Fresh, safe air for people is a basic factor that determines overall well-being and health. In industrial and warehouse complexes, the quality of aeration also cannot be treated superficially: it allows you to maintain the temperature and humidity regime necessary for equipment or goods, removes caustic fumes and dust from the premises. Therefore, the regulatory authorities strictly monitor that during the construction, use of buildings for any purpose, the basic requirements for ventilation systems, as well as specific provisions for the facility, are observed.

Air exchange complexes are generally subdivided into comfortable and technological. The former must comply with the sanitary and hygienic component of the requirements. The latter, in addition, are checked according to the conditions determined by the technology of the industrial facility.

For individual ventilation elements, specific positions are formed. Basic principles:

- for exhaust systems - maintaining an acceptable level of concentration of harmful substances in the air that enters the premises and removing contaminated masses;

- for local sources of supply ventilation - effective capture with the subsequent removal of industrial hazards (gas, corrosive vapors, etc.) and household hazards.

Classification of requirements

The norms that define the "reference" indicators and rules for organizing air exchange are developed at the national level. In general, they can be subdivided into general GOSTs, regulating provisions for ventilation, and SNiPs, which control individual details of the sanitary component. For industries, facilities with an increased risk of fires (warehouses with fuels and lubricants, paint) or with specific conditions of detention (pharmacies, hospitals, chemical plants), separate instructions are being developed.

Requirements for ventilation systems are formed depending on their features. The basic function of any installation is to create an air environment that would satisfy all standards and solve problems:

- removal of waste masses with harmful impurities and excess heat;

- implementation of the influx of fresh, corresponding to SNiP.

Requirements for the installation of ventilation and indicators for its further operation can be classified in separate areas:

- sanitary and hygienic - ensuring the comfort of people in the room and monitoring safety for their health;

- operational - compliance with the simplicity and ease of maintenance, availability for repair, minimizing the need for it;

- architectural, installation - fire safety, vibration and sound insulation of equipment and structural elements, minimization of time and effort for installation and commissioning;

- economic - reducing (as far as possible and justified from the point of view of common sense) the cost of installing systems and their use.

Basic requirements for the ventilation and air conditioning system

Medical University "Reaviz"

abstract

"Basic requirements for the ventilation and air conditioning system"

Completed by: Norboeva S.G., student of group 633

Faculty of Pharmacy

Checked:

Samara 2020

Introduction

Ventilation in industrial premises is an extremely important and effective means of protecting the health of workers and preventing diseases.

In industrial premises, many technological processes are accompanied by the release of heat, moisture, harmful substances in the form of vapors, gases and dust.Along with this, the air of the premises is constantly polluted by carbon dioxide exhaled by a person, decomposition products of sweat, sebaceous glands, organic substances contained in clothes and shoes, as well as chemicals released from polymeric materials. To maintain the specified parameters of the air environment in the room, it is necessary to supply fresh air and remove contaminated air.

The air of chemical-pharmaceutical enterprises and pharmacy production facilities can be contaminated during the manufacture and dispensing of drugs, during the chemical analysis of prepared drugs. For example, when hanging, dosing, pouring, filling, chemical analysis of drugs in the assistant, filling, in the room of the pharmacist-analyst, the air is polluted with dust, vapors and gases of medicinal substances. In a washing, distillation and sterilization room, the air can contain excessive heat and moisture. Prolonged stay of a large number of people in the sales area causes changes in the physical properties and chemical composition of the air (temperature, humidity, carbon dioxide content, the number of microorganisms, etc.).

Maintaining the parameters of the air environment in production facilities that meet hygienic requirements is carried out by various ventilation systems, the design of which takes into account the amount of hazardous emissions.

Ventilation systems

Industrial ventilation occupies an important place in the complex of preventive measures to improve the air environment of industrial premises, aimed at improving the working conditions of workers. Its direct purpose is to combat excess heat and moisture, as well as gases, vapors and dust.

By the way air moves, they are distinguished natural, mechanical and mixed ventilation systems.

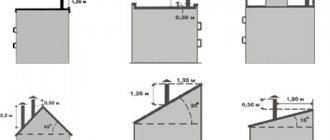

The inducer of air movement during natural ventilation is the wind pressure on the walls of the building. (wind pressure),

ensuring the movement of air through the room in a horizontal direction, and the temperature difference between the room and the outside

(thermal head),

causing vertical movement of convection air currents and removal of heated, polluted air through openings in the upper part of the room.

