Roof insulation with mineral wool

Varieties of mineral wool and options for mounting material on various types of roofs, pros and cons of fiber-based coating, rules for choosing components, installation technology.

- Features of work

- Advantages and disadvantages

- Insulation technology

- Choice of mineral wool

- Sloping roof

- Flat roof

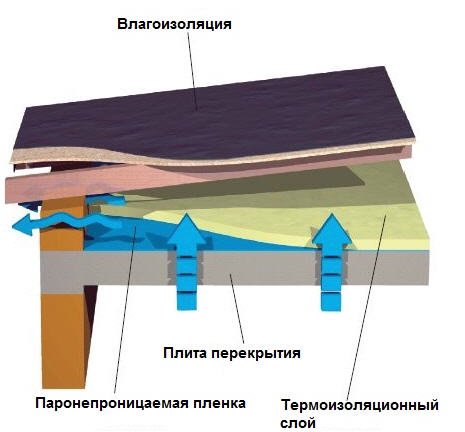

Roof insulation with mineral wool is the creation of a shell for comprehensive protection of the house from cold, overheating, precipitation. The composition of the thermal insulation coating includes, in addition to the main element, steam and waterproofing materials, a screed to protect against mechanical stress. You can learn about the rules for forming a warming "pie" from this article.

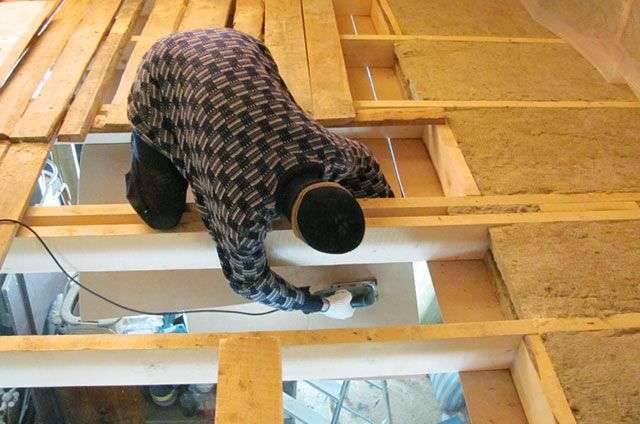

Insulation of the attic floor

Of course, it will be easiest to install thermal insulation in the process of building a building - this will simplify the design and some of the nuances of work. In most cases, following this advice will not work - a lack of finances or time may well interfere, so the overlap remains without insulation. As a rule, this state of affairs persists until the first frost, and the owners have to hastily install thermal insulation.

Before insulating the attic floor, you need to carry out a number of preparatory work, which is especially important when using bulk insulation materials. There are two insulation technologies - traditional and modern.

The traditional method of floor insulation is implemented as follows:

- The first step is to process the boards attached to the ceiling with a clay or lime mortar - such processing will ensure the structure is tight while maintaining normal ventilation;

- When the mixture hardens, you can proceed directly to the insulation work - filling bulk materials into the space between the floor beams on pre-processed boards.

Today, a more modern method of floor insulation is used much more often:

- First of all, a vapor barrier membrane is laid with a 20-cm overlap on the floor and beams, which not only protects the insulation material, but also complements its thermal insulation properties, reducing the amount of heat leaving the building through the ceiling;

- For tightness, the membrane in the overlap areas must be sealed using construction tape;

- The next step is to install the selected insulation (mineral wool, ecowool, expanded clay or one of the bulk materials) using the appropriate technology;

- So that the floor beams do not have cold bridges, it is necessary to ensure that the insulation passes over them;

- Above the insulation, in compliance with the already known rules, another layer of vapor barrier film is laid, which is attached to the beams with counter-rails;

- It remains to lay a covering of boards or sufficiently strong plywood over the finished thermal insulation structure.

Sometimes, instead of insulating the ceiling from the attic side, the thermal insulation is placed inside the building itself. This design is also quite effective in insulating, but requires additional finishing.

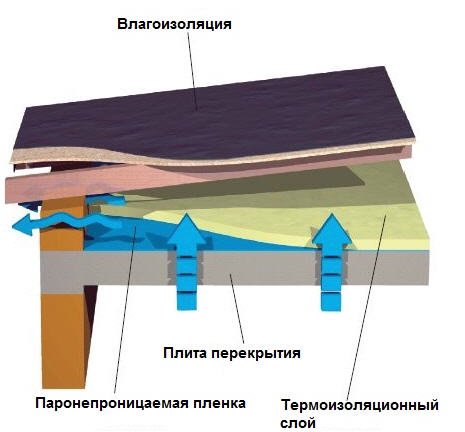

Vapor barrier materials

The most popular vapor barrier material is a special film that protects wood and insulation from the effects of steam, which, as a result of temperature changes, turns into condensation. The negative impact of moisture on the elements of the roofing structure can not be mentioned once again - suffice it to say that it significantly reduces the service life of the roof and the efficiency of the heat-insulating material.

The vapor barrier membrane is attached to the roof or slab before the thermal insulation materials are installed. In rooms where heating has been carried out, the vapor barrier must be installed only under the finishing layer. To protect structures that are constantly in temperature contrast conditions, a vapor barrier layer must be placed on both sides. The exception is concrete floors, which do not require such protection.

For arranging the vapor barrier layer, a film with different characteristics can be used. The simplest option is a nonwoven film, but a foil membrane is a much more efficient option. The last option, as its name implies, has a thin foil layer on one side, which prevents heat from escaping outside the structure. The roof vapor barrier installed from the inside of the house is connected with special tape, which ensures a tight connection.

