Polyfoam and its features

Polyfoam is a class of materials that are foamed (cellular) plastics (gas-filled plastics). Since the bulk of the foam is gas, the density of the foam is significantly lower than the density of its feedstock (polymer). This determines the relatively high heat-insulating (convection flows are practically impossible in a single cell) and sound-insulating (thin and relatively elastic partitions of the cells - a poor conductor of sound vibrations) properties of materials of this class.

Foams were obtained from almost all the most widely used plastics (polymers), therefore the most famous materials of this class are: polyurethane foams, PVC foams, phenol-formaldehyde, urea-formaldehyde foams and polystyrene foam.

Depending on the composition of the raw material and the technology of its processing, it is possible to produce polystyrene of different density, mechanical strength, resistance to various types of impact. These factors determine the choice of a specific type of foam for use in certain conditions and purposes.

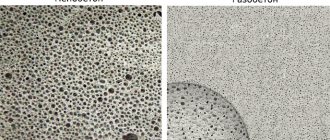

In domestic conditions, a person most often encounters such a type of foam as pressless expanded polystyrene (was invented by BASF in 1951). Styrofoam granules (PSV / EPS) are produced by polymerizing styrene with the simultaneous addition of a pore-forming agent (pentane). Polyfoam PSB-S (expanded polystyrene, styrofoam) is a well-known heat-insulating material, 98% consisting of gas enclosed in microscopic thin-walled polystyrene cells. Content

Foam thermoblocks

To date, the most effective and fastest way to build your own house while making a minimum of effort and money is to use foam thermoblocks.

Working with this type of material is not a big problem, but on the contrary, it even gives pleasure. Since these blocks are lightweight, it is not physically difficult to work with them. But there is also a downside to the technology, these blocks must be poured with concrete, which is a very laborious process. But first things first.

I will not delve into the details that it is necessary to correctly break the site and diagonals for the future house, as well as to dig and pour concrete into a solid foundation. Consider the construction of these blocks

Block dimensions 1000x300x300 inside it is hollow with transverse stiffening ribs. The wall thickness of the block is 50 mm, it is also necessary to purchase end caps in the kit to highlight the slopes of doors and windows. The design also includes special grooves that are located at the top and bottom of the block, representing the so-called daddy mama, which fit tightly to each other, which allows you to achieve a perfectly smooth wall surface. Also, these grooves prevent the flow of liquid concrete through the gaps between the blocks. Installation of blocks is carried out as follows

On a well-displayed zero - the basement is installed two rows of blocks (it is through such a distance that concrete must be poured, otherwise the wall can move out) it is also important to correctly determine the number of blocks on one or another wall so that they fit into the dressing and at the same time they are small overrun. After placing the first row of blocks, it is advisable to pull them together with a knitting wire in order to provide them with greater rigidity and protect them from the formation of cracks.Then, using a punch, we drill holes in the foundation in the lower position, perpendicular to the foundation, right through the block, 100 mm deep. Reinforcement 1200 mm long is hammered into these holes at a distance of 2 - 3 meters from each other, by the way, this must be done at the corners of the building. Then the second row of blocks is exposed, putting them on the reinforcement, and at the same time fastening them together with wire. The result is two rows of blocks with reinforcement sticking out of them. This entire structure is poured with concrete. Every two rows, it is necessary to lay the reinforcement flat along the perimeter, fastening it together. After the concrete hardens to the vertically protruding reinforcement, another batch of rods of the same length (1200 mm) is attached with the help of a wire. Blocks with dressing are put on again and the procedure is repeated. Thus, the walls of the required height are driven out, I had to see buildings of three floors built in this way.

Foundation

The foundation is the most important part of the building. This is the foundation of your home. It must be executed correctly and with high quality in order to avoid in the future many difficulties and problems that may arise both during the construction phase and during the operation of the building. The type of foundation is determined in accordance with the recommendations of geodetic surveys in the "spot" of the building, as well as taking into account the specifics of the project and the development of the designer.

The depth of the foundation should reach the depth of soil freezing in this region, for the Kiev region this figure is 100-120 cm.

Before pouring concrete, it is necessary to fill the entire area under the foundation with an interlayer of river sand and crushed stone, according to the design solution. This is done to drain rainwater from under the foundation. There are also a number of operations required to properly lay the foundation, but we will not describe them in detail as they are similar to traditional construction techniques.

