The purpose of the damper tape. types and sizes of material to protect the floor screed

The last stage of the rough floor cladding is the equipping of the screed. This structural component levels the surface and eliminates existing imperfections.

Some external factors can significantly reduce concrete strength, for example, a high level of moisture or extreme temperature changes. Under their influence, there is expansion of the cement base, which later turns out to be the basis of its crack in a chaotic manner, and flaws may form on the lower edge of the walls.

To eliminate bad consequences, experts advise using a damper tape sold in any store for construction. We will answer the questions about whether it is necessary and how you can change the material.

What is damper tape

Product base - foamed polyethylene. The tape is very soft to the touch and has excellent flexibility. It is used to compensate for thermal expansion of concrete.

The edge tape lies down between the wall surface of the room and the screed being poured... Under pressure, it contracts, and then returns to the first state. This minimizes the distance between the walls and the concrete layer, and further reduces the damage caused by the appearance of loads.

If need be dismantling its edge tape is very simple remove from the groove.

Purpose of foamed polyethylene tape

What is the material used for? The main purpose is compensation of temperature deformations screeds. Side tasks - thermal insulation and soundproofing of the wall groove. Plus, the buffer tape is capable of doing other functions, namely:

- Eliminate spreading solution throughout the coverage area.

- Weaken the influence concrete screeds on the wall surface.

- Play as divider when working on large areas.

- Fill expansion joints.

- Stop spreading bacteria and mold.

Pros and cons of edging (edge) tape

The material's decent workability explains its popularity when compared to alternative wall joint fillers.

The edging tape is considered an environmentally friendly non-hazardous material, thanks to this it can be used for equipping both non-residential and residential premises. The list of its advantages includes the following factors:

- Providing good insulation properties.

- Resistance to temperature drops and to ultraviolet radiation.

- Moisture proof (not prone to damage by mold or bacteria).

- Becoming strong and a completely sealed connection.

- Long term operation (more 10 years old).

- Ease of installation and dismantling.

The only one disadvantage of the product its high cost can be called, which, nevertheless, is fully compensated for by the benefits received.

Types of expansion tapes

Manufacturers recommend more than ten types of damper tapes needed to equip a floor screed. They differ from each other in external performance and working qualities. Divide them like this:

- Typical... Straight tapes without adhesive. For fastening to the wall surface, in most cases, double-sided adhesive tape or a specialized composition is used. Preparatory preparation of the involved surfaces is required - cleaning of small debris after construction work.

- Self-adhesive... On the back of the products there is an adhesive strip, which is protected from above with a specialized backing, which is slowly removed during the installation process.Professionals note the economical consumption of this tape.

- With a "skirt"... The products have a characteristic feature - a "skirt" made of thin oilcloth material, which spreads across the floor during the assembly process. The key purpose of this addition is to ensure complete sealing of the seam.

Standard sizes

There are several standard sizes on the basis of which the expansion tape is made. Products with a width of about 15 cm and thickness ranging from 4 before 10 mm, sold in rolls of 50 meters.

It is recommended to choose the width of the tape taking into account the thickness of the future concrete layer. In the process of rough pouring of concrete, a tape with a width of 10 cm, and for a thickened screed it is best to use strips of size 15 cm.

To create a wall seam required size, you need to provide for the preparatory step square cement grouting and prospective temperature differencesspecific to the room.

| Options | ||

| Width, mm | Thickness, mm | Length, m |

| 100 | 10 | 25 |

| 150 | 10 | 11 |

| 100 | 10 | 11 |

| 100 | 10 | 25 |

| 150 | 10 | 50 |

| 80 | 8 | 20 |

| 100 | 8 | 25 |

How to attach the tape

Installation is required additional fixation damper tape, especially when using typical products without an adhesive backing. Other options for fasteners can be used:

- Scotch tape for painting works... Short-term fixation at the step of pouring the concrete screed.

- Construction stapler... Suitable for working in rooms with walls made of foam concrete and aerated concrete blocks, or wood.

- Liquid Nails... Best for uneven walls.

