05.02.2017

Despite the fact that in recent years pipes made of polymer materials have become increasingly popular, steel products are still in great demand. They are still widely used in a number of construction, industrial sectors, and also in the household. Steel pipes (especially galvanized ones) are characterized by strength, durability and extreme ease of installation. What determines the range of steel pipes? First of all, GOSTs, which were regulated in the period from 2003 to 2006, as well as individual regulatory documents that have been in force since the second half of the last century.

Steel pipe assortment

- 1 Key GOSTs for pipes made of steel

- 2 GOST 10707-80

- 3 GOST 30732-2006

- 4 GOST 10706-76 (91)

- 5 GOST 2591-2006 (88)

- 6 GOST 10705-91 (80)

- 7 GOST 9567-75

- 8 GOST 12336-66

- 9 GOST 31447-2012

- 10 Features of the production of seamless pipes 10.1 Video - How to make seamless steel pipes

To begin with, let's take a brief look at the main GOSTs that determine the characteristics of the products described in the article.

GOST 10707-80

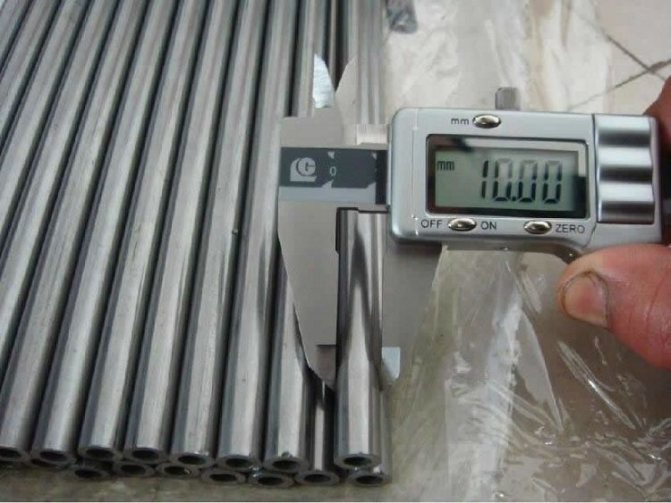

It was developed to regulate cold worked electrowelded products that have varying degrees of accuracy. According to this document, the diameter of the pipes can be from 0.5 to 11 centimeters. Characteristically, only carbon steel is used in the production process. Sometimes another GOST is indicated as a regulatory document (we are talking about 10707-91). This can hardly be considered a mistake, since this year the GOST, regulated in 1980, was extended.

GOST 10707-80. Electric-welded cold-deformed steel pipes. Download file (click on the link below to open the attached file in a new window). GOST 10707-80

Table # 1. Outside diameter and wall thickness of electric-welded cold-deformed steel pipes.

| Outside diameter | Weight 1 m, kg, with wall thickness, mm | |||||||||||||

| pipes, mm | 0,5 | 0,6 | 0,7 | 0,8 | 0,9 | 1,0 | 1,2 | 1,4 | 1,5 | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 |

| 5 | 0,055 | 0,065 | 0,074 | 0,083 | 0,091 | 0,099 | — | — | — | — | — | — | — | — |

| 6 | 0,068 | 0,080 | 0,092 | 0,103 | 0,113 | 0,123 | — | — | — | — | — | — | — | — |

| 7 | 0,080 | 0,095 | 0,109 | 0,122 | 0,135 | 0,148 | — | — | — | — | — | — | — | — |

| 8 | 0,192 | 0,110 | 0,126 | 0,142 | 0,158 | 0,173 | 0,201 | — | — | — | — | — | — | — |

| 9 | 0,105 | 0,124 | 0,143 | 0,162 | 0,180 | 0,197 | 0,231 | — | — | — | — | — | — | — |

| 10 | 0,117 | 0,139 | 0,161 | 0,182 | 0,202 | 0,222 | 0,260 | 0,297 | 0,314 | — | — | — | — | — |

| 11 | 0,129 | 0,154 | 0,178 | 0,201 | 0,224 | 0,247 | 0,290 | 0,331 | 0,351 | 0,371 | 0,408 | 0,444 | 0,447 | 0,524 |

| 12 | 0,142 | 0,169 | 0,195 | 0,221 | 0,246 | 0,271 | 0,320 | 0,336 | 0,388 | 0,410 | 0,453 | 0,493 | 0,532 | 0,586 |

| 13 | — | 0,184 | 0,212 | 0,241 | 0,269 | 0,296 | 0,349 | 0,401 | 0,425 | 0,450 | 0,497 | 0,543 | 0,586 | 0,647- |

| 14 | — | — | 0,230 | 0,260 | 0,291 | 0,321 | 0,378 | 0,435 | 0,462 | 0,489 | 0,542 | 0,592 | 0,640 | 0,709 |

| 15 | — | — | 0,247 | 0,280 | 0,313 | 0,345 | 0,408 | 0,470 | 0,499 | 0,529 | 0,586 | 0,641 | 0,694 | 0,771 |

| 16 | — | — | 0,264 | 0,300 | 0,335 | 0,370 | 0,438 | 0,504 | 0,536 | 0,568 | 0,630 | 0,691 | 0,749 | 0,882- |

| 17 | — | — | — | — | — | 0,395 | 0,468 | 0,532 | 0,573 | 0,608 | 0,675 | 0,740 | 0,803 | 0,894 |

| 18 | — | — | — | — | — | 0,419 | 0,497 | 0,573 | 0,610 | 0,647 | 0,719 | 0,789 | 0,857 | 0,956 |

| 19 | — | — | — | — | — | 0,444 | 0,527 | 0,608 | 0,647 | 0,687 | 0,764 | 0,838 | 0,911 | 1,02 |

| 20 | — | — | — | — | — | 0,469 | 0,556 | 0,642 | 0,684 | 0,726 | 0,808 | 0,888 | 0,966 | 1,08 |

| 21 | — | — | — | — | — | 0,493 | 0,586 | 0,677 | 0,721 | 0,765 | 0,852 | 0,937 | 1,02 | 1,14 |

| 22 | — | — | — | — | — | 0,518 | 0,616 | 0,711 | 0,758 | 0,805 | 0,897 | 0,986 | 1,07 | 1,20 |

| 23 | — | — | — | — | — | 0,543 | 0,645 | 0,746 | 0,795 | 0,844 | 0,941 | 1,04 | 1,13 | 1,26 |

| 24 | — | — | — | — | — | 0,567 | 0,675 | 0,780 | 0,832 | 0,884 | 0,985 | 1,09 | 1,18 | 1,35 |

| 25 | — | — | — | — | — | 0,592 | 0,704 | 0,815 | 0,869 | 0,923 | 1,03 | 1,13 | 1,24 | 1,39 |

| 26 | — | — | — | — | — | 0,617 | 0,734 | 0,849 | 0,906 | 0,963 | 1,07 | 1,18 | 1,29 | 1,45 |

| 27 | — | — | — | — | — | 0,641 | 0,764 | 0,884 | 0,943 | 1,00 | 1,12 | 1,23 | 1,35 | 1,51 |

| 28 | — | — | — | — | — | 0,666 | 0,793 | 0,918 | 0,980 | 1,04 | 1,16 | 1,28 | 1,40 | 1,57 |

| (29) | — | — | — | — | — | 0,691 | 0,823 | 0,953 | 1,02 | 1,08 | 1,21 | 1,33 | 1,45 | 1,63 |

| 30 | — | — | — | — | — | 0,715 | 0,852 | 0,987 | 1,05 | 1,12 | 1,25 | 1,38 | 1,51 | 1,70 |

| 32 | — | — | — | — | — | 0,764 | 0,911 | 1,06 | 1,13 | 1,20 | 1,34 | 1,48 | 1,62 | 1,82 |

| (33) | — | — | — | — | — | 0,789 | 0,941 | 1,09 | 1,17 | 1,24 | 1,39 | 1,53 | 1,67 | 1,88 |

| 34 | — | — | — | — | — | 0,814 | 0,971 | 1,13 | 1,20 | 1,23 | 1,43 | 1,58 | 1,73 | 1,94 |

| 35 | — | — | — | — | — | 0,838 | 1,00 | 1,16 | 1,24 | 1,32 | 1,47 | 1,63 | 1,78 | 2,00 |

| 36 | — | — | — | — | — | 0,863 | 1,03 | 1,20 | 1,28 | 1,36 | 1,52 | 1,68 | 1,83 | 2,07 |

| 38 | — | — | — | — | — | 0,912 | 1,09 | 1,26 | 1,35 | 1,44 | 1,61 | 1,78 | 1,94 | 2,19 |

| 40 | — | — | — | — | — | 0,962 | 1,15 | 1,33 | 1,42 | 1,52 | 1,70 | 1,87 | 2,05 | 2,31 |

| (41,5) | — | — | — | — | — | 0,999 | 1,19 | 1,37 | 1,46 | 1,56 | 1,74 | 1,92 | 2,11 | 2,37 |

| 42 | — | — | — | — | — | 1,010 | 1,21 | 1,40 | 1,50 | 1,59 | 1,79 | 1,97 | 2,16 | 2,44 |

| 43 | — | — | — | — | — | 1,04 | 1,24 | 1,44 | 1,54 | 1,63 | 1,83 | 2,02 | 2,21 | 2,50 |

| 45 | — | — | — | — | — | 1,08 | 1,30 | 1,51 | 1,61 | 1,71 | 1,92 | 2,12 | 2,32 | 2,62 |

| (46) | — | — | — | — | — | 1,11 | 1,33 | 1,54 | 1,64 | 1,75 | 1,96 | 2,17 | 2,38 | 2,68 |

| 48 | — | — | — | — | — | 1,16 | 1,39 | 1,61 | 1,72 | 1,83 | 2,05 | 2,27 | 2,48 | 2,81 |

| (49) | — | — | — | — | — | 1,18 | 1,41 | 1,64 | 1,76 | 1,87 | 2,10 | 2,32 | 2,54 | 2,87 |

| 50 | — | — | — | — | — | 1,21 | 1,44 | 1,63 | 1,79 | 1,91 | 2,14 | 2,37 | 2,59 | 2,93 |