Natural ventilation

can be applied in the form

through ventilation,

carried out by wind pressure, and in the form of controlled ventilation -

aeration.

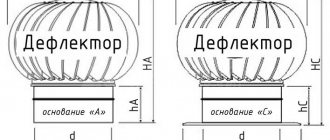

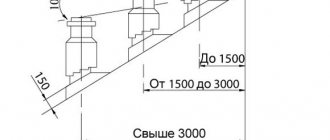

Through ventilation is usually used in industrial premises with a large number of workers and in the absence of harmful emissions (toxic dust, vapors and gases) in the air. Aeration is used only in rooms with excess heat (so-called hot shops) with a heat release of more than 23 W / m3. During aeration, outside air enters the room through open window openings and transoms, and polluted air, which carries away excess heat, moisture, industrial dust, is removed from the workshop through the upper openings or special devices. Local natural exhaust ventilation is organized in the form of exhaust shafts (pipes) located above the places where hot vapors and gases are emitted (heating furnaces, forging forges) and brought out to the roof of the building. To increase the efficiency of natural extraction, deflectors of various designs are installed inside the exhaust shafts.

Special devices (fans, ejectors) serve as a stimulus for air movement during mechanical ventilation.

Mechanical ventilation

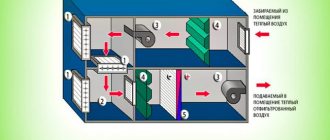

It is subdivided by the direction of the air flow into supply and exhaust. They can be in the form of general (general) and local (local) ventilation.General ventilation is designed to create optimal and acceptable meteorological conditions throughout the room. It is usually used if workplaces are evenly distributed throughout the room, and harmful emissions go directly into the air of the working area. The incoming air must be distributed evenly throughout the entire volume of the room.

General ventilation inlets,

as a rule, air is supplied to the lower (working) area of the room. Air supply to the upper zone is possible in two cases: in the presence of permanent sources of dust in the room (to avoid the rise of settled dust) and water vapor that can condense in the cool supply air, therefore the air is supplied heated to 30-35 C to the upper zone of the room.

Local supply ventilation

(in combination with aeration or mechanical supply and exhaust ventilation) is used, as a rule, in hot shops in the form of

"Air shower",

supplying cool (18 C) air directly to the working person,

"Air oasis",

which is a resting place for workers, enclosed by a water film, inside which cool air is supplied, as well as in the form

"Air heat curtain"

(the flow of warm air is not higher than 50-70 C in the outer doorways of industrial premises and at the outer gates). The speed of air release from the slots or openings of air and air-thermal curtains should be no more than 8 m / s at the outer doors and 25 m / s at the gate.

Exhaust ventilation

is designed to remove air polluted with harmful emissions from the room, for example, from a washing pharmacy, the room of an analytical chemist

General exhaust ventilation

removes polluted air from the upper area of production facilities.

Local exhaust ventilation

is used directly in places where harmful substances are generated during a number of operations (weighing, dosing, loading, etc.), to prevent their spread throughout the room. Local exhaust ventilation is the most effective way to combat excess heat and moisture, gases, vapors, and dust. Since the concentration of harmful emissions at the place of formation is higher, the air consumption for their removal is much lower than with general ventilation.

Local suction units must meet the following requirements: high tightness, ease of maintenance, resistance to aggressive media, low air consumption, high efficiency of trapping harmful substances. Local suction designs can be completely closed, half-open

or

open.

Closed suction systems are most effective. They capture harmful substances as fully as possible with a minimum volume of exhaust air. These include housings, chambers, hermetically or tightly enclosing dusty equipment. In some cases, the sealing of shelters is impossible for technological reasons. In these cases, partial cover suction is used.

(pull out drobe)

or open: hoods, exhaust panels, onboard suction and other devices.

Fume cupboards

almost completely cover the source of harmful secretions. Only the working openings through which the air from the room enters the cabinet remain open.

Exhaust hoods

used to trap harmful secretions that rise up. Umbrellas are installed over the accumulation of heat and moisture sources and other sources of non-toxic hazards released along with heat.

Suction panels

are used to remove harmful emissions in the case when the zone of harmful emissions is relatively large and it is impossible to organize a more complete shelter.

Onboard suction

installed along the perimeter of open baths containing technical solutions, from the surface of which harmful vapors and gases are emitted. The principle of operation of these suction units is that the supply air captures harmful vapors, gases and carries them into the exhaust duct.

