Gas heating boilers made in South Korea are considered to be products of average quality and cost.

This is quite a fair opinion, however, there are pleasant exceptions.

Kiturami products deserve to be put on a par with the most famous and popular boilers of European production.

High quality, advanced design and other advantages of the units made them famous and in demand both all over the world and in Russia.

Boilers demonstrate high competitiveness, have a lot of advantages and require more careful consideration.

Kiturami gas boilers

The South Korean company Kiturami was founded in 1962 as a small metalworking workshop.

During its existence, a small company has managed to develop into a solid and powerful corporation that produces a wide range of heating equipment for various purposes.... Scientific and technical research is underway, new units and parts are being tested.

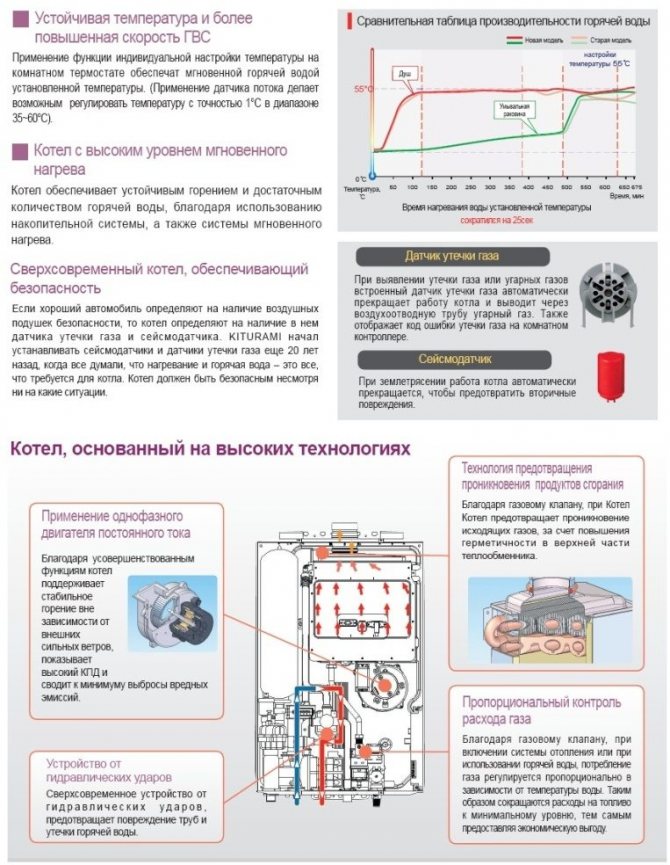

Kiturami gas boilers are created according to the most efficient and advanced technologies, but without excessive oversaturation of unused functions that only increase the cost.

The result of this approach is a range of economical and durable units capable of performing tasks of any complexity and volume, with high reliability, resistance to external loads and durability.

Views

Kiturami gas boilers are available in a wide range and can be conditionally divided into groups according to certain criteria.

By type of installation there are:

- Floor standing... Installed on a special stand or directly on the floor.

- Wall mounted... They are hung on solid walls or on special supporting structures - ramps. Hitching onto temporary or plasterboard partitions is prohibited.

By feature set:

- Single-circuit... Carry out only heating of the coolant for the heating system.

- Double-circuit... In parallel with heating the coolant, they are capable of heating hot water for domestic needs in a flowing manner.

All models are equipped with a closed combustion chamber (turbocharged). This means that air supply and smoke extraction are carried out using a special turbocharger fan, which provides stable draft and independence from external weather conditions or the characteristics of room ventilation.

By type of heat transfer:

- Convection... Normal heating of the heating medium in the flame of a gas burner.

- Condensing... Intermediate heating of the coolant is used from the thermal energy obtained by condensing water vapor from the exhaust smoke. The full operation of such a boiler is possible only on low-temperature heating systems (such as underfloor heating), as well as if the temperature difference inside and outside the room does not exceed 20 °. In other conditions, the boiler operates as a conventional condensing unit.

IMPORTANT!

Among the Kiturami lines, there are condensing boilers that require specific operating conditions that are impossible in most regions of Russia. When choosing a unit, this should be taken into account, since the prices of condensing models are much higher than those of convection ones.

