Roofing profiled metal sheets are one of the most common roofing materials. The popularity of corrugated board is due to the democratic price, ease of installation, and low weight. However, along with the obvious advantages, this material has no less noticeable disadvantages. One of them is increased condensation. Under certain conditions, heavy dew falls on steel sheets, both outside and inside. Because of this, from time to time a little rain literally drizzles under the roof. Wooden structures and insulation have to be protected from condensation. The authors of some articles posted on the Internet claim that a waterproofing layer should be located under the steel sheets and even allow themselves to give advice on the choice of material. However, in fact, waterproofing for corrugated board is not needed, and sometimes it is contraindicated.

What materials insulating against moisture are used in construction

It should be understood: by no means all materials designed to protect against moisture are waterproofing.

Waterproofing ↑

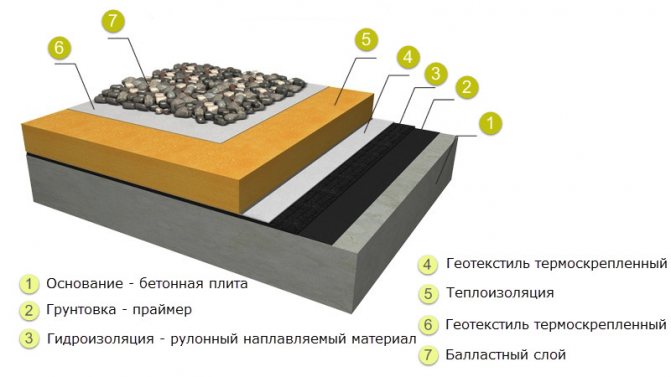

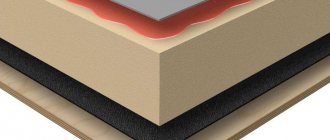

It is absolutely waterproof, withstands a fairly large water pressure (continuous flow of water), is very durable and resistant to atmospheric influences, ultraviolet radiation, which allows it to be used in an open state. Waterproofing is suitable for the construction of hydraulic and underground structures, building foundations, flat roofs. Waterproofing materials include bitumen and bitumen-polymer roll insulation, mastics, polymer membranes, special cement-polymer penetrating compounds, bentonite clay slabs.

When installing a flat roof, the waterproofing layer can simultaneously serve as a roof covering

Vapor barrier ↑

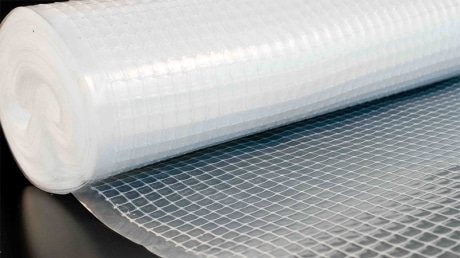

As the name suggests, it does not allow water vapor to pass through. Roll waterproofing materials and polymer membranes can cope with this task, but they are inconvenient for use in lightweight wall and roof structures. It is much easier to attach thin and lightweight reinforced polyethylene vapor barrier films to the frame. And they are much cheaper. The vapor barrier is also waterproof and able to protect against rain. But it does not have sufficient mechanical strength and resistance to ultraviolet radiation, which does not allow the use of vapor barrier in an open form, but only under the protection of roofing and wall cladding.

Reinforced polyethylene and polypropylene vapor barrier films are mainly used for roofing. The mounted truss structures in the warm season are allowed to be left uncovered for a couple of months, protected only by a vapor barrier. It will protect the wood from precipitation. But no longer, the resistance of the film to ultraviolet light is limited, it can also not withstand the snow load.