Features of the ventilation system in pharmacies

In pharmacies, ventilation and air conditioning systems are considered effective if they maintain microclimatic conditions in the premises in accordance with the requirements of sanitary regulations and remove harmful substances from the air of the working area to MPC levels.

In rooms with excessive heat, it is most effective to maintain optimal and permissible air temperatures as a whole due to general exchange natural (aeration) or mechanical ventilation using a local air flow in the form of air spraying for individual workplaces. For hot shops, aeration is the cheapest and most reliable ventilation method.

To ensure a normal thermal balance of the body in rooms with excess moisture, ventilation should help remove excess moisture and prevent the formation of condensation of water vapor in the air and on the inner surfaces of fences. For this, hermetic local exhaust devices in the form of suction units are most rational. If it is impossible to use them, general exchange supply and exhaust ventilation is used with the supply of heated dry air to the working and upper zones and the extraction of moist warm air from the upper zone of the room.

To remove harmful vapors and gases, local exhaust ventilation with the organization of supplying air to the upper zone of the room is most effective. If it is impossible to use it, general exchange ventilation is used, which, when clean air is supplied to the working area (at a height of 1.2-1.5 m from the floor), contributes to the dilution of harmful substances entering the room to the maximum permissible concentration. In these cases, it is recommended to extract the polluted air from the zones closest to the places of hazardous emissions, and in case of excess heat - from the upper zone, even with the release of heavy gases and vapors.

For dust control, the only effective dedusting method is local exhaust ventilation, which removes dust from the source of its formation. In cases where condensation aerosol is formed or work is performed not at fixed workplaces, it is necessary to use general exchange supply ventilation, designed to dilute the aerosol.

The suction rate of contaminated air depends on the dispersion of the pollutants and their toxicity (hazard class). It is recommended to remove coarse dust at a speed of at least 4 m / s, fine dust - 2 m / s. To remove highly toxic vapors and gases, it is recommended to maintain a suction speed of at least 1.5 m / s, for low-toxic ones - 0.7 m / s. Dust extraction ducts should not have sharp corners in places where they change direction and should not be combined with air ducts that remove water vapor or poisonous substances, in order to avoid the accumulation of dust deposits and blockage of the ducts.

The ratio of the total amount of supply and exhaust air (air balance)

The air balance is considered balanced,

if the amount of air entering the room is equal to the amount of air that is removed from the room by the exhaust ventilation during this time. If the amount of organized air supplied to the room is greater than the amount of air removed, an increased pressure is created in the room; in this case air balance

positive.

Usually a positive air balance is used in rooms where contaminated air from neighboring rooms ("clean" rooms: aseptic unit of pharmacies) or cold air from outside is undesirable.Due to the excess air pressure in the aseptic unit, the movement of air flows will be directed from this unit to the adjacent rooms. If more air is removed from the room due to the exhaust ventilation than is supplied by the supply ventilation, the air balance

negative

(premises with harmful emissions).

Also, in the aseptic unit, it is recommended, using special equipment, to create horizontal or vertical laminar flows of clean air throughout the room or in separate local areas to protect the most critical areas or operations (clean chambers). Clean chambers or tables with laminar airflow should have work surfaces and a hood made of smooth, durable material. The laminar flow speed is within 0.3-0.6 m / s with regular monitoring of air sterility at least once a month.

Air conditioning.

Air conditioning is understood as the creation and automatic maintenance in closed rooms of the constancy of such indicators of the air environment as temperature, humidity, pressure, gas and ionic composition, odor and air velocity. A device that performs the required air processing (cleaning, heating or cooling, etc.) is called an air conditioning unit, or air conditioner. With the help of air conditioners in the premises, the necessary microclimate is provided to create conditions of comfort and the normal course of technological processes.

Features of the ventilation air preparation system in the pharmaceutical industry

In connection with the introduction of GMP (“good manufacturing practice”) rules at many pharmaceutical industry enterprises, one of the main issues is the preparation of so-called clean production rooms (NPP), or “clean zones”, in which the most critical technological operations for obtaining drugs take place.

Clean rooms are the main consumer and part of the air preparation system. The main possible sources of air pollution: personnel, equipment, technological process, particles released into the air, forming an aerosol from solid particles suspended in the air, or fog from liquid ones. A multi-stage atmospheric air filtration system is designed to remove particles that form aerosols or mists.

One of the main documents describing the method of multi-stage air filtration is the "Typical ventilation air preparation scheme" developed by the State Scientific Research Center with the participation of GiproNIIMedprom, modernized taking into account new requirements in 2002.

