When creating a heating system in a house with your own hands, care should be taken to ensure that it is efficient, safe, economical, and easy to use. A dead-end heating system meets all these requirements. The installation scheme is quite simple, so there are no special problems during installation.

Types of heating systems

Heating in a home can be done in a variety of ways. For example, a radial (or manifold) method is a system in which each radiator is connected to a distribution manifold through a supply and return pipe. In some cases, radiators located in the same room are connected in pairs. This independent circuit makes it easy to disconnect one battery without stopping the entire line. Disconnection may be necessary in the event of a breakdown of any element or to save money.

When installing the beam system, pipes of the same diameter and approximately equal in length are used. This ensures a uniform pressure drop and each radiator consumes the same amount of coolant. Connecting pipes are often hidden in floors, walls, or behind a stretch ceiling, leaving only the radiators in sight. This makes the heating circuit more aesthetically pleasing.

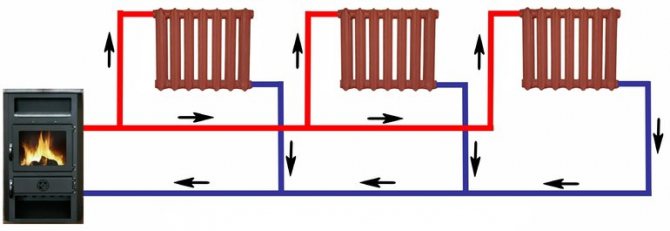

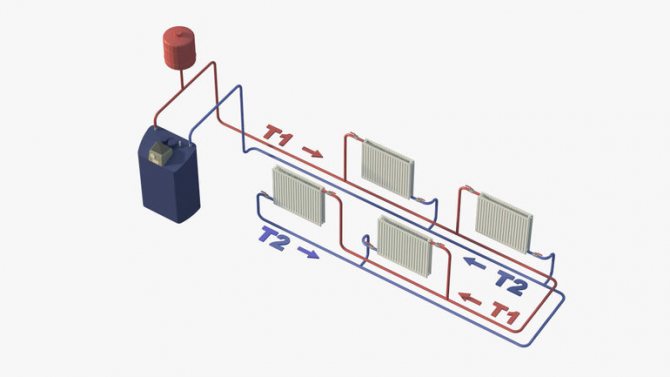

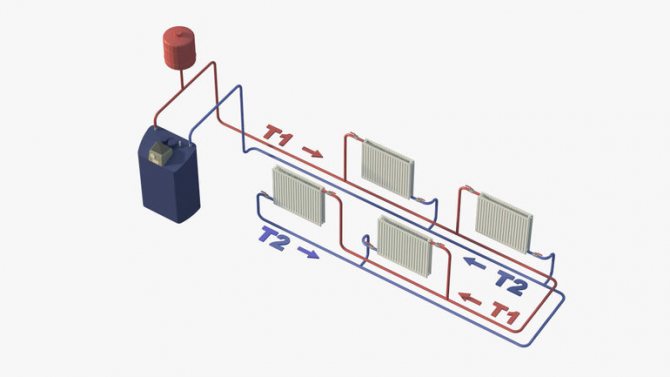

Passing wiring is implemented differently. The supply pipeline in it runs in series from the boiler to the last radiator, and the return pipe connects the batteries from the first to the last and returns to the boiler. The coolant in both lines is transported in the same direction. The efficiency of such a heating scheme depends on correct pressure balancing. If it is more in one circulation ring than in others, the coolant will flow into it, and the pressure in the remaining batteries will significantly decrease.

Another system - one-pipe - is the easiest to implement, but far from the most effective. It is devoid of water return pipes, the batteries are connected in series in it. Because of this, it is not possible to regulate the heating of individual radiators.

For such a wiring to function, a higher pressure is required. Its feature is vertical filling, which is carried out using an expansion tank installed in the attic. The installation of one-pipe heating in multi-storey buildings is unprofitable, since the heating of the batteries from the upper floor to the lower one is provided unevenly.