Wind and moisture insulation ↑

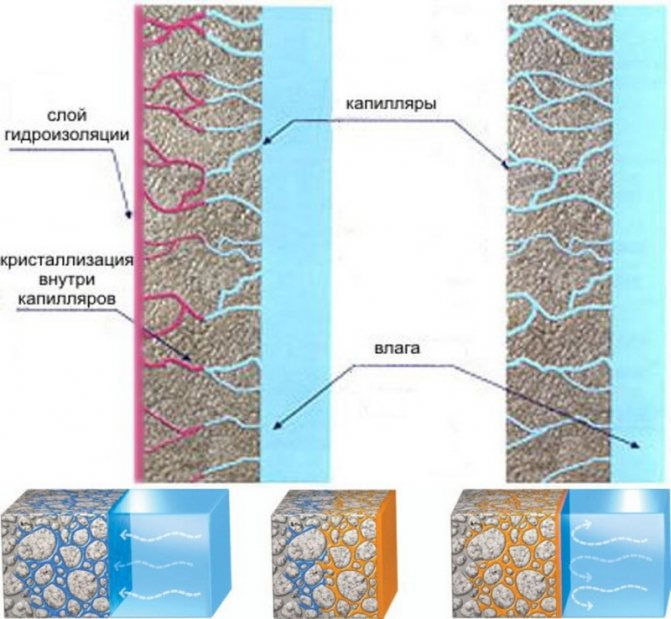

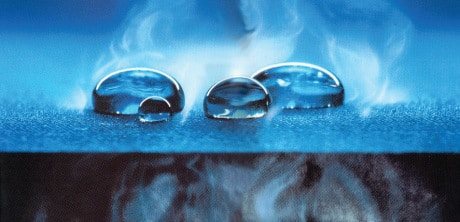

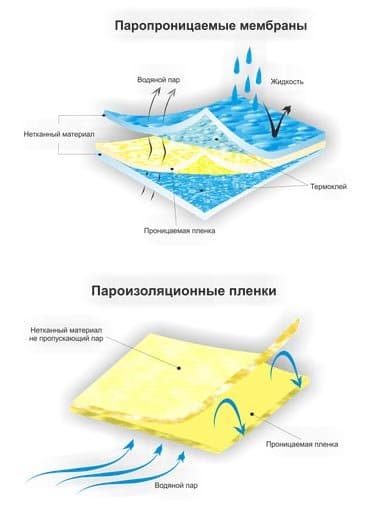

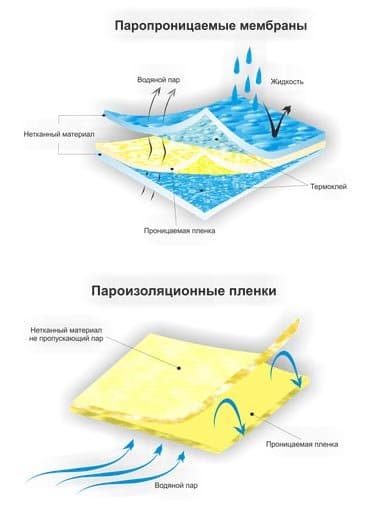

Wind and moisture insulation for the roof is able to protect the fibrous insulation from being blown by the wind, to a certain extent retains liquid water, but at the same time freely passes water vapor. Due to such selective properties of moisture transmission, wind and moisture insulating films are also called diffusion membranes. They can be made of polymer fibers (non-woven canvas) or perforated film, there are also combined options.

Due to the presence of pores, the diffusion, wind and moisture protection membrane allows water vapor to pass through.But the size of these pores is so small that water droplets falling on the surface do not penetrate the film. Surface tension prevents this from happening. However, if the membrane is wetted for a long time and abundantly, sooner or later it will get wet, "it will leak." Wind and moisture protection is not suitable as protection against heavy rain; immediately after its installation, the roof should be covered with a roof covering

Waterproofing materials

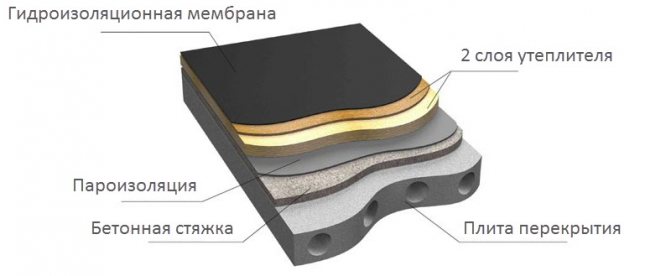

Waterproofing the roof of the house- this is the creation of a layer that prevents the penetration of water and steam into the thickness of the insulation. The materials used for this purpose are either application-curing film formers or sheet membranes or films made off-the-shelf for installation in the desired location.

