Types of sealants for pipes, threaded connections

For sealing small holes and cracks in the heating system the following sealants are used:

- Oligomer based

Easy to operate and cost a little. They are widely used in construction (installation of windows, installation of wall coverings, and so on).

There are many subtypes - polyurethane, polysulfide and others. Not all oligomeric substances are effective for sealing joints in heating systems, so read the instructions before buying.

- Acrylic

Cheap, adhere well to various porous surfaces (wood, concrete, brick, plaster and so on). Easily abraded with sandpaper and other abrasive surfaces. It is allowed to paint and cover with a primer. The main disadvantages are poor water resistance, dependence on ambient temperature, average mechanical strength after drying, and so on.

therefore this composition covers the surfaces located inside the house. It is allowed to cover heating pipes with this connection if the temperature inside the system is not very high.

- Thiokol

Resistant to mechanical damage after hardening. They do not come into contact with gasoline, paints, solvents and other chemically active substances. They tolerate precipitation well. Optimum temperature range for use - from -50 to +80 degrees... Due to its high inertness, it is allowed to coat surfaces and pipes that will come into contact with chemically active substances.

Photo 1. Two cans (1 and 10 kg) of thiokol sealant from the manufacturer Nord-West. A similar substance is used for heating systems.

- Silicone

The most common type. They differ from others in their low price and relatively high quality. Withstand temperature extremes within from -30 to +60 degrees, well tolerate contact with water and mechanical deformation, as well as contact with chemically active substances.

After hardening, it makes no sense to paint in a different color, since paint will peel off the hardened surface (therefore, a dye is added to this compound). There are a large number of subtypes of silicone sealants, which are added with various additives to improve the properties of the formulation. For example, natural or synthetic fungicides are added to this substance to destroy the fungus.

Heating leak Liquid sealant will help to eliminate the leak.

German liquid sealant from BaCoGa Technik.

Eliminating a heating leak is an unpleasant thing. If we are talking about a hidden leak in the heating system, then doubly. There are many reasons why a heating leak occurs. It is corrosion when a steel pipe heating system leaks. These are low-quality materials of fittings, over time, they begin to pass the coolant at the points of contacts of different materials. Leaking heating pipes and systems can appear in places where plastic pipes are not professionally welded. Leaking heating pipes in a "warm floor" can occur if plastic pipes are primitively poured into concrete without compensating for expansion when heated. Even gaskets dry at the joints cause leakage of the heating pipes.

Yes, heating leaks are a problem. But the hidden leak of the heating pipe is just a tragedy.

It's one thing when a fitting or pipe drips in front of the owner of the house. Elimination of a heating system leak can be achieved by one of many known methods.Elastic linings and bandaging with special tapes will help to eliminate the leakage of heating pipes, and "cold welding" and hot welding, and finally, elimination of the heating pipe leak can be achieved by replacing a piece of a defective pipe or fitting. A plumber will handle the elimination of a leak in the heating system.

Another thing is when the pressure sensor shows that the coolant is leaving, and the leakage of the heating pipes cannot be detected and eliminated. If a wet spot appears on the wall or on the floor, it means that you are lucky. It is expensive and troublesome to open parquet and concrete, cut out a piece of a defective pipe and fix a leak in the heating system. But, at least, it is clear how the elimination of the heating pipe leak is achieved.

And if you can't see anything? Resourceful Russian craftsmen drain water, pump air into the pipes of the heating system and crawl with a medical stethoscope, hoping to hear the hiss of air under the parquet floor in the place where the heating pipes and the heating system are leaking. Doesn't fix the leak! Checked. You can call an expensive team with a thermal imager to try to find a leak in the heating pipes. Cases of success are rare.

- How to add BCG to the system?

Remove the dirt filters before the repair is completed. The system must be filled with heating medium. Shake the sealant until the sediment is completely mixed.

Pour BCG into a container with a pump and dilute with water. Connect the system and the pump with a hose with clamps. Open the valve and pump sealant into the system.

Close the valve, disconnect and flush the pump. Switch on the system in normal operating mode. Elimination of the leak occurs within 1 to 7 days.

For such desperate situations, when it is difficult to find leaks in heating pipes and fix them, BCG liquid sealant was created four decades ago in Germany.

