How to make a crate on a balcony

If you decide to insulate your balcony or finish the loggia from the inside, you need to choose the right material for this. These materials can be: siding, lining, drywall, plywood, or decorative panels.

For proper cladding, these building materials must be attached to a special frame, which is called "lathing". It is quite difficult to install it, but anyone can handle it. Correct assembly of the frame can affect the overall insulation and its service life.

The installation of the lathing on the loggia is carried out for further insulation. These works can be done with your own hands, which will help save money. The lathing is performed in two types of materials:

In the event that you want to keep warm on the balcony, then it is more correct to choose the first one from the list. Metal conducts cold well; a metal frame will not work to retain heat.

Features of infrared underfloor heating

This underfloor heating design provides heating of the room due to infrared radiation. It is warm and soft, as well as perfect harmlessness to human health. The infrared floor is also characterized by a high efficiency - radiant heating is incredibly effective in rooms and more economical than traditional systems by 15-20%.

Laying infrared underfloor heating on the loggia

To install a film underfloor heating, you need:

- non-conductive foil backing;

- wires;

- perforated film;

- thermostat;

- insulating tape;

- masking and bituminous tape;

- standard set of tools.

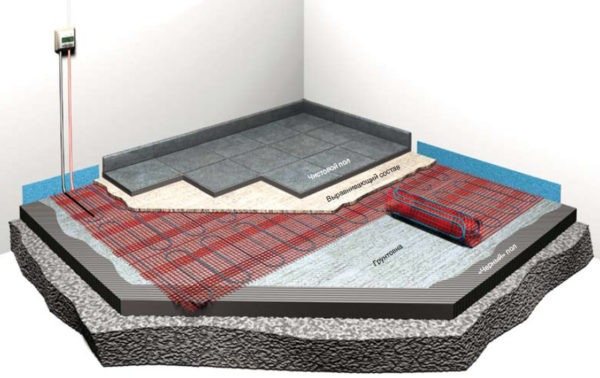

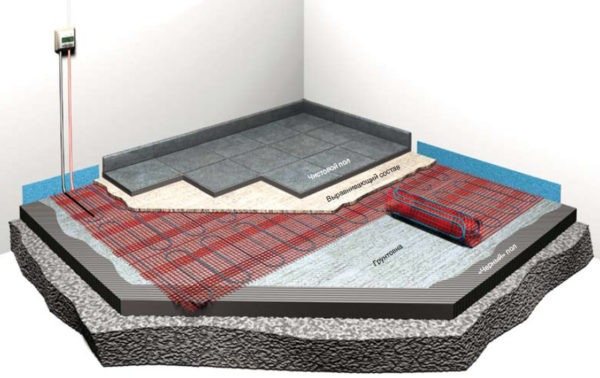

The actual installation of such a floor involves several stages. At the beginning, all debris is removed from the floor surface, after which the surface is marked for laying the film and it is primed. The foil substrate is laid in strips - they are prepared in such sizes that they completely coincide with the strips of the warm floor (both in width and in quantity). It is important that the length of the prepared strips coincides with the total length of the room - it is undesirable to arrange joints between them. If there is a need to make a cut, then it is performed only in the place where there is no graphite layer.

The cut film is laid in such a way that copper contacts were located at the bottom, and at the top was a matte surface. In addition, the contacts should turn to the wall where the thermostat will subsequently be installed. All work with an infrared floor is carried out with extreme caution so as not to damage the ferrite layer.

Laying scheme for infrared film underfloor heating

But an infrared warm floor, despite the positive technical characteristics and ease of installation, is not the best option for a balcony or loggia. Indeed, it does not require pouring into a screed, as is the case with electric cables, but the infrared film is so thin that it can only be mounted on a perfectly flat base. In addition, this system will not work economically at low temperatures (below +20).

Tools, materials and work execution

The execution of the lathing will not be difficult for you and expensive equipment is not required for this. For lathing with your own hands, you will need the following materials and tools:

- saw on wood;

- rail with dimensions of 40 x 10 millimeters;

- roulette;

- pencil;

- puncher;

- polyurethane foam;

- screws and dowels;

- screwdriver.

The first thing that needs to be done is to draw where the beams will be located, according to this drawing the lathing will be carried out. The slats must be fixed from the inside of the window. The rest of the beams must be positioned in the longitudinal direction. Between the holes, the pitch should not exceed 40 centimeters.

After the above, you need to drill holes in the beams and on the wall, this will serve as a fixation for the permanent installation of the wooden frame. Beams must be installed vertically with their own hands. For reliable fastening of one bar, 4-5 holes are enough. For fastening the rails, the step should not exceed 50-60 centimeters. The frame at the bottom must be fastened with a distance of 1 centimeter from the floor, this will help to foam and remove any existing cracks in the future.

The next step is to check the position of the frame. For this, you can apply a building level. The first step is to know if there is a vertical blockage of the wall. In the event that the top of the bar deviates outward, then it is required to adjust it to the same level. After the work done, the structure must be level.

Following the installation of the entire frame and checking the level, the empty space must be foamed with polyurethane foam. This will contribute to the strength, additional thermal insulation and rigidity of the structure.

All work on installing the lathing takes a lot of time, but does not require expensive tools and materials. By making the crate with your own hands, you can save money. It is important to remember that work can only be done on closed balconies or any type of loggia.

- If the lathing made of wood is in contact with something, then there should be no fungus and mold in this place.