It should be noted that for waterproofing a pitched roof, the use of liquid binders is not always convenient, especially if strong heating is required (as, for example, when using bitumen). Nevertheless, there are quite a few types of waterproofing materials (we examined them in detail in this article), we will consider some of them.

- Bituminous mastics (welded waterproofing). The material is convenient for old structures, as it does not require thorough cleaning of the surface. Works well on rust, damp or dusty substrates. Cleaning is only necessary if there is a thick layer of dirt, earth, ice, etc. If the coating process is carried out several times in a row, a fairly thick layer can be achieved. The disadvantages include the exactingness of some types to application temperature reaching 160 °, in addition, the application of thick mastic is physically not always convenient in a pitched roof. Also, bituminous mastic is well suited for waterproofing slate or ondulin roof joints.

- Roofing material, glassine... The material, the installation of which is made by the type of gluing it to the protected surface. Installation on pitched roof is difficult due to the need to use hot bitumen and inconvenient surface location.

- Film materials... For the type of roof under consideration, it is the most convenient and reliable material to work with. Installation is quite simple, you can easily provide all the conditions necessary for proper operation - the gap between the film and the roof, the absence of cracks and gaps. Currently, several types of film waterproofers have been developed - polyethylene film, waterproofing membrane, polypropylene film... Installation of all types is practically the same, the only difference is in the method of joining the joints. This type of waterproofing is also suitable for installation under cold and soft roofs.

IMPORTANT!

Particular attention is paid to integrity the film is tight, no holes or cuts are allowed.

Membrane materials have the property of allowing water vapor to pass through, making it possible to dry the insulation while simultaneously cutting off water from the outside. The question often arises - which side to put the waterproofing on the roof? In most cases, waterproofing is applied the smooth side to the roof, and the fleecy side to the insulation.

What is a roofing film (membrane) ↑

It is clear: if the film is under-roofing, it means that it is placed directly under the roof covering. One of its main functions is to protect the rafter system and insulation (if any) from condensation, which can abundantly fall out on profiled metal sheets. Any of the above insulation materials will cope with it: hydro (steam) insulation, diffusion membrane (wind insulation). However, these are not all the tasks that the roofing film is designed to solve. What exactly is required of it and how to choose the right under-roofing film (membrane) directly depends on the type of roofing. Consider two types of roofs: cold attic and warm attic.

Recently, there has been a tendency to call the vapor barrier a subroofing film, and wind and moisture insulation - a subroofing membrane. This is not entirely correct use of the terms, but it just so happened. The main thing is in the difference in the physical properties of these materials.

It is important to know: unfortunately, the Internet is full of confusion on this topic, ignorant sellers of building materials and illiterate builders also contribute. Often, wind and moisture insulation and vapor barrier are called waterproofing. This is wrong, you need to understand that this is not the same thing, materials have different physical properties, they are designed for different types of roofs.

What you need to know about roof waterproofing - important points

If you are using roll materials, then before installing them, you should make sure that the roof surface is properly prepared for work. You should also remember that:

- it is not recommended to carry out waterproofing work at an air temperature below +5 degrees, as well as during atmospheric precipitation (the exception is waterproofing, which can be laid at a lower temperature);

- waterproofing can only be laid on a flat surface, clean and dry, without sharp protrusions that can damage the waterproofing material;

- one side of the insulating material (the one intended for melting) has a characteristic embossed pattern. When heated with an industrial hair dryer (propane burner), the pattern disappears. This indicates that the material is hot enough to be anchored to the roof;

- waterproofing work should be started from the lowest point of the roof, from the place where the storm (drainage) system is located;

- if separate pieces of insulating material were used, do not forget to carefully seal their joints with special compounds;

- if you use two or more layers of waterproofing, then each next layer should be laid on the lower one with an offset of about 50 cm;

- protecting the waterproofing layer from sunlight with special liquid formulations is an excellent solution if you want to extend the life of the coating.