Characteristics important when choosing a boiler

1) Heat output

The choice of boiler power is very important when purchasing it. Decisions taken "by eye" are absolutely inappropriate here. Otherwise, it may turn out that the new boiler will not cope with its task, and there will be little hot water and not enough heat in the house; or you simply overpay by choosing a much more powerful unit than necessary.To prevent this from happening, you need to take into account the features of the structure, climate, and also make calculations for the power reserve and heat loss. The designer will help you with this. You can save money by using a special method for determining the boiler output. It is taken at the rate of 1 kW per 10 meters. This method is not 100% accurate, so by choosing it, you assume all possible consequences.

2) Fuel consumption

There are many factors that affect fuel consumption:

- correct installation of equipment and adjustment of burners;

- chimney design;

- individual characteristics of the building and its walls;

- operating mode of the building;

- accuracy of calculations when selecting a heating system.

The designers of Kiturami boilers place great emphasis on economy and fuel efficiency. There are many patented developments in this area, and all of them are aimed at improving the efficiency of fuel combustion. Some processes in boiler control are fully automated, which allows you to use them most efficiently in any heating system.

3) Heating system height

Also, an important point when choosing a boiler. And here a huge advantage of the Kiturami company is that you can choose from models for any height of the heating system. Boilers of the TURBO, KSG, TGB, KRM, WORLD 5000 series are used in heating systems up to 20 meters high. And the KSG and KSO models with a capacity of 58 kW to 465 kW are intended for heating systems up to 35 meters high.

Gas series and related models

Among the Kiturami floor standing boilers there are the following series:

- KSG... Powerful heating systems developing from 50 to 200 kW. Designed for heating only, but can be connected to an external storage tank, which makes them capable of supplying the house with hot water. They are capable of heating large areas, if necessary, they can be connected in a cascade of up to 4 units.

- STSG... 4 models of relatively low power (from 16 to 58 kW), designed for heating small and medium-sized private houses. All models are double-circuit, equipped with a separate heat exchanger, with a closed combustion chamber.

Kiturami wall mounted boiler series:

- WORLD PLUS... The series is represented by 5 models with a capacity of 15, 16, 20, 29, 34.9 kW. All models are double-circuit, designed for heating and supplying hot water to rooms up to 350 m2. The series is manufactured specifically for use on the territory of Russia, adapted to technological and climatic conditions.

- TWIN ALPHA... 5 models from 15 to 35 kW. Double-circuit boilers with a separate heat exchanger.

- TWIN ALPHA NEW COAXIAL... A slightly improved TWIN ALPHA series, which includes models with the same parameters. Designed to use a European type coaxial chimney (horizontal),

There is also the Kiturami Eco series, made up of condensing boilers.

Types of boilers Kiturami

Kiturami boilers can be subdivided by design and power as follows:

- Diesel floor standing boilers Kiturami. Turbo series (9000-35000 watts) and KSOG (58000-465000 watts) with Turbo burner.

- Floor standing gas boilers Kiturami. TGB series (35000 watts), KSOG with TGB torch (58000-465000 watts).

- Wall-hung boilers are presented only with gas models from 15 to 35 kW.

Let's look at the characteristics of Kiturami boilers using the example of the Kiturami Turbo diesel boiler.

Specifications

Consider the technical characteristics of Kiturami boilers:

| Parameter | Value |

| Boiler type | Gas heating |

| Heat transfer method | Convection or condensing |

| Functionality | Heating, hot water supply |

| Power | 15-297 kW |

| Efficiency | 92-98 % |

| Installation method | Floor-standing or wall-mounted |

| Gas burner type | Closed |

| Energy consumption | Single-phase current 220 V 50 Hz |

General description of Kiturami boilers

The entire range of Kiturami heating boilers is double-circuit. That is, they are used not only for space heating, but also for the production of hot water in the DHW system. If there is no need for hot water, the DHW circuit can be left out.

At companies you can find both wall-mounted and floor-standing Kiturami boilers. In addition, floor standing boilers are manufactured in vertical or horizontal configurations.

In addition to liquid fuel (diesel) heating boilers, Kiturami produces boilers operating on liquefied gas, as well as combined boilers operating on two types of fuel: liquid and solid.

It is worth noting that it is Kiturami diesel boilers that are considered the most reliable in their class.

Advantages and disadvantages

The advantages of Kiturami gas boilers are:

- High operational capabilities of boilers, reliability, efficiency.

- Stable operation, low failure rate or failure rate.

