Galan electrode boilers

There are one- and three-phase.

Galan electrode boilers are considered the fastest heaters among all existing ones. The point is that there are no intermediaries in heat transfer. The electric current passes directly through the coolant and, thanks to the resistance, the positively and negatively charged ions in the water are accelerated. Due to the friction between the particles, the temperature rises instantly.

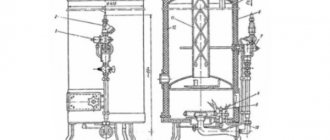

The boiler is very simple:

- a metal case in the form of a flask;

- electrode;

- nozzles for connection to the heating system;

- block of connection to the mains.

There are single-phase and three-phase boilers. In single-phase, there is one electrode, in three-phase - three. The (+) phase is supplied to the electrode (this is the cathode), zero (-) and ground are supplied to the body (this is the anode). When there is water in the boiler, there is a connection between the cathode and the anode in the form of electrical discharges. The current, meeting the resistance of the water, heats it up. It is extremely important to properly prepare the coolant, we will talk about this below.

Before choosing a convector heater, take an interest in the type of heating element. It can be a steel plate with an open heating coil or ceramic.

Ceramic compact home heaters do not burn out oxygen. Details here.

This heating method can effectively heat even large cottages. Galan heating boilers are produced with a capacity of 2, 3, 5, 6, 9, 15, 25, 36, 50 kW. The maximum heated area is 700 sq. M. In this case, several heaters can be installed in a cascade. During operation, the electrode corrodes, it decreases and has to be changed. Too small or oxidized electrode interferes with the operation of the Galan electric boiler. According to reviews, the electrode can be restored. To do this, its surface must be treated with a grinder to remove a layer of corrosion to the shine of the metal.

Two-channel electronic water heater control unit "BeeRT»

Operation manual (TU - U 33.2-3024603335-001-2003)

Content:

1. Purpose

2. Composition

3. Indication of safety measures

4. Installation, preparation for work

5. How to work

6. Joint work of BIRT with the air temperature programmer

7. Maintenance

8. List of possible malfunctions and methods of their elimination

1. Purpose

The temperature measurement and control unit (BeeRT) is designed to maintain a predetermined thermal mode of operation of electric heaters (electric water heaters of the electrode type, heating boilers, heat "guns", heat curtains, convectors, etc.) The use of two temperature sensors in the BeeRT control unit ("supply "," Return "), allows you to reduce the consumption of electrical energy and get the most favorable temperature conditions in the heated room. In BeeRT it is possible to connect a room temperature programmer and control the operation of a circulation pump.

2. Composition

BeeRT consists of a controller module BeeRT 1 (fig. 1), with connected temperature sensors "supply" 6 and "return" 7; relay contactor 2; circuit breaker 3; zero bus 4; fireproof building

3. Indication of safety measures

5.1. By the method of protection against electric shock, the thermostat corresponds to class 0 in accordance with GOST 12.2.007-75.

5.2. The BeeRT uses life-threatening voltages. When troubleshooting, maintenance, installation work, you must disconnect the BeeRT and the devices connected to it from the mains.

5.3. BeeRT is intended for use in non-explosive areas.

5.4. Moisture is not allowed on the contacts of the terminal blocks and the internal electrical elements of BeeRT. It is forbidden to use BeeRT in corrosive environments containing acids, alkalis, oils, etc. in the atmosphere.

5.5.Installation and maintenance of BeeRT should be performed by qualified specialists who have studied this manual.

5.6. During operation and maintenance, it is necessary to comply with the requirements of GOST 12.3.019-80, "Rules for the technical operation of electrical installations of consumers" and "Safety rules for the operation of electrical installations of consumers".

4. Installation, preparation for work

6.1. Attach the BeeRT vertically to the wall in a dry, ventilated area using self-tapping screws. Lay the supply cables by carefully cutting out the windows according to the markings in the block body. To prevent water droplets and foreign objects from entering through the cable entry, a blanking gland must be installed. The recommended cross-sections of power cables for the respective boilers are indicated in table 1.