Roof waterproofing will be durable only if preventive work and maintenance are carried out systematically. You just need to regularly clean the roof and drainage systems from snow and dirt in order to avoid stagnation of sedimentary moisture, check the condition of the joints and the waterproofing material itself, timely carry out repair work, and update the sun protection layer.

Roof above the cold attic ↑

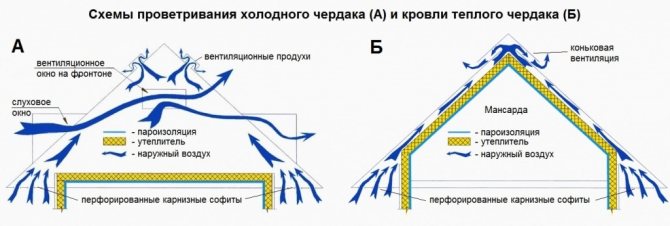

There is no need to insulate the attic roof, but you can ventilate it by arranging holes in the gable walls or filing.

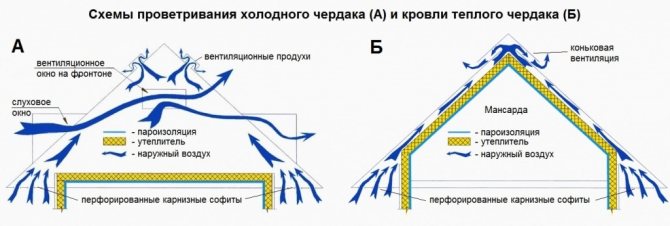

In our case, the fundamental difference between a cold attic and a mansard (combined) roof is how they are ventilated, how excess moisture is removed from wood and insulation

Thus, moisture from the inside of the attic is removed due to good internal ventilation, it is only necessary to protect the structures from condensation that forms on the underside of the roofing. Installation of waterproofing under the corrugated board is possible. Once they did this, they rolled roofing material under corrugated asbestos-cement sheets (slate). Theoretically, you can use old linoleum, sheets of plastic, tin and other unnecessary trash that does not allow water to pass through. However, a special vapor barrier film will last longer, it is easier to fix, it is very inexpensive. You can also use a diffusion membrane, but there is not much sense in this: it will cost more, and its properties of passing water vapor will be unclaimed.

The roof structure of a cold attic should include a vapor barrier film

It is important to know: for a cold attic roof, the best roofing film is a vapor barrier, but any type of moisture-wicking material will do.

Installation of waterproofing under corrugated board

Installation waterproofing works are performed in the following sequence:

- First, the installation of thermal insulation under the corrugated board is carried out.

- Then a crate is mounted on top of it. It is necessary to ensure normal air circulation under the roof.

- Further, depending on the type of roof slope, a waterproofing film is laid. Most often, installation is carried out from the roof ridge to the cornice.

Advice!

If the roof was erected with a slope of 30 degrees, then the waterproofing is mounted in layers with an overlap from the bottom up. The overlap should not exceed 2 cm.If the angle of inclination is less than 30 degrees, then the layers are laid out with an overlap of 2.5-3 cm. Four-slope or hip roofs on each ridge are insulated with a film with an overlap of up to 5 cm.

- The waterproofing film is laid out with sagging between the battens of the battens. There should be at least 3 cm between the thermal insulation layer and the waterproofing, otherwise it will not work to ventilate the under-roof space.

- The film is fixed to the crate with metal staples. The counter battens are nailed to the fasteners with galvanized steel nails.

- The edges of the film are connected with adhesive tape.