Insulation thickness

We talked more about calculating the thermal resistance of enclosing structures about what the thickness of thermal insulation should be in a separate article. Here we can say that there are generally accepted norms that establish the coefficients of thermal resistance of the roof in different regions.

In other words, how strongly the roof should be able to resist the release of heat from the house. It is necessary to divide the coefficient required to obtain the coefficient by the thermal conductivity of the roof insulation materials. Thanks to this calculation, you can find out what thickness of insulation for the roof the house should be on the roof. A little later, we will add a calculator that will allow you to calculate this important indicator.

The choice of material for insulation

Today, the choice of heat-insulating materials is so great, and their characteristics are so different, that making the right choice for a particular case can be very difficult.

Most often, developers prefer the following materials as insulation:

- glass wool;

- mineral wool;

- basalt (stone) slabs (there are ready-made sandwich panels with basalt insulation);

- polystyrene (expanded polystyrene);

- polyurethane foam (liquid sprayed insulation).

Recently, Izover, a fiberglass material with a high level of heat and sound insulation, has been especially popular in the insulation of pitched roofs. Due to the content of air in the structure of this material, its low thermal conductivity is ensured, not exceeding 0.044 W / mK. In addition, this material has tremendous durability (at least fifty years), excellent vapor permeability and high fire resistance (flammability class - G1).

Considering other types of roof insulation, you should pay attention to expanded clay. It is also characterized by excellent heat and sound insulation, environmental friendliness and fire safety.

Since clay is used for its manufacture, it does not lose its properties under the influence of temperature, does not deform and does not emit any substances harmful to humans, which is possible in the case of using synthetic thermal insulation materials.

The principles of choosing insulation for the roof

On our website, we have already devoted quite a few articles to the principles of choosing various thermal insulation materials. In this material, we will consider in detail what kind of insulation to choose for the roof and we will look at the choice of insulation specifically in this section. Here are a few things to consider when it comes to roofing.

- Roofing cladding structures have increased thermal resistance requirements. For example, in 2010 in Finland the coefficient of such resistance for the walls was 5.88 m2 * C / W, and for the roof 11, 11! Almost a twofold difference.

- The material on the roof is more exposed to moisture than others. And, as you know, water is the enemy of thermal insulation.

- Insulation for the roof is installed, in fact, on the principle of ventilated facades. This means that it is not fenced off from fire, for example, concrete or plaster elements. In this regard, the insulation itself must have increased fire resistance.

- And it doesn't matter if we are talking about a flat or pitched roof, the area of insulation is quite high, so the cost of the material should be reasonable and organically fit into the estimate for building or repairing a house.

Instructions for insulating a pitched roof

Laying mineral wool

The entire installation process can be divided into several stages of work:

Stuffing on the rafter legs on the inner side of the lathing boards in increments of 20 to 30 cm. - they are needed to fasten the insulation. Mineral wool is laid on the outside of the rafter legs. Subject to the installation of insulation for cold regions, it is better to increase the number of layers to two or three. The main condition for work is tight pressing of the joints of the slabs to the rafter legs

It is important to ensure that there are no through holes in the mineral wool layer. If, after installation, you still notice holes, then they must be eliminated with polyurethane foam. When the mineral wool installation is finished, it is necessary to install a waterproofing membrane.

To do this, it is simply nailed onto the rafter legs, leaving a slight sagging. Interference mounting is not desirable. The waterproofing membrane must be correctly positioned. The fact is that such material has a front and back side. The first is designed to prevent the passage of moisture, but the lower one, on the contrary, allows moisture and vapors to pass upward. The waterproofing material is laid in strips, leaving a slight overlap. It is also necessary to create a 5 cm gap between the membrane and the mineral wool.