The most common is a dead-end heating scheme, which is simple and inexpensive to install, as well as characterized by long and stable operation. When creating heating in houses, it is chosen in 90% of cases.

There is no heat in one heating circuit of the house

Electric heating and stove supply. Steel pipe 32 at the outlet diverges in two directions. The right wing of the house warms well, the other is cold. The system is one-pipe by gravity, the expansion tank is homemade.

I tried to put a regulating valve, but there is no sense anyway, the cold side does not heat well, although the boiler is boiling with might and main. It is advised to put a pump, but if the electricity is turned off, the whole system will stand up. How to be?

The specialist answers:

A very common question. The lack of heat in one of the circuits can be explained simply - there is no circulation or it is difficult. Why? There are many reasons.

Water moves along the path of least hydraulic resistance. And if it's quite simple, then where it is easier for her to "run", they will "run" there.And if the coolant flows freely into one wing, but not into the other, then there is no circulation. The reason for the lack of circulation may be a narrowing of the pipe diameter (transition to a smaller diameter), poor-quality pipeline installation, faulty shut-off valves (taps), airing of the heating system (the absence of automatic air vents at the highest point of the pipeline), just elementary construction debris or dirt.

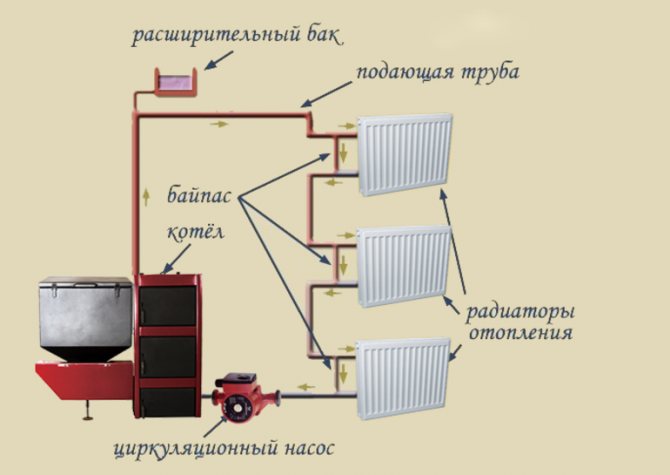

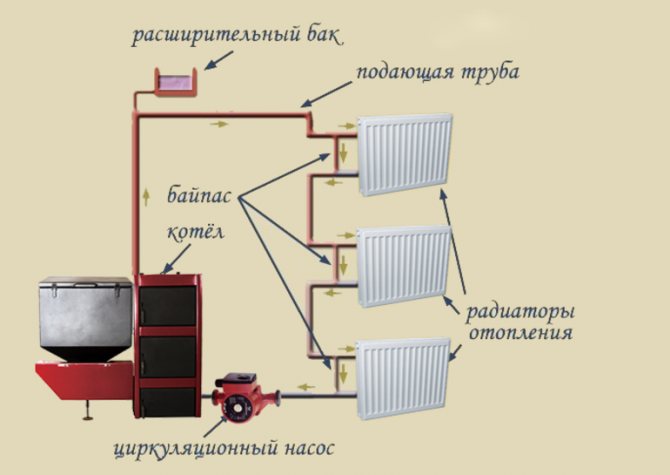

Now for the circulation pump. It is obligatory to bet. And there is no need to be afraid of a power outage. The efficiency of the system will rise. And you will feel it immediately. And so that the circulation in the heating system does not stop, in the absence of electricity, the circulation pump must be installed on the bypass circuit (bypass). Then the coolant, bypassing the bypass and the pump, will go through the main pipe of the gravitational heating system.