- Many experts recommend patching up existing cracks, holes and crevices before lathing.

- Practice on a separate bar before cutting threaded connections, this will prevent you from spoiling the base.

- Look for interesting surprises before purchasing materials in stores. For example, it can be a PVC profile with pre-pollinated edges under 45⁰.

What is a crate and why is it needed

The lathing is a lattice structure made of rectangular or square profile materials, designed for installing cladding, laying and holding insulation, insulating films and roll heat insulators. Most often, the grille is made of materials, the main requirements for which are strength and ease of fixing finishing elements.

A crate on a balcony or loggia is usually used in the following cases:

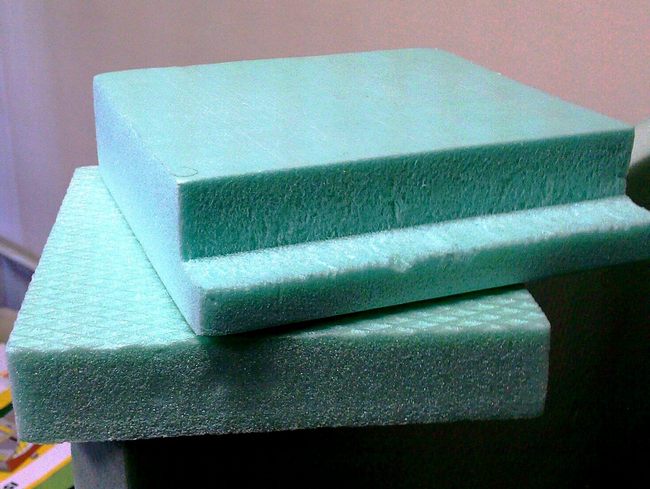

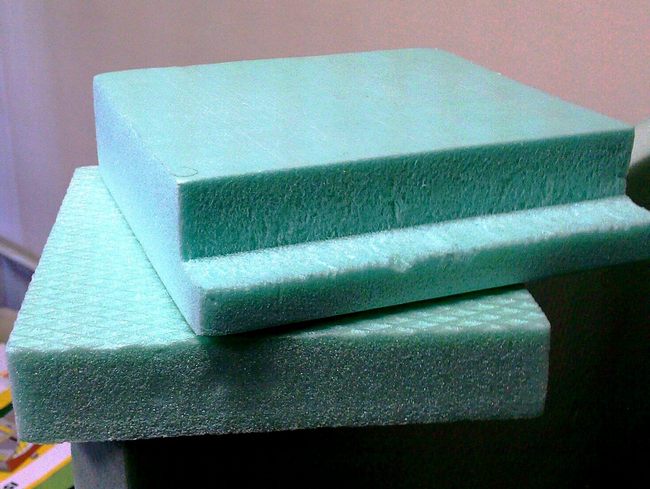

- Installation and floor insulation... Thermal insulation of the floor from a concrete slab is one of the important stages of warming a balcony room after warm glazing from a metal-plastic profile with multi-chamber double-glazed windows is installed in it. Usually, the crate of the floor on the balcony is mounted from a bar, in the cells of which insulation is laid from mineral wool, extruded (Penoplex) or ordinary polystyrene foam (polystyrene). In this case, the balcony floor is raised to a height convenient for the user by laying the logs in one or two rows or using rectangular elements with the required height.

- Insulation and sheathing of the parapet... In order to keep the heat in the balcony room, after installing heat-saving glazing with multidimensional double-glazed windows, the inner walls of the parapet are finished with heat insulators. To fix the insulation, a metal-profile or wooden frame is placed on the surface of the parapet, into which the insulation is inserted, after which it is closed with various types of sheathing.

- Thermal insulation and ceiling decoration... The lathing is often used for laying insulation on the ceiling with the subsequent fastening of finishing building materials and spotlights to it.

- For wall decoration. Often, the walls of the balconies are sheathed with plastic slats or clapboard; for laying panels and boards, according to the instructions, a lattice frame made of wood is used as a basis.

Fig. 2 Laying scheme for the balcony floor

Clapboard decoration

In order to give the balcony coziness, warmth and beauty, it is often sheathed with clapboard made of natural wood. A big plus for her is instant insulation of the balcony, which will help keep warm in winter. It will not be difficult to finish with such material with your own hands, but the amount of work is quite large.

Clapboard is often understood as a product made of wood. But sometimes plastic PVC panels can be called clapboard. The choice of this material is often based on its cost and practical considerations. In different regions, a natural tree stands in different ways.

Most often they prefer to choose wood, as it is a natural material. In practice, of course, PVC is better, because: it is easy to clean, practically does not need maintenance or processing, and retains a presentable appearance for a long time.

The lining, made of wood, is more difficult to operate: before the installation itself, it must be covered with a protective impregnation. Also, if desired, the lining should be painted or varnished, but only after complete installation. But, despite the difficulties in maintaining wood, it is popular when decorating a balcony.

Benefits of underfloor heating

Underfloor heating is an excellent alternative to the "radiator" heating method, as it contributes to a comfortable and rational distribution of heat in the room. And for such "additional" rooms as a balcony - this is generally the only possible option, because it is problematic to take out the battery here, and the constant use of heaters or fan heaters is not always effective.