- Screws and dowels... Suitable for rooms with brick walls.

The last fixing method must be used in an exceptional case, since iron hardware tears the tape, which is why it ceases to be elastic and plastic.

Installation specifics

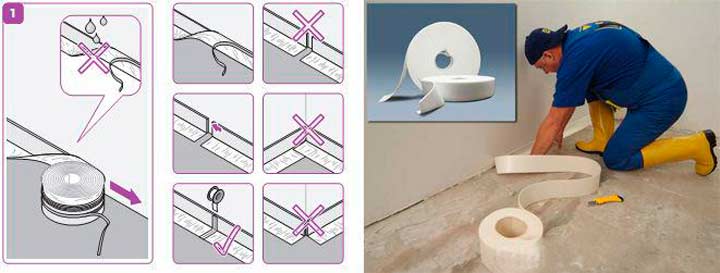

The implementation of the technology of installation of the expansion tape is considered the key to obtaining a high-quality and durable screed. There are three key stages:

- Training... Leveling the wall surface and cleaning up debris caused by construction work.

- Sticking... The tape is laid constantly at a height 1,5—2 cm from the floor, starting at one of the corners of the room along the perimeter. Much attention is paid to fixing at the corners of the room.

- The ending... Cutting the tape after returning to the starting point.

Areas where the tape segments "meet" must be merged overlap... This will improve the tightness of the seam.

How can I change the tape

The price of the product for individual consumers seems high, so they try to find an alternative and try to change the "shock absorber":

- Expanded polystyrene.

- Bars of wood wrapped in polymeric ethylene.

- Isolon.

During the use of these materials, in most cases, certain inconveniences appear. The very first thing, they are required cut into strips of equal thickness and width... Second, when installed, it comes out a considerable number of joints due to insufficient length. Also, no glue layer is present.

Performance of alternative products to mitigate screed deformation loser when compared with damper tape. A real replacement for her does not exist.

Biofilters

Source: https://oracal.net/otdelochnye-raboty/naznachenie-dempfernoj-lenty-vidy-i-razmery.html

Product advantages

Foamed polyethylene material will delight you with the following advantages:

- environmental friendliness;

- hypoallergenic;

- security;

- durability;

- wear resistance;

- strength;

- ease;

- elasticity;

- tightness;

- soundproofing;

- vapor tightness;

- moisture resistance;

- minimum thermal conductivity;

- the ability to restore its original shape;

- resistance to chemical factors;

- resistance to mold and mildew;

- resistance to mechanical stress;

- not susceptibility to temperature fluctuations;

- compatibility with absolutely any construction raw materials;

- ease of installation;

- low price.

Thus, the edging tape is not a tribute to fashion, but a necessity.

Laying a damper tape when installing a warm floor

There are no trifles in the art of building, since all technologies are carefully thought out and tested empirically by numerous specialists.

Over time, new details appear that facilitate work or improve certain designs.

All of them appear on the basis of observations and developments. The same can be said about damper tapes.

More recently, when making a screed, builders used materials at hand, which gave about the same effect as the tape. But each of the devices had its own shortcomings, so they were replaced by foamed polyethylene, which has a number of qualities necessary to keep the screed in for a long time.

Today, in order to do the job efficiently, you cannot do without this element.

Damping tape for floor screed is a material that is installed along the lower part of the wall with an approach to the floors, along the perimeter of the entire room, where the concrete screed will be arranged.

This element acts as a compensator for linear expansion of concrete, the coefficient of which is up to 0.5 mm per 1 m².

The expansion process can arise from a temperature drop, and a destructive stress is created in the screed, as it begins to rest against the walls surrounding it.

If the screed is destroyed, the decorative coating will suffer.

It is especially important to use this useful device when installing electric and water heated floors, since a screed is necessarily arranged above them, which will be constantly exposed to temperature changes.

So that it remains unchanged for many years and does not subject the underfloor heating system to damage and destruction, a damper tape is installed.