| 51 | — | — | — | — | — | — | — | 1,71 | 1,83 | 1,95 | 2,18 | 2,42 | 2,65 | 2,99 |

| 53 | — | — | — | — | — | — | — | 1,78 | 1,91 | 2,03 | 2,27 | 2,52 | 2,76 | 3,11 |

| 54 | — | — | — | — | — | — | — | 1,82 | 1,94 | 2,07 | 2,32 | 2,57 | 2,81 | 3,18 |

| 55 | — | — | — | — | — | — | — | 1,85 | 1,98 | 2,11 | 2,36 | 2,61 | 2,86 | 3,24 |

| 56 | — | — | — | — | — | — | — | 1,89 | 2,02 | 2,15 | 2,41 | 2,66 | 2,92 | 3,30 |

| 57 | — | — | — | — | — | — | — | 1,92 | 2,05 | 2,19 | 2,45 | 2,71 | 2,97 | 3,36 |

| (59) | — | — | — | — | — | — | — | — | 2,13 | 2,27 | 2,54 | 2,81 | 3,08 | 3,48 |

| 60 | — | — | — | — | — | — | — | — | 2,16 | 2,30 | 2,58 | 2,86 | 3,14 | 3,55 |

| 63 | — | — | — | — | — | — | — | — | 2,28 | 2,42 | 2,72 | 3,01 | 3,30 | 3,73 |

| 65 | — | — | — | — | — | — | — | — | 2,35 | 2,50 | 2,81 | 3,11 | 3,41 | 3,85 |

| 68 | — | — | — | — | — | — | — | — | 2,46 | 2,62 | 2,94 | 3,26 | 3,57 | 4,04 |

| 70 | — | — | — | — | — | — | — | — | 2,53 | 2,70 | 3,03 | 3,35 | 3,68 | 4,16 |

| 73 | — | — | — | — | — | — | — | — | 2,65 | 2,82 | 3,16 | 3,50 | 3,84 | 4,35 |

| 75 | — | — | — | — | — | — | — | — | 2,72 | 2,90 | 3,25 | 3,60 | 3,95 | 4,47 |

| 76 | — | — | — | — | — | — | — | — | 2,76 | 2,94 | 3,29 | 3,65 | 4,00 | 4,53 |

| 77 | — | — | — | — | — | — | — | — | — | — | — | — | — | 4,59 |

| 80 | — | — | — | — | — | — | — | — | — | — | — | — | — | 4,78 |

| 83 | — | — | — | — | — | — | — | — | — | — | — | — | — | 4,96 |

| (87) | — | — | — | — | — | — | — | — | — | — | — | — | — | 5,21 |

| 89 | — | — | — | — | — | — | — | — | — | — | — | — | — | 5,33 |

| 90 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 100 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| (101) | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 102 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 110 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

Table 2. Limit deviations for the outer diameter and wall thickness of pipes.

| Pipe dimensions, mm | Limit deviations of pipe sizes with precision manufacturing | ||

| the usual | increased | precision | |

| Outside diameter: | |||

| from 5 to 10 | + -0.15 mm | + -0.10 mm | — |

| St. 10 to 20 | + -0.20 mm | + -0.12 mm | + -0.10 mm |

| » 20 » 30 | + -0.25mm | + -0.15 mm | + -0.12 mm |

| » 30 » 40 | + -0.30mm | + -0.20 mm | + -0.15 mm |

| » 40 » 50 | + -0.35mm | + -0.25mm | + -0.20 mm |

| » 50 » 60 | +-0,75 % | +-0,6 % | + -0.25mm |

| » 60 » 70 | +-0,75 % | +-0,6 % | + -0.30mm |

| » 70 » 80 | +-0,75 % | +-0,6 % | + -0.35mm |

| » 80 » 90 | +-0,75 % | +-0,6 % | + -0.40 mm |

| » 90 | +-0,75 % | +-0,6 % | + -0.45mm |

| Wall thickness: | |||

| up to 1 | + -0.12 mm | + -0.10 mm | + -0.10 mm |

| St. one | +- 10% | +-8 % | +-7,5% |

Table 3. Mechanical properties of thermally treated pipes.

| steel grade | Ultimate tensile strength sВ, N / mm2 (kgf / mm2) | Limitfluidity sТ ,. N / mm2 (kgf / mm2) | Elongation after breaking s5,% |

| not less | |||

| 08kp | 294 (30) | 175 (18) | 27 |

| 08, 08ps, 10kp | 314 (32) | 196 (20) | 25 |

| 10ps, 15kp, St2sp, Ce2ps, St2kp, VSt2sp, VSt2ps, VSt2kp | 333 (34) | 206 (21) | 25 |

| 10 | 353 (36) | 216 (22) | 24 |

| 15, 15ps, 20kp, St3sp, ST3ps, ST3kp | 372 (38) | 225 (23) | 22 |

| 20, 20ps, St4sp, St4ps, St4kp | 412 (42) | 245 (25) | 21 |

| 08U | 255 (26) | 174 (18) | 30 |

Now let's move on to the next variation.

Range of steel round pipes: the main GOSTs

Round steel pipe, produced in accordance with GOST, is mainly used in water and gas supply systems. Like profile structures, round pipes are produced in various ways, they are seam and seamless. The group of round steel pipes to which the GOST applies is the most extensive and has a rather complex systematization.

The assortment that classifies a round steel pipe according to GOST mainly depends on the method of production of products.

Assortment of seamless steel pipes: GOST 8732-78 (91)

The manufacture of seamless hot-deformed steel pipes in accordance with GOST 8732-78 (91) is a rather long and complicated process. This can explain the high cost of these products. Hot-deformed and cold-rolled seamless pipes are used in special conditions requiring excellent strength of the system: where any leak can lead to irreversible consequences.

The raw material from which hot-deformed seamless pipes are made is a metal billet.From it, subsequently, the piercing process and after significant heating, a hollow cylinder is obtained - a liner. Initially, it has an irregular shape, but after passing through the forming on the rollers, the hot-rolled round pipes become smooth.

Cold rolled tubes are shaped by rolling mill rolls

The product is cut into segments from 4 to 12.5 meters, they can be measured or unmeasured. Hot-rolled steel pipes, corresponding to the accepted GOST, may have insignificant differences in wall thickness. Deviations in diameter are also allowed: if their values do not exceed those given in the table. The permissible deviations in diameter for seamless steel pipes in accordance with GOST 8732-78 (91) are presented in Table 1.

Table 1

| Outside diameter | Permissible deviations of steel pipes with manufacturing accuracy, mm,% | |

| Increased | the usual | |

| Up to 50 mm | +/- 0,5 | +/- 0,5 |

| 50 to 220 mm | +/- 0,8% | +/- 1,0% |

| Over 220 mm | +/- 1,0% | +/- 1,3% |

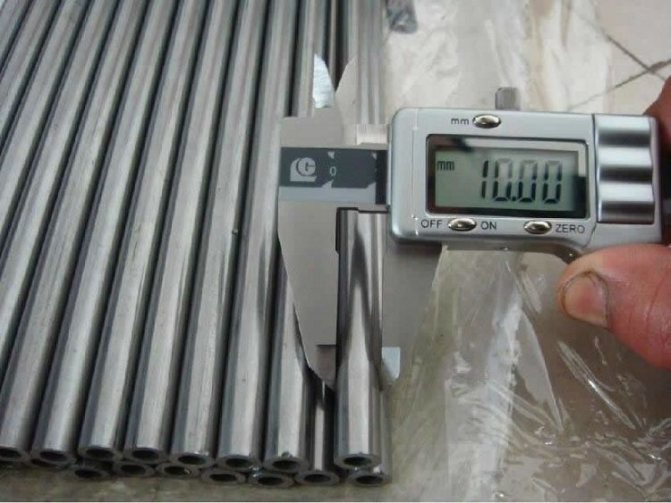

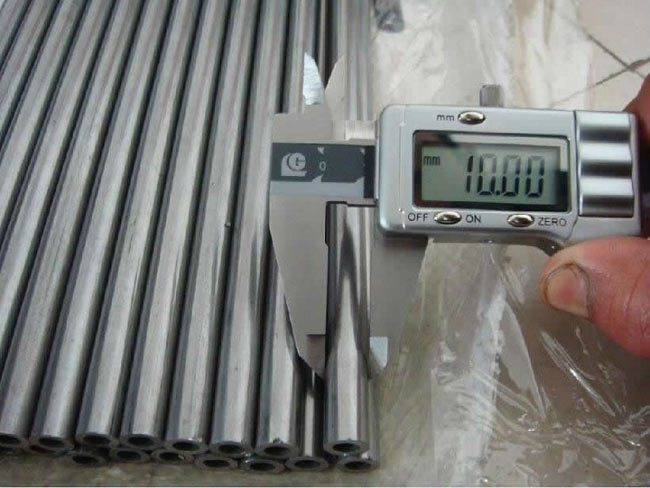

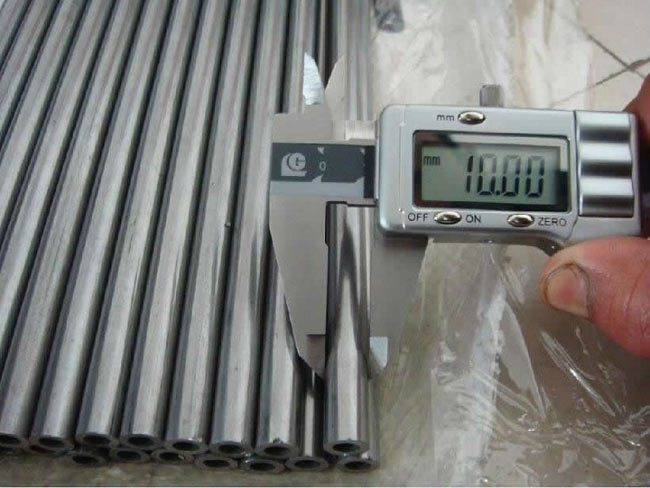

Seamless round steel pipes can also be cold-deformed, in which case their norms will be regulated by GOST 8734-75 (91). The production scheme resembles hot deformation, with the only difference that after passing the piercing process with a press, the metal workpiece is cooled with water.