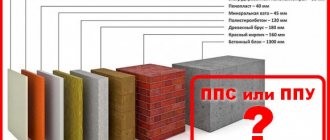

The only important difference is that the wall made of thermoblocks (if we compare it with a brick wall of 2 bricks) is not 50 cm thick, but 25 and weighs not 980 kg, but 360 kg, respectively, the foundation can be much thinner. For the wall of Thermohouse, it is quite enough that the foundation is 30 cm thick, and not 60 cm, as it would be in a brick house. This is quite enough to withstand the required load, plus considerable savings in materials and earthworks. Before erecting the walls, it is necessary to level the foundation with mortar and waterproof the entire area.

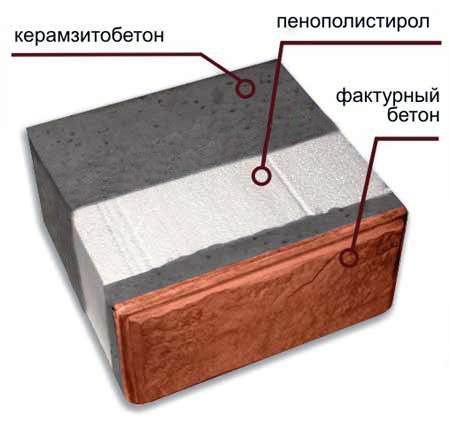

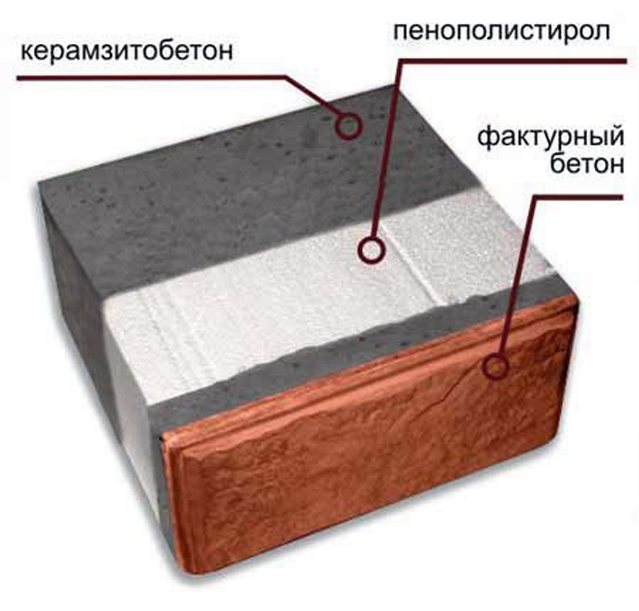

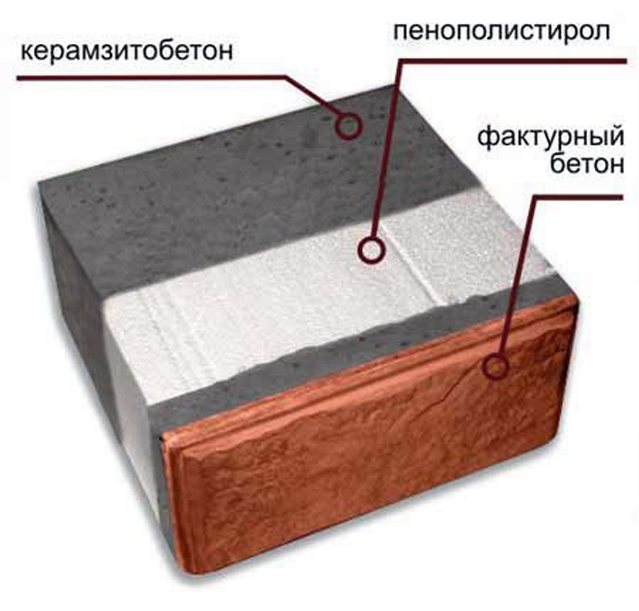

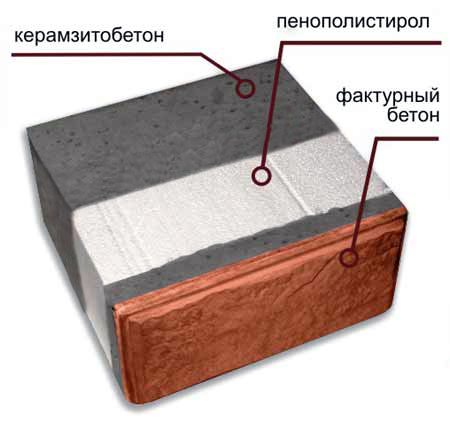

Characteristics of thermal insulation composites

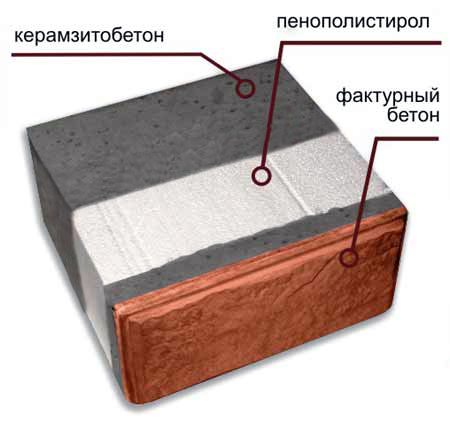

Three-layer blocks have a number of advantages over traditional materials used for construction:

- significant reduction in financial and labor costs in comparison with the construction of a brick building and the subsequent application of additional thermal insulation composition;

- reduction of the time for the implementation of construction activities, since masonry, facade insulation, exterior decoration are carried out at the same time. The dimensions, increased in comparison with brick, allow 2 times to accelerate the time for the construction of walls;

- increased thermal insulation characteristics due to the fact that buildings made of three-layer composites do not require special thermal insulation;