Roof above the warm attic ↑

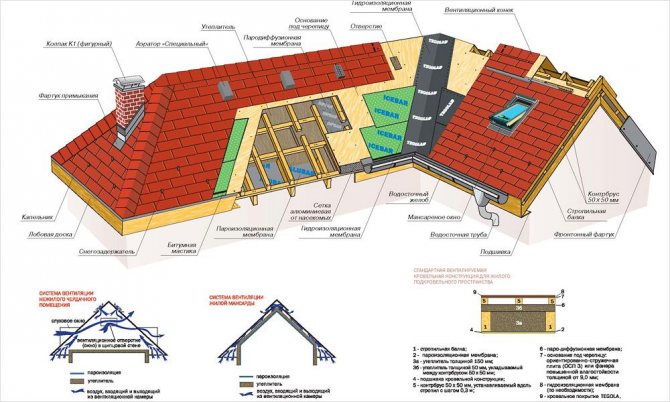

The mansard roof has to be insulated, and the insulation and wooden structures have the ability to absorb moisture from the air. It will not work to ventilate them from below, from the side of the premises, the air there is more humid than outside. On the contrary, from the inside, the roof must be protected from moisture by covering the rafters with a vapor barrier film. The only way to prevent wood and mineral wool from damp is to ensure their ventilation from the outside, be sure to leave a ventilated air gap with a height of at least 4 cm between the roofing and the under-roofing film.Hydro (steam) insulation will not ensure the release of water vapor, therefore, for mansard roofs, only vapor-permeable wind and moisture insulation is used (diffusion membrane).

Correct construction of the attic roof and walls of the frame house. From the inside, the structure should be protected by a vapor barrier, from the outside by wind and moisture protection. But not the other way around!

It is important to know: the only suitable option for a roofing film (membrane) for a standard attic roof structure is a diffusion membrane.

