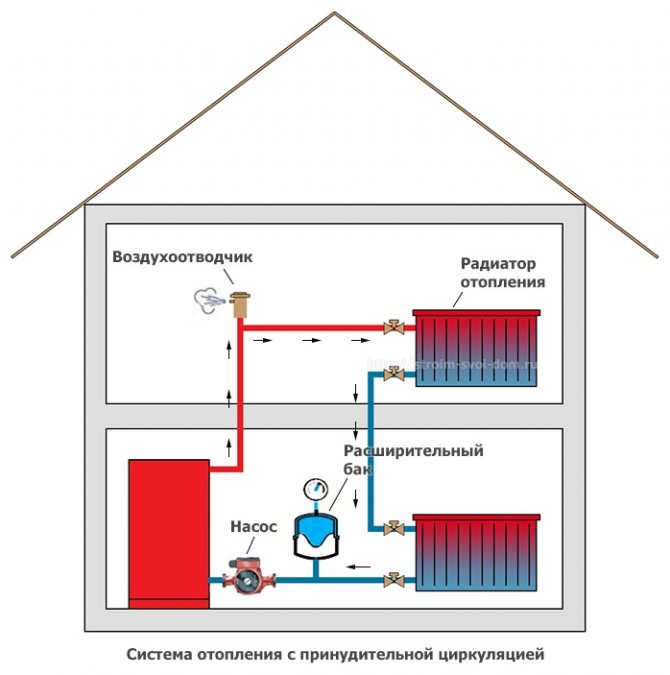

What to do if water boils in batteries

You can often hear sounds such as gurgling water, up to intense boiling. As a rule, this is due to the presence of so-called air locks. They are looking for a way out - as a result of which the water in the system can boil. Moreover, this not only leads to discomfort, but also to the fact that the efficiency of the coolant decreases, since, as you know, the thermal conductivity of air is worse than that of water. In order to eliminate air congestion, special taps are often installed at the upper levels of the heating system, through which excess air is released.

Mayevsky's crane is a device for bleeding air from radiators of central water heating, opened with a special key or screwdriver.

Incorrect burner installation

Quite often, a noise resembling tapping or whistling can be caused by the fact that the gas burner in the boiler was initially incorrectly configured and installed. To check, you will need to compare the level of gas pressure leaving the burner and the recommended indicators in the technical passport of the equipment. Entrust this task to the specialist who installed the gas boiler.

Causes of noise

There are actually not so many reasons for the appearance of knocking in heating pipes during heating. Some of the noises can be ignored - they do not harm the system and heating devices. But such noises as buzzing, crackling, knocking, gurgling, howling should give reason to think and take urgent measures.

- air locks in the system;

- clogging or overgrowing of pipes due to poor-quality coolant;

- pipeline leaks;

- violation of installation work during the installation of cranes, valves and pipe laying;

- failure or wear of working equipment;

- cavitation, pressure increase in places of increase (decrease) in pipe diameter;

- incorrect calculation or non-compliance with design recommendations when installing the heating system.

These circumstances arise in private closed-loop systems and make one think about their urgent elimination.

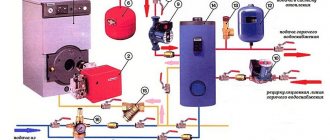

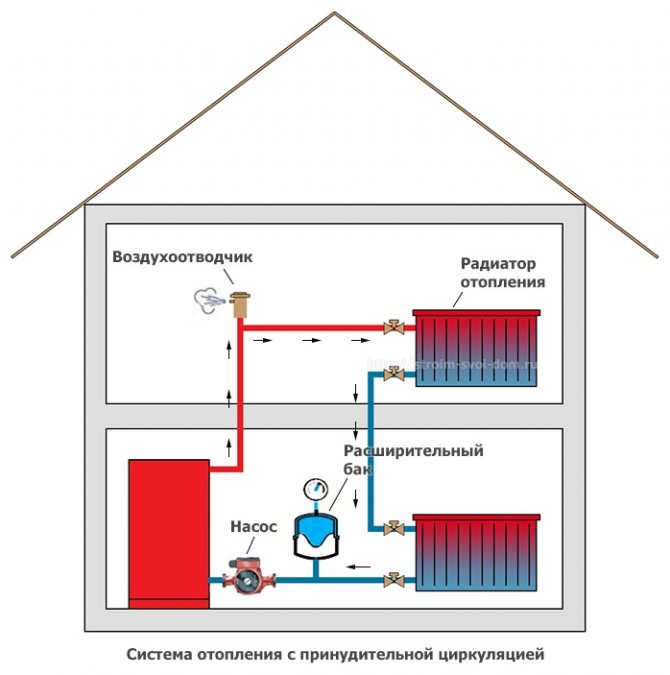

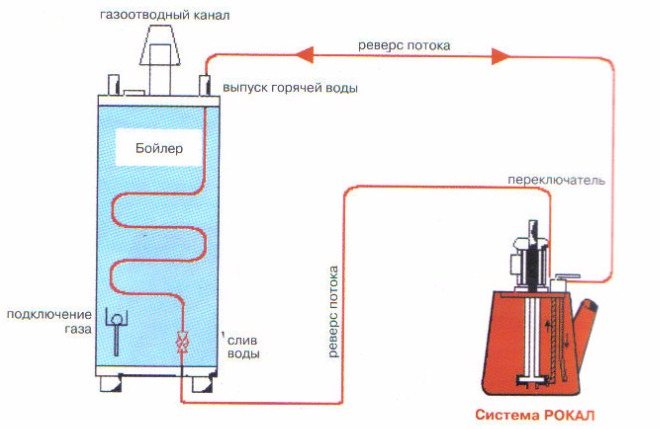

The circulation pump in the heating circuit system contributes to the forced movement of water, which leads to uniform heating and displacement of accumulated air from the system.