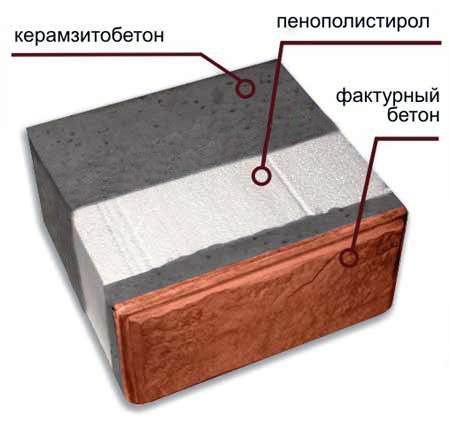

As a rule, the role of the supporting layer is played by porous expanded clay concrete, and dense concrete is used as the front layer, and you can choose colored or textured, imitating natural material

- improved sound insulation provides effective noise suppression, which contributes to the acoustic comfort of the room;

- increased strength of structures due to the reliable connection of the element layers with the help of steel reinforcement;

- increased degree of protection against moisture;

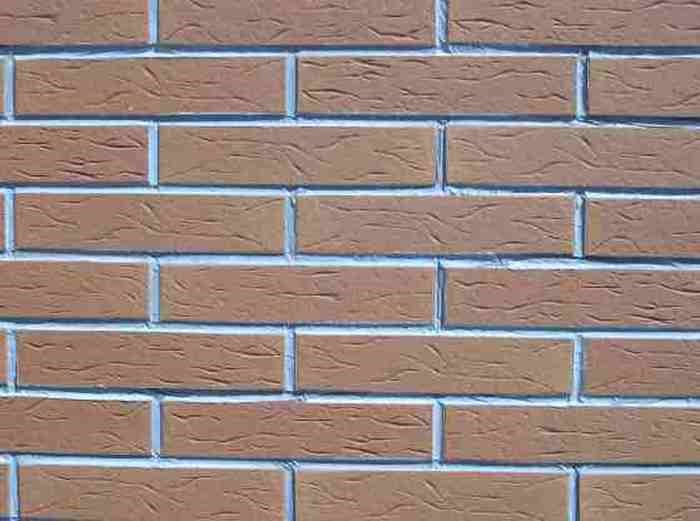

- aesthetics, since wall blocks with insulation and a decorative layer imitate various textures - marble, wood, natural stone or brick;

- high fire resistance;

- resistance to fungal formations, putrefactive deposits.

Thermohouse walls

After all the foundation work is completed, you can proceed to the construction of the walls of the thermal house. An important point is that on the first day, only one row of fixed formwork blocks (thermoblocks) is installed along the entire perimeter of the foundation, i.e. 25 cm in height. Then you should carefully measure the distances (length of walls, diagonals, corners) of the exposed row. With the help of a level, it is necessary to make sure that all formwork blocks are aligned, both vertically and horizontally. This is necessary so that during further construction the wall does not lead to the side and there are no deviations from the project.