GOST for seamless cold-rolled steel pipes repeats the provisions specified in the standard for hot-deformed seamless products. The document allows deviations in the dimensions indicated in the table.

table 2

| Original dimensions, outer diameter | Permissible deviations, mm,% |

| 4 mm - 10 mm | +/- 0,15 |

| 11 mm - 30 mm | +/- 0,3 |

| 31 mm - 50 mm | +/- 0,4 |

| More than 51 mm | +/- 0,8% |

Range of longitudinal electric-welded steel pipes: GOST 10705-91

Technical conditions for the production of steel longitudinal electric-welded pipes are dictated by GOST 10707-91.

The range of longitudinal welded pipes includes products of various diameters, including very large ones for industrial pipelines

The most important provisions of this normative document:

- the curvature of round electric-welded pipes in a section of 1 running meter is allowed at 1.5 mm for thermally processed products and for untreated ones - 2 mm. At the request of the customer, the curvature value can be reduced in the first case to 1 mm, in the second - to 1.5 mm.

- if the pipe will undergo heat treatment, at the request of the customer, this process can take place in a protective atmosphere.

- the ends of the longitudinal electric-welded pipe in accordance with GOST 10707-91 are cut at right angles, and also cleaned from irregularities and burrs.

For industrial gas and oil pipeline steel pipes, a separate GOST was allocated. As mentioned above, GOST 52079-2003 applies to steel longitudinal electric-welded pipes with a large diameter.

Important! Also in a special category are steel pipes (welded and seamless) produced for the motorcycle industry. The provisions are governed by GOST 12132-66. On any section of special pipes, curvature of more than 1.5 mm is not allowed. Regulatory Document 12132-66 only permits high or high precision products.

Range of steel pipes for water supply and gas: GOST 3262-75

Gas and water pipes steel were allocated in a separate GOST, although in fact they are the most common electric-welded.

Electric-welded steel pipes for water and gas pipelines in accordance with GOST 3262-75 are commercially available in measured or off-gauge length. The range of segments in this case is from 4 to 12 m.

Welded pipes are produced in limited lengths - maximum 12 meters

The curvature of water and gas pipes is allowed, but its value should not exceed two mm per linear meter, if the nominal bore is less than 20 mm. For VGP pipes with a nominal bore exceeding 20 mm, the curvature is allowed at 1.5 mm.

Gas and water pipes are threaded, which can be short or long. When sending the pipe to the enterprise, a decrease in the inner diameter of no more than 10% in the places of the rolled thread can be allowed.GOST imposes the requirements for the thread on a steel electric-welded pipe, which are presented in the table.

Table 3

| Conditional pass | Number of threads at conditional passage | Thread lengths | Conditional pass | Number of threads at conditional passage | Thread length (mm) | ||

| long | short | long | short | ||||

| 6 mm | Not | Not | Not | 50 mm | 11 | 24 | 17 |

| 8 mm | Not | Not | Not | 65 mm | 11 | 27 | 19,5 |

| 10 mm | Not | Not | Not | 80 mm | 11 | 30 | 22 |

| 15 mm | 14 | 14 | 9,0 | 90 mm | 11 | 33 | 26 |

| 20 mm | 14 | 16 | 10,5 | 100 mm | 11 | 36 | 30 |

| 25 mm | 11 | 18 | 11,0 | 125 mm | 11 | 38 | 33 |

| 32 mm | 11 | 20 | 13,0 | 150 mm | 11 | 42 | 36 |

| 40 mm | 11 | 22 | 15,0 | ||||

In households, thin-walled VHP pipes are more often used. Their wall thickness does not exceed 4 mm, but it is also not less than 1.8 mm. Thin-walled steel VGP pipes meet all technical requirements and withstand the pressure in the system without any problems.

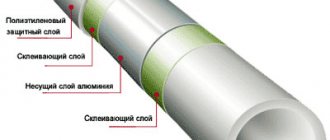

Steel pipe in polyurethane foam insulation according to GOST 30732-2006

Separately, it is necessary to highlight steel pipes insulated with polyurethane foam. They have special technical characteristics that differ from conventional steel products. GOST 30732-2006 also dictates the rules and procedure for the manufacture of shaped products.

Pipes with insulation are used for the installation of heating mains and water pipelines, if they are located above the level of soil freezing

In accordance with the state standard numbered 30732-2006, these pipes have a multilayer structure (pipe in pipe):

- Steel pipe. Directly working tube of circular cross-section, which can be produced in any way. According to GOST 30732-2006, insulated steel pipes can also be galvanized. In this case, their qualities will be even higher. The steel grade is selected depending on the method of further operation: the price of the product will also depend on this.

- PU foam layer for insulation. It is a rather thick layer of polyurethane foam insulating material, applied either by pouring a liquid substance, or by putting on a ready-made "shell" cover. PU foam has increased moisture resistance and helps to retain heat. PU foam insulation can be normal or reinforced, depending on the weather conditions in the region.

- Protective insulation sheath. For long-term preservation of PU foam insulation, special protective shells made of low-pressure polyethylene (HDPE) or an additional layer of galvanized steel are used. The latter option will be more cumbersome and efficient.

According to GOST 30732-2006, bare copper wires are used as indicator conductors for pipes. This technology allows you to remotely track leak points.

The main advantages of a steel pipe in polyurethane foam, manufactured in accordance with the aforementioned GOST 30732-2006, are non-susceptibility to corrosion (products do not require additional anti-corrosion measures), low heat losses (no more than 1-2%) and relatively light weight (pipes in polyurethane foam - insulation is much lighter than PPM or APB insulation). In addition, steel pipes with insulation in accordance with GOST 30732-2006 can be laid without channels and wells.

Pipeline with PU foam insulation requires constant checks for the integrity of the insulating material

At the same time, the isolated structures according to document 30732-2006 have a number of disadvantages. The most significant are the flammability of PU foam insulation and the fairly rapid spread of corrosion in the event of damage to the protective shell. Therefore, such systems require constant monitoring of the integrity of the material. If a certain insulated area is damaged, the entire network will need to be replaced: repair of an individual segment is impossible.

Range of precision steel pipes: GOST 9567-75

A separate GOST 9567-75 applies to this group of steel pipes, since special requirements are imposed on the production of high-precision products. The range includes precision steel pipes, different in the manufacturing method and wall thickness. GOST regulates the following types of wall thicknesses for precision steel pipes:

- especially thin-walled pipes: the ratio of the diameter to the wall thickness is more than 40; wall thickness less than 0.5 mm.

- thin-walled pipes: the first indicator is less than or equal to 40; wall thickness - 1.5 mm or less.

- thick-walled pipes: the first indicator is from 6 to 12.5.

- extra thick-walled pipes: the first indicator is less than 6.

Precision pipes are seamless. They are characterized by increased isotropic rigidity. Even thin-walled steel pipes in accordance with GOST 9567-75 can be used in hydraulic and other fairly complex and precise systems.

Precision pipes are available in galvanized or phosphated, oiled surfaces.

Precision pipes are products with increased demands on quality and dimensional accuracy

A thin-walled or thick-walled precision steel pipe in accordance with GOST 9567-75 is produced in measured or unmeasured lengths up to 8 m. Longer structures are produced in agreement with the customer.

GOST 30732-2006

This document applies not only to steel pipes, but also to various types of connecting elements that have a thermal insulating layer. By the way, pipes, the thermal insulation layer in which is made of polyurethane foam and enclosed in a special PET shell, are actively used in the arrangement of underground heating mains.

Note! The temperature of the working fluid in this case is allowed no more than 140 degrees (or 150 degrees, but this is a short-term indicator).

At the same time, the indicator of the limiting pressure in this case can be a maximum of 1.6 MPa, which is not so much.

GOST 30732-2006. Steel pipes and fittings with thermal insulation made of polyurethane foam with a protective sheath. Download file (click on the link below to open the attached file in a new window). GOST 30732-2006

Table 4. Dimensions of pipes in a polyethylene sheath (in millimeters).

| Outside diameter and minimum wall thickness of steel pipes * | Type 1 | Type 2 | ||||

| Average outer diameter of insulated pipes with polyethylene sheath | Estimated thickness of the polyurethane foam layer | Average outer diameter of insulated pipes with polyethylene sheath | Estimated thickness of the polyurethane foam layer | |||

| Nominal | Limit deviation (+) | Nominal | Limit deviation (+) | |||

| 32?3,0 | 90; 110; 125 | 2,7; 3,5; 3,7 | 26,0; 36,5; 43,5 | — | — | — |

| 38?3,0 | 110; 125 | 3,2; 3,7 | 33,0; 40,5 | — | — | — |

| 45?3,0 | 125 | 3,7 | 37,0 | — | — | — |

| 57?3,0 | 125 | 3,7 | 31,5 | 140 | 4,1 | 38,5 |

| 76?3,0 | 140 | 4,1 | 29,0 | 160 | 4,7 | 39,0 |

| 89?4,0 | 160 | 4,7 | 32,5 | 180 | 5,4 | 42,5 |

| 108?4,0 | 180 | 5,4 | 33,0 | 200 | 5,9 | 43,0 |

| 133?4,0 | 225 | 6,6 | 42,5 | 250 | 7,4 | 54,5 |

| 159?4,5 | 250 | 7,4 | 41,5 | 280 | 8,3 | 55,5 |

| 219?6,0 | 315 | 9,8 | 42,0 | 355 | 10,4 | 62,0 |

| 273?7,0 | 400 | 11,7 | 57,0 | 450 | 13,2 | 81,5 |

| 325?7,0 | 450 | 13,2 | 55,5 | 500 | 14,6 | 79,5 |

| 426?7,0 | 560 | 16,3 | 58,2 | 600; 630 | 16,3 | 77,6; 92,5 |

| 530?7,0 | 710 | 20,4 | 78,9 | — | — | — |

| 630?8,0 | 800 | 23,4 | 72,5 | — | — | — |

| 720?8,0 | 900 | 26,3 | 76,0 | — | — | — |

| 820?9,0 | 1000 | 29,2 | 72,4 | 1100 | 32,1 | 122,5 |

| 920?10,0 | 1100 | 32,1 | 74,4 | 1200 | 35,1 | 120,5 |

| 1020?11,0 | 1200 | 35,1 | 70,4 | — | — | — |

| 1220?11,0 | 1425 | 38,2 | 79,0 | — | — | — |

| 1420?12,0 | 1600 | 41,2 | 90,0 | — | — | — |

| * The wall thickness of the steel pipe is set in the project. By agreement with the design organization, it is also allowed to use pipes of other diameters. | ||||||

