Classification of thermostats

Temperature regulators for heating boilers provide a given temperature regime of the room with a sufficiently high accuracy. The deviations, as a rule, do not exceed 0.50 C - 1.00 C. Their work is carried out by means of a variety of actuators, which actually determines whether the thermostat belongs to one type or another. By the number and content of functions performed devices are classified as follows:

- Single-function (maintaining an exclusively set temperature).

- Multifunctional, or programmable.

According to the type of execution, the thermostats are divided into devices that are connected to the heating boiler by means of wires and wireless. The installation of the control device is carried out in an accessible place that provides sufficient air flow. In addition, it is advisable to exclude the placement of household electrical appliances (TVs, heating and lighting devices, etc.) in the vicinity of the regulator, since this can significantly affect the correctness of its operation.

Programmable room controller

A programmable thermostat for a heating boiler provides the ability to select the required (comfortable) temperature at the desired length of time, it can be easily reconfigured to another operating mode. Equipping the device with a timer allows you to set different patterns for the functioning of the heating system for weekends and weekdays. There are timers that can support certain parameters depending on the day of the week. The presence of such functions in the temperature controller allows you to adjust the space heating system in accordance with the prevailing lifestyle and guarantee the temperature microclimate to be maintained even during the absence of the owners.

This controller has some options that significantly expand the capabilities of the heating system as a whole:

- "Batch", a function that provides periodic shutdown (for several hours) and the subsequent resumption of the system.

- "Holiday". The purpose of this option is to increase or decrease the intensity of space heating for a given number of days.

- "Overlap". A mission that allows you to temporarily change the program settings in one of the periods.

Central fixture

As a rule, a device of this type is used to effectively control the heating system of the whole house and is placed at some distance from the heating boiler. Such devices are equipped with a dilatometric thermostat that works remotely. The principle of its operation is to measure the ambient temperature and, depending on its fluctuations, turn on (off) the heating boiler.

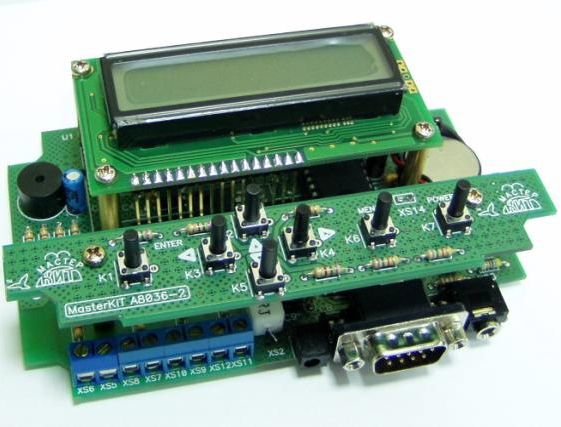

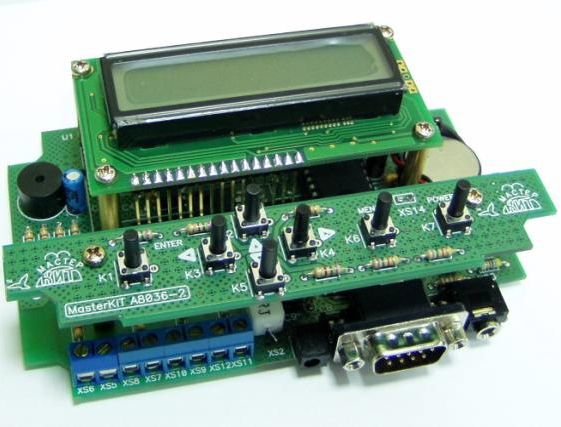

Multifunctional timer-thermostat based on radio-constructor Masterkit

In a subsidiary farm, as well as in a private house or workshop, garage, there are many processes associated with temperature changes and a possible reaction to these changes. Moreover, the reactions can be quite varied and depend on time and calendar. It can be a “big brother” for looking after a terrarium aquarium or a complex step heat treatment in a high-temperature oven, control of a heating and ventilation system at home, or just ringing in an educational institution.