The air purification system in the proposed scheme consists of several filters: a coarse filter, a fine filter, and highly efficient final filters. After passing through the coarse filter, the air enters the central air conditioner, where it is sequentially heated, cooled and reheated in various sections, then it enters the steam humidifier and through the fan into the fine filter, then into the high-efficiency filter. Then the air enters the clean rooms of various zones A, B, C, D, which are subject to the corresponding requirements for the content of mechanical particles with a size of 0.5 microns and the content of microorganisms (Table 46). This variant of the typical scheme also provides a differentiated return of recirculated air, which reduces the cost of air preparation. The system works with two air conditioners.

Table 46.

Technological parameters of ventilation air in clean rooms

| Technological parameters | Standards |

| Temperature | 20? 2? C |

| Relative humidity (subject to technological requirements) | 45?5% according to technological regulations |

| The content of microorganisms with a size of 0.5 microns: Zone A, B Zone C Zone D | 3520 pcs / m3 air 352,000 pcs / m3 air 3,520,000 pcs / m3 air |

| Microorganism content: Zone A Zone B Zone C Zone D | no more than 1 piece / m3 air 10 pieces / m3 air 100 pieces / m3 air 200-500 pieces / m3 air |

Requirements for air conditioning and ventilation systems

Requirements for ventilation and air conditioning systems depend on the tasks for which these systems are installed. However, there are general principles to consider when designing systems.

Sanitary and hygienic requirements

The air comfort of people in a room depends on several parameters that can be controlled by ventilation and air conditioning systems. The microclimate is characterized by:

• Air temperature

• Relative humidity

• Air speed (mobility).

For various types of premises (residential, public, industrial) there are standards and rules (SNiPs, sanitary standards) that establish the optimal and permissible air parameters.

Optimal (recommended) parameters

- these are the most favorable conditions for the best human well-being (area of comfortable air conditioning), conditions for the flow of the technological process, preservation of cultural values (area of technological air conditioning). If a person is in a room with optimal air parameters, he feels thermal comfort and has high efficiency.

Valid (required) parameters

microclimate are set for those cases when the optimal parameters for some reason are not observed (for technical or economic reasons). If a person is in a room with acceptable microclimate parameters, he may feel temporary discomfort and decreased performance.

In addition, sanitary standards regulate:

• Air purity (pollution in the air of the working area should not exceed the MPC)

• Maximum permissible noise level

• Minimum consumption of fresh air per person.

For a number of technological processes, it is necessary to precisely maintain certain air parameters (temperature, humidity, purification). The air conditioning and ventilation system must cope with their implementation.

If the quantity and quality of products in production depends on the accuracy of the technology mode, and not on the productivity of employees, then in such a room it is necessary to maintain the air parameters that are optimal for the production process. If productivity is determined primarily by the people working indoors, then the focus should be on the comfort of the staff.

Fresh air (possibly purified) must be supplied to the room - naturally or mechanically. Contaminated air must be removed from the room. In industrial premises, this is done by local or general exhaust hood, and in residential premises, as a rule, due to natural exhaust.

Architectural and installation requirements.

In addition to sanitary requirements, when choosing and designing a ventilation and air conditioning system, it is imperative to take into account architectural and construction and installation requirements.

• Requirements for system design.

o In some cases, it is impossible to place outdoor units on the building facade.

o Interior elements must be matched with the interior

o If there are false ceilings, then the ducts can be hidden behind them ... etc.

• The equipment of the system should occupy a minimum area, not have too much weight and dimensions. This is especially important when renovating existing buildings.

• Ease of installation, minimal time and labor for commissioning.

• Fire safety - additional protection should be provided for fire and explosion hazardous premises (fire-retardant valves, special communication schemes). Otherwise, smoke and fire can spread through the ventilation ducts and cause enormous damage to buildings and people.

• Vibration and sound insulation of ventilation equipment and air conditioners. Sanitary and hygienic requirements establish the maximum permissible noise level for different types of premises.

• In many cases, the ventilation and air conditioning system must be commissioned in stages and in separate rooms. This should be provided for in its design. Operational Requirements

The fulfillment of these requirements should facilitate the operation of the system after the start of its operation:

• Ensuring sufficiently accurate maintenance of air parameters (especially important in precision air conditioning to maintain technological parameters)

• The minimum need for repair and maintenance, their simplicity and convenience

• Equipment that requires maintenance should be installed in a minimum number of technical rooms.

• Low inertia of the system. Switching from cooling to heating mode and vice versa should be done as quickly as possible.