Table 5. Dimensions of pipes in a steel casing (in millimeters).

| Outside diameter of steel pipe and minimum wall thickness of steel pipe * | Dimensions of galvanized sheet steel sheath | Estimated layer thickness polyurethane foam ** | |

| Nominal diameter | Minimum thickness | ||

| 32?3,0 | 100; 125; 140 | 0,55 | 46,0; 53,5 |

| 38?3,0 | 125; 140 | 0,55 | 43,0; 50,5 |

| 45?3,0 | 125; 140 | 0,55 | 39,5; 47,0 |

| 57?3,0 | 140 | 0,55 | 40,9 |

| 76?3,0 | 160 | 0,55 | 41,4 |

| 89?4,0 | 180 | 0,6 | 44,9 |

| 108?4,0 | 200 | 0,6 | 45,4 |

| 133?4,0 | 225 | 0,6 | 45,4 |

| 159?4,5 | 250 | 0,7 | 44,8 |

| 219?6,0 | 315 | 0,7 | 47,3 |

| 273?7,0 | 400 | 0,8 | 62,7 |

| 325?7,0 | 450 | 0,8 | 61,7 |

| 426?7,0 | 560 | 1,0 | 66,2 |

| 530?7,0 | 675; 710 | 1,0 | 71,5; 89,0 |

| 630?8,0 | 775; 800 | 1,0 | 71,5; 84,0 |

| 720?8,0 | 875; 900 | 1,0 | 76,5; 89,0 |

| 820?9,0 | 975; 1000 | 1,0 | 76,5; 89,0 |

| 920?10,0 | 1075; 1100 | 1,0 | 76,5; 89,0 |

| 1020?11,0 | 1175; 1200 | 1,0 | 76,7; 89,2 |

| 1220?11,0 | 1375; 1400 | 1,0 | 79,0; 91,5 |

| 1420?12,0 | 1575;1600 | 1,0 | 77,0; 89,5 |

| * The wall thickness of the steel pipe is determined by the project. ** The value is for reference. | |||

Table 6. Dimensions of polyethylene sheathing pipes (in millimeters)

| Average outer diameter | Wall thickness | ||

| Nominal | Limit deviation | Minimum | Limit deviation |

| 90 | +0,9 | 2,2 | +0,4 |

| 110 | +1,0 | 2,5 | +0,5 |

| 125 | +1,2 | 2,5 | +0,5 |

| 140 | +1,3 | 3,0 | +0,5 |

| 160 | +1,5 | 3,0 | +0,5 |

| 180 | +1,7 | 3,0 | +0,5 |

| 200 | +1,8 | 3,2 | +0,5 |

| 225 | +2,1 | 3,5 | +0,6 |

| 250 | +2,3 | 3,9 | +0,7 |

| 280 | +2,6 | 4,4 | +0,7 |

| 315 | +2,9 | 4,9 | +0,7 |

| 355 | +3,2 | 5,6 | +0,8 |

| 400 | +3,6 | 5,6 | +0,9 |

| 450 | +4,1 | 5,6 | +1,1 |

| 500 | +4,5 | 6,2 | +1,2 |

| 560 | +5,0 | 7,0 | +1,3 |

| 630 | +5,7 | 7,9 | +1,5 |

| 710 | +6,4 | 8,9 | +1,7 |

| 800 | +7,2 | 10,0 | +1,9 |

| 900 | +8,1 | 11,2 | +2,2 |

| 1000 | +9,0 | 12,4 | +2,4 |

| 1100 | +9,9 | 13,8 | +2,7 |

| 1200 | +10,8 | 14,9 | +2,9 |

| 1425 | +12,6 | 17,3 | +3,4 |

| 1600 | +14,4 | 19,6 | +3,9 |

Table 7. Deviation of the center lines of the steel pipe and shell (in millimeters).

| Outer diameter of shells | Centerline deviation |

| Up to 160 incl. | 3,5 |

| St. 160 to 400 incl. | 5,0 |

| St. 400 to 630 incl. | 8,0 |

| St. 630 to 800 incl. | 10,0 |

| St. 800 to 1200 incl. | 14,0 |

| St. 1200 to 1375 incl. | 16,0 |

| St. 1375 to 1600 incl. | 18,0 |

Table 8. Calculated values of the thickness of the PU foam insulation for different areas (in millimeters).

| Outside diameter of pipes | Calculated values of PU foam insulation thickness / outer diameter of shells | ||||||

| European regions | Ural | Western Siberia | Eastern Siberia | Far East | |||

| South | Centre | North | |||||

| 57 | 31,5/125 | 31,5/125 | 31,5/125 | 31,5/125 | 31,5/125 | 38,5/140 | 31,5/125 |

| 76 | 29/140 | 29/140 | 39/160 | 39/160 | 39/160 | 39/160 | 39/160 |

| 89 | 32,5/160 | 32,5/160 | 42,5/180 | 42,5/180 | 42,5/180 | 42,5/180 | 42,5/180 |

| 108 | 33/180 | 33/180 | 43/200 | 43/200 | 43/200 | 43/200 | 43/200 |

| 133 | 42,5/225 | 42,5/225 | 42,5/225* | 42,5/225 | 42,5/225 | 54,5/250 | 42,5/225 |

| 159 | 41,5/250 | 41,5/250 | 55,5/280 | 41,5/250* | 55,5/280 | 55,5/280 | 55,5/280 |

| 219 | 42/315 | 62/355 | 62/355 | 62/355 | 62/355 | 62/355 | 62/355 |

| 273 | 57/400 | 57/400 | 57/400* | 57/400 | 57/400* | 81,5/450 | 57/400 |

| 325 | 55,5/450 | 55,5/450 | 79,5/500 | 55,5/450* | 79,5/500 | 79,5/500 | 79,5/500 |

| 426 | 58,2/560 | 58,2/560* | 92,4/630 | 92,4/630 | 92,4/630 | 92,4/630 | 92,4/630 |

| 530 | 79/710 | 79/710 | 79/710 | 79/710 | 79/710 | 79/710 | 79/710 |

| 630 | 72,5/800 | 72,5/800 | 72,5/800* | 72,5/800 | 72,5/800 | 72,5/800 | 72,5/800 |

| 720 | 76/900 | 76/900 | 76/900 | 76/900 | 76/900 | 76/900* | 76/900 |

| 820 | 72,5/1000 | 72,5/1000 | 122,5/1100 | 72,5/1000 | 72,5/1000* | 122,5/1100 | 72,5/1000* |

| 920 | 74,5/1100 | 74,5/1100 | 120,5/1200 | 74,5/1100 | 74,5/1100* | 120,5/1200 | 74,5/1100* |

| 1020 | 70,5/1200 | 70,5/1200* | ** | 70,5/1200* | ** | ** | ** |

| 1220 | 79,0/1425 | 79,0/1425 | ** | 79/1400* | ** | ** | ** |

| 1420 | 90,0/1600 | 90,0/1600 | ** | 90,0/1600* | ** | ** | ** |

| * The thickness of the pipe insulation is taken less than the calculated one according to the conditions of normalized heat loss. ** The thickness of the pipe insulation is determined by the non-standard outer diameter of the polyethylene sheath. | |||||||

Technical features of steel pipes

Steel pipes are strong, reliable and durable products that can be used in various areas of construction, industry and everyday life. They can be mounted in an open or closed way. Steel pipelines can be used for transporting gases and liquids, as protection for signal and power cables.

The main disadvantage of steel pipes is the high mass of the product, which depends on the diameter of the structure and the thickness of its wall.

Despite the high strength characteristics, the use of metal pipes has its limitations associated with freezing of products and their low resistance to the formation of corrosion and various deposits. If they are used for cold water supply, it is 10-20 years, for heating - 10-15 years. The material is able to withstand the working temperature of the liquid up to 130 ° C and the pressure up to 30 atm. Metal pipes are characterized by non-flammability and resistance to mechanical damage.

Helpful advice! To ensure a long service life of a steel product, pipes with an anti-corrosion coating should be chosen.

Among the shortcomings of the material, one can single out the high weight of the product, which depends on the diameter of the structure and the thickness of its wall, high thermal conductivity, and increased internal roughness. The installation of metal pipes requires special equipment, high qualifications of the master and significant time costs. Since the material is not resistant to corrosion, the pipe should be painted after installation. Such a procedure will not only improve the aesthetic appearance of the product, but also extend its service life.

Steel pipes have high strength characteristics, but at the same time there are limitations associated with freezing of products and low resistance to corrosion.

GOST 10706-76 (91)

Here we are talking about electrically welded products, still made of steel, but with a straight seam. Pipes of this kind are actively used for general purposes. Note also that the minimum pipe diameter, according to this regulatory document, should be 42.5 centimeters, and the maximum - 162 centimeters.

