One of the most difficult nodes is the passage of the chimney through the roofing system. It is necessary to create a high tightness, as well as eliminate the possibility of fire. In order for the goal to be achieved, many actions were taken at one time, and only professional roofers took up the matter. If problem areas were found, they were filled with asbestos, roofing material and tin were fixed, and they also used a cement solution. Despite the difficult process, all this did not last long, since no one canceled the temperature and atmospheric effects. To significantly facilitate the work and extend the service life, we created the roofing Master Flash. It will allow you to abandon complex and lengthy procedures. Master Flash will provide protection from precipitation, while spending less effort, time and money.

What is Master Flash?

Master Flush is a kind of high elasticity sealing cuff. They are used to seal the intersections of the pipe and roof. Various materials are used for manufacturing.

It should be noted that this device is not used as a seal for chimneys without insulation.

The main advantages of Master Flash:

- Tight fit to the pipe walls due to its elasticity.

- Withstands temperature extremes.

- Corrosion is not terrible.

- High sealing due to low porosity.

- Returns to its shape after expansion from heat.

- High fire resistance.

- Long-term guarantee.

- Installation without special tools.

- It can be installed in any weather conditions.

The main advantage is the reduction in the consumption of materials in this process. No additional waterproofing required.

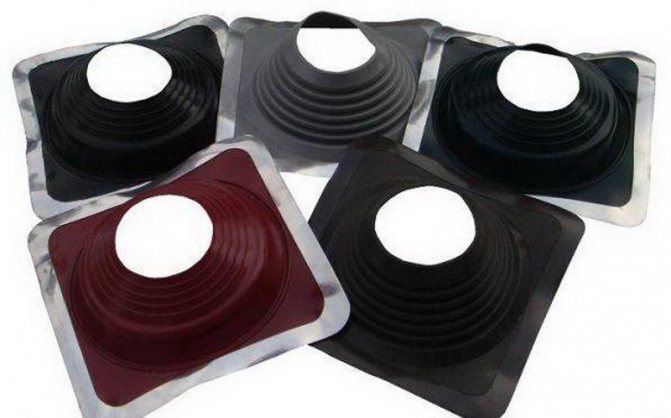

Differences between seals

Roof seals have become a replacement for pipe aprons. They are similar in design to their predecessors, but have some differences:

- Made of rubber, usually silicone, in the form of a tapering cone with a flexible cuff. With the help of it, a tight connection of the pipe to the roof is ensured. In addition, it protects against moisture and dust. The top of the cone follows the shape of the pipe. Bottom connects to the seal.

- Flange - base. Made from various materials. Rubberized or silicone base for roof mounting with massive ribs, with aluminum strips. It allows the flange to take the shape of the profile.

Insulation cuffs for a flat roof are located at a slight angle. Cone-shaped element with corrugations, which forms the contours of oval holes with gradation in diameter. That is, you can change the angle by tilting it at certain intervals. Sometimes it happens that the axis is perpendicular to the base, then the sealant is used for a flat roof.

How to mount?

Flexible seals were able to outstrip their outdated counterparts in many respects. They are able to withstand various temperature ranges, practically do not need to be repaired, and have a long service life. They are unpretentious in installation. You don't need to have any special skills to install. The top of the seal is sheared off to create a narrow hole. Then, the cone is put on the chimney. You need to move it down to the very base. In order for the process to proceed quickly, it is better to soap or moisten the surface of the pipe.

The method of flange fastening depends on the roof material:

- Silicone glue or bitumen mastic is applied to a flat roll coated surface.

- If there is a slope, then the entrance is self-tapping.

After installation, the bottom of the flange and the cut of the cone are lubricated with silicone sealant to ensure greater reliability.Sometimes a clamp is used for the top edge. Despite the strength of the fixation, the master flash will be movable. For example, if thermal expansion occurs, the master flash will not lose its tightness. Also, the cuff will behave if shrinkage occurs at home.