• When one of the air conditioners stops, the other must continue to work, providing at least 50% of the required air exchange (interlocking of systems).

Economic requirements

When designing a ventilation and air conditioning system, you need to minimize its cost. It is necessary to take into account not only the cost of devices and communications, but also the further costs of maintaining the system.

Selection of the ventilation scheme.

The choice of ventilation scheme depends on the following factors:

• purpose of the building

• number of storeys

• type of premises

• emission of harmful substances in the premises.

For most rooms, the air exchange rate is set by the corresponding SNiP, as well as departmental norms (VSN). If the standard rate of air exchange has not been established for the room in question, the ventilation volume of the air is determined by calculation.

In many cases, natural ventilation is sufficient. Ventilation with artificial induction (using fans) is provided in the following cases:

1. If permissible meteorological conditions and air purity are not ensured by natural ventilation

2. If the room does not have natural ventilation (for example, without windows)

3. For public administrative and industrial premises in regions with a design temperature of the coldest five-day period -40C and below.

Conditions for living quarters in the warm season are not standardized at all, and in public and office buildings they are not standardized outside of working hours.

During the cold period of the year, in public and administrative, amenity and industrial premises, it is possible to take the temperature during non-working hours below the normalized (but not lower than 5 degrees), if by the beginning of work it will be possible to restore the normal temperature.

Requirements

GMP.

4.3. Heating. Ventilation. Conditioning.

4.3.1. Heating, ventilation and air conditioning in industrial buildings should be designed in accordance with applicable building codes and regulations, the requirements of the Instruction for building design of medical industry enterprises and this document.

4.3.2. Manufacturing facilities should have an efficient supply and exhaust ventilation system with air flow control equipment and instruments for measuring temperature, humidity, filtration efficiency and pressure drop across filters.

The performance of supply ventilation and air conditioning systems should be determined based on the conditions for ensuring the required air parameters in the working area, taking into account the adopted air exchange organization scheme and the room cleanliness class.

Air intake devices for supply ventilation should be located in places with maximum air purity, taking into account the direction of the prevailing winds.

Purification of the supply air supplied to the premises of cleanliness classes B and C should be at least three-stage.

Purification of the supply air supplied to the premises of cleanliness class D can be two-stage.

Ventilation air preparation systems must ensure its cleanliness in "clean" rooms in accordance with the table and maintain a positive pressure drop in relation to the surrounding rooms of a lower cleanliness class. Neighboring rooms of different cleanliness classes should have a pressure drop, as a rule, 10-15 Pa.

Internal and external surfaces of filter chambers and air ducts of ventilation units of "clean" rooms must have a coating that allows them to be treated with a disinfectant solution.

The performance of the air filters should be regularly assessed using a dust control and a DOP test (tightness and leakage test). Replacement or sealing of filtering equipment should be carried out strictly according to the indications of the instruments in accordance with regulatory requirements. Replacement times should be determined when the resistance to air flow is doubled compared to the original standard value, which indicates a decrease in filter performance or the possibility of damage. Air supply systems in rooms where penicillin antibiotics are produced must be completely isolated from air systems for the production of other drugs.

4.3.3. The capacity of the exhaust ventilation systems should be 80-90% of the capacity of the supply ventilation systems to ensure the required air pressure in the "clean" rooms.

Exhaust air must be cleaned through fine filters to protect the environment from possible harmful emissions from industrial premises.

4.3.4. In the production of sterile medicines, depending on the production needs, it is possible to create, using special equipment, horizontal or vertical laminar flows throughout the room or in separate local areas to protect the most critical areas or operations.

In a “clean” area or in a “clean” room with vertical laminar flow, the supply ventilation filters should be located in the ceiling and the exhaust ventilation openings in the floor or bottom of the walls. In a "clean" room or in a "clean" area with horizontal laminar flow, the supply filters and exhaust ventilation openings should be located on the entire surface of the opposite walls.

4.3.5. "Clean" cameras must meet the following requirements:

- the flow guiding panels, hood and work surfaces must be made of smooth and durable material;

- pre-filters should be disposable or made of material that allows them to be thoroughly cleaned and used again; - final filtration should be carried out through pre-tested and hermetically installed fine filters;

- the speed of the laminar flow should be within the range of 0.45 m / s + 20%. - The operation of sterile air laminar flow units must be constantly monitored according to the relevant instructions and inspection schedule.