GOST 10706-76 (91). Longitudinal electric-welded steel pipes. Download file (click on the link below to open the attached file in a new window). GOST 10706-76 (91)

Table 9. Longitudinal electric-welded steel pipes.

| Outside diameter, mm | Theoretical mass of 1 m of pipes, kg, with wall thickness, mm | ||||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | 3,0 | |

| 10 | 0,222 | 0,260 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| 10,2 | 0,227 | 0,266 | — | — | — | — | — | — | — | — | — |

| 12 | 0,271 | 0,320 | 0,366 | 0,388 | 0,410 | — | — | — | — | — | — |

| 13 | 0,296 | 0,349 | 0,401 | 0,425 | 0,450 | — | — | — | — | — | — |

| 14 | 0,321 | 0,379 | 0,435 | 0,462 | 0,489 | — | — | — . | — | — | — |

| (15) | 0,345 | 0,408 | 0,470 | 0,499 | 0,529 | — | — | — | — | — | — |

| 16 | 0,370 | 0,438 | 0,504 | 0,536 | 0,568 | — | — | — | — | — | — |

| (17) | 0,395 | 0,468 | 0,539 | 0,573 | 0,608 | — | — | — | — | — | — |

| 18 | 0,419 | 0,497 | 0,573 | 0,610 | 0,719 | 0,789 | — | — | — | — | — |

| 19 | 0,444 | 0,527 | 0,608 | 0,647 | 0,687 | 0,764 | 0,838 | — | — | — | — |

| 20 | 0,469 | 0,556 | 0,642 | 0,684 | 0,726 | 0,808 | 0,888 | — | — | — | — |

| 21,3 | 0,501 | 0,595 | 0,687 | 0,732 | 0,777 | 0,866 | 0,952 | — | — | — | — |

| 22 | 0,518 | 0,616 | 0,711 | 0,758 | 0,805 | 0,897 | 0,986 | — | — | — | — |

| (23) | 0,543 | 0,645 | 0,746 | 0,795 | 0,844 | 0,941 | 1,04 | 1,13 | 1,26 | 3/4 | — |

| 24 | 0,567 | 0,675 | 0,780 | 0,832 | 0,884 | 0,985 | 1,09 | 1,18 | 1,33 | — | — |

| 25 | 0,592 | 0,704 | 0,815 | 0,869 | 0,923 | 1,03 | 1,13 | 1,24 | 1,39 | — | — |

| 26 | 0,617 | 0,734 | 0,849 | 0,906 | 0,963 | 1,07 | 1,18 | 1,29 | 1,45 | — | |

| 27 | 0,641 | 0,764 | 0,884 | 0,943 | 1,00 | 1,12 | 1.23 | 1,35 | 1,51 | — | |

| 28 | 0,666 | 0,793 | 0,918 | 0,980 | 1,04 | 1,16 | 1,28 | 1,40 | 1,57 | — | |

| 30 | 0,715 | 0,852 | 0,987 | 1,05 | 1,12 | 1,25 | 1,38 | 1,51 | 1,70 | — | |

| 32 | 0,765 | 0,911 | 1,06 | 1,13 | 1,20 | 1,34 | 1,48 | 1,62 | 1,82 | 2,02 | |

Continuation of table. 8

| Outside diameter, mm | Theoretical mass of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | |

| 33 | 0,789 | 0,941 | 1,09 | 1,17 | 1,24 | 1,38 | 1,53 | 1,67 | 1,88 | 2,09 |

| 33,7 | — | 0,962 | 1,12 | 1,19 | 1,27 | 1,42 | 1,56 | 1,71 | 1,92 | 2,13 |

| 35 | — | 1,00 | 1,16 | 1,24 | 1,32 | 1,47 | 1,63 | 1,78 | 2,00 | 2,22 |

| 36 | — | 1,03 | 1,19 | 1,28 | 1,36 | 1,52 | 1,68 | 1,83 | 2,07 | 2,29 |

| 38 | — | 1,09 | 1,26 | 1,35 | 1,44 | 1,61 | 1,78 | 1,94 | 2,19 | 2,43 |

| 40 | — | 1,15 | 1,33 | 1,42 | 1,52 | 1,70 | 1,87 | 2,05 | 2,31 | 2,57 |

| 42 | — | 1,21 | 1,40 | 1,50 | 1,59 | 1,78 | 1,97 | 2,16 | 2,44 | 2,71 |

| 44,5 | — | 1,28 | 1,49 | 1,59 | 1,69 | 1,90 | 2,10 | 2,29 | 2,59 | 2,88 |

| 45 | — | 1,30 | 1,51 | 1,61 | 1,71 | 1,92 | 2,12 | 2,32 | 2,62 | 2,91 |

| 48 | — | — | 1,61 | 1,72 | 1,83 | 2,05 | 2,27 | 2,48 | 2,81 | 3,12 |

| 48,3 | — | — | 1,62 | 1,73 | 1,84 | 2,06 | 2,28 | 2,50 | 2,82 | 3,14 |

| 51 | — | — | 1,71 | 1,83 | 1,95 | 2,18 | 2,42 | 2,65 | 2,99 | 3,33 |

| 53 | — | — | 1,78 | 1,91 | 2,03 | 2,27 | 2,52 | 2,76 | 3,11 | 3,47 |

| 54 | — | — | 1,82 | 1,94 | 2,07 | 2,32 | 2,56 | 2,81 | 3,18 | 3,54 |

| 57 | — | — | 1,92 | 2,05 | 2,19 | 2,45 | 2,71 | 2,97 | 3,36 | 3,74 |

| 60 | — | — | 2,02 | 2,16 | 2,30 | 2,58 | 2,86 | 3,14 | 3,55 | 3,95 |

| 63,5 | — | — | 2,14 | 2,29 | 2,44 | 2,74 | 3,03 | 3,33 | 3,76 | 4,19 |

| 70 | — | — | 2,37 | 2,53 | 2,70 | 3,03 | 3,35 | 3,68 | 4,16 | 4,64 |

| 73 | 3/4 | 3/4 | 2,47 | 2,64 | 2,82 | 3,16 | 3,50 | 3,84 | 4,35 | 4,85 |

| 76 | — | — | 2,58 | 2,76 | 2,94 | 3,29 | 3,65 | 4,00 | 4,53 | 5,05 |

| 88 | — | — | — | — | 3,21 | 3,60 | 4,00 | 4,38 | 4,96 | 5,54 |

| 89 | — | — | — | — | 3,45 | 3,87 | 4,29 | 4,71 | 5,33 | 5,95 |

| 95 | 3/4 | — | — | — | — | — | 4,59 | — | 5,70 | — |

| 102 | 3/4 | 3/4 | 3/4 | — | — | 4,45 | 4,93 | 5,41 | 6,13 | 6,85 |

| 108 | 3/4 | — | — | — | — | 4,71 | 5,23 | 5,74 | 6,50 | 7,26 |

| 114 | — | — | — | — | — | 4,98 | 5,52 | 6,07 | 6,87 | 7,68 |

| 127 | — | — | — | — | — | 5,56 | 6,17 | 6,77 | 7,68 | 8,58 |

Continuation of table. 8

| Outside diameter, mm | Theoretical mass of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | |

| 133 | — | — | — | — | — | 5,82 | 6,46 | 7,10 | 8,05 | 8,99 |

| 140 | — | — | — | — | — | 6,13 | 6,81 | 7,48 | 8,48 | 9,47 |

| 152 | 3/4 | — | — | — | — | 6,67 | 7,40 | 8,13 | 9,22 | 10,30 |

| 159 | — | — | — | — | — | 6,98 | 7,74 | 8,51 | 9,65 | 10,79 |

| 168 | — | — | — | — | — | 7,38 | 8,19 | 9,00 | 10,20 | 11,41 |

| 177,8 | — | — | — | — | — | 7,81 | 8,67 | 9,53 | 10,81 | 12.08 |

| 180 | — | — | — | — | — | — | — | — | — | — |

| 193,7 | — | — | — | — | — | — | 9,46 | 10,39 | 11,79 | 13,18 |

| 219 | — | — | — | — | — | — | — | — | 13,35 | 14,93 |

| 244,5 | — | — | — | — | — | — | — | — | — | — |

Continuation of table. 8

| Outside diameter, mm | Theoretical mass of 1 m of pipes, kg, with wall thickness, mm | ||||||||||

| 3,0 | 3,2 | 3,5 | 3,8 | 4,0 | 4,5 | 5,0 | 5,5 | 6,0 | 7,0 | 8,0 | |

| 26 | — | — | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| 27 | — | — | — | — | — | — | — | — | — | — | — |

| 28 | — | — | — | — | — | — | — | — | — | — | — |

| 30 | — | — | — | — | — | — | — | — | — | — | — |

| 32 | 2,15 | — | — | — | — | — | — | — | — | — | — |

| 33 | 2,22 | — | — | — | — | — | — | — | — | — | — |

| 33,7 | 2,27 | — | — | — | — | — | — | — | — | — | — |

| 35 | 2,37 | — | — | — | — | — | — | — | — | — | — |

| 36 | 2,44 | — | — | — | — | — | — | — | 3/4 | 3/4 | 3/4 |

| 38 | 2,59 | — | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| 40 | 2,74 | — | — | — | — | — | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| 42 | 2,89 | — | — | — | — | — | — | — | — | — | 3/4 |

| 44,5 | 3,07 | — | — | — | — | — | — | — | — | — | — |

| 45 | 3,11 | — | — | — | — | — | — | — | — | — | 3/4 |

| 48 | 3,33 | 3,54 | 3,84 | — | — | — | — | — | — | — | — |

| 48,3 | 3,35 | 3,56 | 3,87 | — | — | — | — | — | — | — | — |

| 51 | 3,55 | 3,77 | 4,10 | — | — | — | — | — | — | — | — |

| 53 | 3,70 | 3,93 | 4,27 | — | — | — | — | — | — | — | — |

| 54 | 3,77 | 4,01 | 4,36 | — | — | — | — | — | — | — | — |

Table 9. Limit deviations for the outer diameter of the pipe

| Outside diameter of pipes, mm | Limit deviations for the outer diameter with manufacturing accuracy | |

| the usual | increased | |

| 10 | + -0.2 mm | 3/4 |

| St. 10 to 30 incl. | + -0.3 mm | +-0,25 |

| » 30 » 51 » | + -0.4 mm | +-0,35 |

| » 51 » 193,7 » | +-0,8 % | +-0,7 % |

| »193,7 » 426 » | +-0,75 % | +-0,65 % |

| » 426 » 1020 » | +-0,7 % | +-0,65 % |

| » 1020 | +-0,6 % | + -6.0 mm |

Thick-walled steel pipe

The production and assortment of thick-walled steel pipes is regulated by the requirements of GOST 8734-75. Depending on the technology used, these products are of two types:

- seamless;

- welded.