Before pouring concrete, it is necessary to lay sewer and ventilation pipes and reinforce the wall. The reinforcement should not be removed from the foundation, as this will break the waterproofing between the foundation and the wall of the house. A reinforcement cage is laid along the perimeter of the entire building in the first row of thermoblocks. It consists of 4 rods of reinforcement interconnected (the distance between the rods is 10 cm). The same frame should be laid in each corner of the building of the thermal house, in the places of window and door openings and in the last row of blocks in front of the floor panel (sometimes in the last two rows). Reinforcement is done on the basis of a project, and it is rather difficult to give a monosyllabic answer to exactly how this process takes place. The diameter of the reinforcement and the step of reinforcement (vertical and horizontal) are calculated by the designer, and depends on the number of storeys of the house and the loads on the walls. After all the preparatory work has been done, concrete can be poured. The concrete should be poured up to the level of the upper edge of the thermoblock lintel. Until the concrete has completely hardened, you need to check again if the blocks are aligned horizontally and vertically and, if necessary, correct them. After the first row of permanent formwork blocks has been poured with concrete, the entire structure must be left until the next day in order for the concrete to gain sufficient strength for further construction.

The next day, you can erect 4 more rows of thermoblocks (height 1 m) and so on in the following days, until the moment when you need to lay down the floor panel. Before covering a floor with a floor panel, the wall must stand for 12 days to achieve the required strength.

Walls

After all the foundation work is completed, you can start building the walls. An important point is the fact that on the first day, only one row of thermoblocks is installed along the perimeter of the foundation, i.e. 25 cm in height (photo 1).

Then you should carefully measure the distances (length of walls, diagonals, corners) of the exposed row. Using the level, you need to make sure that all blocks are aligned, both vertically and horizontally. This is necessary so that during further construction the wall does not lead to the side and there are no deviations from the project. During the installation of the first row, the architecture of the whole floor is formed, therefore it is important to take into account in the right places the slopes of door and window openings, the junction of the internal walls, install sewer and ventilation pipes inside the thermoblocks (if provided by the project), as well as lay fittings.

We do not recommend using welding equipment when installing fittings, as this is unacceptable in monolithic construction.

The walls should be reinforced on the basis of design calculations, taking into account the loads that will affect the wall, therefore, only a designer participating in the development of the project, or a specialist of Valkyria LLC can give an unambiguous answer about what the reinforcement step will be, and the diameter of the reinforcement. We will introduce you only to the principle of wall reinforcement.A reinforcing cage is laid horizontally along the perimeter of the entire building in the first row of blocks. It consists of 4 rods of reinforcement interconnected (the distance between the rods is 10 cm). The same frame, only vertically, should be laid in every corner of the building, in the places of window and door openings and in the last row of blocks, before laying the floor panel (sometimes in the last two rows). After completing all the above operations, you can start concreting.

The concrete should be poured up to the level of the upper edge of the thermoblock lintel. Until the concrete has completely hardened, you need to double-check whether the blocks are aligned horizontally and vertically and, if necessary, correct them. After the concrete has been poured into the first row of blocks, the structure must be left until the next day so that the concrete gains sufficient strength for further construction.

On the second day, you can put another 4-6 rows of thermoblocks (height 1-1.5 m) and pour concrete. Often in individual construction (if two or three workers are involved) in the manufacture of concrete directly on the construction site, the workers do not have time to prepare the required amount of concrete and pour 2-3 rows of blocks (50-75 cm) per day, which is not a violation of construction technology. It's just that the speed of building the walls will decrease slightly.

“Thermodom” is not a definition from a science fiction novel. Of course, it sounds a little incomprehensible and puzzling. But if you look at it, everything is extremely simple. Foam blocks for construction are used for construction such houses from expanded polystyrene blocks... This construction method is called the permanent formwork method. In this article, we will look at the technology of building a thermal house. First of all, let's talk about the blocks themselves. The blocks are hollow "boxes" made of polystyrene: 95 cm long, 25 cm wide and 25 cm high for a wall block. The dimensions for the wall unit are 95x13x25 cm.