Krayushkin Sergey Olegovich,

domidei.ru

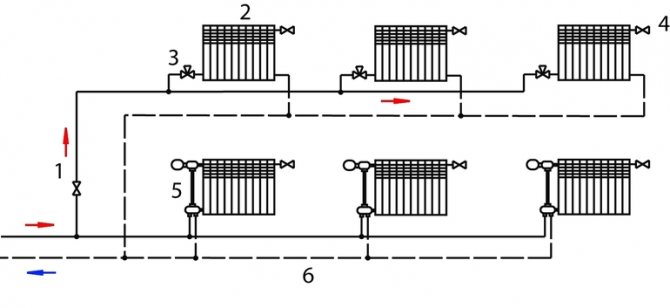

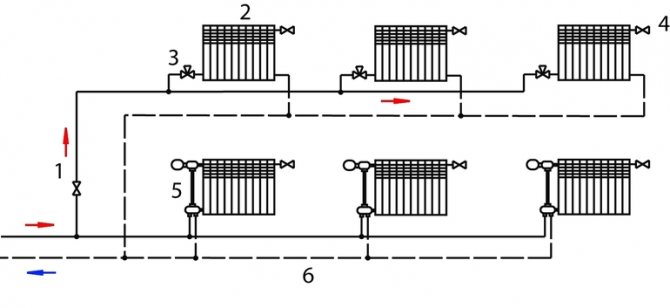

Dead-end wiring device

The main feature that distinguishes the dead-end system from others is that the length of the supply and return pipelines in it is not the same. Its use is suitable for those cases when it is necessary:

- Divide one dead end into several branches with a complex room configuration.

- Install an increased number of batteries on one shoulder, ensuring deep balance. With this balancing, the hydraulic resistance of the first radiators and short arms is increased.

- Hide pipes under the floor or under the headliner (for upper floors).

- Divide one dead end into several branches with a complex room configuration.

- Install an increased number of batteries on one shoulder, ensuring deep balance. With this balancing, the hydraulic resistance of the first radiators and short arms is increased.

- Hide pipes under the floor or under the headliner (for upper floors).

This method of organizing heating implies the presence of two pipeline circuits, due to which the coolant circulates in opposite directions. The water heated in the boiler goes to the radiators through the supply pipe. Having given off thermal energy, the cooled water moves along the return line towards the hot flow and goes back to the boiler, where it is reheated.

Radiators can be connected to the heating circuit in different ways. Depending on the installation method, a two-pipe dead-end heating system is:

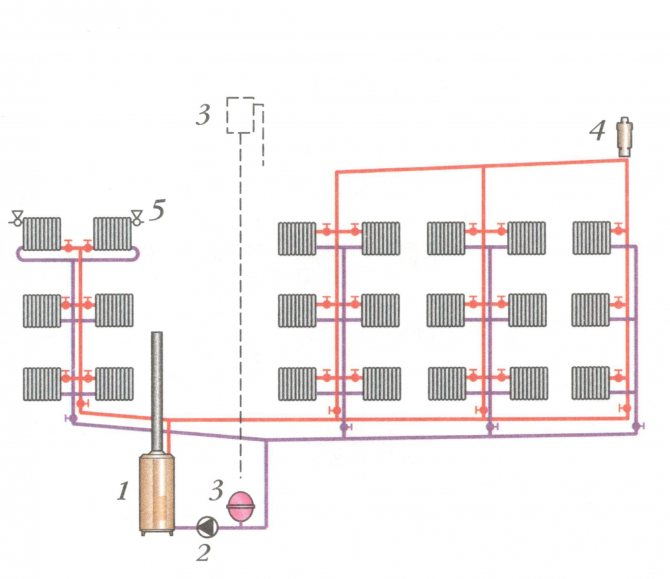

- Vertical. The batteries are attached to the riser. The circulation rings closer to it are smaller than the others. For this reason, the movement of the coolant is uneven. The air in rooms located at a distance from the heat source warms up worse and longer. The vertical scheme is most often used to heat multi-storey buildings.