If, when choosing, strength is at the forefront, that is, the ability to withstand high pressure, the best solution would be to purchase a seamless thick-walled pipe. When the price factor prevails, in order to save money, preference should be given to welded thick-walled products. Weight characteristics of pipes of large diameter with thick walls GOST 10706-76 are presented in the table.

In systems with high pressure, pipes with a large wall thickness must be used.

Table 3

| Outside diameter, mm | Weight of 1 meter (kg) of thick-walled pipe with wall thickness (mm) | |||||||||

| 20 | 18 | 16 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | |

| 1420 | 697,4 | 628,6 | 559,5 | 490,3 | 455,6 | 420,9 | 386,1 | 351,2 | _____ | ______ |

| 1220 | 597,8 | 538,9 | 479,8 | 420,5 | 390,8 | 361,1 | 331,3 | 301,4 | 271,5 | ______ |

| 1120 | 547,9 | 486,0 | 439,9 | 385,7 | 358,5 | 331,2 | 303,9 | 276,5 | 249,1 | 221,6 |

| 1020 | 498,2 | 449,2 | 400,1 | 350,8 | 326,1 | 301,3 | 276,5 | 251,6 | 226,6 | 201,7 |

| 920 | 448,4 | 404,4 | 360,3 | 315,9 | 293,7 | 271,4 | 249,1 | 226,7 | 204,2 | 181,7 |

| 820 | 398,5 | 359,6 | 320,4 | 281,1 | 261,3 | 241,5 | 221,7 | 201,8 | 181,8 | 161,8 |

| 720 | 348,7 | 314,7 | 280,6 | 246,2 | 228,9 | 211,6 | 194,3 | 176,9 | 159,4 | 141,9 |

| 630 | 303,9 | 274,4 | 244,7 | 214,8 | 199,8 | 184,7 | 169,6 | 154,4 | 139,2 | 123,9 |

| 530 | 254,1 | 229,6 | 204,9 | 179,9 | 167,4 | 154,8 | 142,2 | 129,5 | 116,8 | 104,0 |

Taking into account the geometric dimensions of thick-walled pipes, their connection is carried out using a special technology.Standard gas welding is ineffective here, since it cannot heat the entire wall to the melting point of the material. The result is only an unreliable surface seam that can break under high pressure. Therefore, a special tool is required for the installation of thick-walled pipes.

Helpful information! Electric welding is best suited. However, you can only work with electrodes with a diameter greater than 4 mm and only at high voltages. Not every device is capable of producing such indicators over a long time interval when working with thick-walled pipes.

Before starting welding, these products must be cleaned and prepared without fail. Often a special compound is applied to the surface of a thick-walled steel pipe.

It is necessary to understand that the process of creating a high-quality connection will take a lot of time. Electric welding of even ordinary products cannot be called fast. And the duration of work with thick-walled pipes will increase even more.

Steel pipes are connected only by welding, and this is a rather laborious process.

GOST 10705-91 (80)

In this case, we are talking about longitudinal electric-welded products, the diameter of which ranges from 1 to 63 centimeters. In the production process, the same carbon steel is used. Pipes are characterized by a fairly wide scope of application, but, as a rule, they are found in pipelines intended for transporting water.

GOST 10705-91 (80). Electric-welded steel pipes. Download file (click on the link below to open the attached file in a new window). GOST 10705-91 (80)

Table 11. Electric-welded steel pipes - mass fraction of the element,%

| steel grade | Mass fraction of the element,% | ||||||||||

| Carbon | Silicon | Manganese | Aluminum | Titanium | Chromium | Nitrogen | Calcium | Sulfur | Phosphorus | ||

| no more | |||||||||||

| 22GU | 0,15-0,22 | 0,15-0,30 | 1,20-1,40 | 0,02-0,05 | 0,03 | 0,4 | 0,012 | 0,02 | 0,01 | 0,02 | |

Table 12. Mechanical properties of the base metal of heat-treated and hot-rolled carbon steel pipes.

| steel grade | Ultimate resistance in, N / mm2 (kgf / mm2) | Yield strength t N / mm2 (kgf / mm2) | Elongation 5,% | steel grade | Ultimate resistance in, N / mm2 (kgf / mm2) | Yield strength t N / mm2 (kgf / mm2) | Elongation 5,% |

| not less | not less | ||||||

| 08Yu | 255 (26) | 174 (18) | 30 | 15, 15ps, 20kp, St3ps, St3sp, St3kp | 372 (38) | 225 (23) | 22 |

| 08kp | 294 (30) | 174 (18) | 27 | ||||

| 08, 08ps, 10kp | 314 (32) | 196 (20) | 25 | ||||

| 10, 10ps, 15kp, St2sp, St2kp, St2ps | 333 (34) | 206 (21) | 24 | 20, 20ps, St4sp, St4ps, St4kp | 412 (42) | 245 (25) | 21 |

Hot and cold formed seamless steel pipes

Hot and cold rolling are two fundamentally different technologies. Each of them has its own advantages and disadvantages.

For the production of hot rolled pipe, a high temperature is required to heat the billet

Cold rolling involves the processing of plastic material only by pressure. Hot-rolled pipes are made by rolling a billet heated to a predetermined temperature on a continuous mill.

Cold-deformed pipes. The range of products of this type is determined by GOST 8734-75. The full list of possible sizes is extensive here. The diameter can be 5 ... 250 millimeters, and the wall thickness is from 0.3 to 24 millimeters. Pipes are available in measured and unmeasured lengths. In the latter case, the value of this parameter fluctuates in the range of 11.5 meters.

Helpful information! The advantage and distinctive feature of a cold-deformed pipe is a significantly increased safety margin (compared to a conventional pipe - by almost a quarter. Accordingly, the pressure of the working medium can be increased by the same amount.

Hot deformation seamless pipes. The production and assortment of such products is regulated by GOST 8732-78. The size chart is also very large. It includes pipes with a diameter of 20 ... 550 millimeters and with a wall thickness of 2.5 to 75 (!) Millimeters. Such standard sizes determine the considerable weight of hot-deformed products. Suffice it to say that the mass of one running meter of a 550 × 75 pipe is almost a ton, more precisely 878 kg. They are able to withstand high pressure.They are not afraid of even 16 MPa!

Both types of pre-insulated products can be found on the market today. The advantages of an insulated pipe abound. This is resistance to the effects of chemically aggressive compounds, and minimization of heat loss during transportation of the working medium, and so on. But perhaps the most important is that the service life of the insulated steel pipe is about 30 years.

GOST 9567-75

An interesting fact: today the version of GOST is used, which was adopted back in 1975. On the product side, we are talking about precision steel tubes with increased precision. These can be both hot and cold rolled products, as well as chrome / galvanized elements. The scope of such pipes is mainly the engineering industry.

GOST 9567-75. Precision steel pipes. Download file (click on the link below to open the attached file in a new window). GOST 9567-75

Table 13. Dimensions and weight of 1 m of hot-rolled pipes.

| Outside diameter, mm | Weight of 1 m of pipes, kg, with wall thickness, mm | |||||

| 2,5 | 2,8 | 3,0 | 3,5 | 4,0 | 4,5 | |

| 25 | 1,387 | 1,583 | 1,628 | 1,856 | 2,072 | 2,275 |

| 28 | 1,572 | 1,740 | 1,850 | 2,115 | 2,368 | 2,608 |

| 32 | 1,819 | 2,016 | 2,146 | 2,460 | 2,762 | 3,052 |

| 38 | 2,189 | 2,431 | 2,589 | 2,978 | 3,354 | 3,718 |

| 42 | 2,435 | 2,707 | 2,885 | 3,323 | 3,749 | 4,162 |

| 45 | 2,620 | 2,914 | 3,107 | 3,582 | 4,044 | 4,495 |

| 50 | 2,929 | 3,259 | 3,477 | 4,014 | 4,538 | 5,049 |

| 54 | — | — | 3,773 | 4,359 | 4,932 | 5,493 |

| 57 | — | — | 3,995 | 4,618 | 5,228 | 5,826 |

| 60 | — | — | 4,217 | 4,877 | 5,524 | 6,159 |

| 63,5 | — | — | 4,476 | 5,179 | 5,869 | 6,548 |

| 68 | — | — | 4,805 | 5,561 | 6,313 | 7,047 |

| 70 | — | — | 4,957 | 5,740 | 6,511 | 7,269 |

| 73 | — | — | 5,179 | 5,999 | 6,807 | 7,602 |

| 76 | — | — | 5,401 | 6,258 | 7,103 | 7,935 |

| 83 | — | — | — | 6,862 | 7,793 | 8,712 |

| 89 | — | — | — | 7,380 | 8,385 | 9,378 |

| 95 | — | — | — | 7,898 | 8,977 | 10,043 |

| 102 | — | — | — | 8,502 | 9,667 | 10,880 |

| 108 | — | — | — | — | 10,259 | 11,486 |

| 114 | — | — | — | — | 10,851 | 12,152 |

| 121 | — | — | — | — | 11,542 | 12,929 |

| 127 | — | — | — | — | 12,133 | 13,595 |

| 133 | — | — | — | — | 12,725 | 14,261 |

| 140 | — | — | — | — | — | 15,037 |

| 146 | — | — | — | — | — | 15,703 |

| 152 | — | — | — | — | — | 16,369 |

| 159 | — | — | — | — | — | 17,146 |

| 168 | — | — | — | — | — | — |

| 180 | — | — | — | — | — | — |

| 194 | — | — | — | — | — | — |

| 203 | — | — | — | — | — | — |

| 219 | — | — | — | — | — | — |

| 245 | — | — | — | — | — | — |

| 273 | — | — | — | — | — | — |

| 299 | — | — | — | — | — | — |

| 325 | — | — | — | — | — | — |

Table 14. Dimensions and weight of 1 m cold-rolled and cold-drawn pipes.