Table 1.

| Name of the boiler | Hearth 3 | Hearth 5 | Hearth 6 | Geyser 9 | Geyser 15 | Volcano 25 |

| Section, mm2 (220 V) | 2,5 | 4 | 4 | — | — | — |

| Section, mm2 (380 V) | — | — | — | 4x2.5 | 4x4 | 4x6 |

6.2. Lay the connecting wires from the temperature sensors.

6.3. When installing external connections, it is necessary to ensure their reliable contact with the BeeRT terminals. For installation of control cables, use wire with a conductor cross-section of 0.12-2.5 mm2.

Strip the end of the cable for connecting the control circuits by 7 ± 0.5 mm, for power circuits 10 ± 0.5 mm. A longer end can cause a short circuit, and a shorter end can cause an unreliable connection.

Unscrew the terminal screw and insert the stripped end of the wire into the terminal.

Tighten the terminal to the recommended torque for control circuits - 0.5 N * m, for power circuits - 2 N * m. Loose tightening may result in poor connection and malfunction, overtightening or short-circuiting or damage to the terminal block.

Attention! Twist the wire at the stripped end of the cable or use a cable lug before fastening (do not service the end of the wire to avoid poor contact).

6.4. The power supply and external devices are connected according to the diagrams, depending on the boiler used, fig. 2 - 8.

6.5. After making all connections, apply power to the BeeRT. Turn on the circuit breaker. The digital display will show the current temperature of the boiler inlet (return).

5. How to work

On the front panel of the BeeRT controller module there are three buttons “▲«, «R«, «▼“, Two LEDs indicating pump or heater operation and temperature indicator. In the current mode, the temperature indicator displays the current temperature at the heater inlet.

When you click on the "▲"Or"▼"The display will show the temperature at the boiler outlet. The location of the sensors on the boiler must correspond to the connection to the BeeRT controller module. To change the temperature settings, just press the button"R"(Programming). The indicator will show the inscription - "ob»(Setting the return temperature). The return temperature is the temperature at the inlet to the heater. The room temperature is matched by this temperature. By pressing the buttons "▲"Or"▼»The temperature setpoint can be changed. Pressing the button againR"Leads to the appearance of the inscription -"_ob»(Return temperature hysteresis).

Hysteresis Is the difference between the set point temperature and the heater switch-on temperature. The hysteresis value determines the accuracy of the temperature control by the heater.

The return hysteresis is usually in the range of 2 - 6 degrees. The lower value of the hysteresis - allows you to achieve a more accurate temperature regime, the larger value - to reduce energy costs. Further clicks on the button "R"Lead to the appearance of the inscription"po»(Setting the flow temperature). The flow temperature is the temperature at the outlet of the heater.This setting determines the heating rate of the heating system and the temperature of the radiators. By pressing the buttons "▲"Or"▼»The temperature setting can be changed. The next press on the "P" button leads to the appearance of the inscription - "_po»(Flow temperature hysteresis). The value of the feed hysteresis is usually in the range of 5 - 10 degrees. The lower value of the hysteresis - allows you to achieve faster heating of the heating system, a higher value - to reduce the wear of the contact groups of the starting equipment. In the absence of action on the buttons for 5 s, the regulator automatically switches to operating mode. The BeeRT thermostat has a circulating pump control function. Because the coolant at the temperature take-off point cools down faster than in the heating system, the circulation pump is turned on 60 seconds before the heater is turned on, which allows you to exclude unreasonable turning on of the heater and thereby reduce power consumption. The circulation pump is turned off 60 s later after the heater is turned off, in order to exclude the local concentration of the heated heat carrier.

Basically, steel, metal radiators from well-known manufacturers such as KORAD, KORADO are installed in the heating system. In this case, the settings look like this:

Оb - return flow (blue sensor is installed at the boiler inlet) - 65-70 ° С, hysteresis 5.

Po - supply (red sensor is installed at the boiler outlet) - 80 ° С, hysteresis 2.

If you use sectional aluminum or bimetallic radiators from well-known manufacturers MIRADO, NOVA FLORIDA, then the settings look like this:

Оb - return flow (blue sensor is installed at the boiler inlet) - 55 ° С, hysteresis 5-6.

Po - supply (the red sensor is installed at the boiler outlet) - 70 ° С, hysteresis 2.

For old, cast iron radiators, the settings look like this:

Оb - return flow (blue sensor is installed at the boiler inlet) - 60 ° С, hysteresis 7-8.