It is not difficult to solve such a problem by using a microprocessor radio-designer module as a control. For example NM8036 offered by Masterkit.

The main features of the device.

Timer control:

Turning on the load in a certain period of time Manage loads on certain days of the week, days in a month, or on selected months.

Temperature control (thermostatting):

Control as a cooler Control as a heater

Alarm clock sound + light (display backlight).

1. Number of connected temperature sensors: 32. 2. Non-volatile real time clock (full calendar with leap years). 3. Saving all settings in non-volatile memory. Continuation of the correct operation of the program in the event of a temporary disconnection from the network. 4. Outputs: a. opto-isolated cascade for connecting power triacs (optional - 4 optocouplers are already on the board, it is possible to add 8 more to control external thyristor / triac power cascades) b. logic outputs with a maximum current of 10mA.

5. Remote control of the thermostat through the COM port of the computer by means of specially developed software. 6. Ability to update internal software with new versions from the site https://www.masterkit.ru. 7. Indication: 2-line 16-character LCD-display with the ability to programmatically control the contrast and brightness of the backlight. 8. Sound indication by built-in micro-speaker.

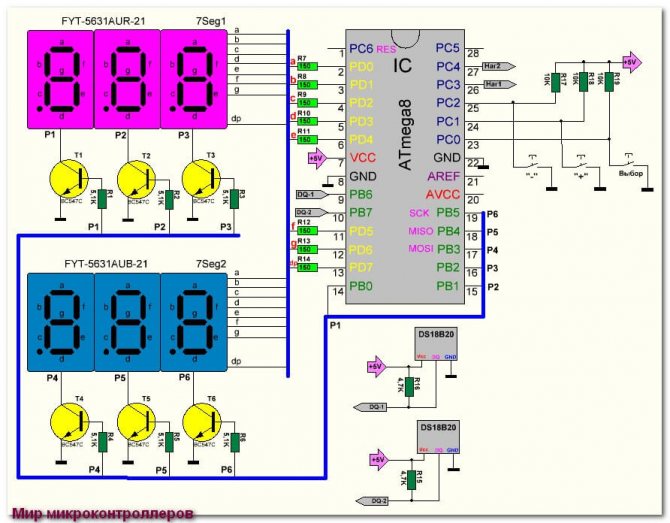

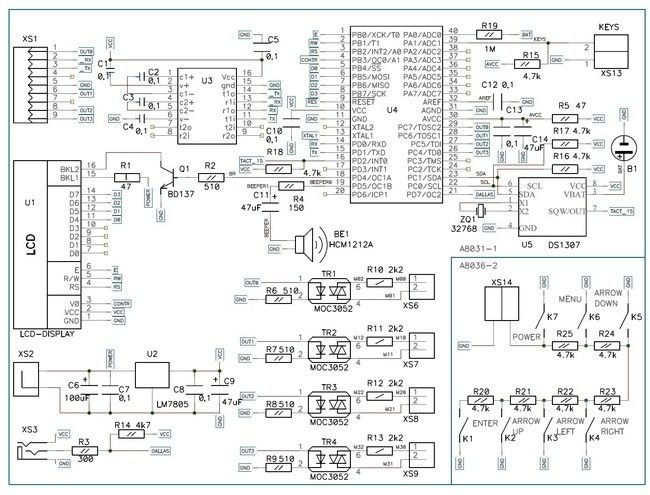

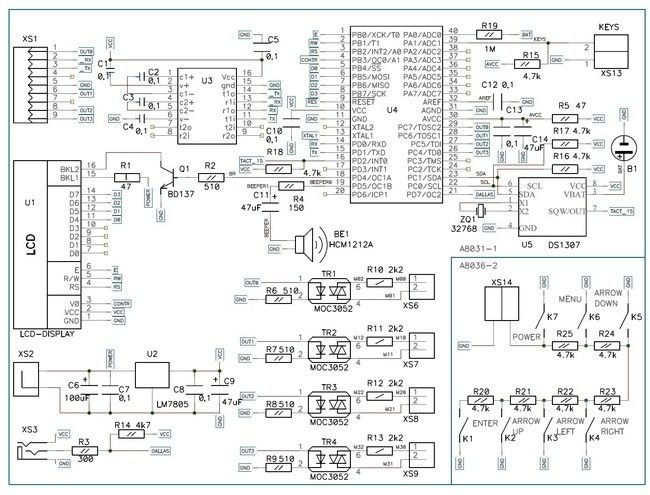

The schematic diagram of the device is presented below.