Roof device

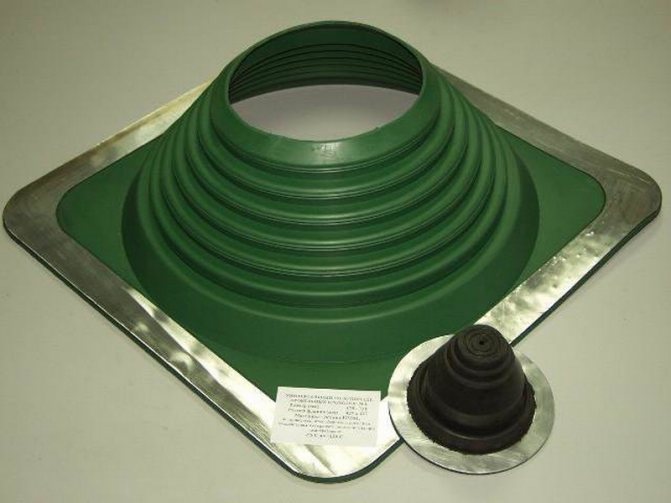

The Flash Master is a pyramid of rings of different diameters, fastened to an elastic base in the shape of a square or rectangle. Each of the rings corresponds to a specific pipe diameter, so this design is universal. The rings can be fastened to the base at a 90 ° angle, or at a 30 or 45 ° angle. Depending on this, the penetration is used for fastening on a flat surface, or on an inclined one.

Advice! If there is no corner master flush on sale that corresponds to the angle of inclination of the slope of your roof, then take a straight line, but of a larger size.

The chimney cover can be made of silicone or rubber. Silicone is a more elastic material and more resistant to high temperatures. But its disadvantage is its insufficient resistance to UV radiation, which leads to its shorter service life. If solid fuel is used for combustion, the temperature of the waste products discharged through the pipe will be higher. In this case, the installation of a silicone master flush is required.

Choosing the right Master Flash

To choose a roof sealant, it is not enough just to know about its dimensions.

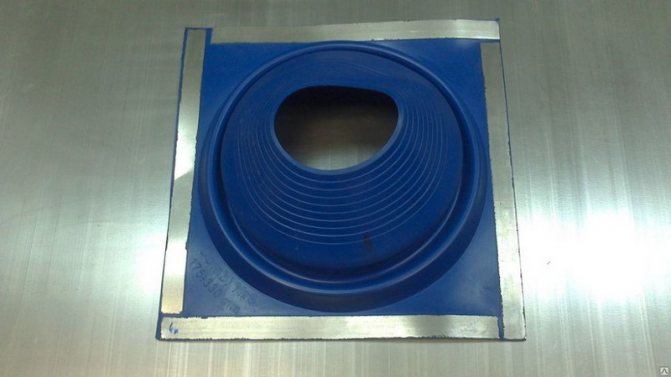

- Flexible seals with round and square base are suitable for roofs that have an angle of inclination of up to 45 degrees. In addition, the roof can be shingles, roofing steel, profiled metal, and so on. Installation of seals is carried out using silicone and with further fastening using self-tapping screws.

- Elastic flange seals are used for pitched roofs up to 60 degrees.

- Sloping roofs with a slope angle of more than 60 degrees are equipped with a gasket, the base of which has an increased area.

- Flat roofs receive collars that are installed perpendicular to the base. To do this, use bituminous mastic or silicone.

- For tiled and slate roofs, seals with a large metal base are suitable.

For the manufacture of Master Flash, the following are used:

- High quality rubber that can withstand high temperatures. It should be noted that the rubber MF lasts longer.

- Silicone, which is also afraid of temperatures in the region of 200 degrees.

Product advantages

- The elasticity of the material ensures the continuous adhesion of the seal to the pipe, even when the pipe size changes during heating and cooling;

- Due to the special design of the compactor, vibration and displacement of pipes are damped, as well as the external pressure of the layer of snow that collects on the surface is reduced.

- The chimney flush master protects the roof from destruction. Even when heated, deformation and expansion of the volume of the product are minimal;

- A large assortment of seals with different sizes allows you to select and qualitatively mount a unit from 0.3 to 66 cm;

- It is used on roofs with any coating (slate, shingles, clay tiles, sand-cement tiles, metal tiles, corrugated board, bituminous tiles, metal sheets, etc.)