Po - supply (the red sensor is installed at the boiler outlet) - 70 ° С, hysteresis 2.

Hysteresis (hysteresis setting) is the difference between the switch-off temperature and the last switch-on temperature, in simple terms it is the desired cooling temperature of the radiator.

6. Collaboration of BeeRT with the air temperature programmer

The air temperature programmer allows you to achieve a comfortable temperature in a heated room. The use of the programmer leads to significant energy savings - 50%. Savings are achieved during the period of your absence from the room due to automatic temperature reduction and during the period of the reduced electricity tariffs (in the case of using a multi-tariff electricity meter). The used temperature programmer can have a COM / NC (normally closed) or COM / NO (normally open) contact group at the input, depending on the manufacturer.

To switch the BeeRT operation to one of these operating modes: Simultaneously press the buttons "▲" and "▼"- the value" COM "readiness to choose. Using buttons "▲" or "▼»Select" NC "or" NO ", depending on the passport conditions of the used remote programmer. After a few seconds, BeeRT will fix the selected position. The air temperature programmer allows you to achieve a comfortable temperature in the heated room. The use of the programmer leads to significant energy savings - 40%.

Savings are achieved during the period of your absence from the room due to automatic temperature reduction and during the period of the reduced electricity tariffs (in the case of using a multi-tariff electricity meter). The BeeRT is connected to the air temperature programmer by means of a telephone wire crimped with telephone connectors on both sides.

In the case of working with the temperature programmer, in the standby mode for turning on the heater, the BeeRT controller module displays the temperature of the heater inlet (return) on the indicator. The temperature is displayed in degrees Celsius with a leading "0" symbol, for example "025"

7. Maintenance

The BeeRT must be serviced at least once every six months. It is necessary to check the condition of the electrical connections, the tightness of the power and control terminals, and remove dust from the terminal blocks.

8. List of possible malfunctions and methods of their elimination

| Possible situation | Probable cause | Elimination method |

| No indication of unit operation | 1. There is no mains voltage. 2. Incorrect network connection. | 1. Check the presence of voltage in the network. 2. Connect the regulator according to the diagram in the manual. |

| The appearance of three dashes on the indicator "-" | 1. Poor contact in the connection of the flow sensor 2. Broken sensor wire 3. Sensor failure | 1. Check the contact on the block 2. Restore the integrity of the wiring 3. Replace the sensor |

| No indication of contactor activation | The set temperature is incorrectly set | Set the value of the set temperature higher than the actual |

| No voltage is supplied to the boiler if there is an indication | Failure of the relay in the thermostat | Thermostat needs repair |

| The boiler continues to operate when the indication is off | Sticking relay contacts | Check the magnitude of the current at the load of the device. Thermostat needs repair |

| The circulation pump does not work | 1. Fuse blown 2. Poor contact of connecting wires | 1. Replace the fuse 2. Check the contacts on the pads |

| The display shows the indication "888" Both indicators are blinking. | Power supply problem | Check the parameters of the power supply. |

| Periodic (within several days) spontaneous reset of the set temperature values. | The thermostat's own safety system has voltage thresholds (180v-270v). Voltage surges below or above these values will cause the processor program to crash. | Install the current normalizer. |

9. If you have any questions, ask in the comments.

Heating element boilers Galan

By type, heating elements are the same as electrode boilers. Only the way they work is different. In them, the water is heated by an ordinary heating element, as in wall-mounted electric boilers, only the process takes place in a small flask. Thanks to this, the Galan electric boiler, according to reviews, is in no way inferior in performance, but it costs much less. After all, the design of the heater is extremely simple.

There is a heating element inside.

The boiler is controlled by an electronic unit. Control over:

- tension;

- the resistance of the coolant;

- supply and return temperature;

- stability of the power grid.

Scale is deposited on the heating elements and over time the metal tube, which contains the tungsten spiral, burns out. An inoperative heating element can be easily replaced with a new one. During active operation, the heating element must be replaced every 3-4 years.

In terms of heating rate, heating elements boilers are much slower than their electrode counterparts. But they are safer. The coolant and electricity in them do not contact, respectively, you will not be electrocuted in the event of a leak. In addition, you do not need to monitor the salt level in the coolant and you can use any type of antifreeze liquid for the heating system.