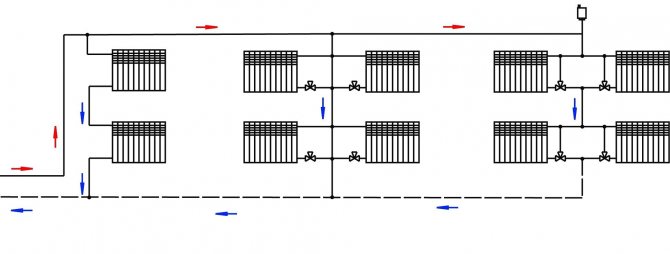

- Horizontal. Consists of pipelines of equal diameter, provides uniform heating of the entire area. The use of reinforced plastic pipes with sliding sleeves allows you to hide the contour in the floor screed without disturbing the design of the premises. An important advantage of the horizontal installation method is the ability to connect heated towel rails and additional lines for floor heating to a common circuit.

If secondary circulation rings are provided in a dead-end system, it must be equipped with a pump and a mixing circuit with a temperature sensor. Without this equipment, the additional line will affect the heating system as a whole. Natural circulation can only be used in rooms with a small area.

No circulation, heating failure - why

A breakdown in the heating system, imperfections, flaws, everything leads to cold radiators. If there is no circulation of the coolant, then the cause must be determined.Most often, the answer to why the heating does not work is on the surface, it is obvious.

Let us analyze in order the main causes of heating malfunctions, why water does not circulate through the pipes, and what needs to be done first.

Let's start with the simplest and most obvious reasons.

Clogged, clogged.

Each heating system must have a coarse filter. A completely small device with a fine mesh and a sump (installed downwards! At least to the side) saves equipment, pumps, a boiler from contamination of the coolant that will be present in any system. Shavings, thread scraps, rust, water sludge…. everything is trapped by the mesh in the filter.

The sump must be periodically untwisted, the mesh must be cleaned.

If circulation is disturbed in the heating system of a private house, then the first step is to check the filter, which should be installed on the return line in front of the boiler.

Air in the system, airing

Bleeding can occur in any closed-circuit piping scheme where no air removal measures have been taken. Air is always present in the coolant, including in a dissolved state, is released during pressure drops, and accumulates at the highest points. Including in the boiler.

Automatic air vents are installed at characteristic, highest points of the system, as well as on collectors and on special separators - the normal circuit is equipped with a special air trapping device, in which air bubbles are released from the coolant.

In addition, Mayevsky taps (manual air vents) should be on each radiator, as well as possibly in other elevated places.

Check airflow, bleed air, install air vents - the usual procedure if circulation stops and the batteries are cold.

The circulation pump does not work

In private houses, the reason for the termination of the heating system is the breakdown of electrical equipment that controlled the movement of the coolant through the pipes.

If the heating suddenly stops working, then you need to check the performance of the circulation pump near the solid fuel boiler or the pump in the automated boiler. In addition, the same unit can be installed in each circuit, which must work properly.

Bad polypropylene pipes

Often, the consumer (customer) believes that polypropylene pipes are absolutely reliable and cannot cause problems with heating, cool batteries.

But polypropylene is much more insidious than old steel or metal-plastic pipelines. Each place of soldering (welding) is a potential increased resistance in the system or the reason for the cessation of circulation (weakened movement of water through the batteries), due to fusion of the material inside.

It is impossible to control the quality of the connections from the outside, all that remains is to cut out pieces, re-solder, redo the polypropylene pipes again.

The malfunctioning of a polypropylene system is a real problem for the home installer. Good professionals don't take this material at all.

Bad project

It is not uncommon for bad circulation where there is bad design. Typically, the batteries are not turned on correctly, according to some sequential scheme, where the last battery in the circuit receives much less coolant.

Another bad project is one-pipe circuits, where it is also difficult to establish the necessary circulation of the coolant through each battery.

If the radiators do not heat up evenly, there is poor circulation of the coolant on individual heating devices, first of all it is necessary to consider how the connection corresponds to the classic schemes - shoulder, passing, radial.It is necessary to bring home heating to the usual design standards, and then expect good circulation from it and the same heating of radiators.