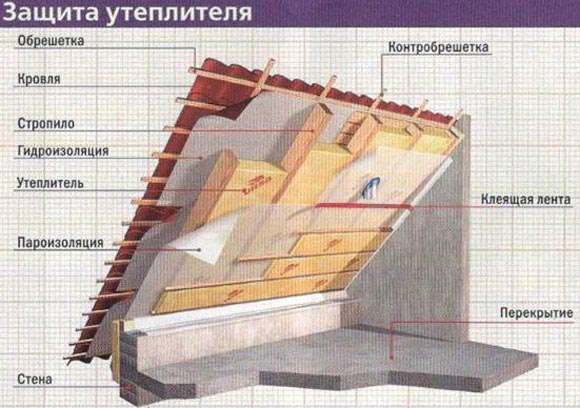

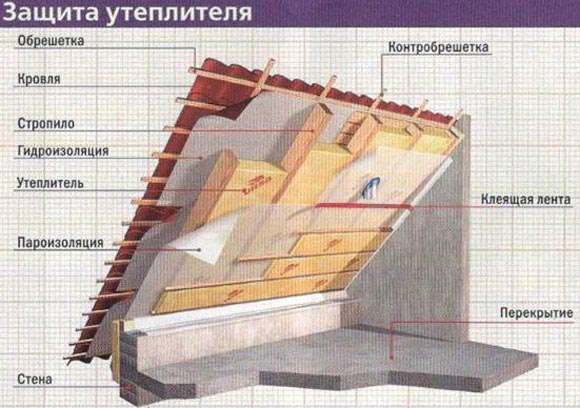

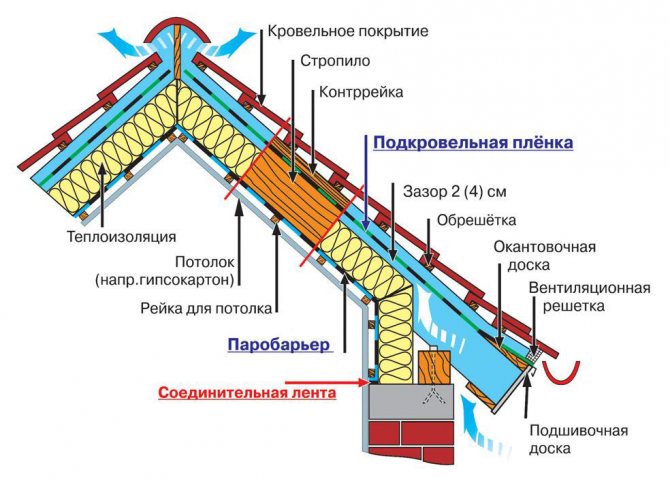

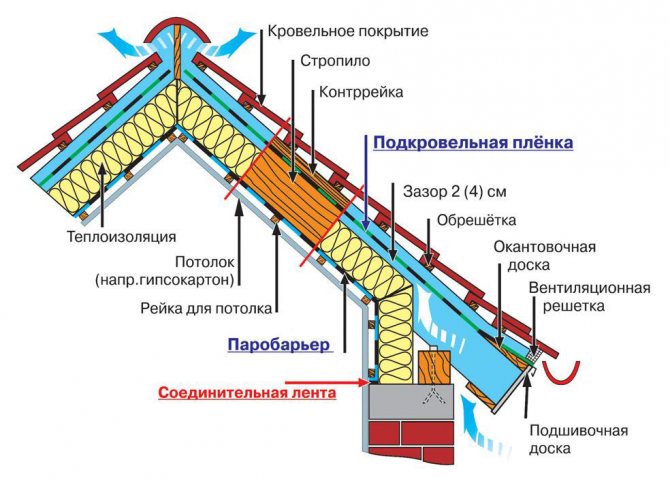

When the waterproofing material is attached in place, go to the additional ventilation device. For this, bars of wood with a section of 25x50 or 50x50 cm are stuffed onto the rafter legs. They can be trimmed bars. The length can vary from one to two meters. When the bars are in place, it is necessary to fill the crate, placing the boards across the rafter legs. This will create a gap that will facilitate the evaporation of condensation and moisture that will collect on the waterproofing membrane. The roofing material is laid on the crate. Do not forget to treat wood with antiseptic solutions. This will help extend the life of the roofing pie structure. The creation of a vapor barrier is an important stage in roof insulation. It will prevent water vapor from entering the mineral wool. The vapor barrier film is stretched over the inside of the rafter system. To be able to decorate the room, it is necessary to lay the sheathing boards on top of the vapor barrier material. For this, slats are used, on which the inner lining in the form of lining, drywall, plywood, etc. will later be attached.

Why do we need insulation?

You can be absolutely sure that any construction always includes the issue of insulation. To create a comfortable temperature in the premises, walls, foundations, and roofs are insulated. The construction industry today offers a wide selection of various insulation materials for every taste and need, the most popular of which in Europe and the CIS is mineral wool.

Roof insulation scheme.

According to the primary composition of raw materials, mineral wool is divided into slag wool, glass wool and stone wool. The latter name may need to be deciphered. The bottom line is that the technology for creating stone wool begins with the manufacture of fiber from a melt of basalt rocks and ends with the formation of heat-insulating plates from it.The binding agent that gives the basalt insulation the necessary strength and density is most often phenol-formaldehyde resin. In the production process, phenol is completely neutralized, and therefore you should not be afraid of its release during the operation of basalt wool, which is used as a heater for the roof.

Features of roof insulation from the inside with mineral wool, and the cost of work

Mineral wool is the collective name for three types of insulation, which have one thing in common - their fibrous structure.

Basalt or stone wool is made from rock. It serves for a very long time, therefore it is used for capital construction. The most expensive type of mineral wool.

Glass wool made from the same components as regular glass. Cheaper than basalt, but its service life is much shorter. It is used in places where it can be replaced quickly and cheaply.

Slag wool, for the manufacture of which wastes from blast furnaces are used. Price and properties are similar to glass wool.

These materials come in a variety of forms. It can be slabs, rolls, mats, and cylinders.

Insulating the roof with glass wool from the inside is the most effective and affordable way to keep warm in the attic.

In order to insulate the roof from the inside, especially when it comes to a structure made of wooden structures, materials that meet serious requirements should be used. They should be:

- Non-flammable (fire safety class from G3 and higher).

- Long lasting.

- Eco-friendly.

- Resistant to decay.

- Possessing not only insulating, but also soundproofing properties.

- Not suffering from temperature extremes.

- Resistant to damage from insects and rodents.

Mineral wool meets these requirements most of all. To insulate the roof from the inside, mineral wool is used in the form of a roll or mattress. The last option is the most convenient for installation.

Prices for mineral wool allow you to use it for the purpose of roof insulation for almost every owner of a cottage, bathhouse or garden house.

The only drawback of this material is its ability to absorb water, while losing up to 40% of its thermal insulation properties. However, the insulation of the roof from the inside with mineral wool, carried out in strict accordance with the technology, helps to prevent liquid from entering the insulation.

Well, the quality of roof insulation can be seen with the help of a thermal imager, which can instantly show the places through which heat loss occurs.

What set of tools and consumables will be needed to insulate the roof from the inside?

When carrying out roof insulation on your own, you should prepare everything you need to carry out the work:

- Minvatu.