Among the main advantages of a warm floor can be distinguished:

- the highest level of thermal comfort, incomparable with any heating system;

- low heater temperature;

- no bulky and unaesthetic radiators requiring decoration and maintenance;

- the broadest functionality of temperature control due to the installation of sensors and automation;

- long service life (for a water floor - several decades);

- the ability to install without special equipment and skills, the ability to carry out local repairs if necessary (for electrical structures).

Often, before final finishing, it is required to raise the floor level on the balcony. Read our guide and you will find out in what ways you can do this.

And this article has all the information on how to choose a plastic window profile and what you need to pay attention to.

Installation of lining

Facing with this material will be the final stage. This stage is conditioned by fairly easy work, which will not cause difficulties. The installation of the lining is quite simple, even if the instructions are completely incomprehensible to you.

- Execution, as a rule, starts from the far corner, moving towards the exit from the balcony itself over time. All existing panels must be placed exclusively vertically; for the correct actions, you must use the level. The first step is to install the first bar, it needs to be nailed to the bars with nails. It will be a guide for subsequent planks.

- In addition to nails, you can also use staples or special clamps, the latter will help you to provide a strong fastening. When using nails, they must be driven exactly into the groove, but rather carefully, since you can easily damage the lining made of wood.

- Following the nailing of the initial bar, it is supposed to proceed with the installation of the next one, for this it is necessary to carefully insert it into the groove, align the position with a rubber hammer, delicately tapping on the other side of the bar.After fixing the desired position, it is worth attaching the panel and proceeding with the installation of the next one. Therefore, it is appropriate to sheathe the entire space in this way.

- For finishing the corners (external and internal), special corners should be used, which in turn will give a more presentable and neat appearance. Skirting boards made of wood should be used near the ceiling and floor, which will give your cladding the final appearance.

You can install window sills immediately after the balcony is sheathed. This will contribute not only to the simplest actions, but also to the quality of work. If the window sill is installed in front of the cladding, it will only interfere with the installation of the panels. In the event that there is no experience in this type of work, then more material may be needed, since there will be much more debris during trimming. After finishing the clapboard, you can start decorative work.

It is important to remember: lining made of wood is quite attractive in its original form, but almost all experts recommend covering it with several layers of varnish.

Thus, we can conclude that many materials can be used for cladding, but the best material is wood lining. The lining will help to make a small room attractive and, moreover, helps in insulation, protects against winds and drafts.

Natural material is considered the most suitable for decoration, because it is environmentally friendly and has a distinctive feature from cheap PVC panels. Everyone can complete the installation, even if there is no experience in construction. Tools for lathing and finishing can be easily found in any home or bought in any specialty store.

Output

To equip a warm floor on a loggia under a tile, it will be necessary to overcome a number of difficulties and technical problems, but the result will fully justify the efforts. After receiving permission for repair work, you should immediately get down to business. A warm floor under the tiles will contain a lot of advantages: ensuring the correct distribution of heat in the room, complete absence of the need for maintenance, energy savings, high functionality, ease of installation without special skills.

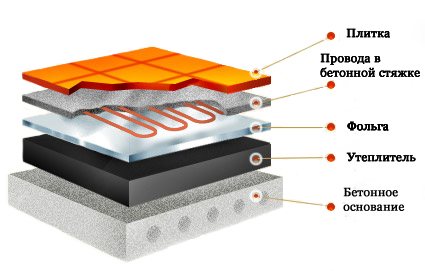

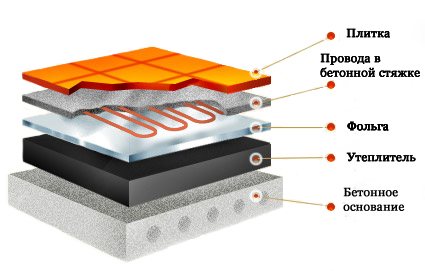

Underfloor heating is an assistant in getting rid of high humidity and cold. The main and most important moments in the technological process of its arrangement is installation. The first step will be the installation of steam insulation. All joints will need to be sealed with metallized tape. There should be no mistakes when installing the heat-saving layer. Otherwise, during cold weather, condensation will develop around the edges. The screed is also carried out without gaps, with a thickness of more than 45 mm. Heating elements are laid at a distance of 30 mm from the upper level.

Yet

The lathing of the balcony or loggia: both under the lining and under the siding!

Have you started insulating your balcony? Have you decided to decorate the loggia from the inside with an attractive, environmentally friendly material? Regardless of what you choose for the interior cladding of the balcony: lining, siding, plywood, drywall, any decorative panels - in any case, these materials should be attached to a pre-installed frame. Which is called the crate.

Since the installation of the lathing is a rather complex and responsible part of the work, on which both the quality of insulation in general and its durability depend, we will dwell on this operation in more detail.

Advantages of tiles when laying a warm floor

The tile serves as an excellent decorative material and has a lot of advantages:

- Durability;

- High indicators of strength and reliability;

- Resistance to temperature extremes;

- Resistance to the effects of active chemical and biological media;

- Fast and easy installation.

To get the longest life for your tiles and underfloor heating, you should choose a tile with a low weight. The correct tile size is calculated depending on the parameters of the balcony, loggia.

Options for installing tiles under a warm floor

When laying tiles under a warm floor, you should choose the best option. Installation is carried out in several versions:

A variant of the standard installation of a single-color tile underfloor heating.

- Standard installation;

- Chess montage;

- Diagonal;

- Herringbone installation.