How are similar problems dealt with in Germany? The team called to eliminate the heating leak offers the owner of the cottage two options. The first is with breaking floors and walls. It is expensive, dirty and takes a long time to eliminate the leakage of heating pipes. And the second is easier, cheaper, cleaner and faster with BCG Liquid Sealant.

The goal is to eliminate the leakage of the heating system.

The use of liquid sealant does not give a 100% guarantee of success, since the reason for the leakage of the heating pipes is not clear, and the place of the leak is hidden. Rarely, but there is a leak in the heating pipe, which the liquid sealant is not able to eliminate.

Here are some of the cases that we encountered in our practice:

Fortunately, such cases are rare. More than 1000 repairs in Russia have been completed successfully. Thanks to the sealant provided by us, the heating leak was eliminated. And in Europe, for several decades, this account exceeded one hundred thousand. If the character of the heating system leak, the amount of heat carrier losses, and other factors correspond to the capabilities of the sealant described in the instructions, then the elimination of the heating leak will be successful. The owner of the house for a long time, if not forever, will forget what a heating system leak and a heating pipe leak.

Liquid sealant for sealing leaks in pipes, use with antifreeze

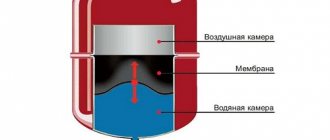

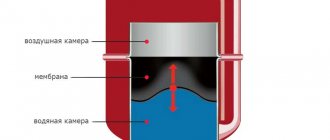

Liquid sealant in the heating system - self-solidifying solution, which is used for sealing seams and small holes in pipes.

The substance is a thick liquid that is poured into pipes; on contact with air, it solidifies, which leads to sealing and elimination of leaks in the pipes.

Liquid mixtures in heating systems are used in the following cases:

- When it is impossible to find the place of the leak.

- The leak is detected, but it is not possible to eliminate it with soldering or a clamp.

- When installing pipes in closed insulated systems, when there is no external access to the pipes.

- When the use of other methods is difficult due to the danger of violating the integrity of the walls and floors.

Due to their properties, liquid mixtures are used in everyday life not only for repairing pipes and heating systems. And also the compositions are used for sealing gaps and cracks in walls, plumbing systems, car engines and so on... Liquid formulations tolerate mechanical deformation well, and their properties do not depend on the ambient temperature (with the exception of acrylics).

Chemical inertness and thermal stability allows the use of sealants in heating systems, where water is used as a heat carrier.

If antifreeze circulates in the heating system, then it is recommended to buy a sealant that matches the temperature properties of antifreeze... It is a good idea to buy a thiokol formulation as it can withstand high temperature extremes. During the sealing of pipes, antifreeze is removed from the heating system, since most of even the most flexible hermetic substances acquire heat resistance after complete solidification.

Attention! Liquid mixtures close up cracks well, but using them against large holes is pointless.

Anaerobic sealants

The most convenient and reliable sealants at the moment. Their fluid structure allows them to easily penetrate the tightest gaps. In air, such a composition does not change its properties, but when it gets into a threaded joint, upon contact with metal and the absence of air, it sharply changes its properties and crystallizes. The result is a strong plastic that reliably seals the threaded gap. In this case, the excess glue squeezed out after assembling the joint can be used to process the next pipe, and the sealant that gets inside can be easily washed off with water.

p, blockquote 22,0,0,0,0 ->

p, blockquote 23,0,0,0,0 -> p, blockquote 24,0,0,0,1 ->

Using anaerobic sealants is very simple:

- All surfaces of the threaded connection must be cleaned and degreased. It is enough to wipe new parts with a solvent, old ones - to treat with a special metal brush.

- The solution is applied over several threads; for convenience, you can use a regular brush.

- The connection is tightened by hand, without the use of keys.

- Excess sealant protruding from the outside is removed with a napkin. You can use it to seal another joint.

- It will take a couple of hours for the material to harden, after which you can safely use the threaded connection. The manufacturer's recommendations will help you more accurately determine the crystallization time. Do not forget that it increases significantly at low temperatures.