- Wooden bars with a cross section of 40 mm.

- A vapor barrier (for example, any waterproofing film).

- Drill.

- Glue.

- Antiseptic solution for wood.

- Nails or screws.

- A hammer.

- Mineral wool dust mask.

What is mineral wool and its characteristics

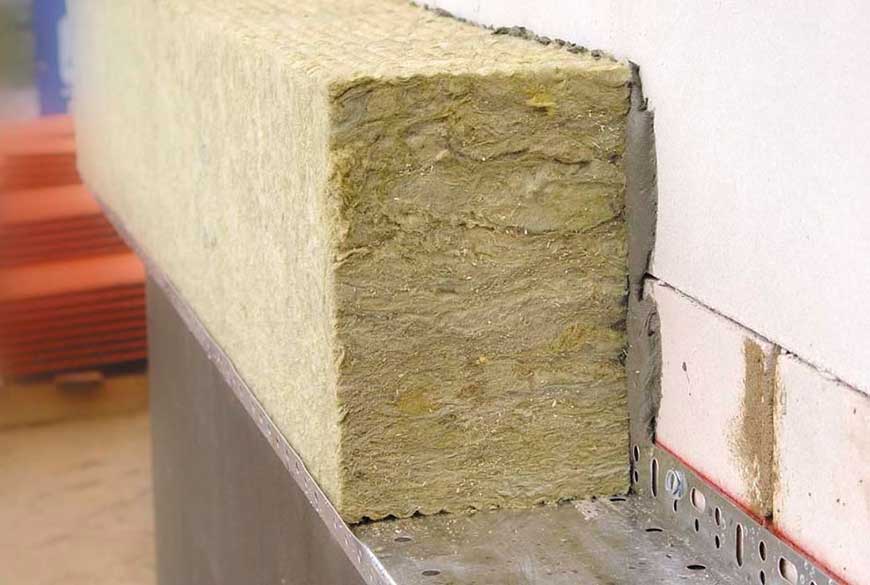

Mineral wool is presented in several forms, which are defined by GOST 52953-2008. Thus, glass wool, slag material, stone wool belong to the category of mineral wool. All of them have a fibrous, airy structure, differing in density and performance. Materials can be presented in the form of slabs, rolls, canvases of various thicknesses.

Minvata is easily mounted regardless of the type

It is stone wool that is used to insulate a residential building and any of its parts, since it has optimal characteristics to obtain a good thermal insulation layer. The fibers of this material are more durable than glass wool, do not scatter around the room and do not enter the human respiratory system.The villi are thornless and highly elastic, which makes it possible to lay slabs or rolls of stone wool even in the most difficult places.

Stone wool emits fewer small particles, so it is more convenient and safer to work with it

Stone wool can contain blast-furnace slags, clay, limestone. Such components attract rodents, reduce resistance to fire and heat, which should be taken into account during installation. The basalt variety of this material does not contain binders or mineral components and therefore is more practical to use. Basalt structure is safe for human health, more resistant to fire and temperature extremes.

The main characteristics of basalt mineral wool:

- resistance to heat up to 1000 ° C;

- possibility of cooling down to -190 ° C;

- elasticity of fibers;

- resistance to moisture, ultraviolet light;

- the possibility of any finishing;

- service life of 40-50 years or more.

Video: comparison of stone and mineral wool

How to choose mineral wool for the roof: brands and manufacturers

Depending on the density, mineral wool is divided into several modifications that are used to insulate certain parts of buildings. Therefore, when choosing, one should take into account not only the general characteristics of mineral wool, but also the properties of each brand, expressed in the following:

- P-75 grade material has a density of 75 kg / m3 and is suitable for thermal insulation of roofs with gentle slopes, as well as other horizontal surfaces that are not subject to heavy loads. A structure with such a density is optimal for insulating pipes of heating plants and gas pipelines;

- grade P-125 is characterized by a density of 125 kg / m3 and is used for thermal insulation of the ceiling and floor, walls and partitions, roofs with steep slopes. This mineral wool has an average degree of sound insulation;

- modification PZh-175 - a rigid high-density material used for insulating reinforced concrete floors and walls made of profiled metal sheets;

- grade PPZh-200 - mineral wool of increased density and rigidity. Suitable for thermal insulation of metal floors and reinforced concrete structures, can be used as additional protection against fire.

Denser mineral wool has poorer thermal insulation properties.

High-quality mineral wool is represented by several well-known manufacturers. One of the main ones is the ISOVER brand, which produces both heat insulators and other materials for the roof. Also in demand are the goods of such companies as:

- URSA, providing a wide range of modern roof structures for various types of roofs;

- PAROC is a Finnish brand specializing in mineral wool insulation;

- Technonikol is a Russian company that offers not only heat insulators, but also materials for hydro and vapor insulation of roofs;

- Rockwool, which produces the most fire-safe products among all manufacturers of insulation materials.

All manufacturers produce mineral wool in rolls, as well as plates or mats

For roof insulation, it is necessary to choose a mineral wool with an appropriate level of density. For this purpose, the P-75 and P-125 brands are optimally suited. Before purchasing, you should make sure that the material has no defects, expressed in the form of deformation of plates or mats, as well as voids inside the canvas. The fibrous structure should be as homogeneous, elastic and strong as possible.

Features of mineral wool

Mineral wool

Minvata is not for nothing that it is very popular as a heater. This material is easy to work with and has a number of advantages, including:

- low thermal conductivity;

- combustion resistance;

- environmental friendliness;

- resistance to aggressive environments;

- high level of heat saving;

- good noise absorption;

- hydrophobicity.This property manifests itself as resistance to wetting; You can not rely only on the hydrophobic qualities of mineral wool. It is imperative to carry out measures to protect the under-roof space from moisture. When wet, any insulation will reduce its effectiveness a couple of times.