Small diameter, overgrown pipes

Old steel pipes from the inside are overgrown with rust, deposits, their throughput capacity significantly decreases over time, and there is only one solution - you need to change to modern ones.

But even during installation, for the sake of economy, mistakes can be made with the choice of the diameter of the pipeline - on the highways, on groups of heating devices, diameters of 16 or 20 mm can be installed. As a result - noise in pipes, excessive consumption of electricity, lack of flow rate of the coolant.

What pipe diameters should be chosen

A complex system

A type of bad design is a complex heating system improperly made, consisting of many heating circuits and several boilers. Here, whole contours will already work incorrectly if the work of one will affect the neighboring one.

As a rule, one boiler (the reserve one does not count) and three circuits - a boiler, radiators, underfloor heating with their pumps are coordinated normally, and there are no questions. But if you connect another working boiler plus a circuit (for example, heating a garage and greenhouse), then the system will become complex. It is difficult to say how the coolant will circulate in it without equalizing the pressure at the connection points.

In complex systems, a competent design is important, the installation of a hydraulic arrow or a ring of equal pressure, you can learn more about the hydraulic separator here

No balancing

Many home heating schemes involve balancing; balancing, control valves are installed in them. For example, between floors, between the shoulders, and for each radiator. The cranes cover the direction with lower hydraulic resistance, respectively, more will go to other points of the coolant.

Children can play around with cranes. Or the system is not initially balanced. Setting up, as a rule, is no problem, you just need to find this tap…. How to set up home heating

Neighbors do not give warmth

But the complex schemes of heating projects are of little concern to the residents of high-rise buildings, which have a separate riser for each radiator in the apartment. And if any radiator stops heating normally, then there is no circulation through the riser, therefore ...

You need to contact the heating network, the housing office (service organization) to adjust the power through the risers, and if this does not help, then with the requirement to check the neighbors.

Often, unauthorized connection, replacement of radiators, pipes in central heating systems leads to a redistribution of pressure, circulation through individual batteries decreases, disappears.

No circulation in a gravity system

In gravity systems, the pressure difference is low, they are especially sensitive to air locks, to pipe diameters, gaps in radiators.

In old schemes, gradual deposits occur in radiators and pipes, circulation may decrease over time, and this treatment is only replacing everything with a more modern one.

You also need to pay attention to the correctness of the circuit itself - the middle heating line is below the cooling line (the boiler heat exchanger is below the radiators), and also - the hot feed rises up to the highest point, and from there goes down to the radiators ... More about gravity circuits further

Various breakdowns in heating systems

- Closed, valves, valves - check if everything is open to ensure circulation.

- Leak in the system - there is little coolant, check the pressure, eliminate the leak.

- Installation with flexible pipes - pipe is pinched.

- Breakdown of automatic equipment - thermal heads on mixing units, radiators, mixing units themselves - silting, failure, it is necessary to check the correctness of work. Also - electronics breakdown.

- Incorrect balancing on the distribution manifold, - in beam circuits, complex systems, collectors with balancing and adjusting equipment can be the reason for the lack of circulation anywhere, due to breakdowns and incorrect settings.

- Low pressure, no air in the expansion tank - check the pressure in the pipes and pumping the tank, automated units will not work at all without the required pressure.

- Violation of the circuit, extra bypass - check the conformity of the installation to the project, the consistency of the circuit, whether there are any short-circuits of the jet, parallel branches to the radiators and circuits.