For plain tiles, choose a standard installation.

Important: the tiles on the balcony are laid from the center of the room.

Lathing the floor of a balcony or loggia

Balcony floor lathing

It is better to start the crate from the floor. Beams (logs) 50x70 mm are laid along the length of the balcony. These are the optimal sizes. Thicker ones from increased humidity can bulge, thinner ones are simply weak for the loads that they have to withstand.

Laying is carried out with a step of 45-65 cm. If you think it is necessary to complete the lathing with the installation of additional cross bars ("in the box"), a hammer and a hacksaw in your hands.

It is necessary to connect these bars with the longitudinal logs "groove to groove": that is, in both longitudinal and transverse bars, cut out to the middle of the notch, into which the mating parts of the bars installed crosswise will enter.

If the floor of the balcony is uneven, then put wedges made of hardwood or just pieces of siding in the places of "sagging" lag. Fix them with polyurethane foam, but try not to get it between the wedge and the beam itself: in this case, the coating will creak strongly when walking on it.

In addition, in this case it is necessary to clean and level not the entire slab of the balcony, but only the areas under the dies. First, dies are attached to the concrete with dowels, and the bars are already nailed to them.

What is the best underfloor heating?

Each of these structures has its own operational features. But there are also common features - the "warm floor" system is mounted exclusively on specially created thermal insulation - the insulating layer protects the floor from significant heat loss. Then the cement screed is performed, after which the finishing flooring is laid.

Water floor (from autonomous or centralized heating) is the most difficult system to install... In addition, it is distinguished by high costs and heat loss, and therefore is unprofitable for such small areas as a balcony.

For balconies and loggias with a cement-sand screed, you can use cable heating concepts... Screed thickness - at least 45 mm. In addition, all gaps that allow air to accumulate inside the structure are excluded - the presence of voids will lead to overheating and breakdown of the system. An electric cable is attached to the subfloor - "snake" with a certain pitch. It is important to choose the right step:

- too large a step will lead to the floor not warming up;

- too small a step will significantly increase your material costs and, in the future, your electricity costs.

Installation diagram of cable underfloor heating under tiles

Ceramic tiles are laid on the screed - all the work is not complicated and can be done independently. However, it will be possible to operate such a warm floor not earlier than in a month. If it is not possible to perform a screed of the required thickness, then cable floor heating is not used, but is used heating mats... The same option is chosen if you do not want to deal with calculations of the number of heating cables and the step of their laying.

The choice of the type of electrical system also depends on the area of the balcony - the heating elements must provide a power of about 150 W per square meter.

Ceiling lathing: "bookmark" under the dryer, and what if there is no balcony on top?

In a similar way, the ceiling lathing of a balcony or loggia is performed. In this case, thinner beams are used - 20x40 mm. But it must be borne in mind that the ceiling beam can be used for the device of the dryer.

Related article: Battery on the loggia the amount of the fine

We check the strength of the mortgage board by the weight of an adult man!

Assume that the weight of a wet carpet will easily exceed the weight of an adult. Therefore, the “bar for the dryer” should be chosen more firmly (50x70 mm) or instead of one thick bar, paired (tightly stitched with nails or bolts, screws) bars of regular thickness (20x40 mm) should be used. It is necessary to nail them to the concrete of the "ceiling" (balcony of the upper floor) with dowels in increments of 30-40 cm (in the area where the dryer will be mounted).

A special case is the lathing of the ceiling of the balcony located on the top floor of the building - where there is actually no “ceiling”.

In this case, above the balcony, at a height of about 2.2 meters, it is necessary to fix a structure, which experts sometimes call a "half-heart" or "visor". Most often it is a right-angled triangle welded from a steel corner profile. Sometimes, instead of a steel profile, a durable wooden (oak, birch) bar is used.

Balcony roof device

With its short “leg”, such a “triangle” is fastened with dowels to the main wall, with a long one overhanging the balcony, and its “hypotenuse” sets the angle of the slope along which snow will melt in winter. 2-3-4 such structures serve as a frame for the roof of the upper floor balcony.

It is rather difficult to install such a "half-hearted" over the balcony. Usually, a team of industrial climbers or experienced builders is hired for this.

But after the "visor" has been strengthened, further work proceeds according to the same scheme: the longitudinal laths of the crate are stretched, the slope is covered with tin, tiles, slate; the ceiling is insulated with mineral wool or other material suitable for this purpose, and sheathed with plywood or siding.

Balcony frame

Before proceeding with the crate, in some cases it is necessary to strengthen the structure of the balcony. How to do it? - Read the article "How to make a frame for a balcony with your own hands?" One of the most difficult renovation tasks is the installation of a canopy over the balcony of the upper floor. A separate article on our website is devoted to its solution. When repairing a loggia, often, along with the crate, it is also necessary to pre-insulate the parapet. Another material on our website is devoted to this - https://oknanagoda.com/balkony-lodzhii/remont-otdelka/kak-otremontirovat-parapet.html

But regardless of what material was used as the frame of the "visor" - a steel profile or a wooden beam, the structure is very massive. Under the influence of the additional weight of snow or gusts of wind, it can collapse, turning out part of the main wall. Therefore, very often the owners of apartments on the upper floors of old panel buildings are asked to refuse such a reconstruction of their balconies.

The choice of material for the lathing

The most common materials from which the lathing of a balcony or loggia is made are:

- wooden bars or slats of square or rectangular cross-section;

- metal profiles, usually made of bent galvanized sheet.