If the heating in a house or apartment is connected to a central pipeline, then starting, accompanied by such sounds, is normal. Water, filling the common system, pushes air out, and, overflowing along the contour, is accompanied by a murmur, thud and crackle.

As soon as the equipment enters the operating mode, the general adjustment of the system will end - the temperature of the batteries will rise, and everything will stop. This is clearly seen in the scheme of heat supply to consumers from the central boiler house.

Causes of noise

There are actually not so many reasons for the appearance of knocking in heating pipes during heating. Some of the noises can be ignored - they do not harm the system and heating devices. But such noises as buzzing, crackling, knocking, gurgling, howling should give reason to think and take urgent measures.

- air locks in the system;

- clogging or overgrowing of pipes due to poor-quality coolant;

- pipeline leaks;

- violation of installation work during the installation of cranes, valves and pipe laying;

- failure or wear of working equipment;

- cavitation, pressure increase in places of increase (decrease) in pipe diameter;

- incorrect calculation or non-compliance with design recommendations when installing the heating system.

These circumstances arise in private closed-loop systems and make one think about their urgent elimination.

The circulation pump in the heating circuit system contributes to the forced movement of water, which leads to uniform heating and displacement of accumulated air from the system.

If the heating in a house or apartment is connected to a central pipeline, then starting, accompanied by such sounds, is normal. Water, filling the common system, pushes air out, and, overflowing along the contour, is accompanied by a murmur, thud and crackle.

As soon as the equipment enters the operating mode, the general adjustment of the system will end - the temperature of the batteries will rise, and everything will stop. This is clearly seen in the scheme of heat supply to consumers from the central boiler house.

Extraneous sounds in the heating boiler

Sometimes boiler lighting is also accompanied by some sounds. When cold equipment heats up and begins to crack, then the characteristic clicks should not cause panic - the metal makes such sounds when it warms up.

Gurgling and gurgling are also possible - this is also a normal phenomenon: the coolant began to heat up and set the system in motion. However, the same sounds can occur when there is not enough coolant in the pipes. In this situation, it is enough to add water to heat evenly.

Cotton

You can hear such sounds if the gas pipes are clogged. This happens when the boiler is fired up: the accumulated gas, not having time to go outside, creates a pop. This is dangerous as a violently escaping flame can cause burns or fire.

If the boiler is gas, then the reasons for this noise are clogged nozzles or a malfunction of the three-way valve. In this situation, it is necessary to clean the equipment from soot.

The occurrence of knocking in the boiler indicates its incorrect installation or unregulated operation of the pumping equipment. If the pump works unevenly, moving the coolant in jerks, a resonance occurs between the boiler and the pump, accompanied by a characteristic knock. In this case, it is necessary to regulate the operation of the pump.

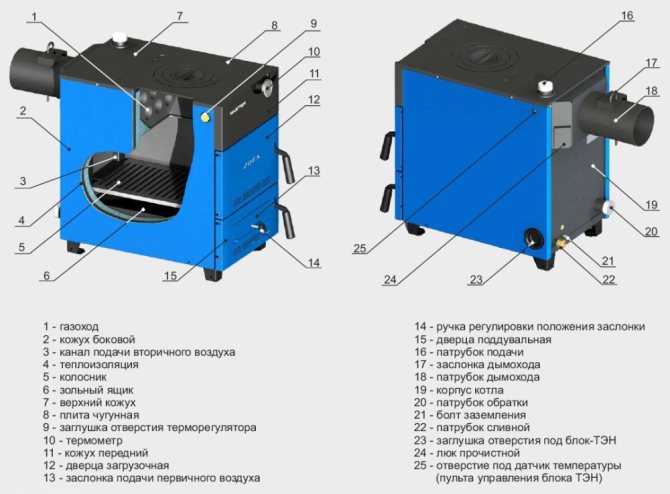

Sounds in different boiler models

Noise can arise for a trivial reason, which lies in the boiler model itself. This is typical for gas boilers equipped with ventilation burners.To avoid such a nuisance, it is necessary to choose boilers with atmospheric burners and an electronic control system.

When choosing a model of a solid fuel or electric boiler for heating a house, it is always necessary to get acquainted with the technical characteristics of the equipment. Often the reason for the noise can be incorrectly selected equipment, as well as the presence of a fan in the boiler.

Double-circuit boilers also sin with noisy work: although not clearly, the overflow of water and the filling of the system are always accompanied by sounds.

ZOTA boilers are very sensitive to the quality of the coolant, therefore, the cause of unpleasant effects can be:

- clogged mud sump;

- oxygenated water;

- scale on working elements;

- broken bearings on the fan.

Therefore, it is worth stopping the choice on single-circuit models, and purchase a boiler for heating hot water.

Prices for boilers ZOTA

Prophylaxis

Timely prophylaxis of all components of the boiler equipment can minimize the likelihood of noise.

So, flushing the system once a year is a prerequisite for trouble-free operation. Moreover, this is becoming a mandatory requirement of many resource supplying organizations in preparation for the heating season.

You can flush the system yourself or use the services of specialists.

Depending on the coolant, the type of cleaning is selected:

- Flushing with water under pressure generated by the compressor. Sometimes this is enough.

- In case of deposits of iron oxides on pipes, appropriate chemicals are used. They eliminate the problem and additionally create a protective barrier against further exposure to an aggressive environment.

- You can use the services of a specialized organization that has the equipment and means to perform the work.

Each operating manual for heating equipment provides a recommendation for preventive inspection and cleaning of the working parts of the boiler from corrosion and all kinds of contamination with partial disassembly - at least once a year. If you do not carry out maintenance, the manufacturer will void the warranty.