teplodom1.ru

Installation features

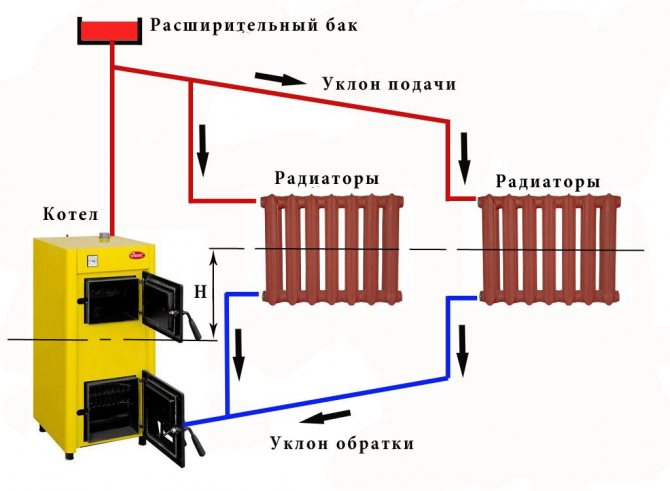

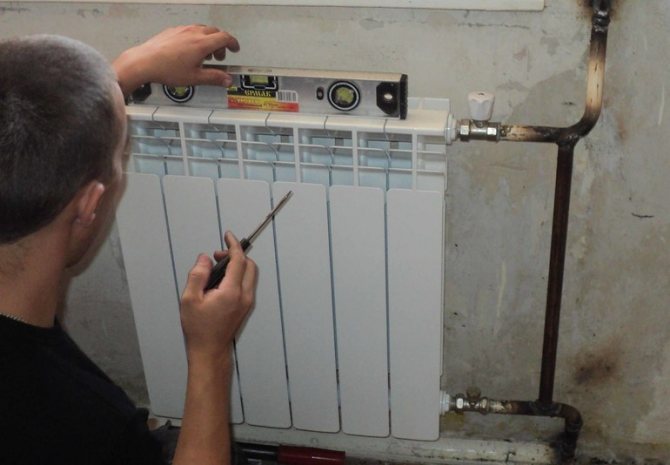

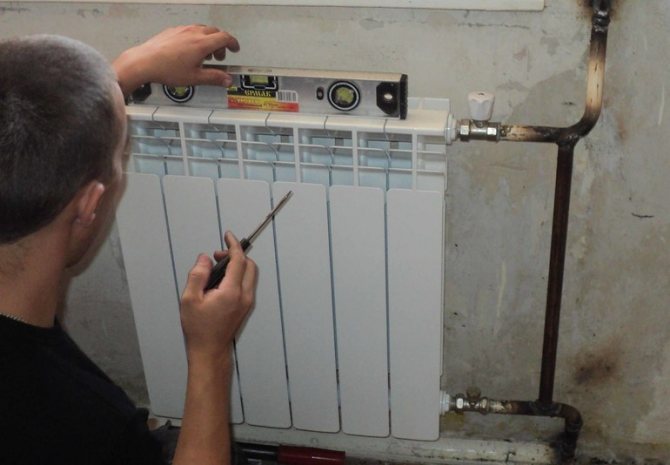

The peculiarities of installing the heating circuit depend on how the heating medium will be supplied - top or bottom. Top routing is used in natural circulation applications. To achieve maximum efficiency, the connecting pipes should be installed with a mandatory slope, and the expansion tank should be fixed at the top of the system. Radiators must be connected diagonally, equipping each of them with a Mayevsky crane or an air vent of another type.

In the case of bottom routing, both pipes are mounted above the floor surface, the supply pipe is located above the return pipe. A closed membrane-type expansion tank and a circulation pump are indispensable elements of the heating circuit and are located inside it. Usually they are implanted into the return pipe at a short distance from the inlet of the heat source. The lower wiring is hidden in the floor screed or masked by a small box behind a wide baseboard.

A significant disadvantage of such a system is the need to connect it to the electrical network. In the absence of electricity, the built-in pump will not work. To solve the problem, it is necessary to purchase an electricity generator.

In order for double-circuit heating of a dead-end type to meet the requirements of efficiency and safety, certain rules must be observed during its installation and commissioning.

When calculating the capacity and power of the circuits, it is necessary to take into account the inner diameter of the pipes used.

The connection should be made in accordance with the diagram. You need to be well versed in the notation that it contains. To avoid startup errors, it is important to know which icon indicates the internal size of the pipeline, and which is the external one.

It is also important to distinguish between modifications of radiator thermostats. Appliances designed for gravity systems have a capacity greater than those suitable for forced circulation.