- high resistance to deformation;

- ease of installation;

- the duration of the operational period.

Unlike Styrofoam, careless handling of the material will not damage it. And thanks to the softness of mineral wool, it is easy to install.

Despite similar insulation procedures, mineral wool differs from ecowool, which appeared not so long ago on the construction market, which is an insulator characterized by looseness and light weight. Ecowool contains cellulose, antiseptics and boric acid.

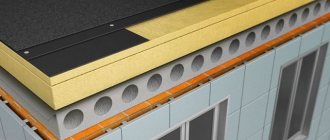

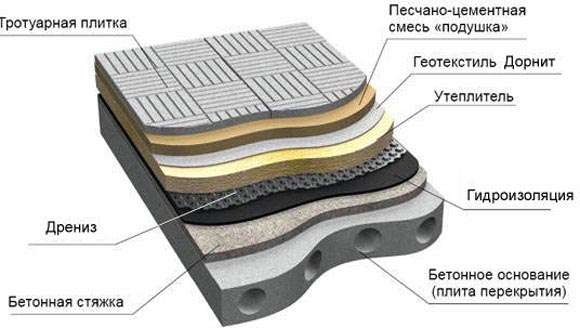

Insulation of a flat roof

Quite often, flat roofs of houses are used to equip terraces, winter gardens, sports or playgrounds. Therefore, such a structure should be as reliable as possible and capable of withstanding significant loads, and the thickness of the insulation for the roof should also be quite significant (also read: "House Roof Scheme - Features").

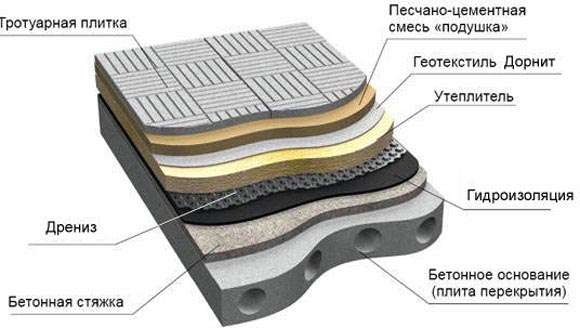

Insulation of such a roof is performed as follows:

- first, a cement screed is arranged along the reinforced concrete floor slab, which forms a slope. Then a layer of waterproofing is laid;

- after that, a layer of extruded polystyrene foam with a density of at least 35 kg per square meter is laid;

- then, to create filtration, everything is covered with fiberglass, covered with a layer of gravel or pebbles, and at the end paving slabs or paving stones are laid.

Foam can also be used for roof insulation or foam concrete applied to the vapor barrier layer and covered with a foam fiber concrete screed. After that, a welded or membrane coating made of polyvinyl chloride is equipped.

In cases where flat roofs are used under the attic, and a soft roof with insulation is supposed to be installed, a vapor barrier and insulation layer is laid in the attic, and a waterproofing layer is laid under the roofing material. It is also possible to insulate the attic floor with expanded clay. If the operation of a flat roof is not foreseen, then it can be insulated both from the outside and from the inside (in more detail: "Insulation of a flat roof and its features").

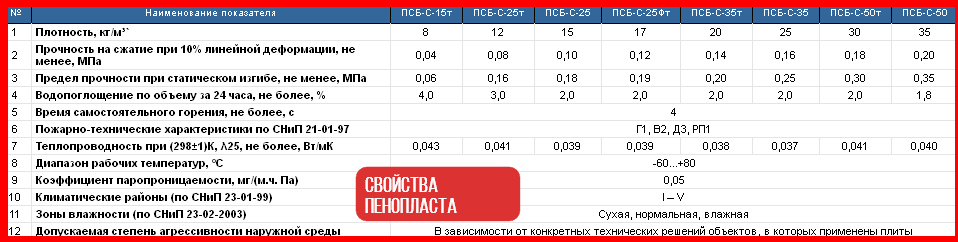

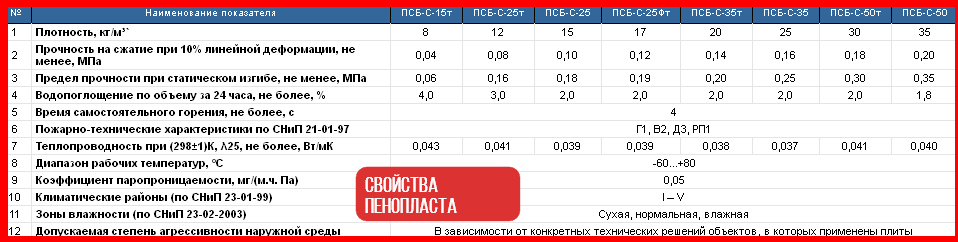

Does the most popular match? - Styrofoam

It is worth making a reservation that by foam we mean here both ordinary, white polystyrene (PSB-15) and extruded polystyrene foam, the density of which can reach 35-45 kg per cubic meter.

So, PSB-15 is not used for flat roofs. Although it is much cheaper, it can still be damaged when the insulation is laid by simply stepping on the sheet. In addition, the foam is made without a quarter. But, for example, penoplex has special grooves at the edges, which are fastened and create one indestructible layer of insulation on the plane.