When choosing, consider the following factors:

- Metal profiles have the best performance, do not require special protection, and are connected to each other using inventory fixtures. The price of such profiles and the cost of their installation can be much more expensive than wooden slats.

- Wooden bars and slats are easy to process, convenient for the manufacture of initial elements of frames and battens. However, wood has disadvantages, such as - when the humidity and temperature of the surrounding space change, it bends and warps, it is easy to be affected by biological contamination, leading to damage by fungus, mold, and rot. Also, wood is a very flammable material that cannot be used without treatment with special substances called flame retardants. It follows from this that wooden frames must be properly prepared and prepared before using them as lathing for covering balconies and loggias with decorative trim.

Lathing of the side walls of a balcony or loggia

Internal lathing of the walls of the balcony

A certain difficulty is the lathing of the side walls of the balcony and its front part. Steel racks installed in the corners of the balcony will have to be used as load-bearing elements. And also - steel bars of the balcony railing.

Some craftsmen are trying to carry out this fastening with the help of dowels. Do not waste time: such fasteners will loosen in a matter of weeks. Fasten both wooden logs and an aluminum profile to metal load-bearing structures only with screws.

To do this, you will need a drill, drill, taps. Threads M6-M8 can be cut in corner posts, M3 - M4 in the fence bars.

If it was not possible to get long M3 or M4 screws, then drill blind recesses - "glasses" with a diameter slightly more than the screw head in the logs, leaving a "bottom" 5-10 mm thick at the bottom, through which the threaded part of the screw will pass. After screwing in the screw, this "glass" can be filled with a wooden stopper or simply covered with epoxy.

There is an option when pieces of wooden beams with a size of 50x70 mm installed at the corners are used as a bearing support. But they also have to be fastened with screws to the corner metal posts, and wooden logs have to be nailed to them.

Often in this case, transverse beams are also installed - "from the floor to the window sill". The construction turns out to be quite massive.

Consider only one thing: welding can only be carried out if there are no flammable materials on the balcony.

Lathing of the inner wall of the balcony

As a rule, insulation of the inner wall of a balcony or loggia (the one located between the balcony and the living space) is not done. She is considered "warm" anyway.

But sometimes, purely for decorative purposes, it is also sheathed with the same material as the rest of the balcony, with the installation of the lathing.

Here there is a difficulty of a slightly different plan: it is necessary to frame the door and windows overlooking the balcony. But this operation does not require anything special, except for accuracy: wooden slats are likewise nailed to the wall with dowels or dowels and serve as the basis for sheathing with finishing material.

Insulation of the sides of the loggias is not a significant difficulty, since in this case, a buttress protruding from the wall can be used as a supporting element. The front part of the loggia is processed in the same way as the front part of the balcony.

Balcony lathing with insulation tab

Currently, it is practical to sheathe balconies and loggias from the inside with siding, PVC panels. In this case, instead of wooden slats and beams for lathing the side walls and ceiling, it makes sense to use the so-called CD-profile. Different manufacturers and different stores may call it differently: "CD-strip", "ceiling rail", "PP", etc. The essence of this does not change: this is a profile made of galvanized sheet, which has a cross-section like the letter "P".

It is produced in a variety of standard sizes, the largest (60x27 mm) can be used to assemble load-bearing structures. It is convenient to fix plasterboard plates in it (take a note, if you decide to use this material to insulate your balcony!), It is available, since many companies and individuals use it to install suspended ceilings.

CD profile appearance

Working with it is fundamentally no different from working with wooden logs or slats. You just need to remember that if you are going to make facing with siding, then you need to fix the CD-profile with the “legs” of the letter “P” to the wall, and with the “crossbar” outward. Otherwise, you will have nothing to attach the siding to. Or you will have to put wooden slats into the grooves of such a crate, which will only make the work more expensive and take a lot of time.

This kind of profile is durable, you can, without fear, fix it with dowels to the wall in blind holes with a pitch of 50-70 cm. The CD-strip differs from the wooden lathing in an advantageous way in that it does not jar, it does not burn, bugs are indifferent to it - woodworms, but ...

A tree is a tree! It accompanies a person throughout his entire history, it is closer and dearer

Insulation types

Next, we will consider how and with what materials you can insulate the floors in the house.

Wood floors

Provided that your balcony or loggia is protected from moisture from outside, the easiest and cheapest way to improve the floor is wood insulation. Wood as a material has a very low heat conductivity, therefore it is recommended to use it on concrete floors. There are two main designs of wood floors:

- If your concrete floor is level enough, the boards can be laid directly on top of it. A significant disadvantage of this method is that most often the concrete floors are not dry enough so that they do not harm the tree.

- The second way is to install floors on logs. This will provide additional ventilation and increase the distance between the planks and the concrete, ensuring less cold transfer from below. Such floors will last much longer compared to the previous version.

Important!

Ensure that the wooden floor has a sufficient slope so that any accidentally ingested liquid can gently drain off the flooring.

Conifers are the ideal material for working with wood. They are relatively cheap, and due to impregnation with natural resin, they have the highest moisture resistance. It is not recommended to use plywood or chipboard - these materials do not have durability.