4.3.6. If necessary, production facilities should be equipped with a supply air conditioning system, which should: - ensure an appropriate degree of air purification from mechanical particles and microorganisms;

- automatically adjust climatic parameters (temperature and relative humidity) to create the most favorable conditions for the technological process and service personnel;

- have high aerodynamic stability to maintain optimal pressure distribution and other air parameters in the building and its individual rooms;

- to exclude the occurrence of static electricity and associated dust accumulation;

- be characterized by a low noise level during operation;

- be constructed using materials and anti-corrosion coatings that are resistant to disinfectants and non-dusting.

4.3.7. Each building must have a system for supplying compressed air, and, if necessary, nitrogen or other inert gas, as well as a technological system for distributing them to all rooms, where necessary.

The air supplied from the oil-free compressors must be free of impurities or oil vapors.

To prevent condensation of water vapor in pipelines, compressed air and nitrogen must be dehydrated.

Conclusion

The climate industry is rapidly moving forward, and every year, month, day, the number of people in the world who actively use air conditioners and progressive ventilation systems is growing. A person always strives to create comfortable conditions around himself: a comfortable chair, good lighting, a favorable microclimate.

List of references

SanPiN 4079-86 "Sanitary Rules for Enterprises for the Production of Medicines"

2. GMP requirements. 4.3. Heating. Ventilation. Conditioning.

The topic is immense

Rules for users

Personnel and private users of ventilation systems are not allowed:

- violate the integrity of the complex, air outlet and connecting elements;

- connect gas appliances to the system;

- disconnect or remove the fire-retarding and ventilation devices provided by the project;

- close openings, ventilation grilles, exhaust ducts;

- burn out the accumulated deposits yourself, and so on.

The requirements for the ventilation system of industrial premises are formulated taking into account the development of a procedure for personnel. Workers who maintain production facilities must act in accordance with the instructions and ensure:

- observance of the terms of cleaning of valves and branches;

- disconnecting the repaired parts of the system from the rest;

- the required frequency with which the efficiency of the ventilation systems is checked and their prevention;

- shutdown of ventilation in case of fire notifications;

- control over the serviceability of the fans - there should be no deflections or breaks on the blades, the wheels should be balanced and their smooth running should be monitored, the grounding devices should be checked regularly.

Key points of requirements

Among all the restrictions, the sanitary direction is especially important, as well as the fire safety requirements for ventilation systems. Failure to comply with them can lead to extremely sad consequences, and compliance with the established parameters is strictly monitored.

Sanitary and hygienic requirements for ventilation systems are put forward by the relevant authorities, and the inspection controls that:

- the volume of the inflow masses exceeded the drawn ones by 10-15%;

- air was supplied to the points with the least pollution, and was removed first of all from the places with the greatest;

- overheating or hypothermia of people in the premises did not occur;

- the level of noise, vibration was not more than permissible;

- microclimate indicators (humidity, speed of movement of air masses, temperature) were at the level of norms.

The ventilation requirements for warehouses, industrial production and household facilities take into account the conditions in which the level of compliance with fire safety is maintained. To do this, the valves are serviced, the system is cleaned of dust, dirt, accumulated deposits that can ignite, and the fasteners are checked. To prevent the ventilation system from causing an avalanche-like spread of fire, it must be properly installed and operated.

Sanitary and hygienic requirements

In addition to the requirement to maintain optimal air parameters in the working area, such as temperature, humidity, cleanliness, dustiness, air velocity, determined for each type of room separately, it is important to emphasize the following requirements:

- Fresh air must be supplied to the room; for this, a recirculation system can be installed.

- Exhaust air (containing CO2, other harmful gases, dust and other impurities) must be completely removed by a natural exhaust system, local suction or extraction.

- The room should not be supplied with untreated air from outside or from other rooms.

- Avoid drafts or areas with sharp air cooling.

In residential buildings with exhaust ventilation with natural impulses, these requirements are added:

- If the rooms have windows, then ventilation is carried out through vents and other devices.

- Exhaust ventilation of the entire apartment can be organized by means of exhaust devices in kitchens and bathrooms. If the apartment has 4 or more living rooms, and there is no through or corner ventilation, natural exhaust ventilation should be carried out directly from the rooms not adjacent to the rooms in which the hood is provided.

- Air ducts from kitchens, bathrooms, toilets with ventilation ducts from boiler rooms, garages and rooms facing different facades of the building must not be combined.

- Closed staircases are ventilated thanks to opening windows and vents, if there are no windows, ventilation is provided through exhaust ducts and shafts.