For the pipeline through which water will flow from the boiler to the radiators, pipes of different diameters should be selected. In the direction from the first to the last, they should gradually decrease. Their slope with forced circulation should be 2-3 mm per 1 meter of length, with natural - 5 mm per 1 meter.

Equipment classification

A two-pipe heating system for a private house can be open or closed. The latter provides for the presence of a membrane expansion tank, which allows the system to operate at high pressure.

Not only water can act as a heat carrier, but also ethylene glycol compounds capable of operating at low temperatures (up to 40 degrees below zero). Ethylene glycol-based formulations are called antifreezes.

It should be noted that the correct operation of the equipment is ensured only when using specialized formulations designed specifically for heating purposes. Automotive antifreeze will not work. The same applies to additives and additives: only those specially adapted for heating can be used.

It is especially important to follow this recommendation when operating expensive models of boilers, which are controlled by automation. In the event of a boiler breakdown, manufacturers usually disclaim responsibility and do not perform warranty repairs, unless the malfunction is directly caused by the heat carrier.

Closed-type systems are distinguished by the highest level of safety, therefore, most of the boilers of modern production are aimed at just such schemes.

Diagram of an open heating system with an expansion tank

In open systems, the expansion tank is mounted in the upper section. An air outlet pipe is attached to the tank, as well as a pipe for draining excess water from the system. Hot water can be taken from the tank for domestic needs, however, in this case, it is advisable to make the water supply automatic. In addition, the water used for the needs of residents should not contain technical additives and additives.

Two-pipe system of vertical and horizontal types

There are two types of organization of a system with two lines - vertical and horizontal. Vertical piping is commonly used in multi-apartment buildings. For the implementation of the system, many pipes are required, but at the same time, the possibility of branching into apartments on each floor is achieved. The main advantage of such a system is the natural return of air, since it rushes upward, where it is removed using an expansion tank or a drain valve.

A two-pipe horizontal heating system is more common in one-story and two-story houses. To remove air, Mayevsky taps are used here.

Top and bottom routing

The distribution of the coolant supply is carried out according to one of two principles: upper or lower. If the wiring is top, the pipeline is located in the under-ceiling space, and the supply pipes go down to the batteries. The return line goes along the floor. The advantage of this option is that it makes it easy to organize natural circulation, since due to the height difference and the pipe specially located at an angle, a good speed of movement of the coolant is provided.

Shoulder connection

One of the varieties of dead-end mains is the shoulder heating system. The scheme of its implementation involves the lateral connection of radiators. The supply pipe is connected to the upper branch pipe, the return pipe to the lower one, both are located on the same side of the battery. In this case, the coolant can serve the entire system at the same time, and each arm can function separately. As a result, it becomes possible to regulate the temperature in each specific room.

The shoulder connection shows good efficiency only when using batteries with a small number of sections. Large radiators will not fully warm up. If there is no other option for installing long heaters, the water flow extension will help solve the problem.

This layout allows fewer pipes to be used than other layouts and is convenient and easy to install. It is easy to organize a bypass between the lines for the installation of control equipment.

Most often, the shoulder system is used to heat multi-storey buildings. To achieve maximum effect, a certain number of batteries are placed on each floor. For example, in a two-story house, the common heating main is divided in such a way that there are two dead-end arms on the first and second floors. On the first one, 9 radiators are installed (5 on the right shoulder, 4 on the left). At the top, 3 batteries are mounted (2 on the right and 1 on the left). Tees are used to divide the general contour into the shoulders. They are located in the supply and return pipelines.

Sometimes a dead-end heating system contains only one pipe circuit.With this scheme, the coolant sequentially passes from the boiler to all heating devices in the forward direction, and is discharged in the opposite direction. To achieve uniform heating, forced transportation of the coolant is organized and the number of sections of distant radiators increases.

Variety of heating schemes for residential premises

All typical heating schemes imply time-tested options. These include the familiar one-pipe and two-pipe designs, collector or beam, as well as the well-known "Leningrad".