Heating systems for private houses, not to mention cottages, contain dozens of threaded pipe connections, fittings, shut-off and control valves. Therefore, choosing the right sealant for heating means solving the problem of sealing, which is understood by everyone who has at least once "tried" threaded connections a second time, because of a leak or because the connection gets wet.

Linen + plumbing paste. Previously, in the absence of other options, flax was used to seal the plumbing thread, which was wound on the thread, having previously been lubricated with plumbing paste. The rest of the linen thread was used to wind up the locknuts. The connections were detachable, but often leaked after the summer break, with the beginning of the heating season. Therefore, flax is now losing ground to modern methods of thread sealing. Of course, linen is still sold in stores today, but it is used the old fashioned way, not trusting modern materials.

Flax is sanitary. Photo: Gusinsk twisting factory

What to rely on when choosing

To eliminate leaks in the heating pipe, almost any sealant (acrylic, silicone, and so on) is used.

When choosing the optimal substance, pay attention to the price, temperature conditions, resistance to water and mechanical deformation.

And also remember some subtleties:

- If the heating unit is not in the house, then it is advisable not to use acrylic sealant, since it does not tolerate water and mechanical damage (for example: if water gets into a crack during prolonged rain, this will lead to cracking of the substance).

- It is also not recommended to use acrylic sealant when a powerful heating boiler is installed, as the agent may crack at very high temperatures. Better to give preference to heat-resistant silicone and thiokol mixtures.

- For sealing threaded connections, it is recommended to use silicone and thiokol sealants, because after hardening, they do not deform and do not clog the threads.

Reference. In everyday life, for most tasks, it is recommended to use silicone sealantas it has good performance and low price.

Requirements for sealing materials for heating systems

If the integrity of the heating system is violated, the first thing to do is to eliminate the leak, temporarily or thoroughly - it is up to the user to decide. During installation, it is very important to ensure reliable tightness.

In order not to be mistaken with a sealant for a heating system, you need to know the requirements for materials. Firstly, they must be easy to use, so that even an untrained person can easily eliminate the leak before the plumber arrives.

The second most important requirement is heat resistance. The temperature of individual elements of the heating system can reach +150 ° C, therefore it is important that the sealant does not crack under such an effect and ensures reliable tightness.

A sealant for sealing leaks in a heating system must also have high adhesion, strength and a fast cure time.

The choice of high-temperature sealant for the boiler and heating system of a private house

If the heating boiler is not in the house, but on the street in a separate extension, then the temperature regime of the pipes connecting the boiler and home radiators is taken into account. This moment is especially critical for the northern regions, where the temperature drops in winter. below -30 degrees... In such cases, it is recommended to give preference to thiokol types. In addition, silicone mixtures are suitable, which contain additives that improve thermal properties.

Photo 2. High-temperature silicone sealant Moment used for heating boilers. Substance is red-brown in color.

If a crack appears in the boiler, then seal the equipment using high temperature composition. To accomplish this task, use thiokol and silicone mixtures.

And also suitable for this purpose anaerobic heat-resistant sealant. Anaerobic mixtures have a slightly different mode of action, so they more easily tolerate high temperatures and quickly solidify. The main disadvantage is the rather high cost, but the use of anaerobic sealant is fully justified in emergency cases.

Technology and methods of using sealant for heating systems

The use of a sealant for internal or external work requires preliminary preparation. The composition is selected according to the type of system. The consumption of liquid sealant for a home heating system is calculated based on the volume of water. For every 60-80 liters, 1 liter of sealant is needed.

It is also necessary to prepare the system itself. All air is removed from it, filters are dismantled, all taps are opened. A pump is installed on the first radiator, with the help of which the remaining air is eliminated and the pipe heats up to 50-60 graus.

Outdoor processing

Measures for sealing joints and threaded connections are carried out in a specific order.

- The damaged area is located.

- All liquid is drained from the system.

- The damaged area is cleaned of dust, old sealant (if any at the joint), degreased.

- The sealant is applied in accordance with the instructions.

Only after the insulating composition has completely solidified, the coolant is again poured into the system.

Internal processing

For interior work, a liquid sealant is used for the heating system. After preparation with air bleeding and dismantling of filters, hot water is drained from all radiators in the volume required according to the recipe. To do this, you need to stock up on a container of the appropriate size.