- The materials from which the flash seal is made provide high-quality sealing;

- Installation of the device does not require special skills; you can remove and strengthen the chimney on the roof yourself, quickly enough and without the involvement of specialists.

Sealing sandwich pipes.

A cone-shaped device consisting of rings of different diameters, each of which is larger than the previous one, connected by silicone jumpers.As a standard - the rings are arranged vertically at an angle of 90 °, however, special models are produced for a pitched roof, with an inclination of 10-30 ° or 20-55 °. The rings are located on a square or round rigid base (flange), which is fixed to the roof of the house with self-tapping screws.

Attention! If you are unable to find a sealer for pitched roofs, a straight model can be used. But it is worth considering that the diameter of the seal flange will have to overlap the ellipse of the roof gap, the higher the slope, the larger the diameter of the ellipse along the major axis. Therefore, when buying a sealant, the choice should also be doused in favor of a larger size.

Roof passage Master Flash.

Installing the seal

Installing Master Flash is a fairly simple process. This was discussed above. But, there are some nuances that you need to know about.

On a flexible basis

Seals with a flexible base are used on metal roofs.

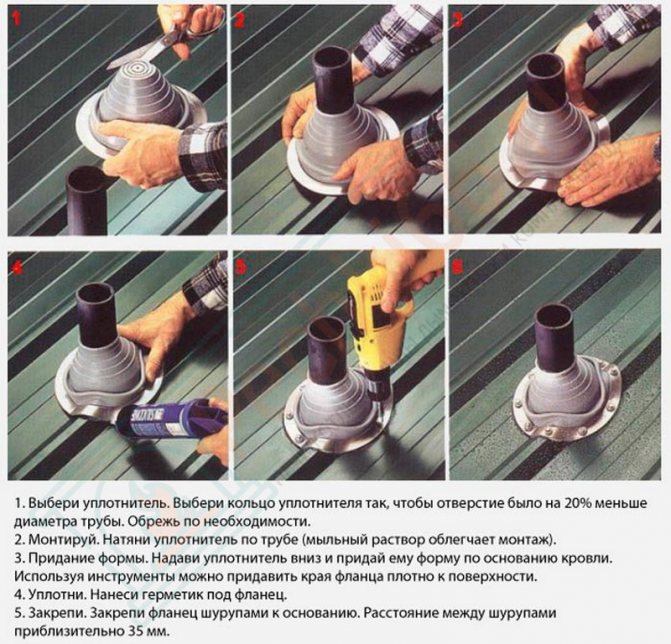

Installation process:

- It is necessary to choose a location for the cut. We must not forget that it should be 20 percent narrower than the diameter of the chimney.

- This requires roofing shears. Try to keep the section to be cut straight.

- The surface of the chimney must be moistened. Then, pull the seal over the pipe.

- Once installed on the roof, draw a line around the edges of the base.

- By lifting the seal, the adhesive is applied.

- Press down.

- Apply sealant to all required areas.

You need to choose an adhesive based on the type of roof covering.

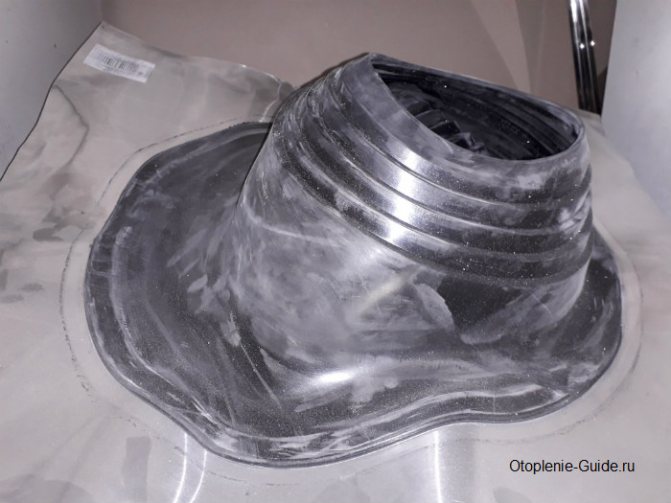

Master Flush with Hard Snap

The gaskets, which have aluminum strips at the edges, are installed in the same way as described above. There is only one difference. Before installation, the base must be profiled to ensure a snug fit to the roof. To install them, you need hex screws. The mount is screwed to the very bottom of the profile.