- High build quality, reliability of assemblies and parts.

- A wide range of models to suit any need.

- Optimal set of functions, lack of unused features that increase the price of the boiler.

- Silent operation, simple operation.

- Relatively low cost.

- Compactness, attractive appearance.

The disadvantages include:

- Volatility. When the power is cut off, the heating system will stop working. In addition, Boilers are sensitive to correct connection and stability of the power supply.

- The need for maintenance by qualified personnel.

NOTE!

These disadvantages are inherent in any gas boilers and can be considered specific design features.

Summarizing

Heating boilers are popular not only in country houses, but also in urban areas, because autonomous heating gives a lot of advantages over centralized heating. Kiturami boilers can be attributed to one of the most high-tech offers on the market, high efficiency, durability, the possibility of flexible regulation of work only contribute to the growth of the popularity of the products of this manufacturer.

The video shows in detail the principle of operation of the Kiturami gas boiler.

Did you like the article? Subscribe to our channel Yandex.Zen

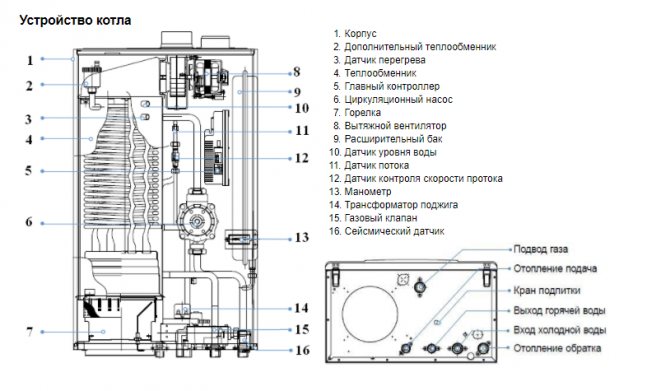

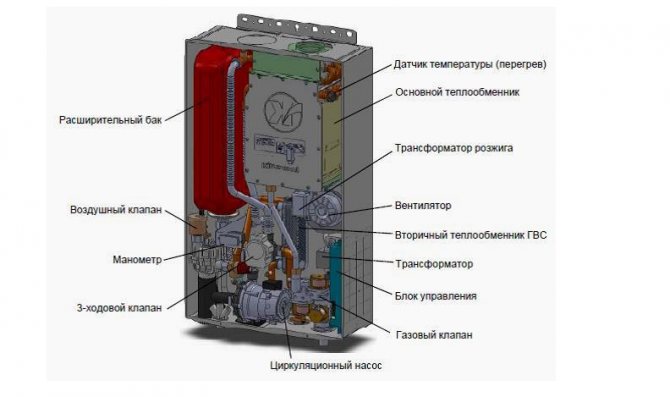

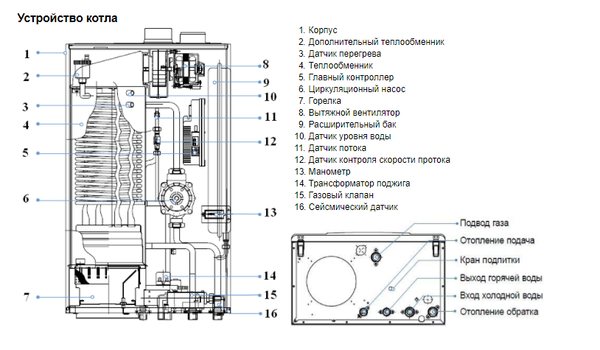

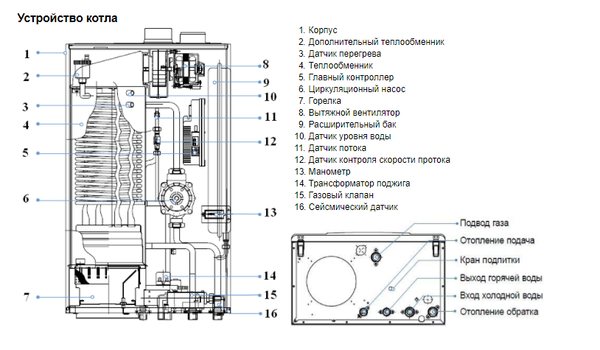

Device

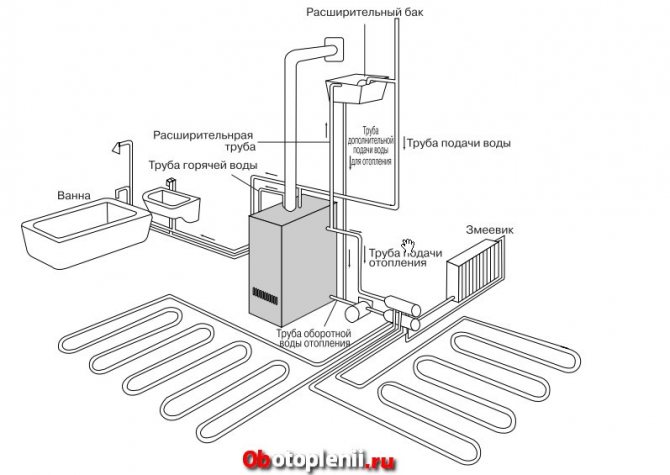

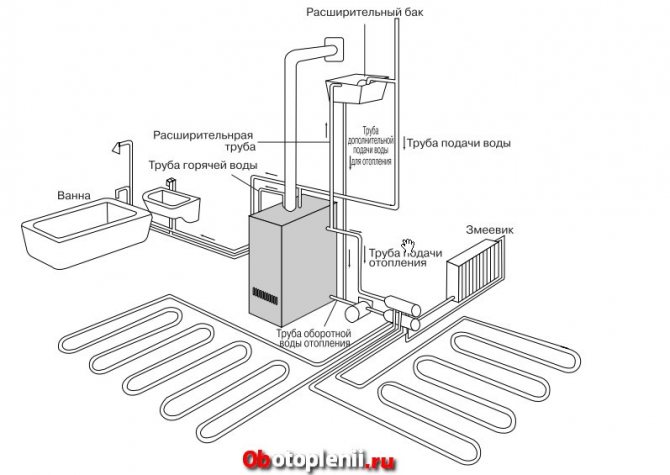

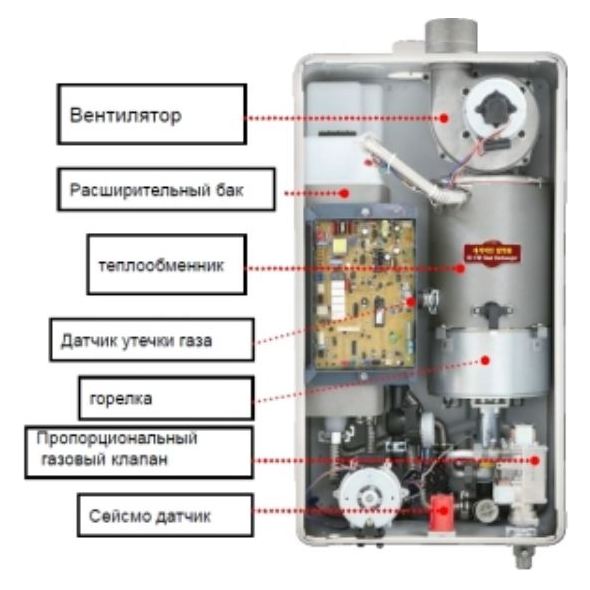

The main structural elements of the boilers are the gas burner and the heat exchanger. These are independent units, but they work in pairs and are structurally combined.

The heat carrier under the action of the circulation pump enters the heat exchanger, heats up and leaves the secondary plate heat exchanger, where it gives off part of the thermal energy for the preparation of hot water. After that, the coolant flows into the heating circuit.

Exhaust and air supply for normal combustion is provided by the turbocharger fan, and the control board controls the operation of the system.

A system of self-diagnosis sensors is connected to it, detecting malfunctions and giving signals to the control board, which immediately triggers an alert on the boiler display.