The beam system is characterized by the installation of a pair of pipes for each radiator. Very easy to install and maintain. For effective heat dissipation, it needs preliminary balancing.

"Leningradka" is known for its solution of independent regulation of each radiator in a one-pipe scheme. This is achieved by bypassing each battery with a bypass pipe and by using valves on the radiators.

An interesting heating scheme for two wings. It is convenient for use in a multi-storey building. It can be used with one or two circulation pumps. As in the case of the beam scheme, it requires tuning and balancing the "wings".

Symbols in heating schemes are not particularly complex. Most often, these are rectangles - a boiler and radiators, connected by straight lines - pipes of a heating main. The valves are designated in the form of an hourglass. Modern schemes are more like pictures, where each element is represented by its own picture. Therefore, the symbols on the heating schemes are drawn in simple language.

Advantages and disadvantages

The prevalence of a dead-end heating scheme is determined by certain advantages that it provides. With its help, you can organize a comfortable temperature regime in houses with a large area. The shoulder connection makes it possible to set different temperatures in separate rooms.

The creation of a two-pipe dead-end wiring does not imply any special difficulties, therefore it can be carried out without the involvement of expensive specialists. To install it yourself, you will need:

- Install the boiler, which will act as the main source of heat.

- Bring the supply pipe to the boiler by connecting it to the expansion vessel. The tank must have a signal connection and a device for draining the liquid.

- Cut the radiator taps into the upper line extending from the tank.

- Lay a pipe line for the cold water return. It also needs to provide for the connection points for the batteries.

- Connect the return circuit to the boiler.

- Fix the heating devices in the designated places, equipping them with thermostats and drain valves.

Upon completion of the installation work, it remains only to carry out a pressure test. The system will then be ready for use.

The main disadvantage of such heating is the need to use elongated pipelines, shaped joints, valves and fasteners. In comparison with a single-circuit, the installation of a double-circuit will cost more. However, the funds invested at the first stage will be justified as the system is used.

In contact with

What is a two-pipe heating system

In recent years, two-pipe heating has been used more and more often, despite the fact that the installation of a one-pipe version is usually much cheaper. This model makes it possible to adjust the temperature in each room of a residential building at will, because a special control valve is provided for this. As for the one-pipe scheme, in contrast to the two-pipe scheme, its coolant during circulation sequentially passes through absolutely all radiators.

As for the model of two pipes, here a pipe is separately supplied to each radiator, intended for pumping the coolant.And the return pipeline is collected from each battery into a separate circuit, the function of which is to deliver the cooled medium back to the flow-through or wall-mounted boiler. This circuit (natural / forced circulation) is called a return and it has gained especially great popularity in apartment buildings, when it becomes necessary to heat all floors with a single boiler.

Dignity

Double-circuit heating, despite the higher installation cost compared to some other analogues, is suitable for objects of any configuration and number of storeys - this is a very important advantage. In addition, the coolant that enters all heating devices has an identical temperature, which makes it possible to uniformly heat all rooms.

The remaining advantages of a two-pipe heating system are the possibility of installing special thermostats on the radiators and the fact that the breakdown of one of the devices will in no way affect the operation of others. In addition, by installing valves on each battery, you can reduce water consumption, which is a big plus for the family budget.

disadvantages

The above-named system has one significant drawback, which is that all its components and their installation are much more expensive than organizing a one-pipe model. It turns out that not all residents can afford it. Other disadvantages of a two-pipe heating system are the complexity of the installation and the large number of pipes and special fittings.

Horizontal heating system

There is also such a type of scheme as a two-pipe horizontal heating system, which has found wide application in one- and two-story houses. It is also used in houses with a basement, where you can easily place the necessary communication networks and devices. When using such a wiring, the installation of the supply pipeline can be carried out under the radiators or at the same level with them. But this scheme has a disadvantage, which is the frequent formation of air congestion. In order to get rid of them, the installation of Mayevsky cranes on each device is required.