Description of the circuit

The thermostat is based on the Atmel Mega32 microcontroller. The following are connected to the input-output ports: a textual 2-line indicator, a DS1307 real-time clock microcircuit, a MAX232IN level driver, optosimistors. The keyboard unit is designed as a separate board. The code of the pressed key is decoded by the analog-to-digital converter (ADC) of the controller. In addition, the ADC monitors the status of the clock back-up battery. The voltage regulator is made on the LM7805 microcircuit. DS18B20 temperature sensors are connected via 1-wire protocol. The brightness of the backlight is controlled using a transistor switch. Using a miniature speaker connected through a decoupling capacitor and a damping resistor to the controller port, the device can generate audio signals. The operability of the circuit is ensured by the internal program of the microcontroller. At the start, the program analyzes the 1-wire bus and initializes the "registered" temperature sensors into a 12-bit thermal conversion mode. Then all other blocks are initialized (text indicator, RS232 port, clock microcircuit). After initialization, the system enters the main loop mode. In this mode, there is a constant processing of updated information from the clock, from the sensors, and also polls the state of the control buttons. In addition, the process responsible for the timer control is constantly running.

The device is offered in the form of a set of radio elements with printed circuit boards, including a microcontroller with a program. Structurally, the assembled thermostat-timer looks like a three-dimensional module assembled from three boards. On the largest "motherboard" board, on metal screw supports, two additional boards are installed - an indicator and a keyboard.

What was used.

Tools.

A set of tools for radio installation, understandably a soldering iron with accessories, a multimeter. A jewelry jigsaw came in handy. Small locksmith tools. Anything for drilling holes, plus drills. I used hot melt glue. Building hair dryer for working with heat pipes. Soldering iron with a capacity of about 60 watts, for constructive soldering. In some places, a drill, a small gas burner, and a screwdriver came in handy.

Materials.

The radio designer himself. Radioelements for electronic keys, power supply, pieces of foil-clad material for printed circuit boards, different thermal tubes, mounting wire, fasteners were also used. Galvanized sheet steel for the front panel, a piece of plexiglass.Access to a computer with a printer.

Initially, the module was used as an underfloor heating control device in a city apartment.

The entire heated area (corridor, kitchen, bath-toilet) consisted of four independent heaters. "Thin underfloor heating" was laid in a layer of tile adhesive. Together with each heating grid, a DS18B20 digital temperature sensor was walled up. All wires were led into a dedicated cabinet in the kitchen. There were also some electrical components not related to floor heating - a block for smooth switching on of halogen lamps in the bathroom (as in a theater, without it they had an extremely low resource), an RCD of a boiler. The control unit was equipped with triac keys on powerful radiators, a power supply. The cabinet had two ventilation grilles and a door with a lock.

Above, a diagram of one of the triac switches. The RC circuits shown in the figure, connected in parallel with thyristors, are recommended to be used to improve their dynamic characteristics. The lower of the range, the resistance of the resistor corresponds to the resistive load, and the larger is the inductive one. Parallel to the load, a neon lamp was switched on. Placed in plain sight, very convenient for setting up and monitoring work.

In the village, the thermostat-timer was relocated to the case from the old computer system unit. The main field of his activity is the control of heating elements in the furnace. At that time, I often had to leave for several days, including in winter. Heating the house, the process is very inertial - the first one and a half to two days after arrival I had to freeze. Automatic control of the electric heating inside the oven, avoided this, with a reasonable consumption of electricity.

Since the control unit was located outside - in the unfinished basement of the house, the case was insulated, and one of the channels was loaded with a small heater of several watts from five watt wire resistors in a rectangular ceramic case (arrow in the photo). They maintained a few degrees above zero inside the hull. A small contactor was used to switch the heater.