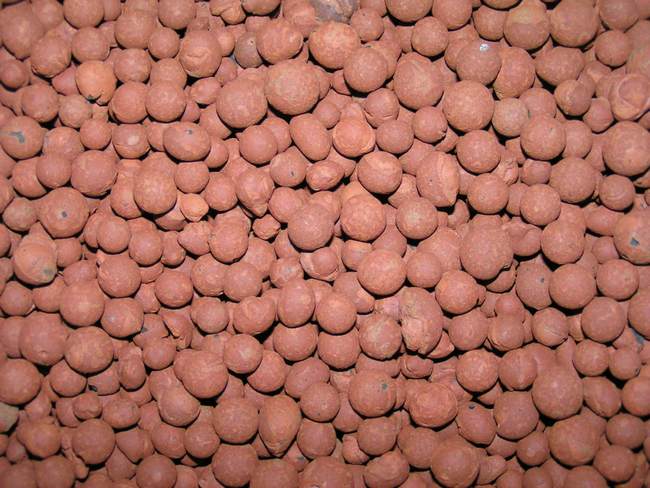

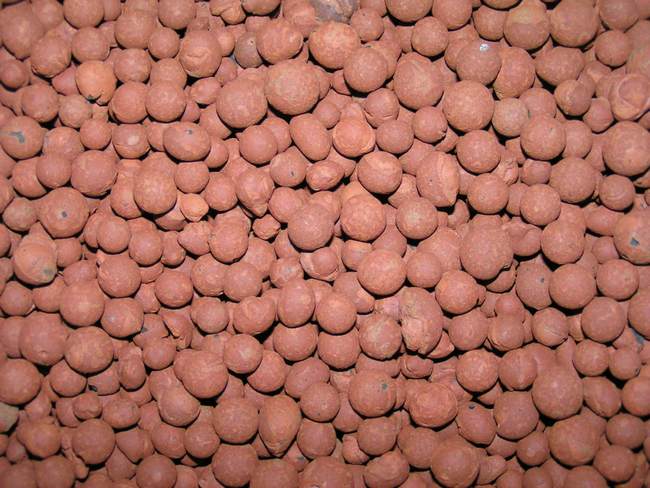

Expanded clay

As an addition to the wooden floor, you can use expanded clay insulation. It should be noted right away that this option is unacceptable for weak structures that cannot withstand a lot of weight - after all, of all known heaters, high-quality expanded clay is the heaviest. It is used in a layer of ten to fifteen centimeters, sprinkling between the lags.

Mineral wool

There are three main types of mineral wool, which differ in chemical composition - glass wool, slag wool and stone wool. Their structures are strong and resilient, they have high ignition temperatures, the operating temperature range ranges from -60 ° C to 450 ° C, which makes them fireproof enough for installation in residential premises.

However, there are a number of significant disadvantages that make you think when choosing this particular method of insulation:

- Despite the high fire safety indicators, the evaporation of the substances impregnating the cotton wool occurs already at 250 ° C. To seal the structure of the material, phenol-formaldehyde resins are used, the fumes of which are carcinogenic.

- Installation of glass and slag wool is very hazardous to health. Glass wool contains microscopic glass particles that can injure your hands even with very careful handling. If inhaled, it causes acute irritation of the mucous membrane. Slag wool absorbs moisture very well, while releasing caustic and very dangerous acids.

Important!

Installation of the floor using these materials must be carried out in special clothing that covers the maximum area of the body, in thick gloves, glasses and a good respirator. Overalls after the end of the installation of cotton wool must be destroyed without fail.

Based on the listed disadvantages, if you nevertheless decide to use this material, then it is recommended to use it under a thin concrete screed. Wool is allowed for installation, which before unpacking was found in a sealed undamaged film. The total weight of the structure should be carefully calculated when used on balconies or loggias with non-capital overlap.

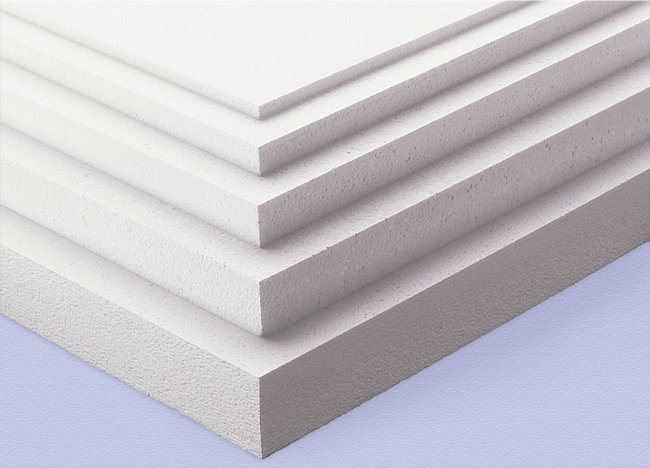

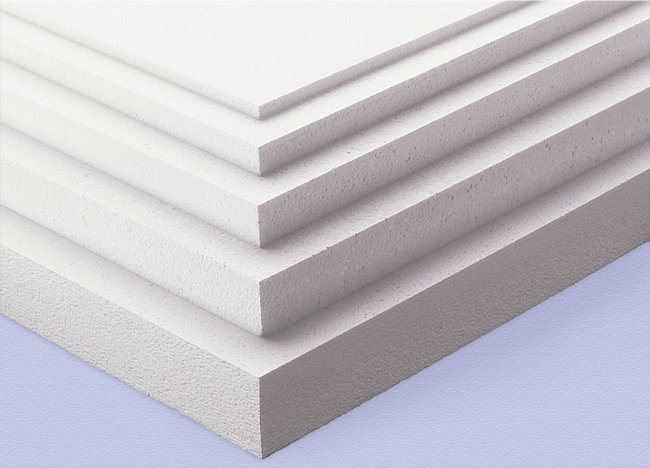

Styrofoam

This option is the second cheapest and easiest after expanded clay. The main advantage of foam is its light weight. It practically does not absorb moisture, relatively resistant to chemical attack.