Liquid sealant is diluted with water to eliminate leaks in the heating system. In this case, a couple of liters of coolant is left in a clean state for subsequent flushing. The Mayevsky crane is dismantled from the radiator, and a pump is connected instead. With its help, the system is filled with a liquid with a sealant diluted in it. The pressure increases to 1.5 atmospheres. In this position, the system should work for about 6-8 hours until the entire composition hardens.

After that, the coolant is drained again, but first you need to make sure that all problems have been eliminated. Water without sealant is poured into the heating system, drained and poured again. Thus, the radiator is flushed from material residues.

After 3-4 days, it is checked again for cracks and leaks. If necessary, the sealing process is repeated.

It should be remembered that this option for eliminating holes in the heating system of a private house only works if the water leak does not exceed 30 liters per day. In case of an increase in this indicator, a major overhaul is required with a complete replacement of the pipeline section. If you are not a master, then for these purposes it is better to consult a specialist, otherwise the problem can only get worse.

Working with the sealant will not cause difficulties if all manipulations are carried out in accordance with the instructions.

Liquid sealants are used to seal cracks in the heating system

... This substance is sold in any hardware store and costs little.

However, the tool is used only to eliminate small cracks; it is useless to seal large holes with it.

Preparatory work before refueling batteries and pipes

First, choose the best sealant for your system. Before buying, pay attention to the consumption of the active ingredient. For every 60 liters of water the coolant in the pipes is required about 1 liter of sealant, however, these figures may differ depending on the type of sealant. To determine the volume of the coolant, multiply the cross-sectional area by the total length of the pipe. And also add to this indicator the volume of the radiators and the boiler (this information is indicated in the passport for the installation).

Important! You can count by direct measurement - for this, all the water from the pipes is drained and the volume is measured using containers of a known size. This method is more time consuming but more reliable.

Fill setup process

Follow the process of setting up the system for pouring:

- Remove air from the heating system, since premature solidification will lead to the formation of unwanted clots in the system.

- If the system has filtersthen dismantle themso as not to damage the system.

- Open all heating system tapsto allow the sealant to penetrate each work area.

- Install an automatic pump on the first radiator... Turn it on 1-2 hours to warm up the pipe and vented out the remaining air (the optimal pressure level is 1 bar).

Pouring procedure

After that, start filling:

- Prepare a large container for solution preparation.

- Pour the required amount of water into it.

- Add sealant and stir the solution.

- At once inject the solution into the heating system using a pumpto minimize contact of the sealant with air.

- Start the heating system in normal mode (optimal water temperature - not less than 50 degrees).

- You need to drive a sealant with a coolant for at least 4 days, but on day 5 it is recommended to carry out control measures to check whether the sealing is effective or not.

FUM tape for heating

FUM tape stands in second place in popularity among fans to install plumbing with their own hands. Yes, the simplicity and cheapness of FUMka beckons to use it to seal threaded connections of the heating system, but this is not recommended, because:

1. On sale it is difficult to find a truly high quality FUM tape, which will be elastic, well wound on the thread and not torn to shreds at the slightest tension. The last time I bought several FUMoks from different manufacturers and came to the conclusion that FUM should be sent to rest, where the flax is.

2. FUM tape, even of high quality, well suited for cold water pipelines, where there are no sudden temperature changes, which means that the threaded connection does not undergo thermal deformation. Therefore, FUM is suitable for heating with reservations, and there are fewer and fewer people who like to completely or partially drain water from the system to seal the leaked connection.

3. FUM does not tolerate winding on rusty threads and threads with notches, therefore it is poorly suited for sealing modern fittings of polypropylene and metal-plastic pipes. The fact is that the fittings are initially made for modern sealants, so the thread is loosened and not always pipe, and I will keep silent about the notches on the thread.

Based on personal experience, I can say that FUM tape is a bad solution for sealing threads in heating systems, especially if you need to seal manifolds or valves connected in series. The principle is simple: if you need to seal one joint, FUM will do, and if there are dozens of joints that are undesirable or time consuming to disassemble several times, you should avoid using the FUM tape.