Repair seal

Split roof gaskets are required when it is not possible to slide the insulation onto the pipe. They are usually used to repair obsolete chimney insulation.

Installation process:

- Powerful scissors need to cut off the top of the cone 20% less than the pipe diameter.

- Open the lock and wrap the chimney.

- Connect the cut of the seal and close the lock.

- Raise the edge of the base to apply the silicone sealant to the roof.

- Press down on everything and apply glue to the required areas and to the lock itself.

Installation on slate and roof tiles

For roofs made of tiles or slate, seals with an aluminum or lead flange are produced. Their cone is also cut off for a snug fit of the cuff to the pipe. The top of the metal base is brought under the roof, the bottom and side parts are laid on the roof. To prevent moisture from getting under it, it is necessary to bend the upper edge. At the end, you need to fill the problem joints with silicone.

Installation features

The chimney master flush can be installed on any roof format. Whether it is a sloped or flat roof, as well as for any type of roofing material.

To ensure maximum contact with the pitched roof, you can use a special master flush, in which the “skirt” outlet from the base is at an angle, which makes it easier to install and secure.

When using a regular vertical master flush on a pitched roof, you must select a larger model, because on the passage it will be installed in an inclined position and overlap the pipe in an ellipse when viewed in section.

All work on installing the seal can be performed at any time of the year and in any weather. A minimum of tools are involved. If everything is done correctly, the result is a tight connection to the pipe and a strong, reliable connection to the roof.

What you need to have to install a roof

To install a protective structure on a roof covering, you will need:

- roof, corresponding to the size of the chimney and the temperature of the exhaust gases;

- a bowl without a bottom in galvanized steel, which protects the otter made of soft polymer from UV rays. You can make it yourself or buy it at the nearest hardware store;

- self-tapping screws;

- screwdriver;

- sealant for places with high thermal stress;

- special scissors for metal.

Before starting installation work, prepare all the necessary materials. To fasten the structure, you will need about six self-tapping screws, a screwdriver or screwdriver, sealant, special scissors. After preliminary preparation, you can proceed with the installation.

In case of independent work, you should study the installation instructions and follow all instructions. The algorithm of actions is simple and does not present any great difficulties:

- The upper part of the cone of the device is cut so that the diameter of the lumen is less than the cross-section of the chimney pipe by 20%. In this case, the rat will fit snugly against the chimney.

- Excess rubber or silicone is cut as smoothly as possible with special scissors.

- At the next stage of work, the Master Flash is put on the upper end of the pipe.

- It is then slowly pushed down to the roof surface. It is recommended to moisten the pipe to improve sliding.

- The lower base is attached to the roof surface with a sealant.

- For reliability, fix the structure with self-tapping screws.

- An elastic sealant is applied along the perimeter of the edge of the upper cut.

We offer you to familiarize yourself with: Log sauna interior decoration

Installation nuances

To work on the installation of the penetration, the following inventory is required:

- Hardware with a press head;

- Pliers;

- Drill screwdriver;

- Sharp knife;

- Carpenter's hammer;

- Flash master device;

- Steel clamp;

- Silicone glue;

- Parts lubricant;

- Level.

Installation of the Master Flash penetration includes the following steps:

- Before starting the installation, check that the hole of the Flash Master seal for the chimney is 20% less than the pipe diameter. To adjust the product to the required size, you can independently cut the edge of the penetration hole by 20%;

- Next, the Master Flush is put on the pipe. To make it easier to put on the device, you can use a lubricant without petrochemical impurities;

- The seal is now pressed down and tightly fitted to the roof profile. Any blunt object can be used to fit;

- Next, a special sealing substance is introduced into the gap between the roof and the lower region of the seal;

- The resulting structure is attached to the roof deck with self-tapping screws. The fastening pitch should be 0.15 cm for optimal sealing.