| Outside diameter, mm | Weight of 1 m of pipes, kg, with wall thickness, mm | ||||||||

| 0,2 | 0,25 | 0,3 | 0,4 | 0,5 | 0,8 | 1,0 | 1,2 | 1,5 | |

| 4 | 0,0187 | 0,0231 | 0,0274 | 0,0355 | 0,043 | 0,063 | 0,074 | 0,083 | — |

| 5 | 0,0237 | 0,0293 | 0,0348 | 0,0454 | 0,0555 | 0,0829 | 0,0986 | 0,112 | 0,129 |

| 6 | 0,0286 | 0,0355 | 0,0422 | 0,0552 | 0,0678 | 0,103 | 0,123 | 0,142 | 0,166 |

| 7 | 0,0335 | 0,0416 | 0,0496 | 0,0651 | 0,0801 | 0,122 | 0,148 | 0,172 | 0,203 |

| 8 | 0,0385 | 0,0478 | 0,0570 | 0,0750 | 0,0925 | 0,142 | 0,173 | 0,201 | 0,240 |

| 9 | 0,0434 | 0,0540 | 0,0644 | 0,0847 | 0,105 | 0,162 | 0,197 | 0,231 | 0,277 |

| 10 | 0,0483 | 0,0601 | 0,0718 | 0,0947 | 0,117 | 0,182 | 0,222 | 0,260 | 0,314 |

| 11 | 0,0533 | 0,0631 | 0,0792 | 0,105 | 0,129 | 0,201 | 0,247 | 0,290 | 0,351 |

| 12 | 0,0582 | 0,0724 | 0,0886 | 0,114 | 0,142 | 0,221 | 0,271 | 0,320 | 0,388 |

| 13 | 0,0631 | 0,0786 | 0,0940 | 0,124 | 0,154 | 0,241 | 0,296 | 0,349 | 0,42 |

| 14 | 0,0681 | 0,0848 | 0,101 | 0,134 | 0,166 | 0,260 | 0,321 | 0,435 | 0,462 |

| 15 | 0,0730 | 0,0909 | 0,199 | 0,144 | 0,179 | 0,280 | 0,345 | 0,408 | 0,499 |

| 16 | 0,0779 | 0,0971 | 0,166 | 0,134 | 0,191 | 0,300 | 0,370 | 0,438 | 0,536 |

| 18 | 0,0878 | 0,109 | 0,131 | 0,174 | 0,216 | 0,339 | 0,419 | 0,497 | 0,610 |

| 19 | 0,0927 | 0,116 | 0,138 | 0,183 | 0,228 | 0,359 | 0,444 | 0,527 | 0,647 |

| 20 | 0,0977 | 0,122 | 0,146 | 0,193 | 0,240 | 0,379 | 0,469 | 0,556 | 0,684 |

| 21 | 0,103 | 0,128 | 0,153 | 0,203 | 0,253 | 0,399 | 0,493 | 0,586 | 0,721 |

| 22 | 0,108 | 0,134 | 0,161 | 0,213 | 0,265 | 0,418 | 0,518 | 0,616 | 0,758 |

| 23 | 0,112 | 0,140 | 0,168 | 0,223 | 0,277 | 0,438 | 0,543 | 0,645 | 0,795 |

| 24 | 0,117 | 0,146 | 0,175 | 0,233 | 0,290 | 0,458 | 0,567 | 0,375 | 0,832 |

| 25 | 0,122 | 0,153 | 0,183 | 0,243 | 0,302 | 0,477 | 0,592 | 0,704 | 0,859 |

| 26 | 0,127 | 0,159 | 0,190 | 0,253 | 0,314 | 0,497 | 0,617 | 0,734 | 0,906 |

| 27 | 0,132 | 0,165 | 0,198 | 0,262 | 0,327 | 0,517 | 0,641 | 0,764 | 0,943 |

| 28 | 0,137 | 0,171 | 0,205 | 0,272 | 0,339 | 0,537 | 0,666 | 0,793 | 0,980 |

| 30 | 0,147 | 0,183 | 0,220 | 0,292 | 0,364 | 0,576 | 0,715 | 0,852 | 1,054 |

| 32 | 0,157 | 0,196 | 0,235 | 0,312 | 0,388 | 0,616 | 0,764 | 0,911 | 1,128 |

| 34 | 0,167 | 0,208 | 0,249 | 0,331 | 0,413 | 0,655 | 0,814 | 0,971 | 1,202 |

| 35 | 0,172 | 0,214 | 0,257 | 0,341 | 0,425 | 0,675 | 0,838 | 1,000 | 1,239 |

| 36 | 0,177 | 0,220 | 0,264 | 0,351 | 0,438 | 0,694 | 0,863 | 1,030 | 1,276 |

| 38 | 0,186 | 0,233 | 0,279 | 0,371 | 0,462 | 0,734 | 0,912 | 1,089 | 1,350 |

| 40 | 0,196 | 0,245 | 0,294 | 0,391 | 0,487 | 0,773 | 0,962 | 1,148 | 1,424 |

| 42 | — | — | 0,309 | 0,410 | 0,512 | 0,813 | 1,011 | 1,207 | 1,498 |

| 45 | — | — | 0,331 | 0,440 | 0,549 | 0,872 | 1,085 | 1,296 | 1,609 |

| 48 | — | — | 0,353 | 0,470 | 0,586 | 0,931 | 1,159 | 1,385 | 1,720 |

| 50 | — | — | 0,368 | 0,489 | 0,610 | 0,971 | 1,208 | 1,444 | 1,794 |

| 51 | — | — | 0,375 | 0,499 | 0,623 | 0,990 | 1,233 | 1,474 | 1,831 |

| 53 | — | — | 0,390 | 0,519 | 0,647 | 1,030 | 1,282 | 1,533 | 1,905 |

| 54 | — | — | 0,397 | 0,529 | 0,660 | 1,050 | 1,307 | 1,563 | 1,942 |

| 56 | — | — | 0,412 | 0,548 | 0,684 | 1,089 | 1,356 | 1,622 | 2,016 |

| 57 | — | — | 0,419 | 0,558 | 0,697 | 1,109 | 1,381 | 1,651 | 2,053 |

| 60 | — | — | 0,442 | 0,588 | 0,734 | 1,168 | 1,455 | 1,740 | 2,164 |

| 63 | — | — | — | — | — | 1,227 | 1,529 | 1,829 | 2,275 |

| 65 | — | — | — | — | — | 1,267 | 1,578 | 1,888 | 2,349 |

| 68 | — | — | — | — | — | 1,326 | 1,652 | 1,977 | 2,460 |

| 70 | — | — | — | — | — | 1,365 | 1,702 | 2,036 | 2,534 |

| 73 | — | — | — | — | — | 1,424 | 1,776 | 2,125 | 2,645 |

| 75 | — | — | — | — | — | 1,464 | 1,825 | 2,184 | 2,71 |

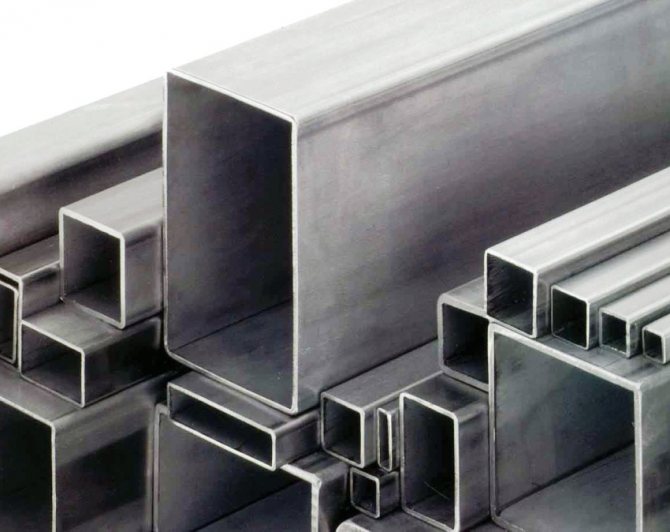

GOST 12336-66

This normative document was developed to regulate closed-type profile pipes, which have a square or rectangular cross-section. It is worth noting that the effect of this GOST was canceled at the beginning of 1981 (instead, they began to use TU 14-2-361-79), however, the key provisions of the document are still relevant even today. Therefore, we attach the corresponding tables.

Table 15. Rectangular pipes in accordance with GOST 12336-66.

| h | b | s | r1 | A | Iy | Wy | iy | Sy | Iz | Wz | iz | |||||

| mm | mm | mm | mm | cm2 | cm4 | cm3 | mm | cm3 | cm4 | cm3 | mm | |||||

| 63x32x2 | 63.000 | 32.000 | 2.000 | 4.000 | 3.470 | 17.100 | 5.420 | 22.200 | 3.420 | 5.980 | 3.740 | 13.100 | ||||

| 63x32x2.5 | 63.000 | 32.000 | 2.500 | 5.000 | 4.230 | 20.100 | 6.390 | 21.800 | 4.100 | 7.020 | 4.390 | 13.000 | ||||

| 63x45x2.5 | 63.000 | 45.000 | 2.500 | 5.000 | 4.880 | 26.100 | 8.280 | 23.100 | 5.080 | 15.570 | 6.920 | 17.900 | ||||

| 63x45x3 | 63.000 | 45.000 | 3.000 | 6.000 | 5.730 | 29.800 | 9.460 | 22.800 | 5.880 | 17.700 | 7.890 | 17.600 | ||||

| 70x36x2 | 70.000 | 36.000 | 2.000 | 4.000 | 3.910 | 24.100 | 6.900 | 24.900 | 4.330 | 8.650 | 4.800 | 14.900 | ||||

| 70x36x2.5 | 70.000 | 36.000 | 2.500 | 5.000 | 4.780 | 28.700 | 8.200 | 24.500 | 5.210 | 10.200 | 5.680 | 14.600 | ||||

| 70x50x2.5 | 70.000 | 50.000 | 2.500 | 5.000 | 5.480 | 36.700 | 10.500 | 25.900 | 6.390 | 21.900 | 8.760 | 20.000 | ||||

| 70x50x3 | 70.000 | 50.000 | 3.000 | 6.000 | 6.450 | 42.100 | 12.000 | 25.500 | 7.420 | 25.100 | 10.000 | 19.700 | ||||

| 80x40x2.5 | 80.000 | 40.000 | 2.500 | 5.000 | 5.480 | 43.400 | 10.800 | 28.100 | 6.850 | 14.800 | 7.410 | 16.400 | ||||

| 80x40x3 | 80.000 | 40.000 | 3.000 | 6.000 | 6.450 | 49.700 | 12.400 | 27.800 | 7.960 | 16.900 | 8.460 | 16.200 | ||||

| 80x56x3 | 80.000 | 56.000 | 3.000 | 6.000 | 7.410 | 64.000 | 16.000 | 29.400 | 9.810 | 37.000 | 13.200 | 22.300 | ||||