After a while, such a furnace mode was no longer necessary and the control unit was modernized for use in a greenhouse with a ground battery. The insulation of the case was removed, the module was moved to one of the walls, so that it was convenient to use it from the outside. The contactor has been removed, a powerful thyristor switch has been added for one channel - heater control. The rest of the keys are low-power, their load is low - fans and possibly additional lighting (seedlings) lamps.

The control module is disassembled into separate boards, all of them are fixed on the same plane with the help of racks, so that it is convenient to use it from the outside - the screen is at the top, buttons under it. Opposite the screen, of course, a rectangular opening is cut out. Brass posts, with a flat end, were simply soldered to galvanized steel (it is well tinned with "soldering acid" - zinc chloride). On the "motherboard", to improve reliability, removed the power connector, the connector for the sensors. The leads from the wiring harness are soldered to their contact pads.

A metal mounting plate with a thermostat installed, fixed to the front of the enclosure. Blind rivets.

The front panel is printed on a color printer and covered with a piece of plexiglass. In general, the design turned out to be "industrial", and it is not bad.

The thyristor key was assembled according to the diagram above. The advantages in comparison with the triac should be attributed to the "spacing" of the key crystal into two cases - a much larger heat removal area. The rest, see the diagram with a triac.

The thermostat module has been updated to firmware version 1.9.This made it possible to use several more useful functions of the device, for example, it became most convenient to use analog sensors, a very useful ability appeared - the dependence of different stages of the program on each other. The new version also includes an alternative version of the control program for a computer, the most useful difference of which, I see, the mode of "data collection" - recording the temperatures of the sensors in a file. Let me remind you that updates are distributed by the developer and are located at the links above.

Until the garden season, the thermostat was involved in ancillary work - loaded with an impromptu "drying cabinet" from an old oven, for drying photo varnish on blanks of printed circuit boards and other pieces of iron - the process assumes a fairly accurate temperature range.

Become an author of the site, publish your own articles, descriptions of homemade products with payment per text. More details here.

Operating principle

Regardless of the type, the design of the thermostats corresponds to one general scheme. The device consists of 3 key modules (blocks):

- a temperature sensor for a heating boiler with a temperature sensitive element;

- settings block;

- control unit.

A thermal sensor with a temperature sensitive element monitors the degree of heating of the surrounding environment. Changes in ambient temperature cause changes in the physical parameters of the element, which are captured by the control unit. The control unit, in turn, transmits a signal to one of the executive devices:

- mechanical valve;

- electromagnetic relay;

- digital (analog) device performing post-processing of the signal.

The functional purpose of the tuner is to fix the parameter values, the achievement of which initiates the operation of the thermostat itself.

Installation of a temperature controller for a heating boiler is carried out with the obligatory observance of certain mandatory conditions:

- The device must be protected from UV radiation.

- The external sensor is installed in places characterized by a stable ambient temperature (no proximity to heating devices, drafts, etc.).

- The sensor is mounted at the height recommended by the manufacturer.

- It is unacceptable to cover the device with screens, curtains, furniture, etc.

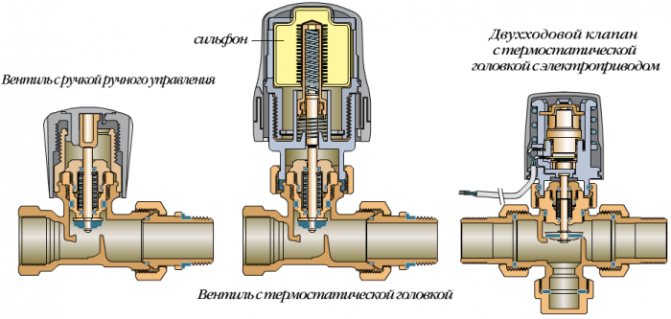

Regulating thermostatic valve

This regulating device, called a thermostatic valve (valve), is the simplest solution to the problem of obtaining a heat carrier of a certain temperature. The result is achieved by mixing cold and warm water. The control of the coolant temperature is carried out not by controlling the heating boiler, but by changing the intensity of the coolant flow through the radiator.