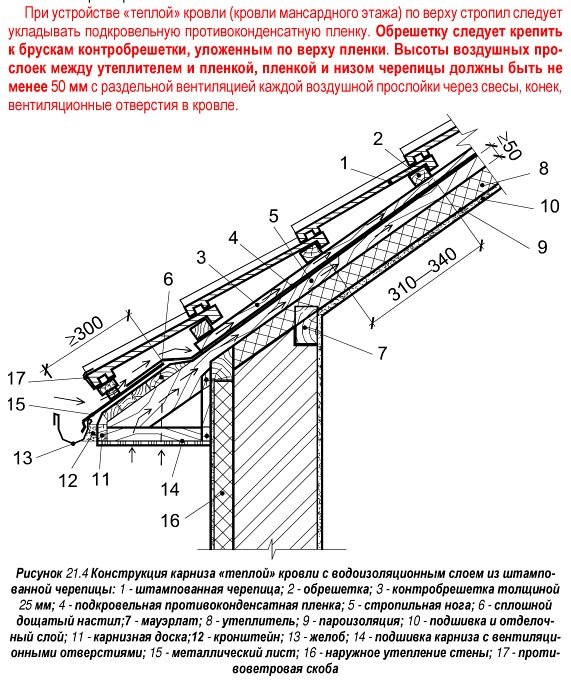

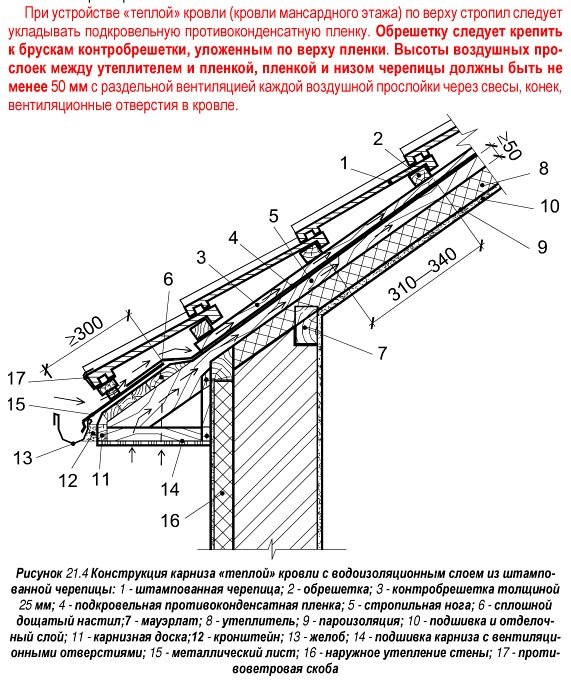

There is a version of the combined (mansard) roof, in which a vapor-proof hydro or vapor barrier is used as a roofing film. But in this case, it is necessary to ensure effective ventilation of the space both above and below the film, the total height of the ventilation gaps will reach 10 cm. This solution is effective, but complicates the design and is rarely used. Please note that the underlay (4) is brought out over the steel apron (15) closer to the overhang, and that into the gutter of the gutter system. This should always be done, this is to ensure that condensate flows out of the roof structure.

In conclusion, let us say that not only the comfort of living in the house, but also the durability of the structure depends on how correctly the roof structure is selected and the materials for its installation are chosen. If you do not have sufficient knowledge in the field of construction, do not have the time or desire to delve into the intricacies of modern technologies, the best solution would be to entrust the execution of important work to experienced professionals.

Films antioxidants

In some cases, during long-term operation, condensation appears on the surface of the waterproofing film. Moreover, the formation takes place on the side that faces the insulation. It should be noted right away that the situation is not the most pleasant.

In order to prevent such formations, and to prevent the ingress of condensate drops when there is an excess of it, on the surface of the insulation, it is advisable to use viscose fiber and cellulose. A layer of such material is applied to the inside of the waterproofing layer, acting as a barrier on the way of condensate to the insulation. At the moment when the possible conditions for the formation of condensation disappear, the antioxidant layer dries up.

This kind of protective films is one-sided. That is why the installation of the element should be performed correctly, without confusing the sides. Here it is necessary to place the antioxidant against the waterproofing layer with the smooth side, and the rough side turns to the insulation. When using this material, the ventilation layer between the waterproofing and the insulation remains unchanged.

It might be interesting

Waterproofing

Clean water is a guarantee of health, waterproofing of concrete ...

Waterproofing

Pool waterproofing instructions

Waterproofing

The choice of materials, the method of carrying out works on waterproofing ...

Waterproofing

Types of gluing waterproofing

It should be noted that the following actions are not allowed:

- In this case, materials that do not allow air to pass through cannot be used as waterproofing. Otherwise, the vapors that appear in the insulation will not come out.

- The film for the roof of the house does not allow for any rearrangements. The waterproofing layer and the vapor barrier must not be interchanged. Such actions will lead to the most negative consequences.