Table No. 16. Square pipes in accordance with GOST 12336-66.

| b | s | r1 | A | Iy = Iz | Wy = Wz | iy = iz | Sy = Sz | P | |

| mm | mm | mm | cm2 | cm4 | cm3 | mm | cm3 | kg / m | |

| 63×3 | 63.000 | 3.000 | 6.000 | 6.810 | 39.500 | 12.550 | 24.100 | 7.500 | 5.350 |

| 63×4 | 63.000 | 4.000 | 8.000 | 8.750 | 48.300 | 15.340 | 23.500 | 9.380 | 6.870 |

| 63×5 | 63.000 | 5.000 | 10.000 | 10.500 | 55.100 | 17.500 | 22.900 | 11.000 | 8.260 |

| 70×3 | 70.000 | 3.000 | 6.000 | 7.650 | 55.600 | 15.900 | 27.000 | 9.430 | 6.010 |

| 70×4 | 70.000 | 4.000 | 8.000 | 9.870 | 68.700 | 19.600 | 26.400 | 11.900 | 7.750 |

| 70×5 | 70.000 | 5.000 | 10.000 | 11.900 | 79.200 | 22.600 | 25.800 | 14.000 | 9.360 |

| 80×3 | 80.000 | 3.000 | 6.000 | 8.850 | 85.300 | 21.300 | 31.000 | 12.600 | 6.950 |

| 80×4 | 80.000 | 4.000 | 8.000 | 11.500 | 100.700 | 26.600 | 30.500 | 16.000 | 9.010 |

| 80×5 | 80.000 | 5.000 | 10.000 | 13.900 | 124.000 | 31.100 | 29.900 | 19.000 | 10.900 |

| 80×6 | 80.000 | 6.000 | 12.000 | 16.200 | 139.000 | 34.800 | 29.300 | 21.600 | 12.700 |

| 90×3 | 90.000 | 3.000 | 6.000 | 10.100 | 124.000 | 27.600 | 35.100 | 16.200 | 7.890 |

| 90×4 | 90.000 | 4.000 | 8.000 | 13.100 | 156.000 | 34.700 | 34.600 | 20.700 | 10.300 |

| 90×5 | 90.000 | 5.000 | 10.000 | 15.900 | 184.000 | 40.900 | 34.000 | 24.700 | 2.500 |

| 90×6 | 90.000 | 6.000 | 12.000 | 18.600 | 208.000 | 46.100 | 33.400 | 28.400 | 14.600 |

| 100×3 | 100.000 | 3.000 | 6.000 | 11.300 | 173.000 | 34.600 | 39.200 | 20.200 | 8.830 |

| 100×4 | 100.000 | 4.000 | 8.000 | 14.700 | 219.000 | 43.900 | 38.700 | 26.000 | 11.500 |

| 100×5 | 100.000 | 5.000 | 10.000 | 17.900 | 260.000 | 52.000 | 38.100 | 31.200 | 14.100 |

| 100×6 | 100.000 | 6.000 | 12.000 | 21.000 | 296.000 | 59.100 | 37.500 | 36.000 | 16.500 |

| 100×7 | 100.000 | 7.000 | 14.000 | 23.900 | 326.000 | 65.200 | 36.900 | 40.300 | 18.800 |

| 110×3 | 110.000 | 3.000 | 6.000 | 12.500 | 234.000 | 42.500 | 43.300 | 24.700 | 9.780 |

GOST 31447-2012

Establishes standards for spiral / longitudinal seam products made of steel. The diameter of pipes of this type starts from 11.4 centimeters and ends with 142 centimeters. Agree, very large pipes, therefore, are used mainly in the arrangement of large gas and oil pipelines. The working pressure indicator at this time should be no more than 9.8 MPa, while the minimum air temperature around the pipeline is -60 degrees.

GOST 31447-2012. Welded steel pipes for main gas pipelines, oil pipelines and oil product pipelines. Download file (click on the link below to open the attached file in a new window). GOST 31447-2012

Table 17. Assortment and theoretical weight of pipes.

| Nominal outer diameter of pipes, mm | Theoretical mass of 1 m of pipe, kg, at nominal wall thickness, mm | ||||||||||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| 114 | 8,21 | 10,85 | 13,44 | 15,98 | 18,47 | 20,91 | — | — | — | — | — | — | — |

| 121 | 8,73 | 11,54 | 14,30 | 17,02 | 19,68 | 22,29 | 24,86 | 27,37 | — | — | — | — | — |

| 133 | 9,62 | 12,72 | 15,78 | 18,79 | 21,75 | 24,66 | 27,52 | 30,33 | — | — | — | — | — |

| 140 | 10,14 | 13,42 | 16,65 | 19,83 | 22,96 | 26,04 | 29,07 | 32,06 | 34,99 | 37,87 | 40,71 | — | — |

| 146 | 10,58 | 14,01 | 17,39 | 20,71 | 23,99 | 27,22 | 30,41 | 33,54 | 36,62 | 39,65 | 42,64 | — | — |

| 152 | 11,02 | 14,60 | 18,13 | 20,60 | — | — | — | — | — | — | — | — | — |

| 159 | 11,54 | 15,29 | 18,99 | 22,64 | 26,24 | 29,79 | 33,29 | 36,74 | 40,15 | 43,50 | 46,80 | — | — |

| 168 | 12,21 | 16,18 | 20,10 | 23,97 | 27,79 | 31,57 | 35,29 | 38,96 | 42,59 | 46,16 | 49,69 | — | — |

| 178 | 12,95 | 17,16 | 21,33 | 25,45 | 29,52 | 33,54 | 37,51 | 41,43 | 45,30 | 49,12 | 52,90 | — | — |

| 219 | 15,98 | 21,21 | 26,39 | 31,52 | 36,60 | 41,63 | 46,61 | 51,54 | 56,42 | 61,26 | 66,04 | 70,77 | — |

| 245 | — | 23,77 | 29,59 | 35,36 | 41,09 | 46,76 | 52,38 | 57,95 | 63,47 | 68,95 | 47,37 | 79,75 | — |

| 273 | — | 26,54 | 33,04 | 39,51 | 45,92 | 52,28 | 58,59 | 64,86 | 71,07 | 77,24 | 83,35 | 89,42 | |

| 325 | — | 31,67 | 39,46 | 47,20 | 54,89 | 62,54 | 70,13 | 77,68 | 85,18 | 92,62 | 100,03 | 107,38 | 114,68 |

| 356 | — | 34,72 | 43,28 | 51,79 | 60,24 | 68,65 | 77,01 | 85,32 | 93,58 | 101,80 | 109,96 | 118,07 | 126,14 |

| 377 | — | — | 45,87 | 54,89 | 63,87 | 72,80 | 81,68 | 90,51 | 99,28 | 108,01 | 116,70 | 125,33 | 133,91 |

| 426 | — | — | 51,91 | 62,15 | 72,33 | 82,47 | 92,55 | 102,59 | 112,57 | 122,51 | 132,41 | 142,25 | 152,04 |

| 530 | — | — | — | 77,53 | 90,29 | 102,99 | 115,64 | 128,24 | 140,79 | 153,30 | 165,75 | 178,15 | 190,50 |

| 630 | — | — | — | — | 107,55 | 122,72 | 137,83 | 152,90 | 167,91 | 182,88 | 197,80 | 212,67 | 227,49 |

| 720 | — | — | — | — | — | 140,47 | 157,80 | 175,09 | 192,32 | 209,51 | 226,65 | 243,74 | 260,78 |

| 820 | — | — | — | — | — | 160,20 | 180,00 | 199,75 | 219,46 | 239,12 | 258,71 | 278,28 | 297,77 |

So, we examined the range of steel pipes, as well as the key GOST standards that establish their characteristics. Therefore, it remains only to dwell on some other less important points.

Features of the production of seamless pipes

These products are manufactured from grade 35 or 45 steel using a special continuous mill. What is characteristic, in the process, special blanks are used (the latter are called black blanks), which are first stitched by means of a roller machine, and then transported to a circular saw, which cuts off the end of the pipe. Further, the shape of the pipe is straightened using a cross-roll mill, and the ovality of its cross-section is correspondingly reduced.

So now you know everything there is to know about steel pipe assortment. There is a lot of information, but we are sure that you can easily figure it out. For even more familiarity with the technology for the production of pipes from steel, we recommend watching the thematic video material below. That's all, good luck and warm winters!

Main technologies for the production of steel pipes

Steel pipes can be made with or without welded seam. In the first variant, the production of products is based on rolling a flat sheet of steel. To obtain a straight joint, the steel strip is rolled into a pipe using rollers.The seam is welded by means of a high frequency current or a tungsten electrode in an inert gas.

Important! This welding method ensures the tightness and strength of the welded joint of water-gas supply steel pipes. GOST 3262-75 establishes general technical requirements for the manufacture of these products.

To obtain a spiral seam, the steel tape is rolled up in a spiral.

Seamless products are made from steel rods using drilling, casting, hot or cold forming technologies. In the first case, the raw material is poured into a special mold with a rod. The second option involves drilling a hole in a steel cylinder. Both of the above methods are rarely used in practice, which is associated with the laboriousness of the manufacturing process and high financial costs. Manufacturers predominantly use deformation methods.

The production of pipes with a welded seam is based on rolling a flat sheet of steel and welding its joints

Seamless hot-rolled steel is made by heating a metal rod in a furnace to turn it into a cylinder, which is easy to do after the material has reached a ductile state. The resulting billet of irregular shape is processed on rollers, where a seamless hot-deformed steel pipe is brought to the required diameter and length.

With the cold deformation method, the cylindrical workpiece is pre-cooled before processing on the rollers. Then, until the final calibration, it is fired.

Important! Thick-walled steel pipes are made exclusively by hot or cold deformation.