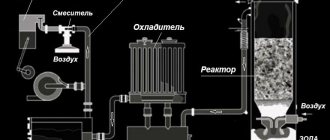

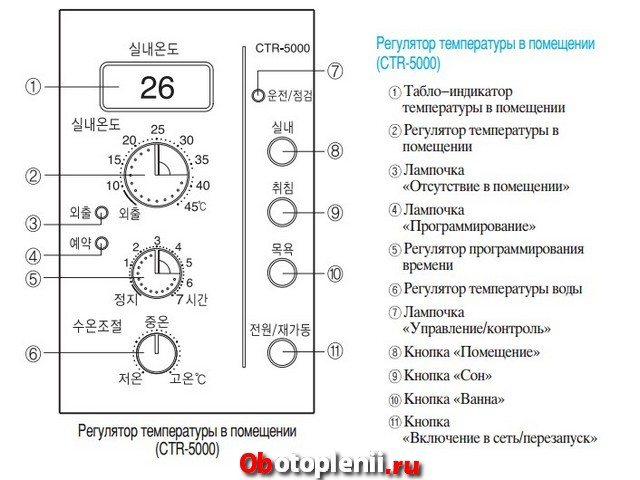

Kiturami KRP

Kiturami KRP pellet boilers for heating and hot water supply. Pellets are used as fuel - a form of solid fuel in the form of pellets made from compressed wood waste. Pellet boilers Kiturami KRP use wood pellets of the 1st and 2nd category Ø 6 - 8 mm and length 10-30 mm. Pellets exposed to water or moisture turn into wood flour, as a result of which they lose their fuel properties. The use of such wood meal as fuel can seriously reduce the efficiency of the unit, including a decrease in power and an increase in ash production. The built-in circulation pump is used when supplying hot water in order to evenly distribute heat in the heat exchanger. This design guarantees efficient hot water supply. The package includes a room thermostat. It has a number of useful functions, such as: season selection for setting the heating water temperature, switching on and off by time, the autonomous operation function maintains a minimum room temperature and prevents the boiler from bursting, the flushing function provides a large amount of hot water and others. Some technical features of the Kiturami KRP pellet boiler

- Used for heating and water heating;

- Automatic dosing of fuel, depending on the need for heat and the stage of combustion, into the boiler furnace by means of a feed auger;

- The circulation pump and expansion tank are built-in, which naturally simplifies its installation;

- The ash collector is in the form of a box, it is easy to empty it, and due to its special design, cleaning the boiler is not difficult;

- The use of a special heater in the Kiturami KRP pellet boiler allows you to increase the ignition area;

- The design of the boiler prevents the back blow of the torch;

- For safe operation: frost protection function, double overheating protection, built-in overheating and water level detectors, etc.

Kiturami KRP Premium instructions and documentation:

- Kiturami KRP booklet

- Kiturami KRP User Manual

- Kiturami KRP User Manual - A (Premium)

| 1. | Operation of the Kiturami KRP-A boiler on sunflower husk pellets. To view, click on the camera. |

| 2. | Start-up of the Kiturami KRP 20-A boiler. Burner ignition |

Operation and setup

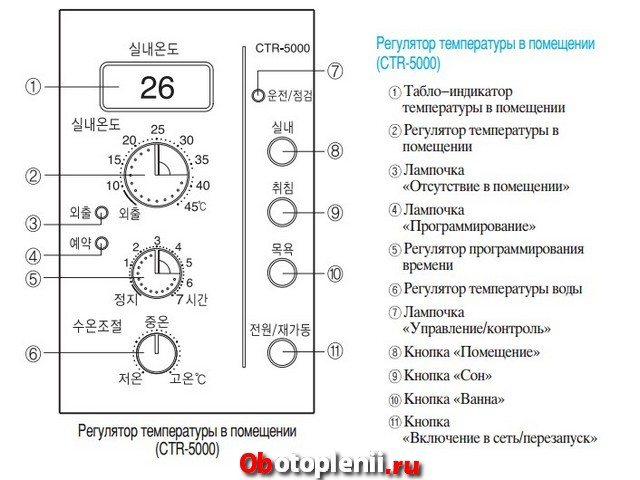

The operation of Kiturami boilers is automatic.

From the user, in order to configure, only a few actions are required:

- Adjustment of temperature, carried out in the working order.

- Draining and filling the system with water.

- Periodic cleaning of the boiler body from soot or dust.

All other actions take place either automatically or by the forces of invited specialists. This is especially true for the initial setup, which overrides the factory settings for greater performance and economy.

Download instruction

Download instructions for gas boilers Kiturami.

Unauthorized intervention in the boiler structure may cause its breakdown and void the warranty agreement.