Its work is effective, thanks to the material from which it is made - it is polyethylene foam, it has the ability to compress, thereby giving the concrete the opportunity to expand.

In addition, polyethylene has other positive qualities:

- low heat and sound conductivity;

- moisture resistance and water resistance;

- resistance to temperature extremes;

- environmental safety;

- durability and low cost.

These properties of foamed polyethylene are used to seal cracks and gaps formed in any construction.

Damping tape is often called expansion or edge tape. The material is produced in rolls, the length of which varies from 10 to 100 m, its width is from 5 to 15 cm, the thickness of the damper tape is from 3 to 10 mm.

It should be noted that on factory products, cuts are provided along the entire length of the tape, which are made at a distance of 8-10 cm. They are designed so that, if necessary, you can remove the excess protruding part of the tape when the screed is ready.

Varieties of tape

There are several types of tape by design:

- ordinary (straight),

- with a "skirt"

- self-adhesive tape.

A common damper tape is a flat strip with the parameters described above, which is simply installed along the walls around the entire perimeter of the room.

Self-adhesive damper tape is characterized by the fact that it has an adhesive strip on the back, protected by a backing.

The protection is removed gradually as it is glued to the walls.

Such a tape is convenient for installation and when installing a tie, since it is fixed in one position.

Plain and self-adhesive tapes can have a so-called "skirt".

When installed against a wall, the skirt spreads out across the floor, thereby sealing the wall-to-floor joint.

"Skirt" has a width of 3-10 cm, and is made of thinner oilcloth material.

Some builders are trying to replace the damper tape with isolon or penofol, others think they can do with wooden slats.

But, all these materials do not have the necessary qualities that are inherent in foamed polyethylene:

- isolon and penofol do not have a heat and sound insulation effect;

- the tree is susceptible to rotting and the formation of fungus, and also does not have sufficient shock absorber properties.

Therefore, saving on the damper tape, you can ruin all the work done, in this case, such savings correspond to the proverb "a miser pays twice."

The best option is to do everything thoroughly at once, observing the technology and using the recommended structural elements.

Damper tape application

Knowing what this material is and what it is intended for, you need to understand a little about the process of its application.

The damper tape, as mentioned above, is laid along the entire perimeter of the room, as well as around all architectural elements, if present, these can be partitions or columns.

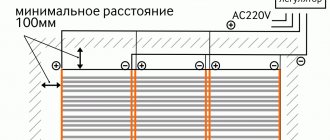

It is also necessary to take into account the size of the area on which the screed will be arranged.

If it is too large, it is necessary to make additional spacers of expansion joints. One layer of tape with linear expansion of concrete is designed for 10 m of the screed.

The tape is installed slightly higher than the screed will be poured. After it hardens, the excess part of the tape is cut or torn off along the notches.

If a decorative coating is laid on top of the screed, and a plinth is installed along the walls, which will cover the protruding part of the damper tape, then it is better not to cut it.

The tape plays an important role in the pouring of wet cement screed, not only as a compensator for expansion, but also as a retaining barrier to the mortar from spreading.

When installing an electric and water underfloor heating, the edge tape can be laid under the vapor barrier or between the underfloor heating structure and the vapor barrier, this does not matter in principle.

The main thing is that the "skirt" of the tape is under the screed or self-leveling floor.

But it is best to attach the damper tape to the subfloor after waterproofing.

Installation of underfloor heating using a damper tape

If you want this auxiliary element to fully fulfill its function, the installation when installing a warm floor must be done correctly.

- First of all, the subfloor must be tidied up. For this, all cracks and chips are repaired.

- Next comes the waterproofing device, which will keep the floors from moisture, and therefore from the occurrence of fungus and rot.

- The next step is to secure the damper tape.

- Then mats for a warm water floor or another type of insulation are laid.

- A plastic wrap is laid on the insulation.

- The next detail of the structure will be the reinforcement mesh.

- Pipes made of sewn polyethylene (or other material) for the water floor or heating wires are distributed and fixed on the grid.

- All laid layers are filled with a screed.