For a wooden floor, foam is laid between the logs with a layer of the required thickness. In the absence of solid plates of this material, you can use foam chips, which are used in the same way. If you plan to cover the floor in the loggia with ceramic tiles or finish it with natural stone, then special preparations must be made before installing the foam.

Below is a step-by-step instruction:

- To prevent the formation of unevenness on the new floor, first of all, it is necessary to level the existing floor. For this, a slurry of cement, sand and water is kneaded. Irregularities on the old surface are poured with a thin concrete screed. It should be noted that the thickness of the layer in its thinnest part must be at least 7 mm, otherwise it will immediately crack after drying. For extra hardness, it is recommended to sprinkle the layer while still wet with dry cement.

- After the new layer has dried, a layer of roofing material up to five millimeters thick is laid. It is a layer of rubber impregnated with bituminous resins, which gives it a high level of waterproofing. Waterproof glue is used as fixing - it is necessary for trouble-free work with the next layer.

- Foam is then laid out as a thermal insulating material. In this case, the thickness of the layer is selected depending on the height that remains to bring the balcony floor to the level with the room. Usually a thickness of 2-3 cm is used. The foam is also fixed to the roofing material with waterproof glue to avoid free movement of the blocks during further work.

- After the foam, a layer of one-piece polymer film is unrolled. It serves as the final waterproofing layer. It is important that the film is solid, without tearing and damage - this will significantly increase heat retention.

- On top of this structure, another thin concrete screed is poured, which is carefully leveled. She is allowed to stand and dry, and tiles or natural stone are already laid out on it, using a special glue as a fixing substance.

Important!

All joints at all levels of insulation (joints of roofing material strips, gaps between foam blocks) are recommended to be sealed with construction tape or adhesive aluminum tape. When laying foam, you can also coat the sides of the blocks with waterproof glue for their end connection to each other and to the walls. By taking these steps, you will provide the greatest possible isolation.

The amount of material is calculated as follows:

- The volume of cement, sand and water is calculated on site, depending on the number and size of irregularities, taking into account the above recommendations for pouring the screed.

- The required area of roofing material is equal to the area of the room, taking into account its launch on the side walls by 4-5 cm. This will help to avoid the penetration of moisture through irregularities in the walls. The launch must be thoroughly coated with waterproof glue and attached to the walls.

- The square of the foam is equal to the area of the balcony of the floor of the balcony or loggia. It is necessary to very accurately calculate its amount so that it fits snugly against each other and the side walls.

- The size of the polymer film is calculated similarly to roofing material, not forgetting about a small launch on the walls (1-2 cm) with gluing.

- The length of the construction tape is the same as the length of all the joints you want to glue. It is relatively inexpensive but effective, so spare it for extra insulation.

Expanded polystyrene

This material is very similar in chemical composition to foam.However, if the foam is made from gas-filled plastics (polyurethane or polyvinyl chloride), where the pores are open, which does not give the proper density of the structure, then the expanded polystyrene is made as a solid, monolithic mass. Due to the more perfect and ergonomic structure, polystyrene foam surpasses foam in physical properties, because its density exceeds the previous one by five times. The absence of voids in the structure reduces the water permeability of the material by 10 times, which ensures a much longer service life. At the same time, the flexural strength exceeds the strength of the foam by 5-6 times.

The technology of insulation with expanded polystyrene in the case of floor covering with tiles or natural stone is similar to insulation with expanded polystyrene. The difference lies in the fact that instead of foam plastic, expanded polystyrene is laid on the roofing material, which is attached to the rubber layer with waterproof glue. It must also be laid tightly using waterproof cross-cut adhesive. The use of this material will make the thermal insulation layer thinner while maintaining efficiency (this is suitable for installing floors on balconies, the level of which is not very different from that of the adjacent room).

Floor insulation with tiles

Ceramic tiles or natural stone have a very high thermal conductivity, so their independent use as heat-shielding materials is impractical. Simply put, if you lay them out immediately on a concrete floor without any lining, then apart from a beautiful floor you will get absolutely nothing. Warming with the above materials has only two significant disadvantages - firstly, it is the most expensive and time-consuming method. And secondly, due to the colossal weight, these structures are strictly contraindicated for balconies, even with a capital overlap.

All of the above materials can be used to create a thermal protective gasket between the initial layer of concrete and the tile - expanded clay, polystyrene or expanded polystyrene. The alternative is a new technology - "warm floor". There are three main types of underfloor heating - electric, water and infrared. Installation of water structures involves connection to a central heating system, therefore, their operation on balconies is prohibited. Most often, electrical elements are used due to their lower cost in comparison with infrared. They do not require special preparation, they can be laid directly into the layer of adhesive-fixer for the tiles. The big advantage is the small layer thickness, which allows you to keep the original distance between the floor and the ceiling as much as possible.