The lineup

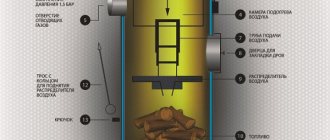

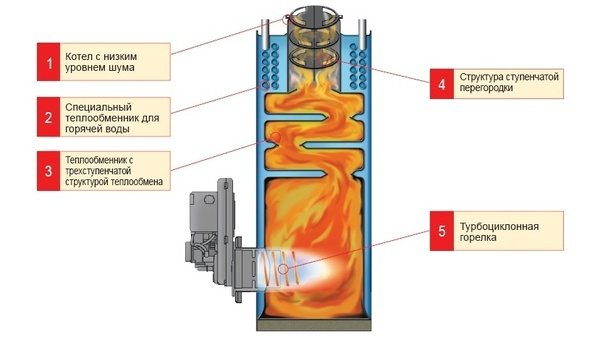

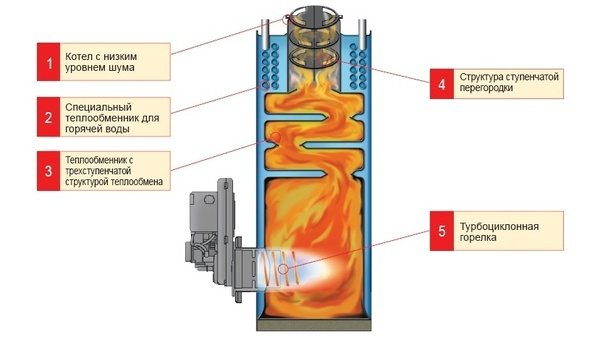

The development of the KSO models was initially carried out as a gas-fired equipment. After, changing the type of burner and slightly changing the monitoring and control system, it became possible to use other energy sources. Diesel fuel became the main one. The turbo-cyclone burner has contributed to 100% fuel combustion and increased efficiency. The advantages of the model are simplicity of design, ease of maintenance and low price.

Biofuel boilers KRM-30R and KRM -70R with the changes made to their design, both diesel fuel and other solid fuels are used. The transition from one type of fuel to another is quick. The forced circulation system improves the efficiency of the heater. These models differ only in power.

Turbo 13r model generates 13,000 kcal / hour of thermal energy or 15.1 kW, which is enough to heat 150 sq. m. Heat costs for the preparation of hot water supply are taken into account. With significant regular waste of boiling water, the thermal circuit power is lower.

Turbo 17 model has a thermal power parameter of 19.8 kW, sufficient to heat 180 sq. m. To increase the limit of the upper performance threshold, nozzles on the burner are selected, which can affect fuel consumption.

Turbo 21r model with a capacity of 24.4 kW has an increased productivity of the DHW circuit. In this case, the dimensions of the boiler remain unchanged.

Liquid fuel turbo 30 r model has a capacity of 34.9 kW, sufficient for heating 350 sq. m. Equipped with torch-shaped burners, the fuel combustion mode is optimal. Due to the low amount of nitrogen oxides, it is a highly environmentally friendly equipment.

Major malfunctions

Kiturami boilers are renowned for their reliability and durability of parts. However, the possibility of individual problems cannot be ruled out.

Most often, the components that are under maximum load fail - the heat exchanger and the gas burner.

A layer of lime scale builds up in the heat exchanger, which reduces the heat transfer efficiency.

It is necessary to increase the combustion temperature, as a result of which the outer part of the unit gets too hot and fails.

A gas burner is susceptible to clogged nozzles and other problems that lead to flame extinguishing and difficulty in firing up the boiler..

Often there are malfunctions of the self-diagnosis system sensors themselves - poor contact, open circuit, short circuit.

Floor standing boilers

Each Kiturami floor standing machine is equipped with a turbo cyclone burner. If necessary, it can be replaced with a diesel one. The manufacturer offers three versions:

- STSG. Heating capacity 15-35 kW. Compact. Capacious DHW tank. Steel radiator - welded using innovative technologies that exclude leaks.

- TURBO. Low noise level. The original structure of the heat exchanger chamber - combustion products pass through it repeatedly.

- KSOG. They differ from other versions in large dimensions, higher heat output - 58-454 kW, and the use of special heat transfer pipes. Pressed pipes increase efficiency.