Equipment features

The main difference between the products of CJSC "Galan" from similar devices, including according to customer reviews, is:

- high efficiency (up to 98%);

- light weight and compact dimensions;

- excellent quality inherent in the goods of the defense industry;

- possibility of installation on a new or old heating system;

- silent operating mode;

- parallel connection with other heat generators;

- ecological cleanliness.

At this stage, the company owns factories in Moscow, Ryazan, Stavropol and Pskov. Official representations were opened in the Baltic States and in Ukraine.

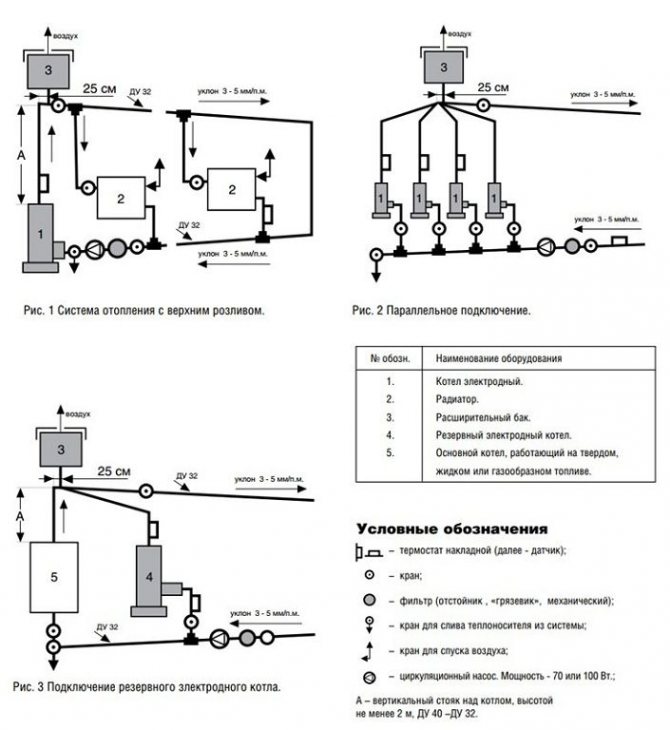

Galan electric boiler connection

Boiler installation consists of two stages. On the first, the heater is connected to the heating circuit, and on the second - to the mains.The unit is installed on the circuit through the American women, the main thing is that the pipes are beaten correctly and brought to the nozzles. There is nothing difficult in this. Mandatory strapping elements:

- circulation pump;

One of the strapping options. - expansion tank;

- security group;

- Ball Valves.

In the connection diagram of the Galan boiler, you need to correctly arrange all these elements. Shut-off valves (ball valves) are screwed onto the pipe threads, followed by American women. It is advisable to install the circulation pump on the return line, although installation on the supply is allowed. It is always placed together with a sump so that various debris does not fall on the impeller. The expansion tank must be in front of the pump. The safety group is placed at the highest point of the circuit or in the place where air accumulates.

It is impossible to simply power the boiler into the network, since it will work constantly. The heater is first connected to a control unit called a navigator.

The configuration of the Galan navigator can be different, which determines its cost. The most "pumped" units work in tandem with remote thermostats, which take air temperature readings and transmit them to the control panel. That, in turn, gives commands to turn on or off the boiler to maintain the set temperature at the same level.

Preparing the coolant and starting the Galan boiler

Galan heating boilers need a special coolant, they do not work with ordinary water, since its resistance is not strong enough. To increase resistance, edible salt is added to the water. For 100 liters of distilled water, you need 5-8 mg of salt (the edge of a teaspoon). The salt is diluted in a small amount of water and poured into the general circuit.

A fan heater for a home will cost the least, they are bought most often.

Read about what kind of automatic home heaters are in this article.

Then the circulation pump is turned on, which mixes the coolant to a homogeneous structure. You can check the correctness of the preparation of the coolant with a current clamp. The readings must match the tabular values indicated in the boiler passport. If the voltage is too high, you need to make the water less salty, if the voltage is not enough, you can add salt. You should not rush to make changes, since the system will fully stabilize only after three days.

In addition to salty distilled water, antifreeze liquid produced by the manufacturer of boilers Galan can be used as a heat carrier. This is a specially designed heat carrier that does not freeze down to -40 degrees.