- After its hardening, the final stage of work takes place - this is a decorative coating device.

Damper tape prices

The price of the material depends on its density, manufacturer and size. Average price table for damper tape:

| Belt name, country of origin | Dimensions in mm (width, thickness) | Number of meters in a package | Price per package |

| Kromochnaya (Russia) | 50×8 | 20 | 156.64 |

| Kromochnaya (Russia) | 100×8 | 20 | 289.52 |

| Damper self-adhesive "Kermi" (Germany) | 100×8 | 25 | 878.00 |

| Self-adhesive damper "Oventrop" (Germany) | 150×10 | 2550 | 791.003074.00 |

| Damper self-adhesive "Uponor" (Sheitsaria) | 150×10 | 50 | 3690.00 |

| Self-adhesive damper with a "skirt" (Russia) | 50×3-8 | 20 | 65.66 |

| Self-adhesive damper with a "skirt" (Russia) | 100×3-8 | 20 | 131.32 |

From all of the above, it can be concluded that the damper tape plays one of the main roles in the durability of any screed, and even more so for the device of a concrete covering of warm floors.

This structural element will not only serve as a shock absorber for it, but will provide good sound insulation of the floor and reduce heat loss, which means it will save you money.

Source: https://nastilaem.com/dempfernaya-lenta-dlya-teplogo-pola.html

How to choose?

A material such as deformation tape is sold in the market in a large number and range. Therefore, it is quite easy to select the tape of the right size. The packages in which it is sold are easy to transport, since the product is very light due to its porosity. Its average cost depends on the manufacturer and is approximately 300-400 rubles per roll.

But the purchase of construction tape is not always successful, and in the process of work, significant flaws in the product become obvious. Therefore, when choosing this type of product, you need to pay attention to the following factors:

- Product integrity and no deformation. The tape in a roll should be even on all sides, without obvious damage, there should be no crooked or torn edges. Holes, dents and other flaws indicate improper storage of goods, therefore, such a product is not worth buying, otherwise it may negatively affect the quality of construction work.

- External parameters. The canvas must be clean and free of visible defects.

- Density. If there are cracks, voids and crevices in the roll, then there is a high probability that the sticky surface is damaged, which means that it is unusable and should not be fixed.

Damper tape - what is it for?

In construction, there can be no trifles, because everything under construction involves long-term use, taking into account all the subtleties of each material.

It is difficult to grasp the immensity, but this is precisely why there are construction engineers who know almost everything and about everything. Even such subtle things as linear expansion coefficients.

But today we are not talking about physics, but about a simple material that performs an important function and is in almost any home.

Why use a damper

It was not in vain that we began to approach the issue with the coefficient of thermal expansion, because its values differ for each of the building materials.

Studying their properties and the effect of average temperatures on them takes a lot of time, but remains one of the most important indicators of compatibility.

If you ignore thermal expansion or take it lightly, nothing good will come of it. No, the building will not fall apart overnight, but everything has its limits.

Even different types of wood have different coefficients of linear expansion, and if you try to achieve tightness by combining pine and oak, then nothing will work, since they expand at different distances and at different temperatures.

But if a layer of material is laid between them, which can compensate for the expansion, while maintaining the tightness of the interface, then it will provide the necessary tightness of the structure.

That is why damping materials are used, and tape in particular.

Damper tape price

At almost every stage of construction, a damper tape is used. Why is it needed, in principle, it is clear - compensation for thermal and other expansions. The material is quite in demand, and it would be nice to know its price, which will definitely appear in the construction estimate.

Damper tape cannot be called an expensive material, nevertheless, many are trying to save money by replacing it with other materials that at first glance are similar in properties, but this is not worth doing.

Let's consider the tape in a little more detail, then it will become clearer why it is necessary at many stages of construction.

Damper tape for floor screed

When a floor screed is applied, a damper tape is placed between the screed itself and the wall. As we have already noted, its main task is to compensate for thermal expansion, but in this case, it plays several more roles.

But first about its main functions.Depending on the area of the screed, the tape can be laid not only around the perimeter of the room, but also dividing large arrays of the screed.