Error codes, decryption and how to fix

Consider the most common errors of Kiturami boilers:

| The code | Decoding | Remedy |

| 01-03 | Unsuccessful ignition of the flame | Check the condition of the burner nozzles, the presence of gas in the line, the condition of the valves and the supply valve |

| 04 | Temperature sensor malfunction | Checking the status of contacts, calling the wizard |

| 05 | Failure of the boiler overheating sensor | Call the master |

| 06 | Fan operating mode is not detected | Check the status of contacts, call the wizard |

| 07 | Incorrect fan speed | Call the master |

| 08 | The wire length of the room temperature controller is exceeded | Cut the wire, check if it is in contact with the telephone line |

| 95 and 98 | Low water level in the heating circuit | Add water, check system for leaks |

| 96 | Overheating of the coolant | Check the operation of the circulation pump, increase the liquid level in the system, call the master |

| 97 | Leak of gas | Turn off the boiler, open windows, call specialists |

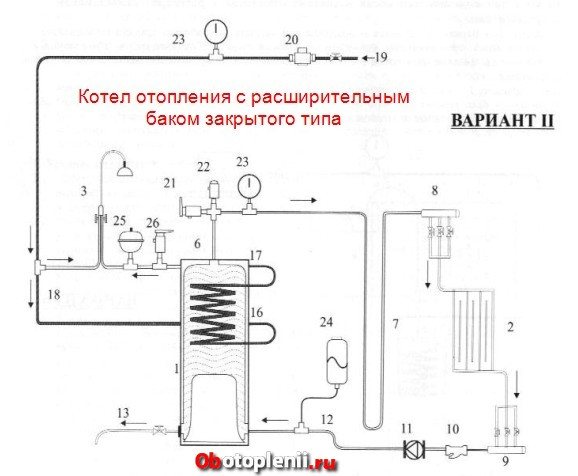

Installation of Kiturami boilers

- Liquid fuel boilers are installed in a room with a temperature corresponding to the temperature of the heated room ± 10-15%;

- The room must be provided with supply and exhaust ventilation in accordance with the standards for furnace equipment;

- The storage of building and flammable materials is not allowed in the furnace;

- The floor in the boiler room must be washed. A floor is made with a slope for draining water and oil products. The sewerage system must be equipped with a filter for oil products;

- The ceiling height in the boiler room is at least 2300 mm;

- The boiler is placed on a non-combustible platform no thinner than 50 mm. It is recommended to make a platform of brick or concrete;

- The distance from the boiler drum to the walls and ceiling (niche) must be at least 600 mm;

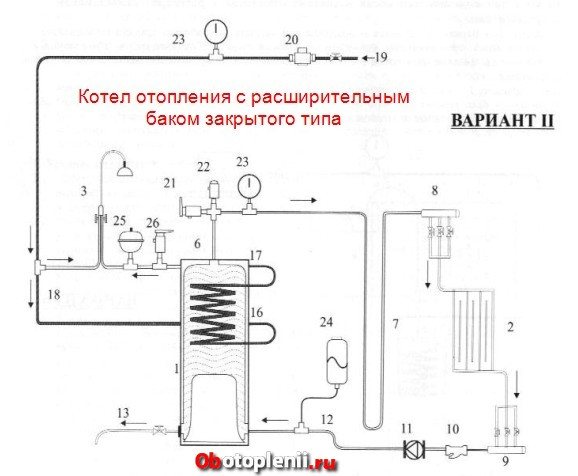

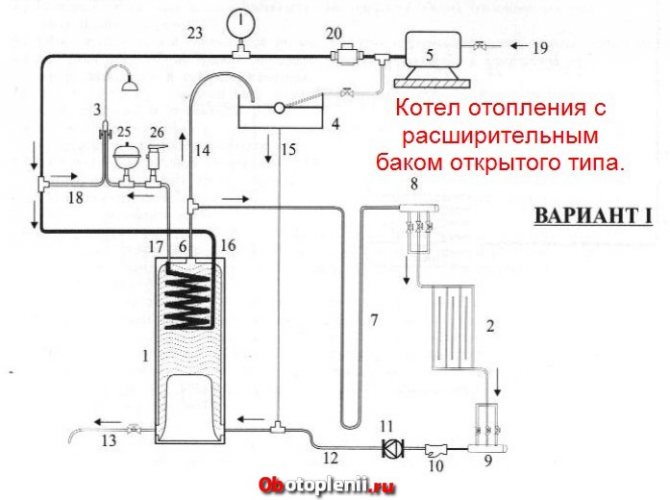

- The expansion tank of the boiler is installed at a height of more than one meter from the top of the boiler;

- Direct water supply to the boiler is prohibited. Supply from a storage tank is recommended;

- It is necessary to use a circulation pump in the system and make a drain system with a valve;

- For the electrical connection of the boiler, a separate wiring group is required, with an earthing contact protected by a circuit breaker + RCD (residual current device), or a differential circuit breaker.