The overlap of the cold roof is often insulated with foam plastic in the frame when it is placed between the logs. For the same purposes, more moisture-resistant polystyrene foam is also used, which, by the way, has a much higher compressive strength.

The issue of using this material for a residential floor under the roof was discussed separately, and this is generally a whole topic.

Insulation materials start with foam. But, alas, for the title - the best insulation for the roof, it does not fit. That's why they mentioned him at the very beginning. Further - more interesting. [flat_ab>

Flat roof insulation instructions

All flat roofs are divided into ventilated and non-ventilated. Let's consider both types.

Ventilated flat roof

Ventilated flat roof structure

The process of insulating it is similar to the scheme for working with a non-residential attic.Such a roof design provides a minimum distance between the slope and the ceiling, which makes it difficult to move in the under-roof space and reduces the functions of the room to only technical ones.

Mineral wool slabs 20 cm thick are suitable for work. The material is laid on the floor of the attic. Dowels are used as fasteners. In addition to the mechanical installation method, it is allowed to use glue or hot mastic, but the latter method has not gained much popularity. For the insulation to work properly, it is necessary to place the construction film under it in one layer.

Stages of work

- To begin with, the condition of the entire roofing cake is checked. Damaged elements must be replaced.

- For additional insulation of the attic, it is possible to lay a layer of mineral wool on an existing one.

- Before starting the installation of mineral wool boards, you should clean the surface of the floor, which will be insulated. When using reinforced concrete floor slabs, a vapor barrier is not necessary, because concrete does not allow moisture to pass through.

- The beams must also be insulated or covered with insulating materials, or mats (roll insulation can be used) between the beams. But before that, it is necessary to mount a vapor barrier layer.

- When using foil-clad material, laying is carried out with the plates facing down with the foil.

- Leave a ventilation gap near the eaves.

Unventilated flat roof

Unventilated flat roof structure

Concrete slabs or wood are used as the base, depending on the material from which the house was built. The peculiarity of this type of roof is in the absence of any gap between the roof and the ceiling. Therefore, it is necessary to install mineral wool directly on the base.

Stages of work

- The vapor barrier foil is applied to the base of the roof.

- After that, you can start laying the mineral wool boards. It is recommended to do this with a staggered arrangement of the material so that the joints are not located along the same line. Fitting the slabs must be done with a tight abutment. The most suitable thickness of the thermal insulation layer is 25 cm.

- Then the roofing material is laid on top of the mineral wool slabs.

An unventilated flat roof can have various types of thermal insulation:

- Single layer. For this, hard mineral wool slabs are used, which have increased strength. But their thermal insulation qualities are not great.

- Two-layer system. For this, elastic plates are suitable to form the first row, and for the second, harder plates are used. Thus, a structure is obtained in which the lower layer exhibits excellent thermal insulation qualities, and the upper one helps to compensate for the sensitivity of the first row to various mechanical damage. Basalt mineral wool is used as a material.

- Mixed system of two layers. This option is similar in design to the previous one, but differs in the use of two types of mineral wool boards. Glass wool is used for the lower layer, and basalt wool for the upper layer.

Roof insulation technology with mineral wool

Warming is carried out in two stages. On the first, surfaces are leveled (if work is carried out on a flat roof) or treated with protective equipment (if a pitched roof is being repaired). The preparatory work also includes the selection of the grade of fibrous material and the determination of its thickness. Next, the heat insulator is mounted according to the chosen installation method.

The choice of mineral wool for roof insulation

Mineral wool functions under extreme conditions, so only high-quality insulators can show good results. When purchasing products, use our recommendations.

During the insulation of the pitched roof, the mineral wool is placed between the rafters. In this case, the dimensions of the sheets are important.Choose the width of the glass wool blocks a few centimeters more than the distance between the beams. The products are soft and resilient and are able to stay in their original place without additional fixings. Do not mount narrow panels - gaps will increase heat loss.

It is recommended to insulate the sloped roof with sheets with a density of 75-160 kg / m3. The denser specimens are very heavy and require additional fastening. The thickness of the panels should be 1/3 less than the height of the rafters.

Standard sheets of stone wool cannot be fixed in this way. The panels do not regain their shape after compression, therefore they do not hold on their own. To fix them, fasten them to the slats from the side of the attic to the crate. For roof insulation, buy special sheets with soft edges. The special structure holds heavy specimens in the same way as glass wool.

It is recommended to lay stone wool on a flat roof, it is denser and withstands high mechanical stress. However, other types of insulator can be used if their density is more than 160 kg / m3.

If there are no slabs of estimated dimensions, buy sheets of lesser thickness and stack them in several rows. Usually, panels are mounted in this way if the estimated thickness of the coating exceeds 150 mm.

It is impossible to check the quality of the material upon purchase, but it is possible to determine the condition of the insulator if you follow our recommendations:

- Do not buy wet products. Water reduces the basic characteristics of the slabs and causes rotting of wooden beams and battens.

- Sheets must be stored in a dry place. If the product is stored outdoors, the product must be wrapped in an airtight plastic wrap.

- Buy mineral wool in company stores. In this case, the chance to buy a fake is minimal.

- Examine the product information on the label. It should contain recommendations on the use of the product, the main characteristics, the manufacturer, the date of release of the product.

- If you are on a budget, keep in mind that the price of a product is influenced by the degree of popularity of the manufacturer, the stiffness of the sheets, the type of mineral wool, and the uniformity of the density of the blocks.

- The products of German manufacturers are considered to be of the highest quality: in this country they take the certification of insulators very seriously.