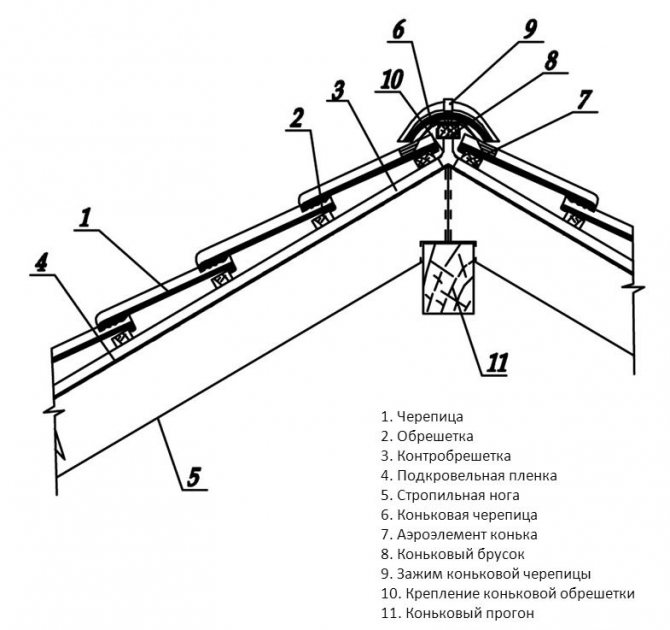

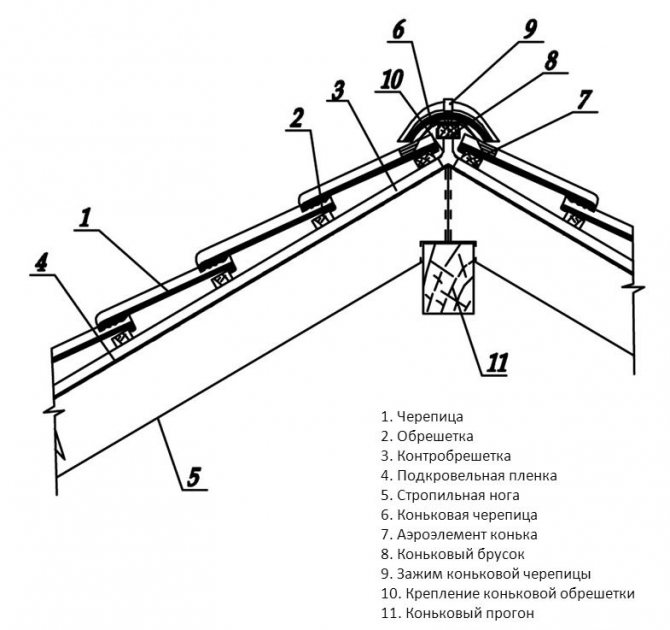

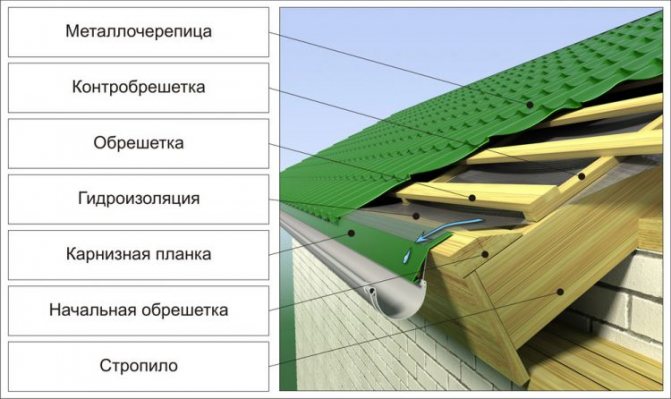

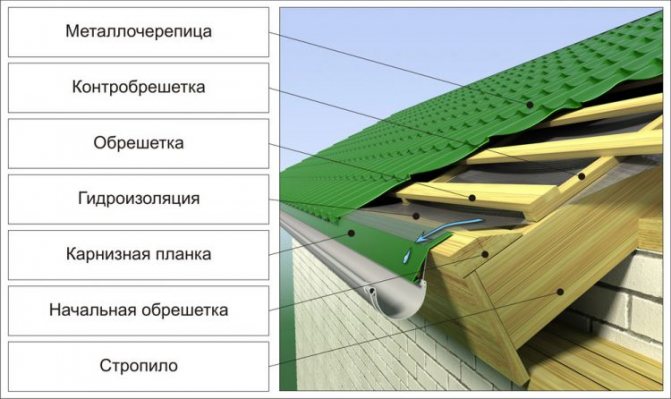

Metal roofing scheme

II. Installation of rafters of a pitched roof

For rafters, you can use boards of five by ten centimeters. The length is 30-50 cm longer than the length of the slope (the excess will go to the overhang of the lean-to roof).

The pitch between the rafters depends on the slope of the pitched roof and the weight of the roofing material, for example:

- Ceramic tiles, slate - meter-meter twenty; Decking - one and a half.

1. Mark places on the Mauerlat for the grooves for inserting the rafters. Leave a gap of five centimeters between the extreme legs and the sloping walls.

2.

Cut grooves. The width is slightly more than the thickness of the rafter leg, the slope corresponds to the slope of the roof. We will put the boards vertically.

3. Place the two outer rafter legs in the grooves.

4. Stretch the line between them. It will regulate the installation plane of the remaining rafters.

5. Put the rest of the rafters, nail each to the Mauerlat with several long nails (12 centimeters or more).