Such blocks are produced (see video production of polystyrene foam blocks) from expanded polystyrene by industrial conveyor production. One production line can produce about 120 blocks per shift.

Advantages of polystyrene foam blocks

* Blocks are not hygroscopic - i.e. they do not absorb moisture, they are resistant even to direct and prolonged exposure to moisture. * Blocks are excellent noise isolators. * Double - outer and outer - foam layer provides excellent thermal insulation. * Blocks "breathe", ie they slowly let air through. This makes them resistant to fungal diseases and rotting. * Blocks are lightweight, lightweight. * Blocks are convenient and easy to mount and handle.

Disadvantages of polystyrene foam blocks

* Blocks do not withstand high temperatures. The limiting temperature is 90 ° C. * Blocks are fire hazardous. Additional fire safety measures are required. * Blocks are easy to damage. Despite the apparent strength, the block is easy to pierce even with a finger. It is necessary to putty the walls.

In addition, some argue that expanded polystyrene, like any "chemistry", is not environmentally friendly and even harmful. I cannot categorically refute this fact. There are various requirements, GOST and norms, including sanitary, polystyrene foam blocks fully comply with them. But sometimes it's hard to convince a person of something that would seem obvious. The psychological factor is at work here. Although polystyrene has been widely used for a long time for interior decoration and insulation of buildings.

The cost of the polystyrene foam block about 4-5 USD In principle, this is a normal price. For comparison, you can calculate the total construction costs, for example, from bricks. Thermodom provides you with a finished wall, both inside and outside the house. In the decoration, you can use almost any material: putty, bark beetle plaster, wallpaper, paint, siding, etc.In a house built of brick, you will need to plaster and putty at least the internal walls, and even insulate the surfaces with the same foam, which will be even more expensive.

Thus, you should not be afraid of the high price, because it already includes ready-made, finished, insulated walls. Is it profitable? Yes, I think so!

At the moment, GOST allows the construction of thermal houses up to 15 meters high, which is already 4-5 floors.

How to build a thermohome Tools and materials:

* expanded polystyrene blocks * reinforcement 12 * tying wire * concrete mixer * sand * cement * crushed stone

Ready-made 600 grade cement can be used if desired.

* Construction from expanded polystyrene blocks is very similar to the assembly of a constructor - you assemble blocks into walls, joining them groove into groove, and shifting them horizontally and vertically with reinforcement. * After driving 4-5 rows, pour liquid concrete, tapping on the sides of the blocks with your palm (this will make the concrete more dense). * Then collect 4-5 more rows and repeat the process.

Of course, the number of rows is dictated by the overall dimensions of the building. If the building is small, then 4-5 rows around it will not take long to fill, and if the building has many walls and load-bearing walls, then the number next to it for filling is reduced. Here you should practice, calculate your strength, how much you pour at a time, how much concrete.

Installation of water supply, sewerage, electrical wiring and other systems is carried out by laying pipes for water and sewerage and corrugated hoses for wiring directly into the walls of the building.

Reinforcement

Reinforcement of blocks can be performed using a reinforcing mesh, filling it with masonry glue. You can reinforce every third or fourth row of masonry. Internal partitions with load-bearing walls are connected using grooves, which can be made with a chisel with a chasing cutter or a perforator. Sometimes fiberglass or steel embedded elements are used. The base of the insulated block can be easily processed with dowels or standard nails. For expected heavy loads, injection dowels can be used.

The cost price of a house built from insulated three-in-one building materials can be compared with popular houses built using Canadian technologies. Only a house made of heat blocks turns out to be much more environmentally friendly and durable, and in terms of its operational characteristics, it can belong to the premium class of capital structure.

Thermal house construction technology

Construction technology "Termodom" is the technology of the so-called "fixed formwork", which means: the construction of the walls of a house built from blocks made of high-quality expanded polystyrene, the inner space of the blocks is filled with concrete and reinforced. Thus, a very strong concrete wall is obtained, reinforced vertically and horizontally, and insulated on both sides, resulting in a "thermos" effect. This, in turn, allows you to significantly reduce the cost of heating and cooling the internal space of the house. The walls of a house designed and made using the Termodom technology are much stronger than capital brick walls 38 cm thick. The cost of installing interfloor ceilings on walls erected using the termodom technology is much lower than the cost of installing similar ceilings on walls erected from any other material. The cost of building a thermal house box is one third cheaper than building a brick box. Specially developed construction technology and construction of the foundation under the walls using the termodom technology allows you to reduce the cost of building the foundation, basements and basements.