Some nuances to remember

Important:

before the crate, the balcony must be well cleaned

Tapping

If you take up the drill immediately, then for sure break a bunch of taps... And they are expensive. And their fragments cannot be removed in any way. No pliers can pull out and no drill can be drilled: the metal of the tap is usually harder than the metal of the drill.

6. When buying materials in specialized stores look for pleasant surprises... For example, PVC profiles with pre-sawn at 45 degrees edges (for convenience of joining in corners), and products of even more complex configuration, which are perfect for framing doors, windows, corner balcony structures, etc., can await you. The guys who are engaged in the processing of oil into plastic, only think about how to please the most sophisticated needs of consumers!

How to make a floor on a balcony with your own hands: lathing vs filling the screed

Most owners of balcony rooms turn them into full-fledged living rooms or equip recreation areas in open spaces. This is not surprising: in small apartments every square centimeter counts.Quality glazing and good finishes are essential, but this will not be enough. It is necessary to start with the subfloor on the balcony: what to make it from, how to organize the work correctly, we will tell you today.

Arrangement of a wooden floor on the balcony

The wooden floor should only be installed on the glazed balcony. This is the most labor-intensive and time-consuming job, requiring a lot of carpentry and power tools.

Arrangement of a wooden floor begins with laying the lathing - wooden bars with a section of 40x40 or 50x50 mm. The lathing can be made in one tier, when it is not required to raise the floor, or in two tiers - when the floor on the balcony is brought to the floor level of the room to which the balcony adjoins.

When performing the lathing in 1 tier, the bars are laid in the direction perpendicular to the direction in which the boards will be laid.

If you plan to lay boards along the length of the balcony, the lathing bars are fixed across the balcony. If the boards are laid out across, the crate is arranged along the balcony.

With a transverse lathing, the gaps between the bars should be 400-500 mm, with a longitudinal arrangement, it is enough to use three parallel bars, the outermost of which is 40-50 mm. must be away from the wall and the balcony parapet.

The bars are drilled to the balcony slab and fixed with self-tapping screws. The fastening strength directly depends on the length of the screws. Use self-tapping screws 40-50 mm. exceeding the thickness of the lathing bar.

After fixing the bars with a building level, check their horizontalness. Use a level of at least 1000 mm in length. If a skew is detected, the screws are slightly loosened, and fiberboard gaskets are placed in the gap between the plate and the bar or wooden (plastic) wedges are hammered. After that, the screws are tightened.

The board is laid from the parapet to the wall - with a longitudinal arrangement, from the corner of the balcony farthest from the entrance to the door - with transverse laying.

The first board is fixed to the lathing bar with nails or self-tapping screws through and through. Hammer in a nail or self-tapping screw at a distance of 15-20 mm. from the outer edge. Subsequently, it will be covered with a plinth. Subsequent boards are fixed by hammering construction nails into the bottom shelf of the groove, using a core and a hammer of 300-400 gr.

The boards are fitted into the groove with a white rubber or soft wood mallet.

When laying boards across the length of the balcony, special attention is paid to perpendicularity relative to the wall (parapet). Before fixing, each board is checked with a carpenter's corner and, if necessary, its position is corrected.

The ideal option before applying impregnation and varnishes (paints) to the boards is scraping (if it is possible to use a scraping machine).

Lastly, a wooden plinth is mounted.

It is better to walk on a freshly laid floor in felt slippers or socks.

After completing the work, the floor is swept (you can use a vacuum cleaner) and wiped with a well-wrung out damp cloth. 10-20 minutes after that with a paint brush made of soft natural hair or a paint roller with a pile height of 5-7 mm. apply a hydrophobic impregnation (you can - mixed with a toning pigment). After the impregnation has completely dried (24-72 hours), it is treated twice with transparent floor varnish.

If the floor is planned to be insulated, waterproofing is laid before the sheathing. After the installation of the lathing, the plates of mineral (glass) wool are laid out in the interlag gaps.

Cotton wool should fit tightly between the lags without leaving gaps. When using polystyrene or polystyrene foam, you can use the cheapest (soft) brands of insulation.

The laid insulation is covered with Penofol (Izolon) 3 mm thick. foil up. After that, the flooring is laid from the floorboards.If the floor, in addition to insulation, is planned to be equipped with heating - the best option is an IR film - which is laid on top of Penofol (Izolon). She does not need fastening. After laying it on the logs, it is necessary to fill in thin wooden slats 5-10 mm thick so as not to damage the IR film when installing the boardwalk.

If floor heating is performed from an electric cable or pipes, slots are arranged in the logs into which the cable is laid.

The device of the floor on the balcony requires certain skills in handling construction tools and materials. A well-made balcony flooring will last for many years, delighting you with its appearance.

Video

You may be interested in:

How to hang a TV on the wall: looking for the best option The emergence of "flat" TVs (plasma, liquid crystal panels) made it possible not only to significantly save room space, but also to use an empty wall to implement ...

A sink with a vanity unit in the bathroom: we choose and install with our own hands A bathroom is a small room, where every centimeter of free space counts. Therefore, an ergonomic washbasin with a vanity unit will not only provide comfort ...

Slatted ceiling in the bathroom - choose and install with our own hands The suspended ceiling in the bathroom is installed after the completion of all tiling. When the wall tiles are laid and the seams are sealed, it is easier to find one ...

DIY water floor heating A warm water floor is by far the most economical option for creating comfortable temperature conditions in living quarters. It does not require additional ...