All this is done in order to minimize the pressure of the floor screed on the walls and their mutual destruction.

Under the influence of temperature and possible moisture, the screed can change its size both upward and downward. When enlarged, it will inevitably press on the wall and, over time, can paint over its surface.

Naturally, the larger the screed area, the greater the expansion coefficient. On average, it can reach 0.5 mm per meter. This is not so small when you consider the entire floor area.

In addition, the thickness of the screed can be different, which also cannot but affect the expansion coefficient.

Damper tape properties

The tape is a strip with a thickness of 8 or 10 mm. It is usually made of polyethylene foam, but other similar materials can also be found.

The table at the beginning of the material shows almost all standard sizes and delivery forms of the tape. Depending on the thickness, it can also perform soundproofing and vibration-damping functions.

The main characteristics of the tape, especially in demand for flooring, are called:

- waterproofing and resistance to biological influences;

- the tape is convenient for installation, has a self-adhesive layer;

- the alkaline environment of the cement does not affect its properties;

- the tape is resilient and elastic, able to take its original shape.

Such properties of the damper tape make it in demand not only when laying floors, but in any other places where different materials are joined.

Appointment

In construction, edging tape is used quite widely, but we will consider its use when arranging self-leveling floors.

So what does it give:

- increases the reliability and strength of the floor base;

- prevents the ingress of moisture under the coating by sealing the joints, while not subject to rotting;

- the material has a closed cellular structure, so it can serve as an excellent heat insulator, which helps to save on electricity and heating;

- due to the sealing of the gaps, the room becomes more soundproof;

- compensates for the effect of the concrete layer on the walls in case of inevitable expansion after pouring. That makes it possible to exclude the occurrence of cracks.

As a result, it turns out that the deformation tape for self-leveling coating allows not only to reduce costs, but also ensures the strength, normal functionality and wear resistance of a self-leveling floor.

Types of products

As mentioned above, the damping tape is produced in various widths (from 5 to 15 centimeters), with perforations in length, and is supplied in rolls up to 100 meters. In addition, manufacturers offer:

- simple product format, made of foamed polyethylene;

- tape fitted with a skirt. This part is thin, it is a plastic waterproof film. Such a product is laid on the wall, the skirt is located on the floor surface, forming a reliable protection of the walls from moisture;

- product equipped with a self-adhesive backing. With such a damping gasket, it is extremely convenient to work on walls covered with ceramic tiles or that have undergone a waterproofing procedure by coating with polymer mastics.

Depending on the nature, material of the walls, the thickness of the screed, the presence of an underfloor heating system, one or another class of tape can be purchased.

Methods for fastening the edge strip

The damper tape must be fixed during installation. However, if it does not have an adhesive strip, then alternative fastening methods can be used.

- Furniture stapler and staples will allow you to fix the tape on walls made of foam or aerated concrete, as well as wood.

- Self-tapping screws, dowels, hammer drill and screwdriver. Not the best option, since the tightness of the material is greatly impaired. Method suitable for brick walls.

- Liquid Nails.Suitable for poorly aligned walls.

- Masking tape will allow you to temporarily fix the tape while pouring the screed.

Damper tape when installing underfloor heating

Cost and manufacturers

To buy quality edging tape, you need to look at the manufacturer who made it. Buy tape from a reputable manufacturer in the construction market. The best manufacturers of damper tapes are Knauff and Energoflex.

High quality Knauff tape. It is sold in rolls of 40m length. The width of the strip is 10cm. Most often it is a ribbon with a skirt. The material from which it is made is polyethylene foam. The tape is expensive.

Energoflex is a high quality damping tape 10mm wide. It has high heat and sound insulation properties. The tape is an excellent compensator for screed expansion. Sold in rolls of 11m. Stows around the perimeter of the room. It is better if the area of the screed is less than 10 square meters, otherwise expansion joints are necessary. The thickness of the damper tape of this manufacturer is 10mm.