Heat transfer and lack of seasonality in construction.

Construction technology "Termodom" (termodom) is universal and suitable for almost all climatic zones and does not depend on the season. The construction of a thermal house is possible both in winter and in summer, and the temperature of the external environment will not affect either the appearance or the durability of the walls. It is cool in the house, built according to the "Termodom" technology, and warm in cold weather. That is, regardless of the climate and season, such a house is always a comfortable warm home. Expanded polystyrene is an excellent thermal insulator. In winter, it makes sense to start heating with a thermal house at a temperature of -2 ° C or -3 ° C, and in warmer weather, the heat emitted by household appliances will be enough to maintain a comfortable temperature. Thermodom (termodom) in winter does not cool down as quickly as a brick building, and perfectly stores heat.

Structural strength and number of storeys of buildings.

Recently, more and more often, customers prefer the construction of a private cottage from thermoblocks, but in principle, the Termodom technology is also suitable for projects of apartment buildings up to nine floors, as well as for kindergartens, hospitals, schools, technical rooms, workshops, office buildings , and so on. As for strength, a nail driven into a polystyrene foam wall and planted with a dowel can withstand a load of about 70 kg. The walls themselves are much thinner, lighter and at the same time durable and warm. According to the standard, a thermal house serves for more than 120 years, but in practice, if the construction is carried out in strict accordance with the technology, then a 120-year period is far from the limit. Turnkey construction of Thermohouse has been used for a long time in the world and has become widespread in Europe, USA and Canada.

Aeration and resistance to microorganisms.

Expanded polystyrene walls of houses and cottages built according to the "Turnkey Thermodom" technology not only "breathe", but at the same time they are resistant to moisture, which increases their thermal insulation properties. Many other materials accumulate moisture, which gradually leads to a decrease in their quality, which requires an increase in heating costs and maintaining a comfortable indoor microclimate. Firstly, excessive humidity negatively affects the health of people and animals living in such a house, in addition, it provokes increased energy consumption for heating, which can cause the formation of fungus and gradually destroy the walls of the building, especially as a result of temperature changes. Such problems are not terrible for expanded polystyrene, even with prolonged high humidity and when the temperature rises to + 90 ° C. The chemical composition of such blocks does not contain absolutely any elements that fungi and other microorganisms can feed on.

Construction time and ease of construction.

From an engineering point of view, the weight of a foam block structure is much less than that of a brick - about three times. Therefore, you can completely safely use a lightweight foundation structure and be glad that the construction of such a house or cottage will take much less time than you expected.

Thermal house construction: Expanded polystyrene.

Expanded polystyrene is a light gas-filled material of the foam plastic class based on polystyrene, its derivatives (polymonochlorostyrene, polydichlorostyrene) or copolymers of styrene with acrylonitrile and butadiene. The method for the production of expanded polystyrene was obtained back in 1928, and after 9 years in 1937 its industrial production was established. Since then, the method of producing expanded polystyrene has undergone a number of changes due to regional differences in the concepts of development of the chemical industry.

Expanded polystyrene is a fairly common material, and its scope is not limited only to the construction of houses, cottages and other objects. Expanded polystyrene has found wide application in industry - it is the production of packaging material for household appliances and decorative elements, food packaging and disposable tableware, insulated containers for food and energy-absorbing elements in the automotive industry.

Expanded polystyrene is used where environmental friendliness and harmlessness as a material play an important role. Regardless of the ambient temperature, expanded polystyrene does not emit any substances harmful to health, and that is why even hospitals and kindergartens can be built from expanded polystyrene blocks.For the construction of houses using the "Termodom" technology, a special, hardly flammable expanded polystyrene foam is used, which guarantees its complete fire safety.

Quality and benefits

An important indicator is the density of D500 polystyrene concrete blocks. This value is a guarantee of higher strength, which increases over time, since the structure is petrified, excellent moisture resistance, absolute non-flammability and better thermal insulation, resistance to decay and harmful bacteria. The absence of allergens in the composition and light weight make this material a leader in the construction market, and its properties make it possible to use the material in any climatic conditions.