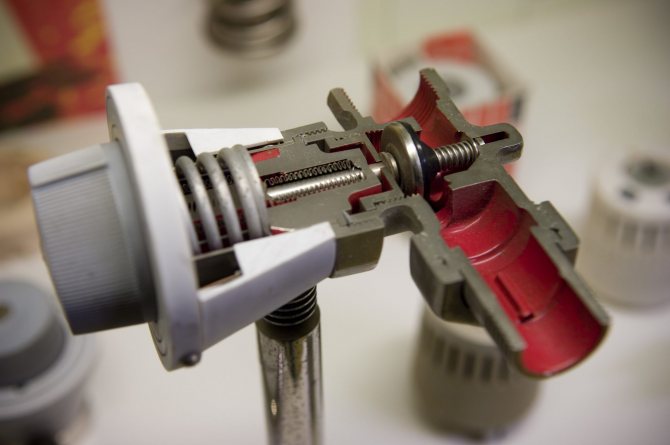

The design of the device is quite simple and includes two main elements:

- The valve itself (valve), which is, in fact, an ordinary shut-off valve that closes the opening at the entrance to the heating radiator. The overlap occurs in whole or in part, which, in essence, determines the amount of the coolant passed through.

- Thermostatic element with a thermostatic bulb filled with a special liquid (gas) that expands when the temperature of the coolant changes.

In addition, the thermostatic valve can be considered as an effective addition to mechanical or electronic thermostats. The advantages of such devices are their low cost and ease of use, however, they need to periodically check the operating parameters.

What parameters should you pay attention to when choosing?

Thermal relays can be configured for specific temperature characteristics or adjustable. There are, in addition, devices for the simultaneous closing / opening of contacts, and for the separate performance of these functions.

There are some technical characteristics that you need to study before purchasing such a device:

- temperature at which the device is triggered - parameters, when reaching which, the contacts open or close;

- temperature return indicator - at the moment this parameter is reached, the device takes its original position;

- differential - represents the difference during which the device is at rest, that is, from the moment of triggering to returning;

- the switched current and voltage are indicators of "durability", because of this, starting from the parameters of the current in the home network, it is necessary to choose a device with a slightly higher value;

- contact resistance;

- time indicator of operation;

- error - this characteristic can have a value of ± 10% of the specified value.

These are the main parameters that each thermostat has. But based on modification, their meaning may change.

If we consider prices, then everything depends on the device:

- Mechanical thermostats. The simplest bottom-type options will cost about $ 20, while its payback is measured literally by the end of its first heating season.

- Programmable thermal relay. Prices for this type of relay start at $ 30; the disadvantages of this type of devices include the presence of batteries, which you need to remember to change periodically.

The range of choice of thermostat is quite large, and naturally their prices can vary quite a lot. But this does not mean that it is necessary to chase the cheapness of the device in order to integrate it into the system. Less high-quality devices cost from 2,000 rubles, you should not pay attention to everything that is cheaper.

Useful Tips

To ensure high-quality and uninterrupted operation of the thermostat for the boiler, and the entire heating system as a whole, it is necessary to take into account some nuances. In this regard, some useful tips:

- The purchase of control equipment is preceded by a calculation that considers such parameters as the required temperature and the area of the heated room. This calculation will avoid the low efficiency of the system and the problems with electrical wiring, which are inevitable when connecting heavy equipment.

- Despite the fairly good compatibility of thermostats with most models of heating boilers, the use of equipment from one manufacturer will provide not only ease of installation, but also ease of use.

- If in doubt about the need to buy expensive equipment, buy a cheaper (mechanical) option and test its capabilities. Perhaps its functionality will be enough.

- Before installing the thermostat, carry out thermal insulation measures in a heated room, since large heat losses will negate the efficiency of the device.

Summarizing the above, we can state that thermostats for heating boilers (water circuits, gas appliances) are increasingly positioned as irreplaceable heating system equipment that provides energy savings, comfortable warmth and coziness in the room.