The cheapest damper tape can be purchased from Teploflex, Uponor, Uponor Minitec, Viega Fonterra. Tape 20-50m in size is produced in rolls. A roll costs 100 rubles. The most expensive product will be Tilit-Super. The cost of one roll 25 m long is 700 rubles.

Consider the features of a damper tape from different manufacturers.

Kermi is available in 25m rolls. The thickness of the edge tape is 8mm, the width is 16mm. The material is made in Germany and is perfectly combined with the Kermi "warm floor" system. The damper tape performs a compensating function in the process of expansion of the screed when heated. The material is made of porous polyethylene, which increases its moisture resistance, heat and sound insulation properties. The cost of one roll is 60 rubles.

An Oventrop product is expensive. Its price ranges from 1,500 to 5,900 rubles. The material is produced in rolls with a length of 25-50m. The thickness of the tape is 10mm, the width is 12-15cm. The foamed polyethylene from which the product is made takes over the tension of the screed, softens it. The damper tape has an adhesive layer and perforations. Quality material from Germany is environmentally friendly, comfortable. Fits around the entire perimeter of the room.

Uponor is a Swedish company. One of the products in the range of building materials produced by this manufacturer is an edge band. Rolls of 50 meters are unwound quickly, and the adhesive layer allows you to firmly fix the edging tape on the wall. The product does not have freon, it is environmentally friendly. The cost of the edge tape 10mm thick, 15cm wide is in the range of 80-380 rubles.

Tilit Super-famous manufacturer of damper tape. The product of this brand has absorbed all the best properties of polyethylene foam building materials. On the inside, the products are equipped with an apron that protects against mechanical and chemical influences. The tape has increased moisture resistance.

Since the material has a low thermal conductivity, the edging tape allows you to keep warm in the room. Sounds and noises are also damped. Tilit Super damper tape is resistant to ultraviolet radiation, destruction due to it. The tape is strong, strong, reliable. The service life is high. The edge tape of this manufacturer can withstand a temperature range of -40 to 95 degrees. There are only 10 m of material in a roll, 10mm thick and 25cm wide.

Energofloor edge tape is made of polyethylene foam. It is successfully used in construction work during the installation of the screed.

Rolls of 11m fit perfectly into the perimeter of the walls of a small room.

We invite you to familiarize yourself with Floor making on a concrete screed

Convenient tape dimensions: thickness 10mm, width 10-15cm help to compensate for thermal expansion of the screed.

The vibration damping tape of the Teploflex company is produced in rolls of 50m in size. Its thickness is 6-15mm, and its width reaches 1m. The product can be cut into strips of a certain size, required for you. The price of the product depends on the model. You can buy the material individually for 120-370 rubles, or in a package that costs 1200-3640 rubles.

Professional advice

Demand generates supply, therefore, in the modern building materials market, there is a wide selection of options for damper tapes from foreign and domestic manufacturers. Products differ in appearance, technical properties and, of course, in price. For this reason, many, especially inexperienced craftsmen, find it quite difficult to make a choice of one or another tape.

Experts advise buying damping tapes with a width of 100 mm for laying single and double-layer screeds. For prefabricated systems, purchase products with a width of at least 150 mm with a divider.

You can learn how to properly install the damper tape in the next video.

What to replace?

The damper tape perfectly fulfills its main task, being distinguished by a lot of advantages. Due to the excellent properties of the base material, for many it is indispensable for other products that must be used for screeds.

However, some craftsmen, in pursuit of cost savings, are trying to replace the edge tape with other, cheaper goods. Often an alternative to industrial construction (damper) tape is wooden slats wrapped in polyethylene, polystyrene (in the process of use, it is cut to the required size), isolon (soft insulation).

But each of these budget substitutes has significant drawbacks. For example, izolon does not differ in excellent sound and heat insulation properties, since it is porous, and wooden bars are difficult to fix correctly, it is not easy to work with them and they deteriorate very quickly, since they are subject to fiber destruction processes. In the event of a break, the foam will not be able to return to its original shape, it crumbles and can break at the most inopportune moment.