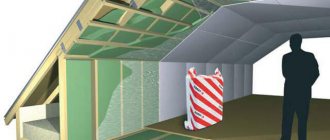

Insulation of a sloped roof with mineral wool

The attic roof is insulated in two ways - by filling the gap between the rafters or by attaching cotton wool over the slats (top or bottom). The second option is considered more reliable, since in this case, the sheets form a covering that is not separated by beams. But most often the material is placed inside the frame, which reduces the operating time.

It is recommended to insulate the pitched roof during the construction of the house, together with the thermal insulation of the walls of the house. At this stage of the construction of the dwelling, the rafters can be placed taking into account the dimensions of the mineral wool and not modifying it. Make sure that the dimensions of the panels are 2-3 cm larger than the distance between the beams.

The work must be performed only in dry weather, therefore, in the fall, the roof cladding is installed first, and the insulator is placed in its regular place from the attic side. Insulation of the roof with mineral wool from the inside is also carried out in old buildings.

Let's consider in detail the method of laying the material into the frame:

- Cover the stacks and slats with a special liquid to protect against rotting, burning, and insects.

- Measure the gaps between the beams, add 2-3 cm and trim the sheets to the required dimensions. The specimens should enter with little effort into the regular place and be fixed in this position without additional means.

- Fill all the space in the frame with mineral wool.

- Carefully inspect the coating, if any cracks are found, fill them with cotton wool scraps.

- Check that the sheets are securely fixed. If necessary, additionally fix the panels in any other way.

- Cover the wooden structure from the street side with a waterproofing film with an overlap of 15-20 cm on adjacent cuts and on the walls. Roll out the membrane from the attic floor to the skates. Do not stretch the canvas, it should hang down a little.

- Seal the joints with special adhesive tape. The sheet will retain water in the event of a roof leak, but will not impede the movement of moisture from the insulating layer, if it is present there.

- Fit the battens and counter battens under the roofing. Make sure that after the installation of the outer cladding there is a gap of 50 mm between it and the foil for ventilation.

- Install slate, shingles or other material.

- Attach a vapor barrier membrane to the rafters from below, which will protect mineral wool and wooden structures from humid air from living quarters. Lay the film with an overlap of 15-20 cm on adjacent pieces and on the walls. Do not stretch the canvas, the allowable deflection is within 1 cm. The best option for protecting the insulation from the inside of the room is a reinforced three-layer foil membrane.

- It is not necessary to cover the inside of the insulator with decorative panels.

High density slabs are heavy and will not be able to self-support between the beams. In this case, before installation, it is necessary to make a crate of rails on which they will rest.

Thermal insulation of a flat roof

Rigid mats are used to insulate a flat roof. For these purposes, stone wool is best suited, but high density glass wool also does an excellent job. Do not use soft samples. They sag when walking on a roof, from snow or strong winds, which can lead to rupture of the vapor barrier.

In order not to disturb the waterproofing, the sheets are covered with a cement-sand screed. The additional layer increases the load on the floor, so the decision to use a screed is made depending on the strength of the structure.

The most common are two ways of insulating a flat roof with mineral wool - one-layer and two-layer. The first option involves the use of a single layer of insulator.

Work on the installation of mineral wool in one layer is performed in the following sequence:

- Clean the roof from foreign objects, dirt, old coating.

- Check that there are no gaps and depressions. If found, fill the cavities with cement mortar or putty.

- Place a long ruler against the base and make sure there are no gaps underneath. Shoot down the protruding parts.

- If uneven areas occupy a large area, fill the entire overlap with cement-sand mortar with a slope of 2-5 degrees relative to the horizon. Wait for the surface to dry and continue working.

- Prime the surface.

- Waterproof the roof. Reinforced concrete slabs are usually protected with coating agents. The most popular substance is bituminous mastic. Wooden surfaces are covered with film materials such as thick polyethylene.

- Apply bitumen mastic to a small area of the roof and distribute it evenly over the surface. Place a sheet of rock wool on top and press down well to the base. Install the second block in the same way and press it against the first. Lay the panels with an offset in the horizontal plane so that the joints do not line up.

- On top, waterproof the insulation with roofing material and bitumen. It is not recommended to walk on such a roof, it will bend. To increase the rigidity of the coating, before laying the roofing material, the mats are covered with a layer of cement-sand screed.

A two-level roof covering is created from mineral wool of various densities. At the bottom, thick sheets of low density are laid - 100-125 kg / m3, on top - thin samples, but more dense - 180-200 kg / m3, they are more expensive. The upper blocks should overlap the joints of the lower row.Before laying the outer panels, the bottom row is covered with bitumen mastic. Cover the insulation layer with bituminous sheets for waterproofing.

How to insulate a roof with mineral wool - watch the video:

The creation of a protective layer based on mineral wool is considered the best option for thermal insulation of the upper part of the house. To achieve a good result, little is required - to carry out the insulation installation technology and to take work seriously.

Thermal insulation methods

Depending on which element of the building structure is insulated, 2 methods can be distinguished.

Floor insulation

The first option is floor insulation. The method is inexpensive, very simple to implement. It consists in laying cotton wool on concrete base slabs or, in the case of a wooden floor, between structural elements. Any kind of mineral wool will do, even soft and granular. Installation is simple, you do not need to bypass the rafters, as when insulating the roof slopes, you can easily fill in all the gaps and cracks.

Heat protection of skates

The second option is to insulate the roof slopes. If the premises in the attic are not used, then this option is economically unprofitable. The consumption of materials increases significantly, it takes more time due to the bypass of the rafters and additional fastening of the mineral wool.