- Fume extraction from the boiler is done with a chimney in the shape of the letter "L", with a bend of at least 50 cm. The incline of the pipe to the main chimney must be 5˚. The length of the chimney must be at least 3 meters from the boiler surface.

These are the general rules for installing a Kiturami oil boiler. To install the boilers and maintain the warranty, you need to invite specialists.

© ObOtoplenii.ru

Price range

The model range of Kiturami gas boilers is very wide. The cost of household models (for a private house) is in the range of 30-60 thousand rubles, but there are also more powerful models that will cost 100-800 thousand rubles.

Such a price difference is due to the degree of power and capabilities of the boiler, its purpose and design features..

As a rule, users choose units of lower power and, accordingly, cost.

Please check the terms of delivery before purchasing. Boilers in the basic configuration do not have a chimney, so you must immediately decide which type is needed and order it. You should also immediately get filters and a voltage stabilizer..

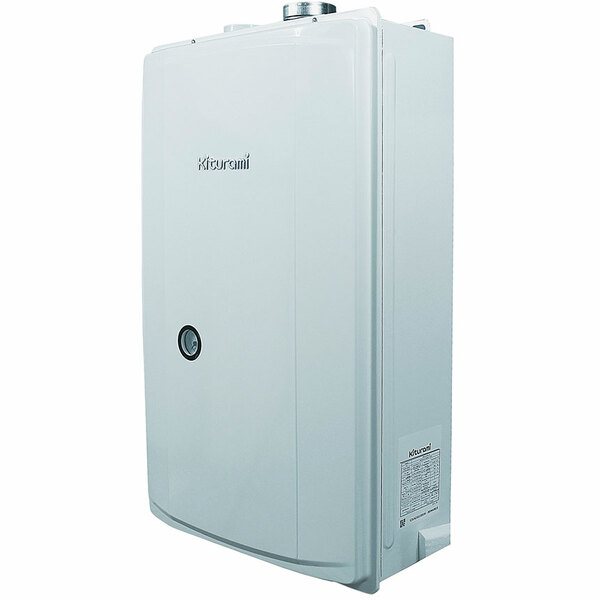

Hinged boilers

The most popular are wall-mounted gas boilers of the Korean manufacturer, since they are light in weight and compact in size. Such a boiler can be installed in the kitchen or in the corridor or in another small room.

Consider the models of wall-mounted gas boilers by KITURAMI:

- The KITURAMI World 5000 model is one of the most powerful and can heat a room with an area of 350 m2. In this boiler, you can use absolutely any coolant. The equipment is equipped with a built-in expansion tank and a circulation pump. Thanks to the solenoid valve, gas consumption is reduced, and it is quite convenient to use the boiler in the summer. You can control the device remotely.

- Model KITURAMI world 3000. With the additional purchase of nozzles, the boiler can be converted to operate on reduced gas. The boiler includes a separate copper heat exchanger and a coaxial chimney.

- The KITURAMI world plus model was specially made for Russia. This model has two built-in heat exchangers, so you can heat the water without turning off the heating. In this model, there is a complete combustion of fuel and its economy, thanks to a gas burner with internal combustion. Using the controller, you can set the operating mode for heating the room, taking into account individual needs. An external thermostat is installed as standard.

- The KITURAMI ECO Condensing model is a condensing boiler that receives additional heat energy by using condensation. Thermal energy is extracted about 10% of the total. Such a boiler is the most economical of all models produced by the Korean manufacturer. The boiler is equipped with all the necessary functions. To obtain thermal energy equal to 16 kW, about 1.6 m3 of fuel will be required. It is very profitable to use such a condensing boiler for space heating.

- Model KITURAMI twin Alpha. In such a boiler, there is a forced removal of combustion products and air injection. The design uses a heat exchanger made of copper and aluminum. Thanks to several modes, you can fine-tune your working settings. And also a system is installed in the boiler to protect against overheating of the coolant and against the ingress of carbon dioxide.