Thermal insulation of slopes can be done in two ways: over open rafters or between them. In the first version, wooden beams remain visible inside the room and have an additional decorative function.

The better to insulate the roof of the house from the inside

It's about mineral wool. Some prefer stone wool, others quartz-based insulation. Experts from ISOVER, the only Russian manufacturer of two types of mineral wool, will help you what is better and how to choose the right material. When choosing to insulate, first of all, pay attention to its technical characteristics.

- Thermal conductivity. The most important factor for thermal insulation is the coefficient of thermal conductivity. The lower it is, the better the house will be insulated. For example, in the material ISOVER Warm Roof Strong based on quartz, it is only 0.034 W / (m * K).

- Soundproofing... A distinctive feature of high-quality mineral wool materials is the combination of excellent thermal insulation and sound insulation characteristics in one product. An example is the material mentioned above. It is able to significantly reduce the level of noise exposure.

- Non-flammability and safety. Quartz-based mineral wool is similar to stone fiber wool in that both belong to the group of non-combustible materials and are made from natural components. The first is based on quartz, and rocks are the raw material for stone wool. Consequently, such a heat-insulating material is safe for health and significantly increases the fire safety of the room.

- Moisture resistance. Thermal insulation materials for roofs are subject to increased moisture resistance requirements. Insulation with low water absorption will help reduce the risk of moisture accumulation in the structure outside and inside the room. The AquaProtect technology used in the production of ISOVER Warm Roof Strong provides it with enhanced moisture resistance.

- Good dimensional stability and elasticity of the material significantly simplify the installation process and provide reliable fixation of the insulation without additional fasteners for many years, both in a horizontal, and in an inclined, and vertical structure. Thanks to these properties, even those who insulate the house with their own hands for the first time like to work with mineral wool.

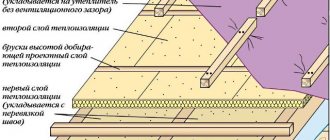

Insulation of a pitched roof

The technology for insulating a pitched roof depends on its structural features, as well as on the purpose of the attic space. So, if the attic is uninhabited, then the insulation is laid on the ceiling (attic floor), and not between the rafters.If mineral wool is used, then the following roof insulation scheme is recommended, a photo of which can be seen on the pages of many specialized publications or sites: walkways are made along the lags of the attic, and a special membrane is laid on the wool layer, which ensures steam removal and fiber filtration. After that, the floor is sewn up with OSB plates, and any floor covering is laid on top of them (useful article: "Types of pitched roofs").

How to properly insulate a pitched roof, see the video:

https://youtube.com/watch?v=C4QOujBaYVQ

In the event that a residential attic is planned, then they resort to a different insulation technology:

How to make roof insulation with mineral wool from the inside

Roof slopes can be equipped using different technologies, but their design always includes a heat, hydro and vapor barrier layer, as well as a counter lattice that creates a ventilation gap and is used for additional fastening of materials.

Roof mounting technology involves the following actions:

- Waterproofing is laid on the assembled and installed truss system. Most often, high-density polyethylene is used as a waterproofing material, which can protect the roof from both moisture and gusty winds. The waterproofing of the roof is laid from the inside of the house with an overlap of about 20 cm and is attached to the rafters with a construction stapler.

- A counter-rail is installed above the film along each rafter. This element forms a small gap between the film and the roof covering, due to which the structure is constantly ventilated.

- For laying a soft roof, sheets of moisture-resistant plywood are attached above the counter-batten. Before insulating a metal roof, or a roof made of other solid roofing materials, you will need to create an ordinary crate with a well-calculated distance between its elements.

- After the lathing is assembled, you can start installing the roofing.

How to insulate the roof with mineral wool

Arranging a roof requires the creation of a roofing cake, consisting of several layers of materials that perform specific functions. If we consider the sequence of layers from the bottom up, then first the inner lining of the ceiling of the room follows, and then the lower lathing and the vapor barrier film are located. Insulation is placed between the rafter legs, followed by waterproofing material, lathing and external roofing. This structure is suitable for mansard roofs and insulated attic spaces.

For insulated roofs, it is very important to observe the technology of laying the roofing cake with the obligatory arrangement of ventilation gaps.

Following the scheme, the following main stages of roof insulation with mineral wool can be distinguished:

- Warming is carried out after the installation of waterproofing and roofing. The distance between the rafters is measured and the slabs are cut into layers, the size of which is 2-3 cm larger than the opening between the rafters.

- Pieces of mineral wool are tightly placed in each opening, while fasteners are not used, since the plates must fit tightly.

- On top of the laid insulation, a vapor barrier film is fixed to the rafter legs, and then the inner surface of the roof is sheathed with plasterboard, clapboard or other finishing material.

Video: roof insulation with mineral wool

Determination of layer thickness

When arranging a warm roof, special attention is paid to the thickness of the mineral wool layer. This parameter depends on the region and climatic features, the dimensions of the rafter legs, the height of the roof. For the calculation, you can use online programs, but you can determine the approximate layer thickness yourself.

The thickness of the insulation layer of the roof is selected depending on the climatic conditions at the place of construction work

Averages can serve as a starting point. For example, for central Russia, it is enough to create a layer of insulation with a thickness of 100 to 150 mm. Thus, the thickness of the slabs should be sufficient for arranging such a layer, and the height of the rafter legs should be another 5 cm larger to create a ventilated layer. So, if the height of the rafter supports is 150 mm, and the mineral wool slabs are 180 mm thick, then to increase the size of the rafters, additional bars need to be filled on them to create a total height of the rafter legs of 220 mm.